Method for preparing microcrystalline celluloses by acid hydrolysis after pretreatment through high shear machinery

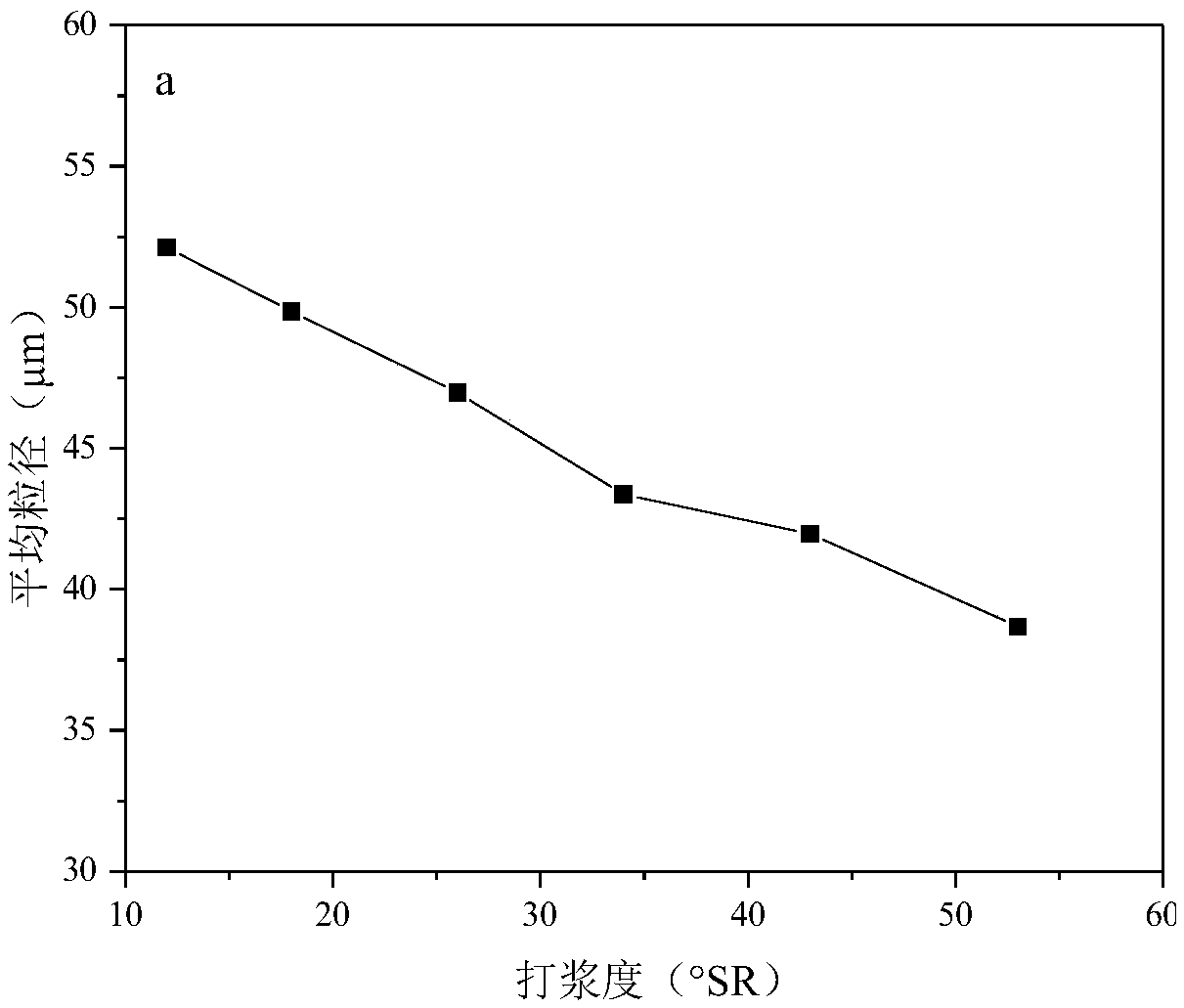

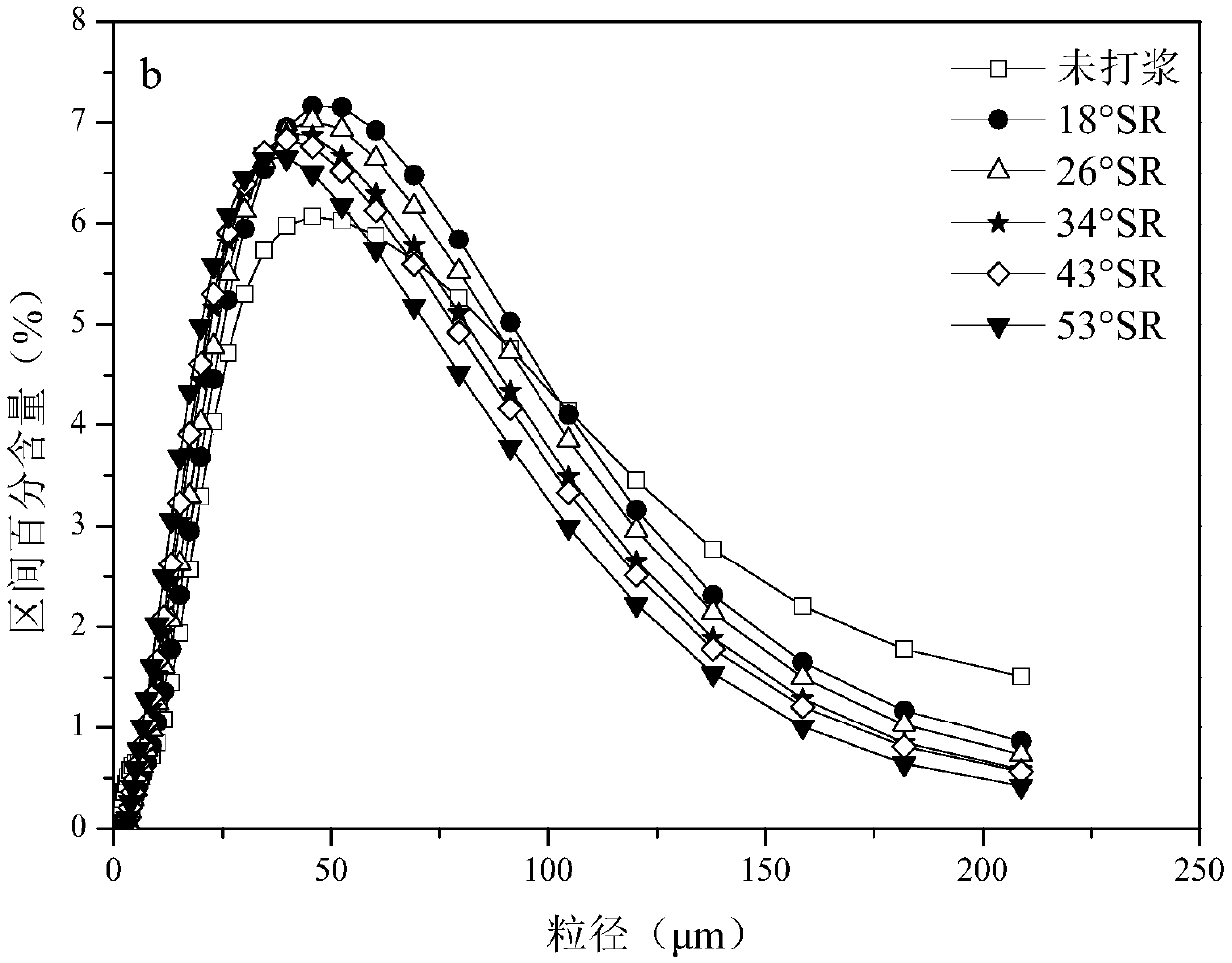

A microcrystalline cellulose and pretreatment technology is applied in the field of preparation of microcrystalline cellulose by acid hydrolysis after high-shear mechanical pretreatment. The effect of large acid hydrolysis rate, improvement of particle size uniformity, and increase of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing microcrystalline cellulose by acid hydrolysis after high-shear mechanical pretreatment, comprising the following steps:

[0034] Step 1, pretreatment, first add water to the wood-dissolving pulp and soak at room temperature for 6 hours to obtain thick pulp after soaking, the mass percentage of wood-dissolving pulp in the thick pulp after soaking is 1%; then put the thick pulp after soaking into the Valley beater In the process, under the condition of no pressure, decompressed for 20 minutes to obtain the decomposed slurry; finally, under the pressure of 10kg heavy thallium, the pretreated slurry was beaten with a Valley beater until the beating degree was 15°SR Post slurry;

[0035] Step 2, acid hydrolysis, the pretreated slurry obtained in step 1 is mixed with a solid-to-liquid ratio of hydrochloric acid in a ratio of 1:15 (g:mL), and acid hydrolysis reaction is carried out to obtain an acid hydrolysis reaction product; acid hydrolysis reaction ...

Embodiment 2

[0038] A method for preparing microcrystalline cellulose by acid hydrolysis after high-shear mechanical pretreatment, comprising the following steps:

[0039] Step 1, pretreatment, first add water to the wood-dissolving pulp and soak at room temperature for 8 hours to obtain thick pulp after soaking, the mass percentage of wood-dissolving pulp in the thick pulp after soaking is 2%; then put the thick pulp after soaking into the Valley beater In the process, under the condition of no pressure, decompose for 18 minutes to obtain the decomposed slurry; finally, under the condition of 12kg heavy thallium, the pretreated slurry is beaten with a Valley beater until the beating degree is 18°SR Post slurry;

[0040] Step 2, acid hydrolysis, the pretreated slurry obtained in step 1 is mixed with a solid-to-liquid ratio of hydrochloric acid in a ratio of 1:16 (g:mL), and acid hydrolysis reaction is carried out to obtain an acid hydrolysis reaction product; acid hydrolysis reaction When...

Embodiment 3

[0043] A method for preparing microcrystalline cellulose by acid hydrolysis after high-shear mechanical pretreatment, comprising the following steps:

[0044] Step 1, pretreatment, first add water to the wood-dissolving pulp and soak at room temperature for 9 hours to obtain thick pulp after soaking, the mass percentage of wood-dissolving pulp in the thick pulp after soaking is 2%; then put the thick pulp after soaking into the Valley beater In the process, under the condition of no pressure, decompose for 15 minutes to obtain the decomposed pulp; finally, under the pressure condition of 15kg heavy thallium, use the Valley beater to beat the decomposed pulp until the beating degree is 26°SR. Post slurry;

[0045] Step 2, acid hydrolysis, the pretreated slurry obtained in step 1 is mixed with a solid-to-liquid ratio of hydrochloric acid in a ratio of 1:17 (g:mL), and acid hydrolysis reaction is carried out to obtain an acid hydrolysis reaction product; acid hydrolysis reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com