Knittable seawater uranium extraction adsorption material and flexible regulation and control preparation method thereof

A seawater and deionized water technology, applied in the field of uranium adsorption materials, can solve the problems of difficulty in realizing flexible regulation of bamboo strips, difficulty in realizing suspension and complete recovery of adsorbent materials, and difficulty in realizing macroscopic large-area molding application, etc. The effect of accelerating the mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

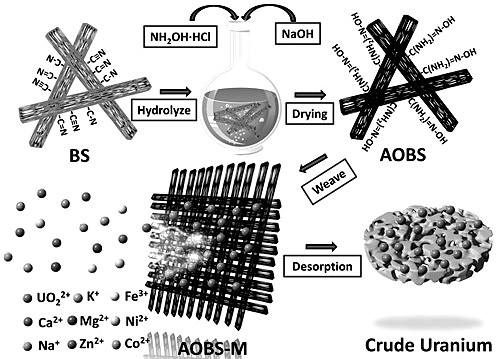

[0036] Example 1: A preparation method of woven amidoximated bamboo strips for extracting uranium from seawater, the preparation process is shown in Figure 1, including the following steps:

[0037] Step 1: BS was sonicated with acetone, ethanol and deionized water for 0.5 h, respectively. Then, put BS into the reactor, and pour a certain volume mass fraction of 30% H 2 o 2 . Finally, load the above into BS and H 2 o 2 The reactor was placed in an oven, the temperature was set at 65°C, and the time was 6h.

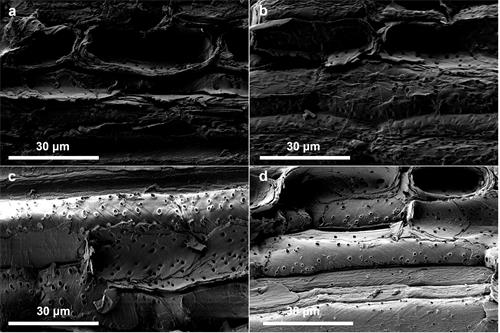

[0038] Step 2: Accurately weigh 2.0g NH 2 OH·HCl and 1.0 g NaOH were poured into 50 mL of ethanol and stirred vigorously with a magnetic stirrer until the solids were completely dissolved. At the same time, 2.0 g of the treated BS was put into a three-necked flask for reflux reaction with an oil bath, the temperature was set at 70° C., and the time was 24 h. After the reaction was complete, the sample was taken out, rinsed with deionized water several times, and dri...

Embodiment 2

[0043] Embodiment 2: The method described in this embodiment and embodiment 1 is basically the same, the difference is that in step 1, add H 2 o 2 The concentration is 10%.

[0044] In this example, 10% H 2 o 2 Hydroxylation reaction was carried out in the environment, and the amidoximated bamboo strips prepared, denoted as AOBS-2, kept the original flexibility and weavability of BS.

Embodiment 3

[0045] Embodiment 3: The method described in this embodiment and embodiment 1 is basically the same, the difference is that in step 1, add H 2 o 2 The concentration is 20%.

[0046] In this example, 10% H 2 o 2 The environment was subjected to hydroxylation reaction, and the amidoximated bamboo strips prepared, denoted as AOBS-3, kept the original flexibility and weavability of BS, indicating that H 2 o 2 The concentration does not change the flexibility of BS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com