Black color paste preparing and black color paste printing and air drying technology

A color paste and printing technology, which is applied in the field of black color paste preparation and printing air-drying process, can solve the problems of small output capacity of color paste mixing device, low color brightness, slow printing speed, etc., and overcome the low pattern clarity , Overcome the effect of not bright colors and increased printing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

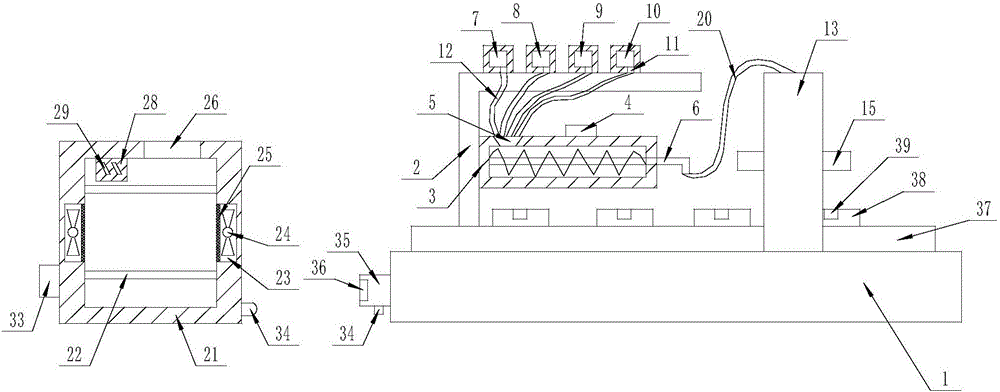

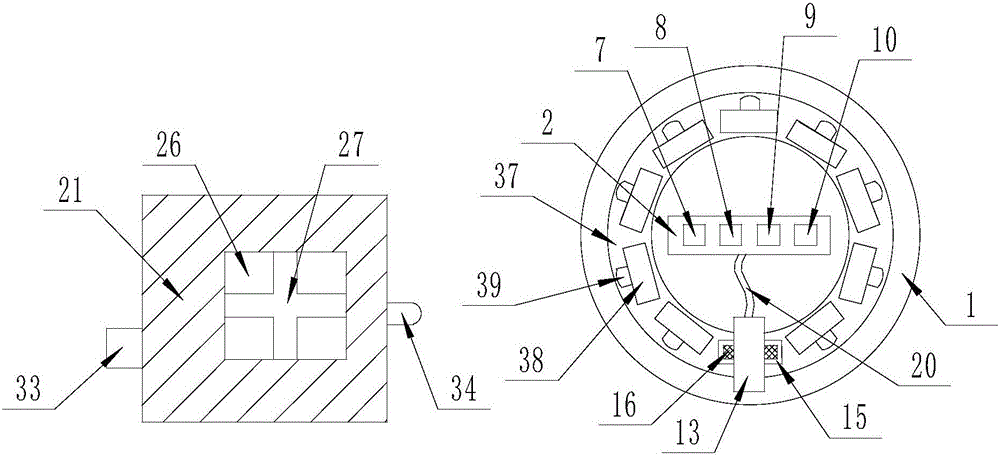

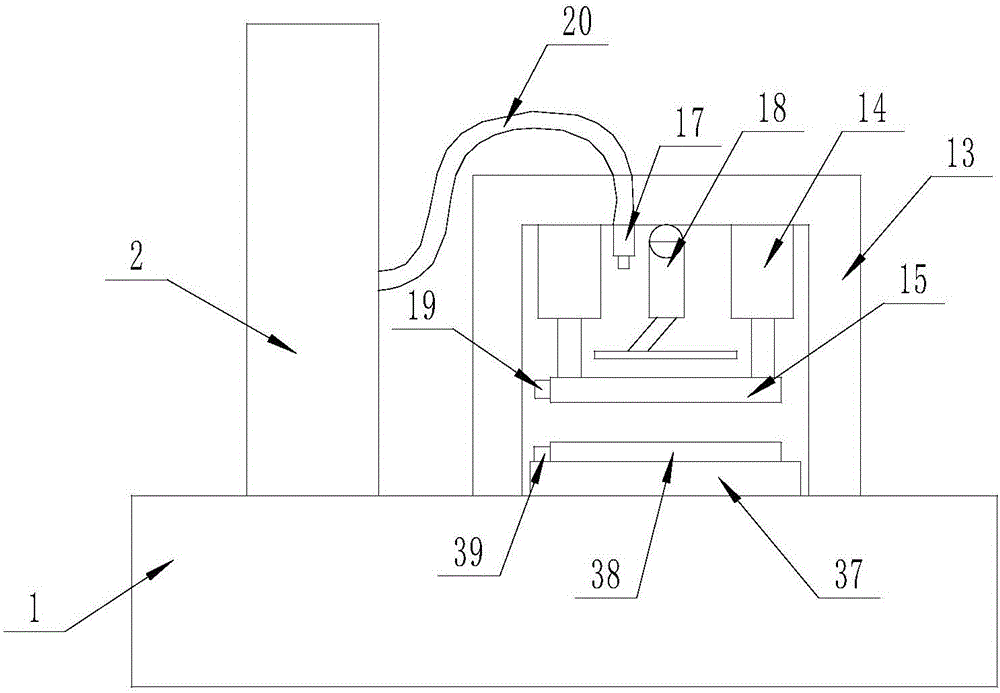

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a kind of black color paste preparation and its printing air-drying process comprise workbench (1), and described workbench (1) upper surface one side is provided with printing unit, and described workbench (1) upper surface other side A support frame (2) is provided, the lower surface of the support frame (2) is provided with a conveying auger (3), the conveying auger (3) is provided with a vibrating block (4), and the conveying auger (3) ) is processed with a material inlet (5), one end of the conveying auger (3) is provided with a curved pipe (6), and the upper surface of the support frame (2) is provided with a dye bucket (7), an acrylic emulsion bucket (8), water storage bucket (9) and thickener bucket (10), on described dye bucket (7), acrylic emulsion bucket (8), water storage bucket (9) and thickener bucket (10) all A discharge port (11) is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com