Patents

Literature

37results about How to "Maintain porous structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

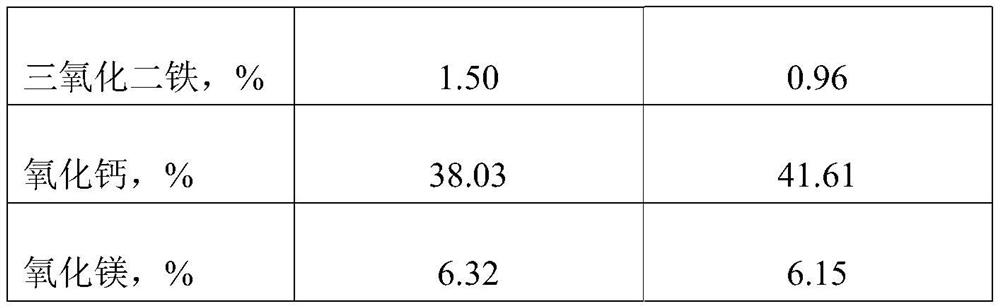

Modified fly ash with surface coated with SiO2 and preparation method and use thereof

ActiveCN104403401AProtect the porous structureGood heat insulationSolid waste managementCoatingsPolymer scienceThermal insulation

The invention belongs to the technical field of inorganic powder surface modification, and in particular relates to modified fly ash with surface coated with SiO2 and a preparation method and use thereof, the method is as follows: Step 1) fly ash iron removal, step 2) capillary adsorption paraffin, step 3) coating of the surface with SiO2, the water absorption rate of the modified fly ash prepared by the method is 20%-22%, the whiteness is 20-30, the near infrared reflectivity is 60-80%, the coefficient of thermal conductivity is less than 0.25W / M.K; and the modified fly ash prepared by the method has good barrier thermal insulation and reflective thermal insulation performances. A thermal insulation coating prepared from the modified fly ash has excellent thermal insulating property, can be used in epoxy floor coatings, acrylic coatings for exterior wall, casting coatings and the like, and is free of the color and the construction problems, and high in added value.

Owner:SHAANXI UNIV OF TECH

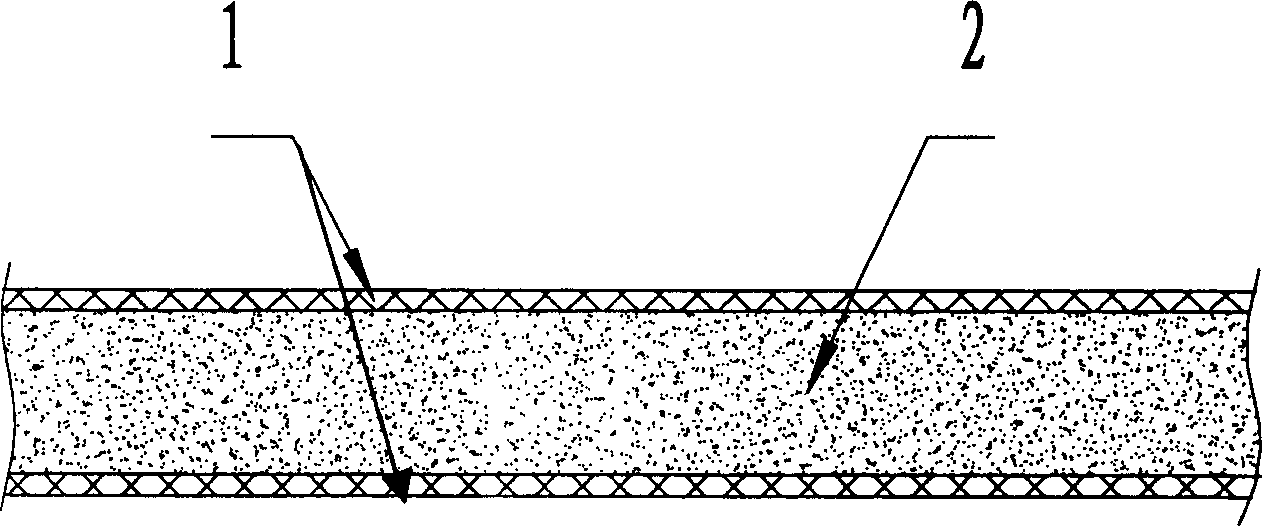

Carbon board and preparation method

InactiveCN1796097AMeet the shape requirementsMaintain porous structureLayered productsAdhesiveFar infrared

The present invention relates to a carbon plate and its preparation method, belonging to the field of indoor decorative material. Said carbon plate is composed of veneer material and intermediate mixture sandwich. Said intermediate mixture sandwich composition includes (by dry base weight portion) 100 portions of granular carbon and 5-33 portions of adhesive. Said carbon plate has the functions of adsorbing and purifying gas, regulating moisture and radiating far-infrared ray, and contains no the components of formaldehyde, toluene and dimethylbenzene, etc.

Owner:林文炳 +1

Cathode material of lithium sulfur battery and preparation method of cathode material

ActiveCN105514396AGrowth inhibitionLarge specific surface areaFinal product manufactureNon-aqueous electrolyte accumulator electrodesAdhesiveCarbon nanotube

The invention relates to a cathode material of a lithium sulfur battery and a preparation method of the cathode material. The cathode material is characterized by comprising the following raw material composition in parts by mass: 7 to 10 parts of steady-state lithium powder, 3 to 8 parts of a carbon material and a solvent. A mixture formed by mixing the steady-state lithium powder, a vertical array carbon nano tube (VACNT) and mesoporous carbon according to the mass ratio of 10:1 is specially adopted to serve as a carbon material in a cathode to prepare a cathode mixing slurry; therefore, use of an adhesive in the cathode slurry is avoided, and the cathode material of the lithium sulfur battery is better in performance. Meanwhile, the battery which is matched with an optimally selected anode material and is prepared by the preparation method disclosed by the invention is lower in impedance; the shuttle effect and dendritic crystal growth in the continuous charging and discharging processes can be effectively weakened; compared with a conventional metal lithium foil, the cathode material is higher in circulation performance and rate capability.

Owner:东莞市技领科技有限公司

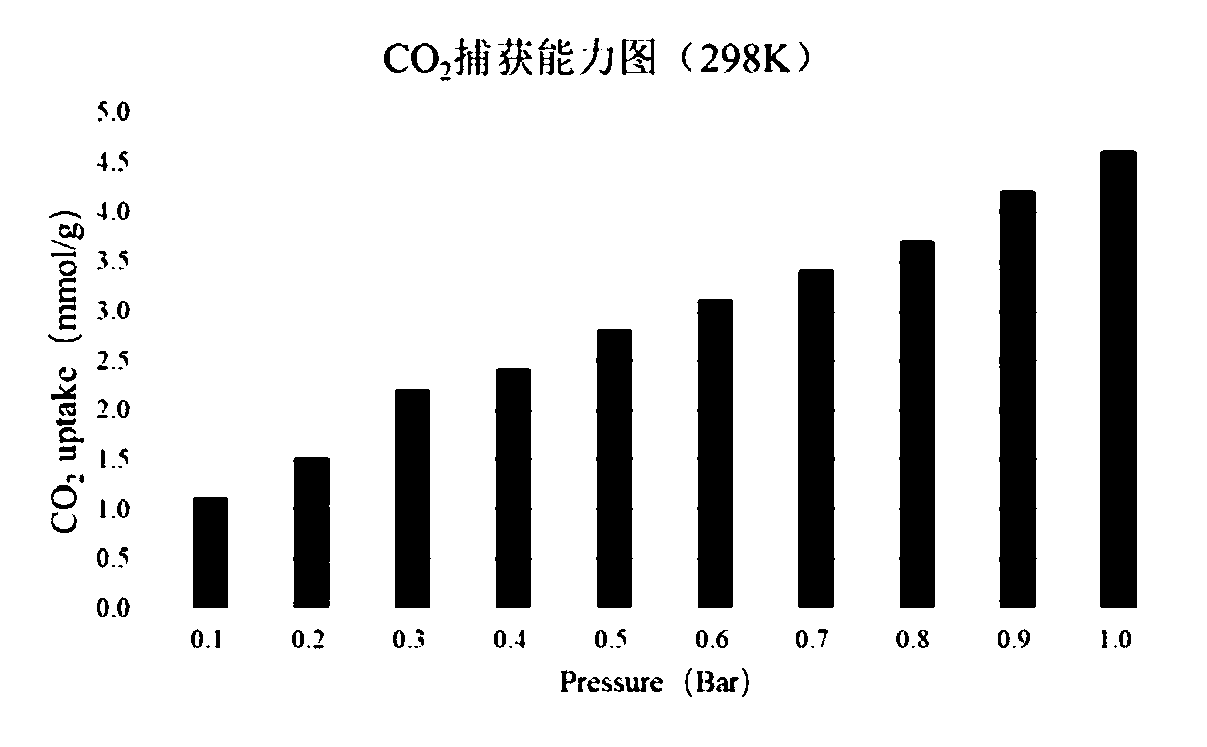

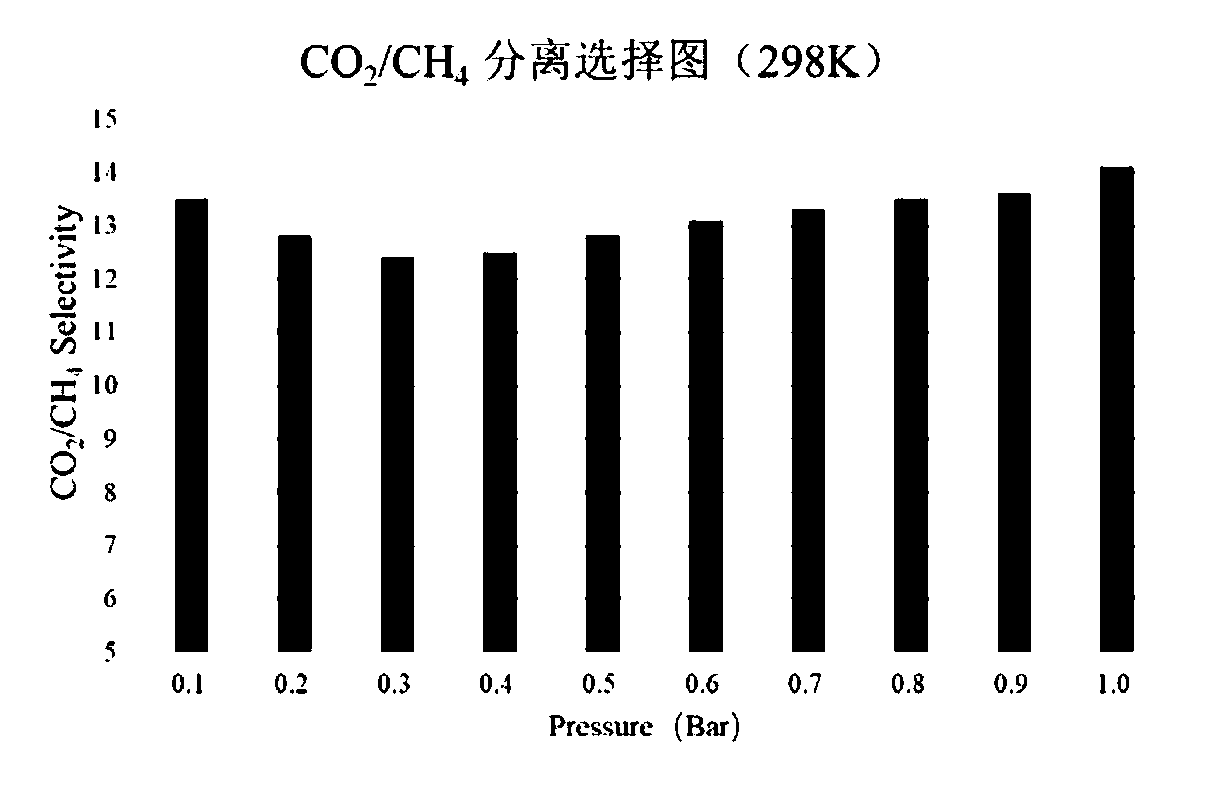

MOF (metal-organic framework) derived gas separation membrane as well as preparation method and application thereof

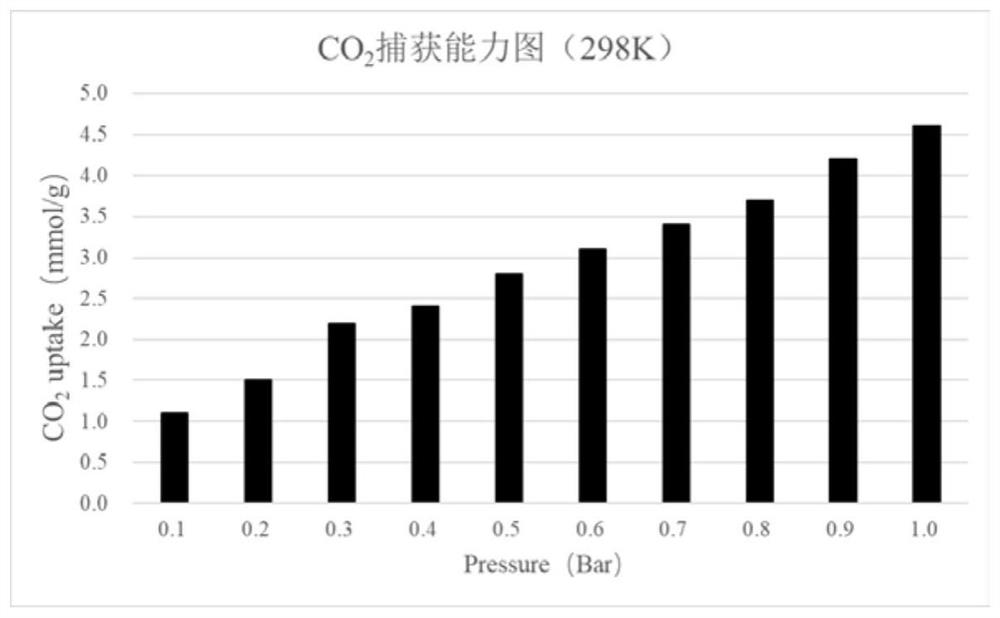

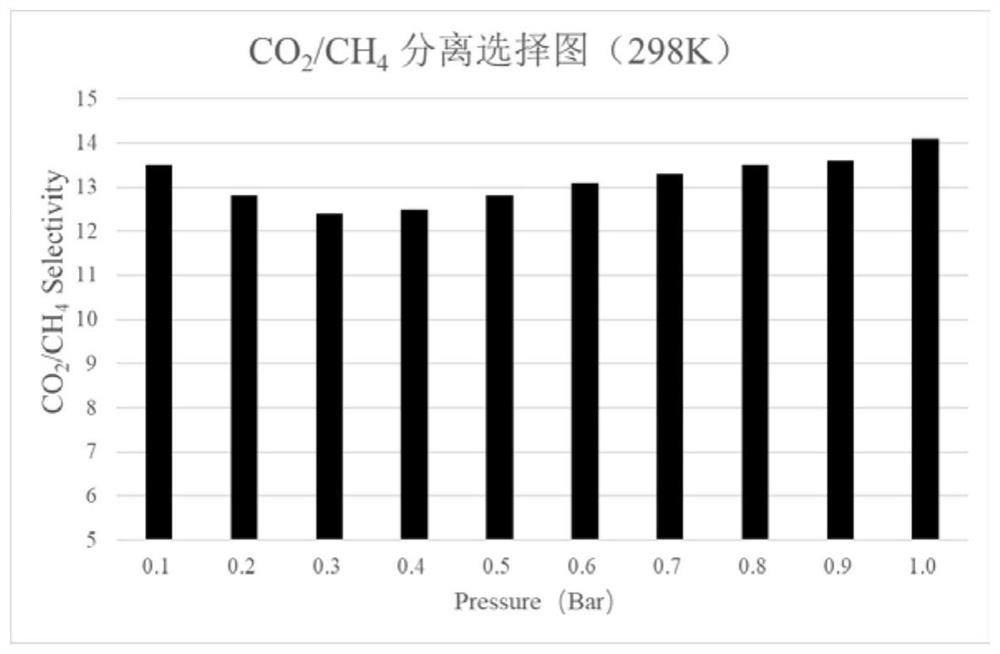

ActiveCN110270231ASimple methodReduce raw material costsSemi-permeable membranesGas treatmentIonChemistry

The invention discloses an MOF (metal-organic framework) derived gas separation membrane as well as a preparation method and application thereof. The preparation method of the MOF derived gas separation membrane comprises the following steps: dissolving H3BTC and Al(NO3)3*9H2O into deionized water, adjusting the pH value of the system to 1.9-2.0, adding aids, carrying out a complete reaction so as to obtain MIL-100Al and a triblock copolymer, dissolving the MIL-100Al and the triblock copolymer into an alcohol at room temperature under an ultrasonic condition, adding the components into a 37wt% hydrochloric acid solution, carrying out ultrasonic mixing for 24 hours at room temperature, further carrying out a copolymerization reaction for 24 hours at 100-120 DEG C so as to obtain a solid mixture after the reaction is completed, carrying out high-temperature carbonization so as to obtain an MIL-100Al porous carbon material, dissolving the MIL-100Al porous carbon material into an NMP (N-methyl pyrrolidone) solution, carrying out mixing and stirring so as to obtain a clear and uniform viscous solution, and carrying out casting, so as to obtain the MOF derived gas separation membrane. The prepared membrane structure has rich micropores, has an outstanding CO2 capturing capability at normal pressure, in addition has good separation selectivity upon CO2 and CH4, has a good circulation use capability, and provides valuable references for application of an MOF derived material in the field of membrane materials.

Owner:ZHEJIANG UNIV OF TECH

Negative electrode material of lithium-sulfur battery and preparation method of negative electrode material

ActiveCN105552307AGrowth inhibitionLarge specific surface areaCell electrodesLithium–sulfur batteryElectrical battery

The invention relates to a negative electrode material of a lithium-sulfur battery and a preparation method of the negative electrode material. The negative electrode material comprises the following compositions based on mass: 5-10 parts of steady-state lithium powder, 3-7 parts of carbon material, 1 part of binding agent and a solvent. According to the preparation method, a mixture mixed by the steady-state lithium powder, carbon nanosphere / carbon nanotube and mesoporous carbon according to mass ratios of 5:2:1 is particularly selected as the carbon material in a negative electrode to prepare a negative electrode mixed paste, so that the negative electrode material of the lithium-sulfur battery has more excellent performance; the prepared battery according to the method is endowed with relatively small impedance, a shuttle effect and dendrite growth during the continuous charging / discharging process can be effectively reduced, and the battery shows batter cycle performance and rate performance than those of a conventional metal lithium foil.

Owner:湖南高瑞电源材料有限公司

Electrode material of nanometer porous film capacitor and preparation method thereof

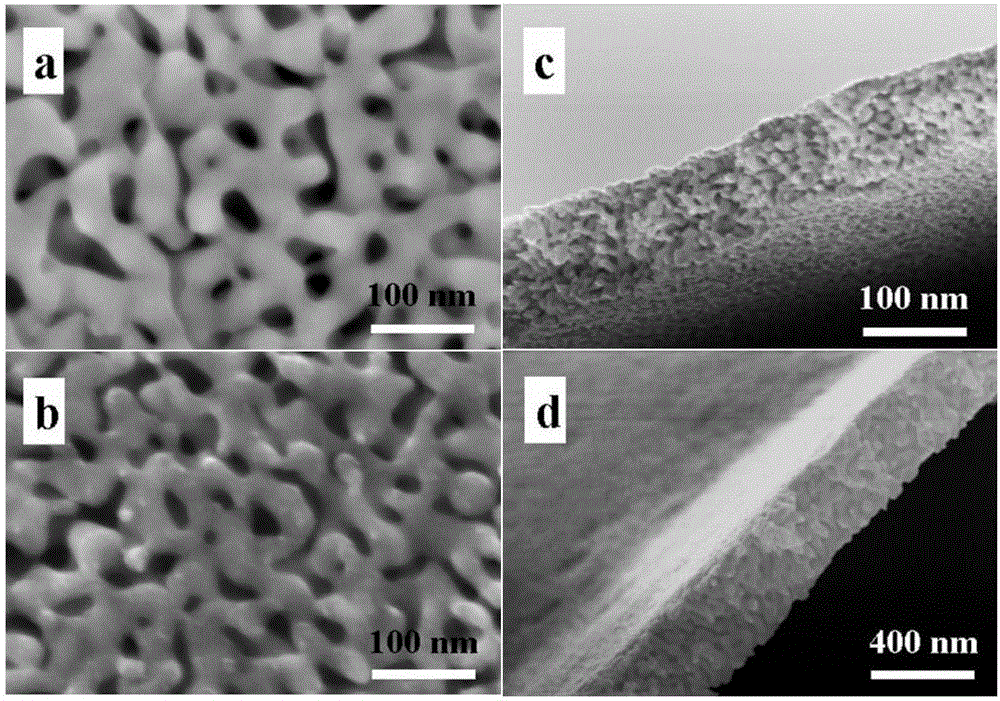

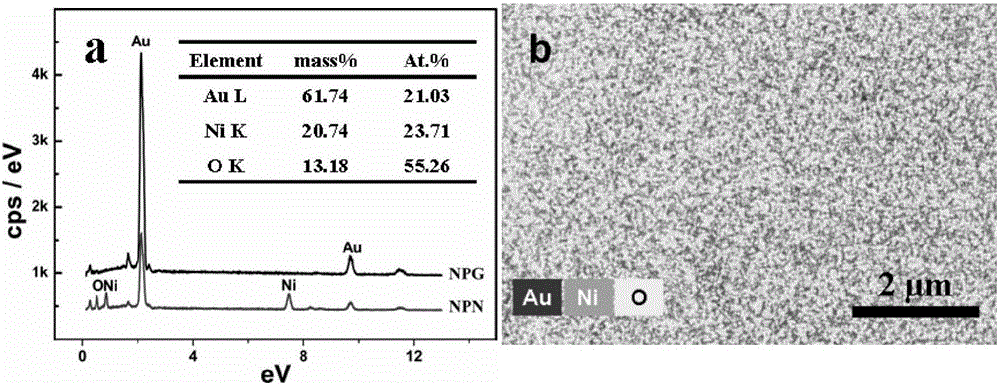

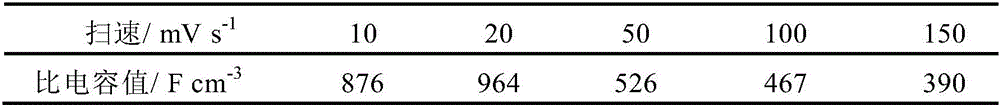

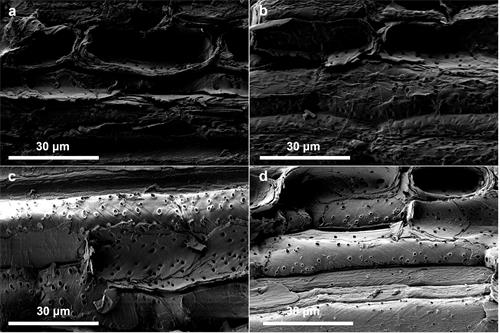

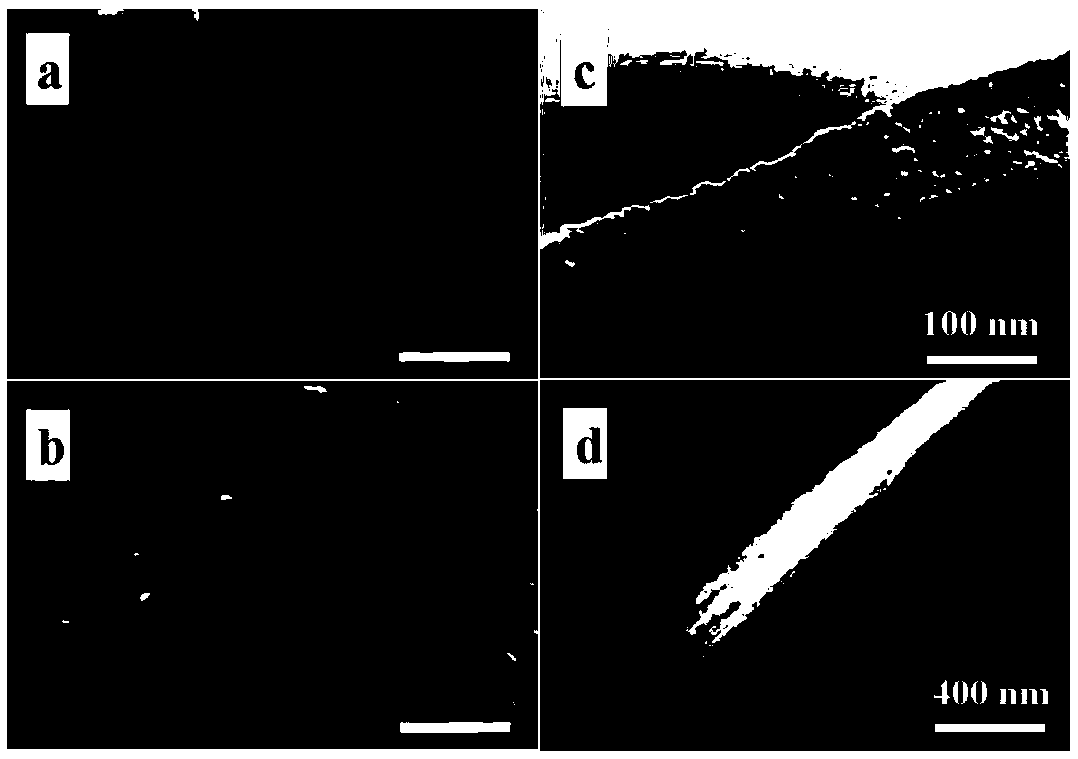

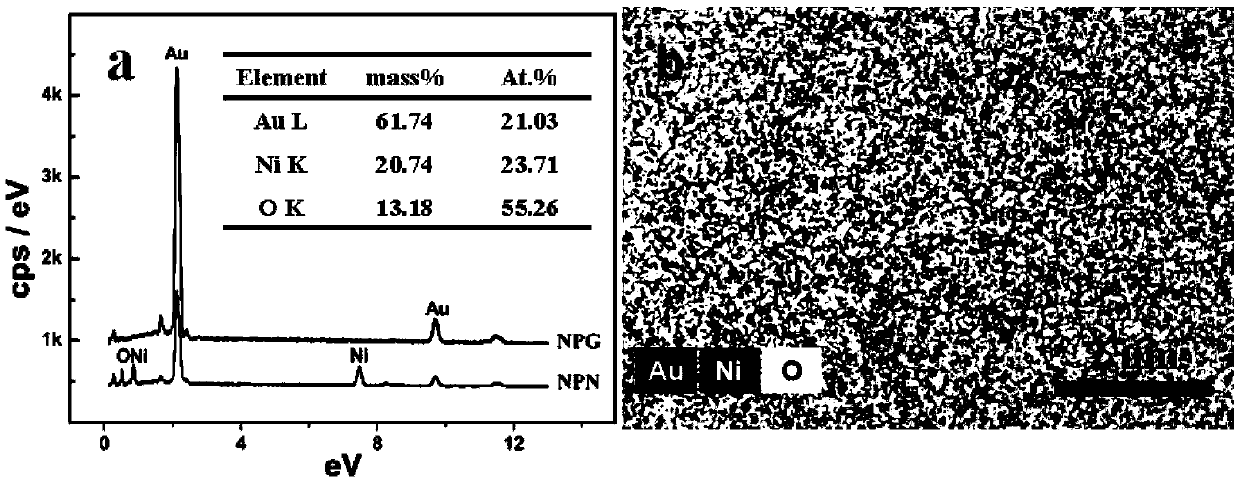

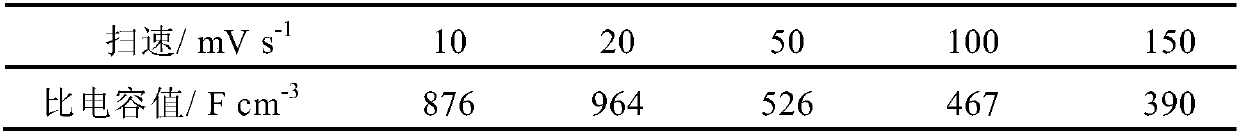

InactiveCN106098415AMaintain porous structureImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureChemical platingOxygen

The invention provides an electrode material of a nanometer porous film capacitor and a preparation method thereof. The method comprises the following steps of: taking nanometer porous gold as a substrate material, putting the nanometer porous gold into a plating solution with nickel nitrate as a main component, and loading nickel on a nanometer porous gold surface by using a chemical plating method; and keeping the nanometer porous gold loaded with the nickel in the air for a certain time. The nanometer porous gold is taken as a substrate, and the metal Ni is modified on the surface of the nanometer porous gold by the interface chemical plating method. The Ni is contacted with oxygen in the air to form NiO, and a nanometer porous nickel oxide film material is obtained. SEM and EDS tests show that the prepared NiO material keeps the porous structure of the substrate and improves the electrical conductivity and ion conductivity of the electrode material. The prepared porous nickel oxide is good super capacitor electrode material with exploitation potential.

Owner:YILI NORMAL UNIV

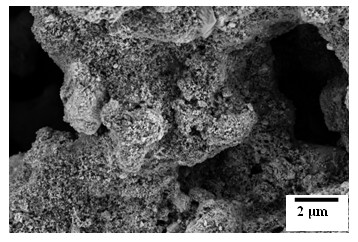

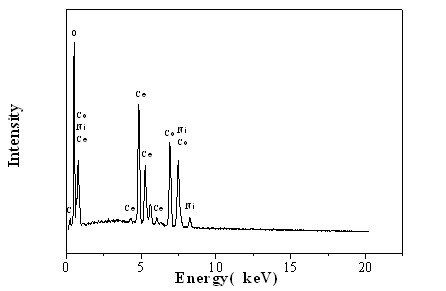

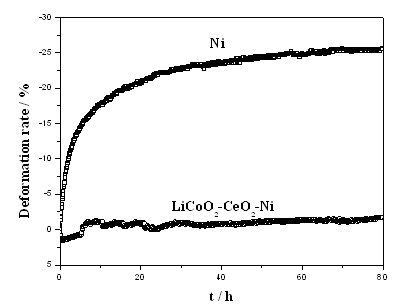

Ternary composite matrix anode material for molten carbonate fuel cell (MCFC) and preparation method of ternary composite matrix anode material

InactiveCN102306806AImprove toughnessHigh strengthCell electrodesMolten carbonate fuel cellNanoceramic

The invention discloses a ternary composite matrix anode material for a molten carbonate fuel cell (MCFC) and a preparation method of the ternary composite matrix anode material. The preparation method comprises the following steps of: depositing two nano ceramic particles with high properties on a porous nickel matrix simultaneously; and sintering under an inert atmosphere, and thus obtaining a composite matrix anode, wherein the nano ceramic particles mainly comprise LiCoO2 and one of LiFeO2 and CeO2, and the deposited polynary nano ceramic particle layer is uniformly distributed on the surface of the porous nickel matrix and has high bonding force together with the matrix. The ternary composite matrix anode material has high mechanical strength, high deformation resistance, high dissolving resistance, a simple preparation process and extremely short preparation time and can be used for MCFC stack actual industries.

Owner:ZHEJIANG SCI-TECH UNIV

Diatom-ooze decorative material and preparation method thereof

The invention discloses a diatom-ooze decorative material and a preparation method thereof. The diatom-ooze decorative material is prepared from the following raw materials in parts by weight: 40-60 parts of diatomite, 1.0-1.5 parts of palygorskite, 3.0-3.5 parts of magnesium silicate, 1.5-2 parts of cellulose, 50-60 parts of heavy calcium carbonate, 20-25 parts of coarse sand, 4-5 parts of ash calcium powder, 2.0-2.5 parts of nano titanium dioxide, 1-3 parts of antibacterial agent and 0.2-0.4 part of defoaming agent. The diatom-ooze decorative material prepared by the method has the advantages that because of no need of adding chemical adhesive and no-adhesive wall decoration, the environment-friendly effect is achieved; because of better water absorptivity and insulating-oxygenating effects and a better adsorbing effect and wall-surface texture, the environment-friendly effect is achieved and the comprehensive effect is good.

Owner:东莞市爱乐居环保科技有限公司

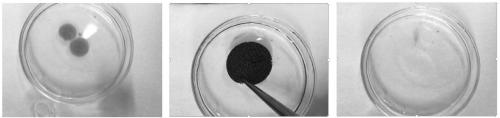

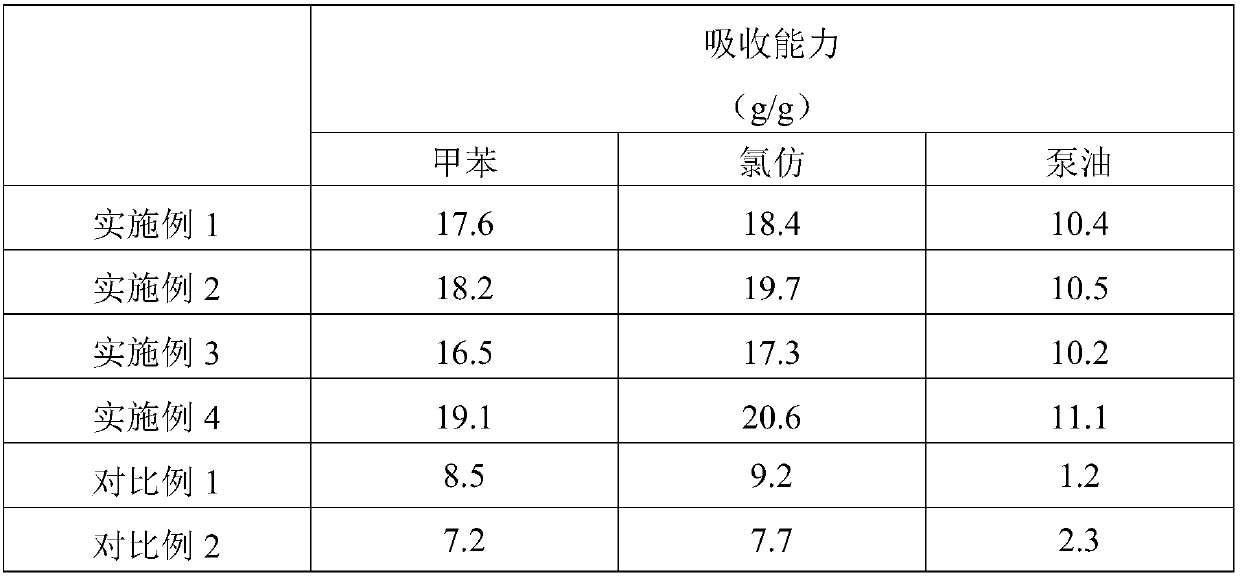

Preparation method of hydrophobic and oleophylic porous material

The invention discloses a preparation method of a hydrophobic and oleophylic porous material. The preparation method comprises the following steps: providing a precursor solution containing nanoscalegraphite particles, a polymer monomer, an initiator, a cross-linking agent, a pore opening agent, a surfactant and water; carrying out pre-polymerization treatment on the precursor solution at a firsttemperature to form a prepolymer; and at a second temperature, carrying out polymerization pore opening treatment on the prepolymer to obtain the hydrophobic and oleophylic porous material, wherein the first temperature is lower than the second temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

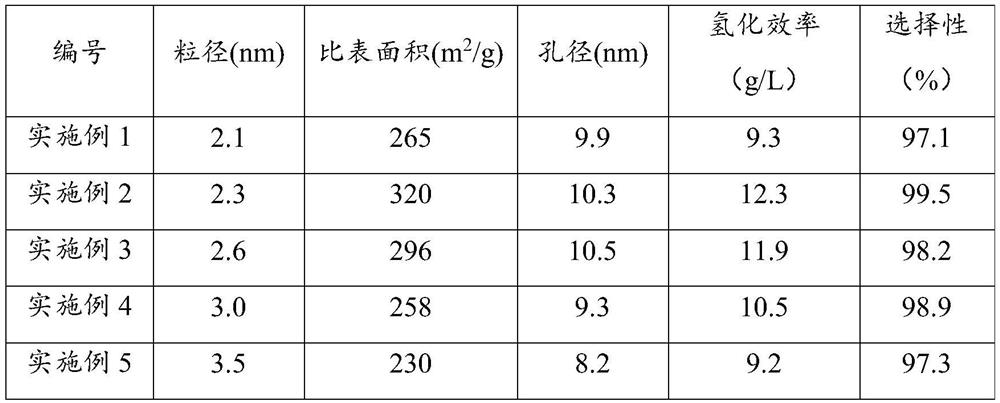

Preparation method of modified alumina carrier, palladium catalyst and preparation method thereof

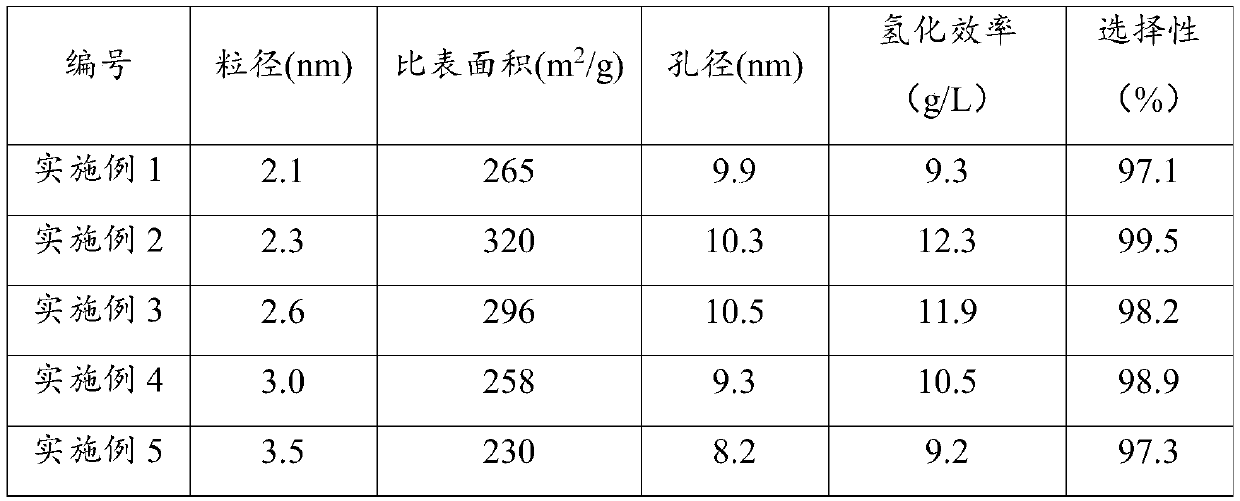

ActiveCN109967132AHigh mechanical strengthStable structureMaterial nanotechnologyCatalyst carriersReduction treatmentFiltration

The invention relates to the technical field of catalysts, and provides a preparation method of a modified alumina carrier. The method comprises the following steps: preparing alumina colloid; evenlymixing the alumina colloid with silica sol to form a spherical carrier; and successively performing aging, drying and roasting on the spherical carrier to obtain the modified alumina carrier. According to the method, pseudo-boehmite does not need to be prepared, the aluminum source can be directly formed after gelling, filtration and acid dissolution, the production technological process is greatly shortened, the equipment cost is reduced, and the industrialized production is convenient. The prepared carrier has the advantages of many acidic active sites, large pore size, high strength and large specific surface area. The invention provides a palladium catalyst containing the above carrier and a preparation method thereof. According to the method, the reduction process of a metal does notneed high temperature roasting and hydrogen reduction treatment, the method has the advantages of safety, high efficiency and low energy consumption. The prepared catalyst has the advantages of smallparticle size of palladium nanoparticles, large specific surface area, moderate pore size and high hydrogenation efficiency and selectivity.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

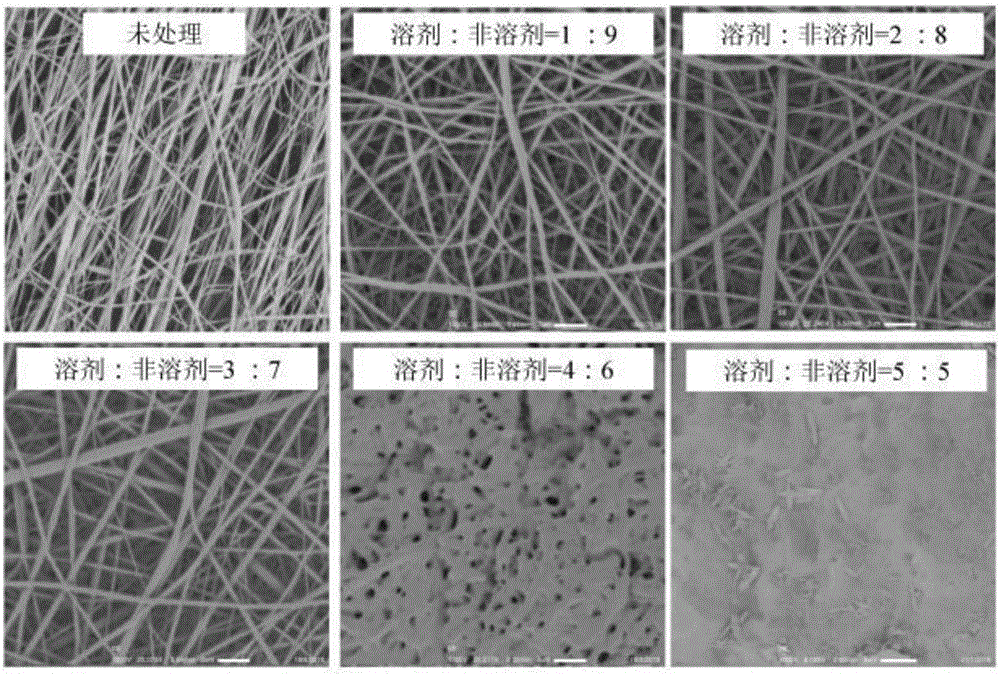

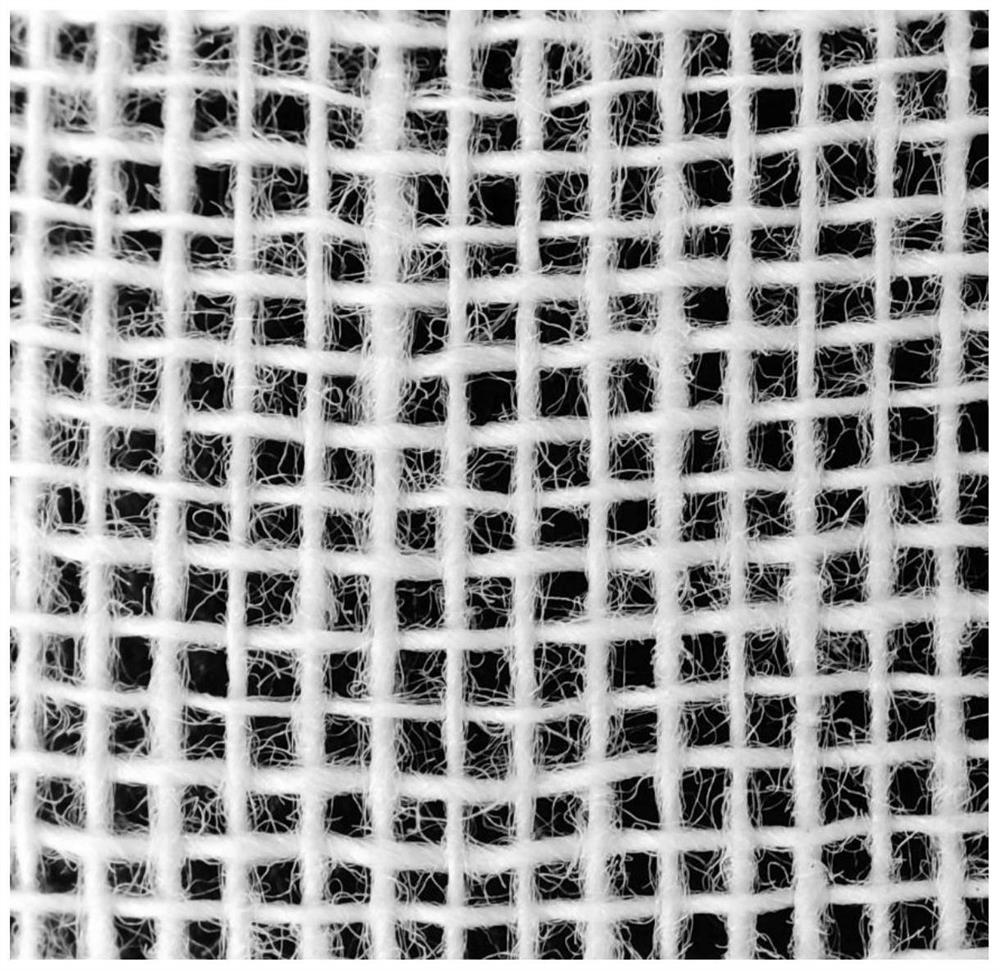

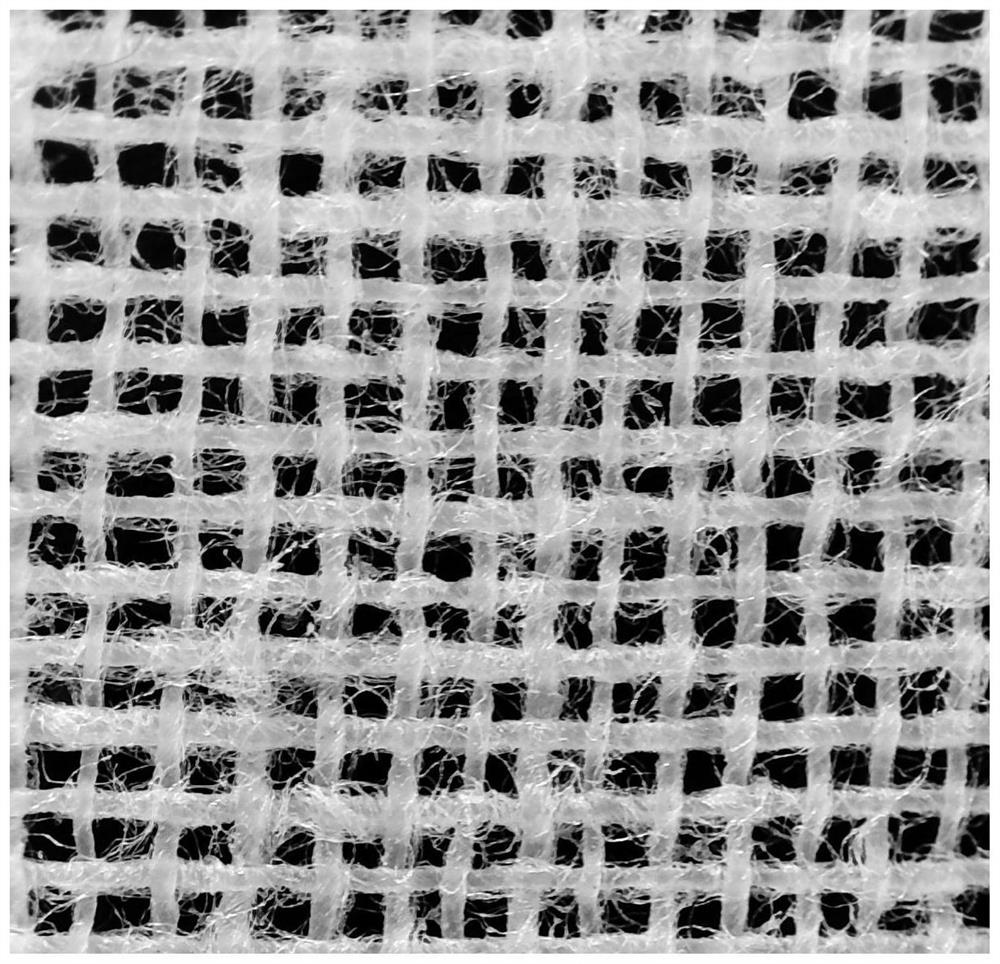

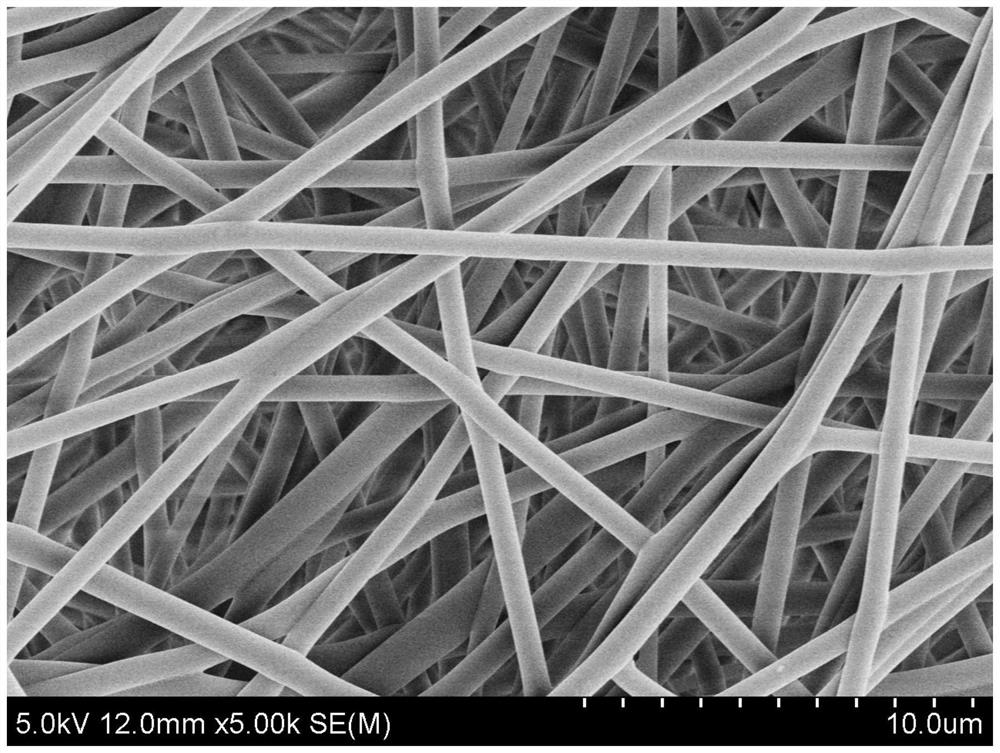

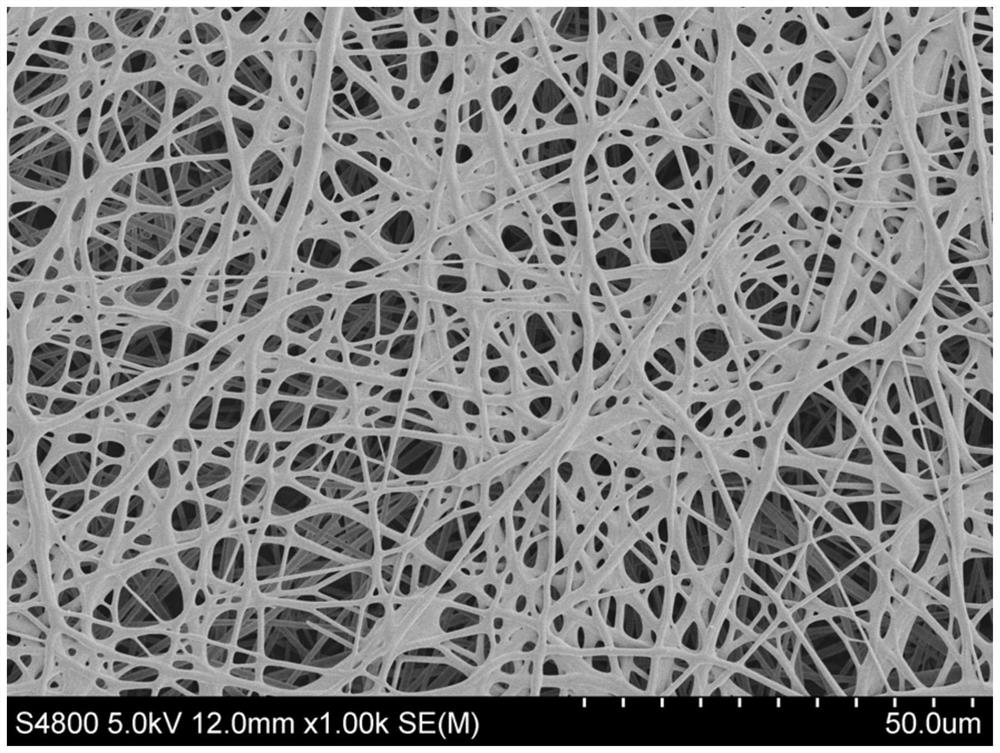

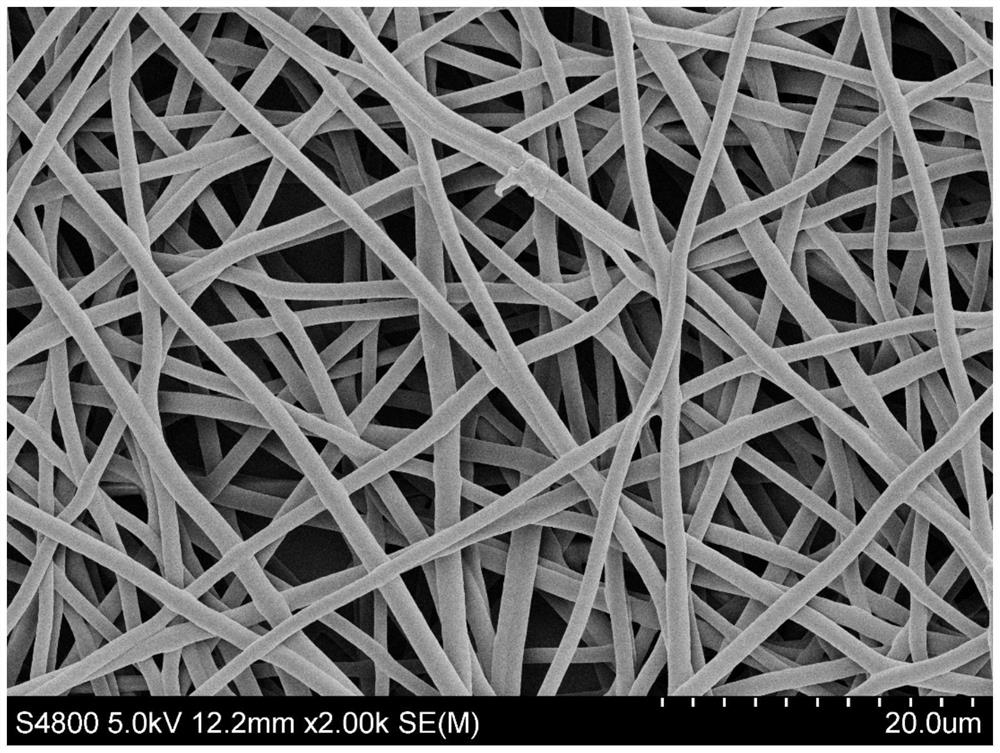

Reagent and method for enhancing mechanical performance of electrostatic spinning film

InactiveCN106436276AImprove the degree of adhesionMaintain porous structureFibre typesElectro-spinningNon solventBreaking strength

The invention provides a reagent for enhancing the mechanical performance of an electrostatic spinning film. The regent is prepared from a solvent and a nonsolvent for a film material in a mixed mode; the solvent is a substance capable of dissolving the electrostatic spinning film or a mixture of two substances capable of dissolving the electrostatic spinning film, and the nonsolvent is a substance incapable of dissolving the electrostatic spinning film or a mixture of two substances incapable of dissolving the electrostatic spinning film; as for the mixed ratio of the solvent to the nonsolvent, the quantity of the solvent can be continuously increased in a certain quantity of the nonsolvent till the material of the electrostatic spinning film is swelled; after contact parts between fibers are swelled, combining is tighter, and after the solvent is volatilized, the mechanical performance of the film can be greatly improved. According to the reagent and method for enhancing the mechanical performance of the electrostatic spinning film, the elasticity modulus, the breaking strength and the toughness of the electrostatic spinning film can be enhanced at the same time.

Owner:ZHENGZHOU UNIV

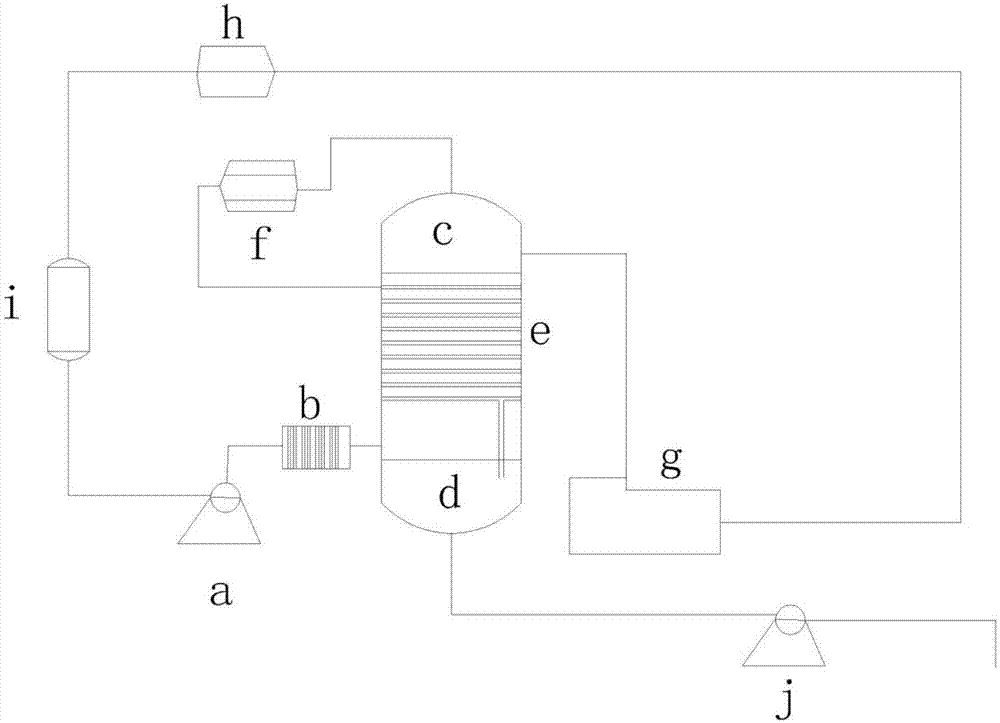

Low-temperature antibacterial drying equipment and drying processing method of material

InactiveCN107485039AReduce wasteLow costDrying solid materials without heatDrying gas arrangementsNutrientProcess engineering

The invention discloses low-temperature antibacterial drying equipment. The low-temperature antibacterial drying equipment comprises a gas delivery device (a), a heat exchanger (b), a drying tower (c), a compressor (f), a vacuum pump (g), a compressor (h) and a gas tank (i), wherein the heat exchanger (b), the compressor (f) and the vacuum pump (g) are connected to the drying tower (c); the gas delivery device (a) is connected with the gas tank (i) and the heat exchanger (b); the compressor (h) is connected with the gas tank (i) and the vacuum pump (g); and a heat exchanger (e) is arranged in the drying tower (c). Through adoption of the equipment provided by the invention, materials can be vacuum-dried at low temperature, and loss of heat-sensitive nutrient substances in the materials can be avoided; and besides, because the materials are in a vacuum state, the materials can be effectively prevented from shrinking and deforming, and the porous structure of the product is maintained.

Owner:LINYI YUWANG VEGETABLE PROTEIN

A kind of lithium-sulfur battery negative electrode material and preparation method thereof

ActiveCN105552307BGrowth inhibitionLarge specific surface areaCell electrodesMass ratioLithium–sulfur battery

The invention relates to a negative electrode material of a lithium-sulfur battery and a preparation method of the negative electrode material. The negative electrode material comprises the following compositions based on mass: 5-10 parts of steady-state lithium powder, 3-7 parts of carbon material, 1 part of binding agent and a solvent. According to the preparation method, a mixture mixed by the steady-state lithium powder, carbon nanosphere / carbon nanotube and mesoporous carbon according to mass ratios of 5:2:1 is particularly selected as the carbon material in a negative electrode to prepare a negative electrode mixed paste, so that the negative electrode material of the lithium-sulfur battery has more excellent performance; the prepared battery according to the method is endowed with relatively small impedance, a shuttle effect and dendrite growth during the continuous charging / discharging process can be effectively reduced, and the battery shows batter cycle performance and rate performance than those of a conventional metal lithium foil.

Owner:湖南高瑞电源材料有限公司

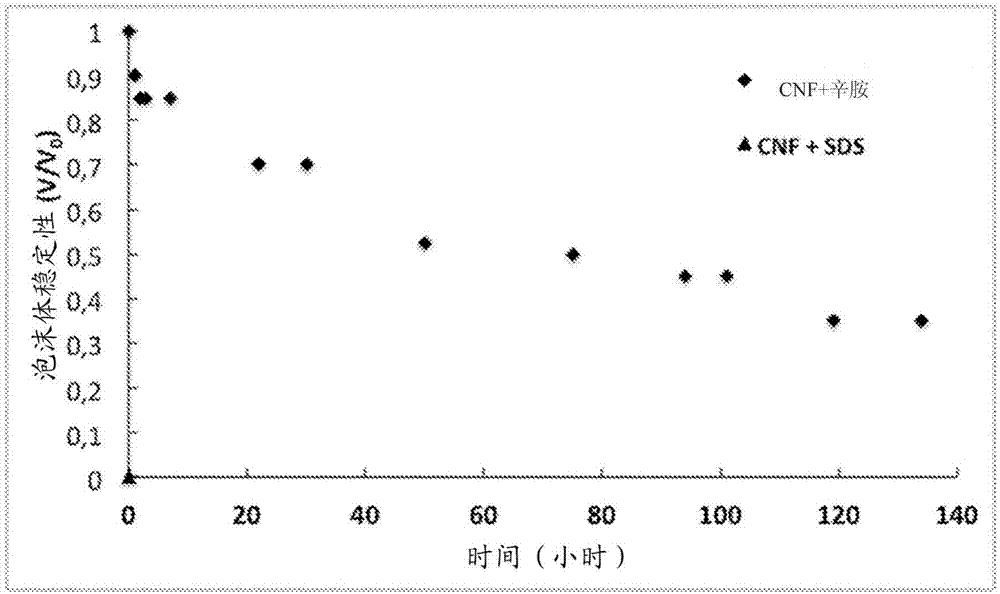

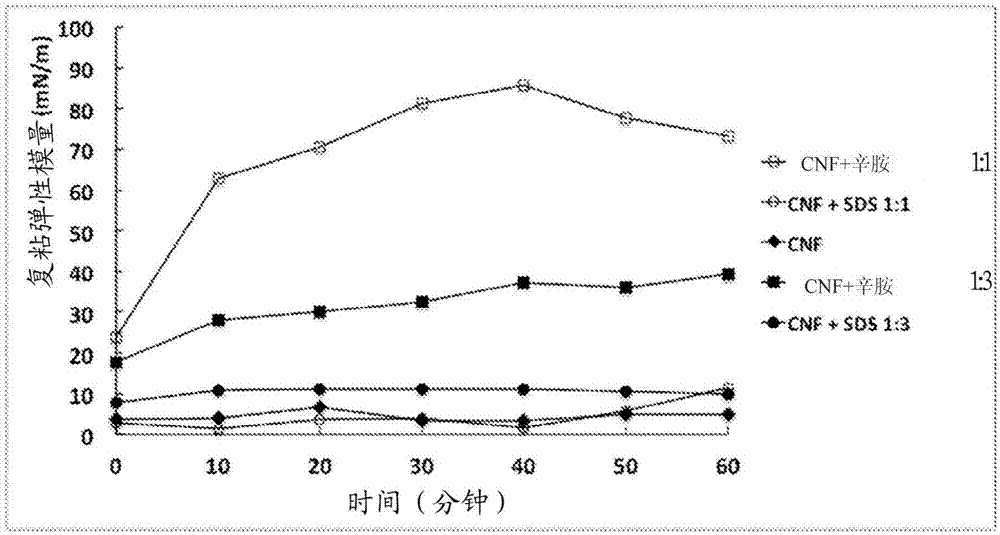

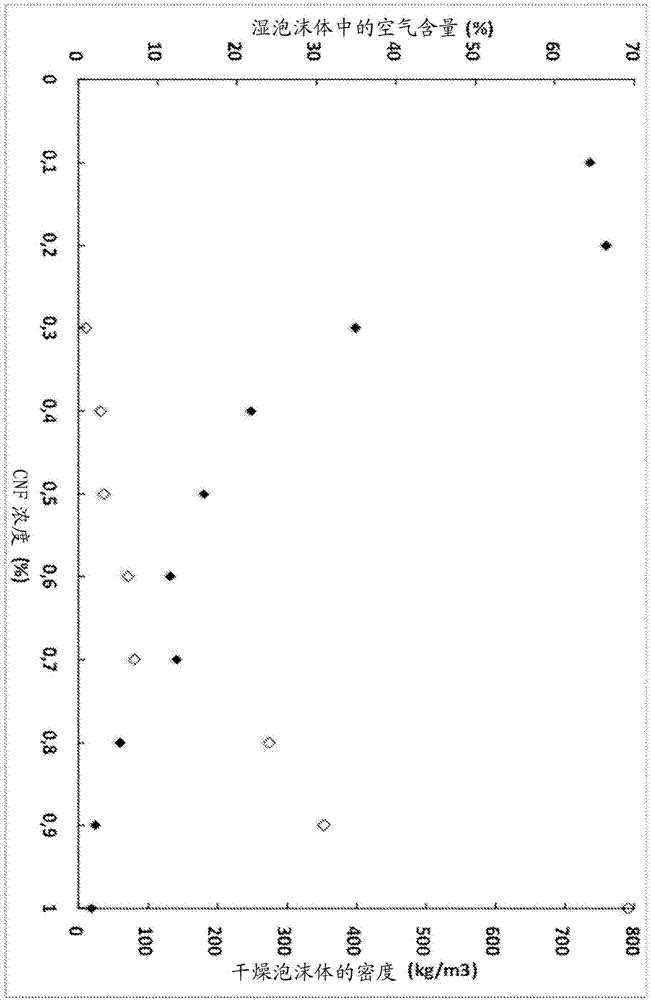

CNF cellular solid material with anionic surfactants

ActiveCN107108946AMaintain porous structureExcellent mechanical propertiesFlexible coversWrappersCelluloseFiber

Owner:CELLUTECH

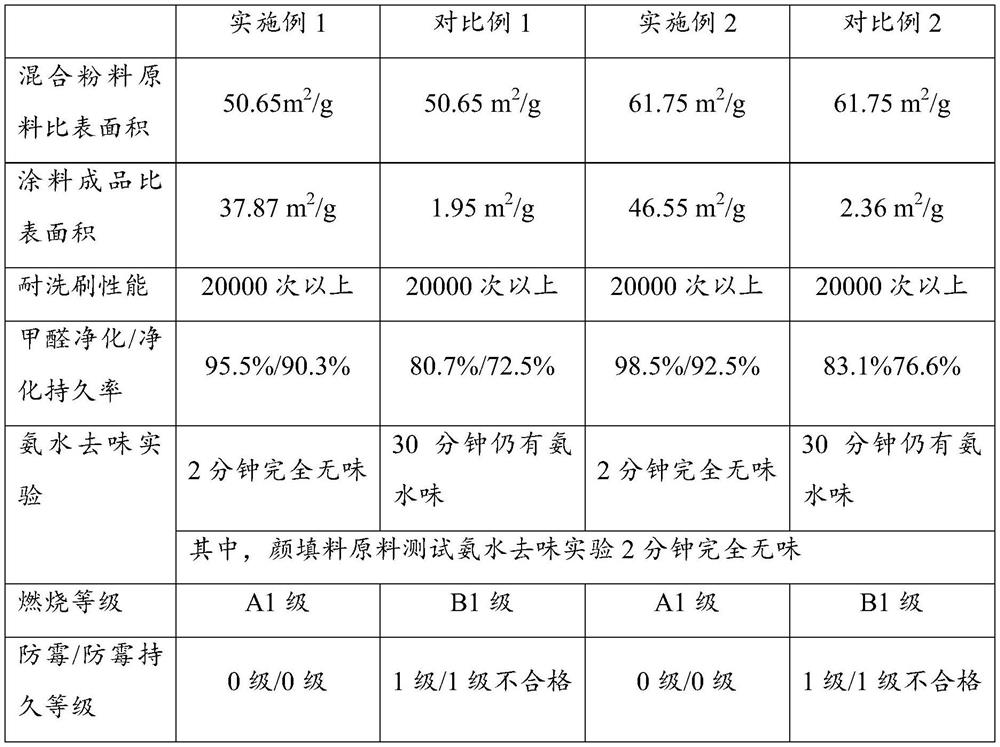

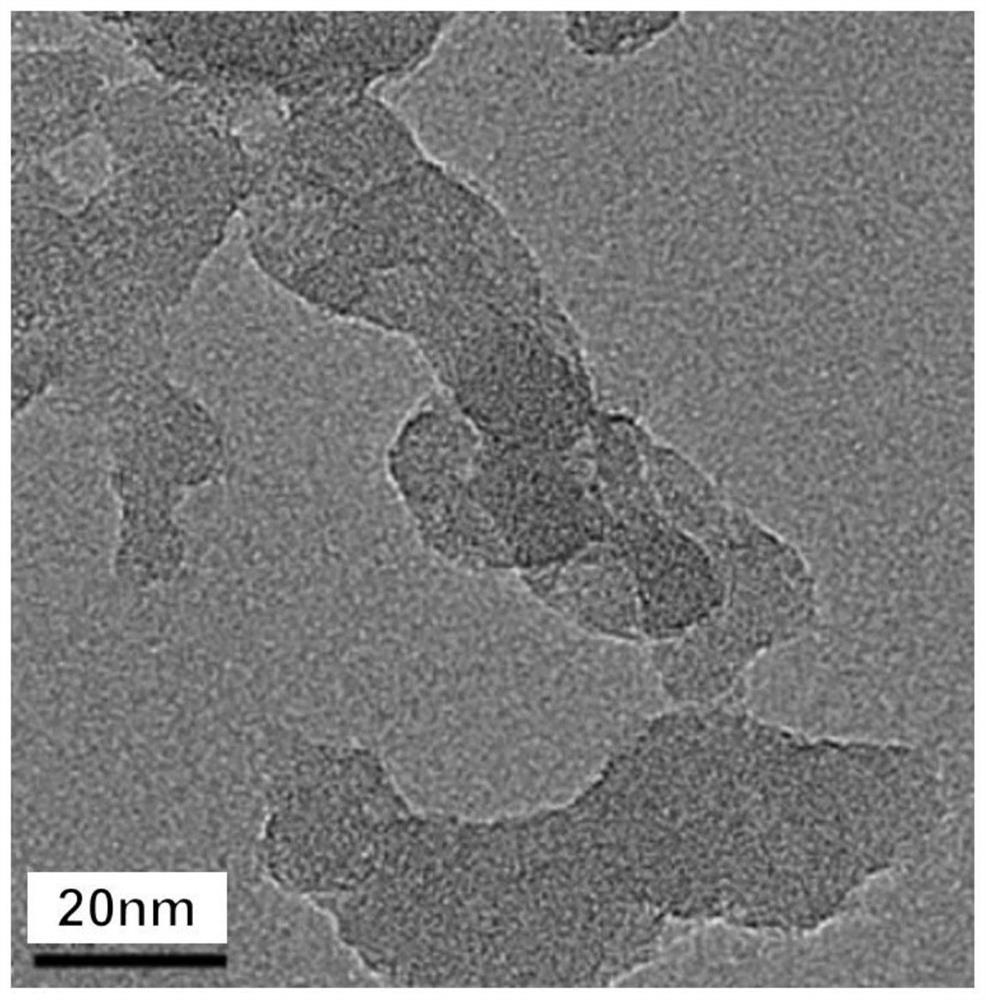

Purifying coating as well as preparation method and application thereof

PendingCN114686024AImprove purification effectLarge specific surface areaAlkali metal silicate coatingsPotassium silicateSilicic acid

The invention relates to a purification coating as well as a preparation method and application thereof. According to the purification coating disclosed by the invention, the potassium silicate solution is used as an inorganic binding material, the porous adsorbent is used as an adsorbent, and binding can be realized in a discontinuous film forming manner, so that the porous structure of the powder raw material is kept to a greater extent, the specific surface area of the coating is increased, and the purification effect of the coating is finally improved. The invention further provides a preparation method of the purification coating and a purification coating, the purification coating is bonded in a discontinuous film forming mode, after the coating is hardened during construction, the porous structure of the material can still be reserved, and the coating is a water-based coating which is resistant to water, resistant to scrubbing, super-strong in mildew resistance and high in purification effect and is especially suitable for coating of an inner wall.

Owner:长沙标朗住工科技有限公司

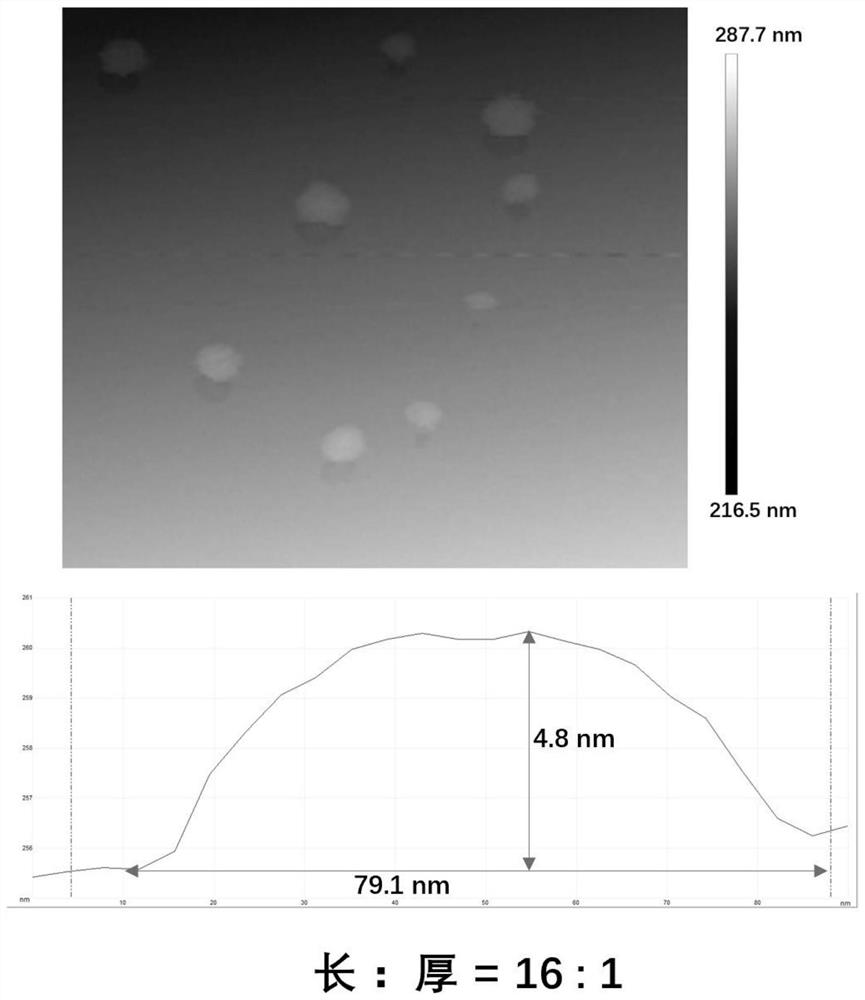

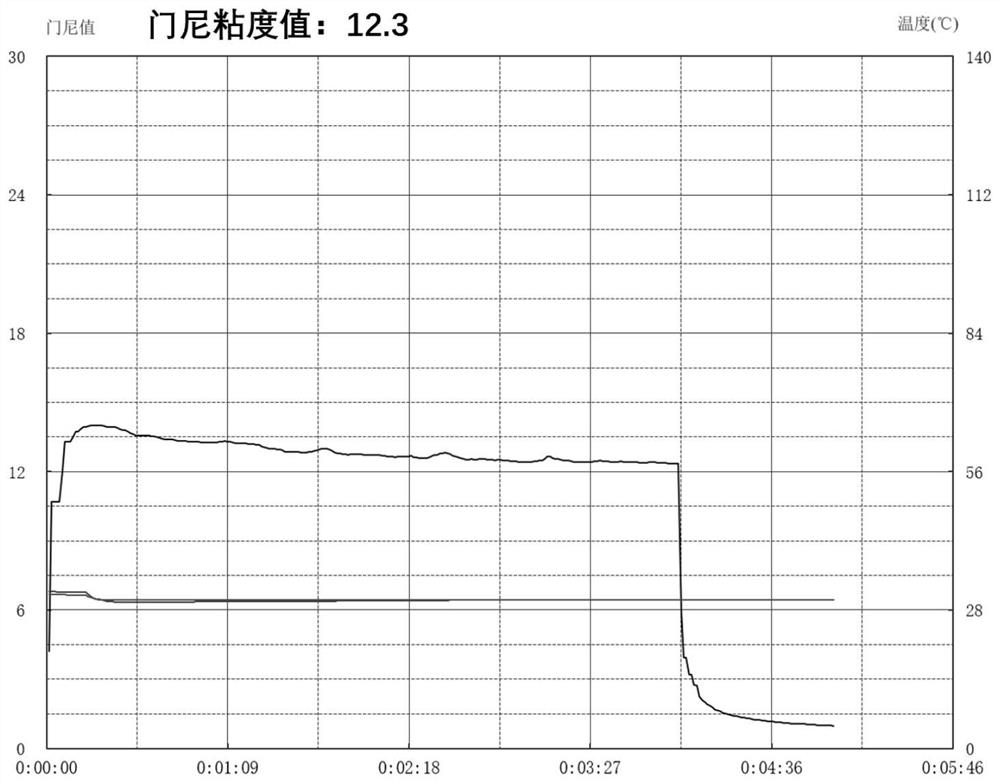

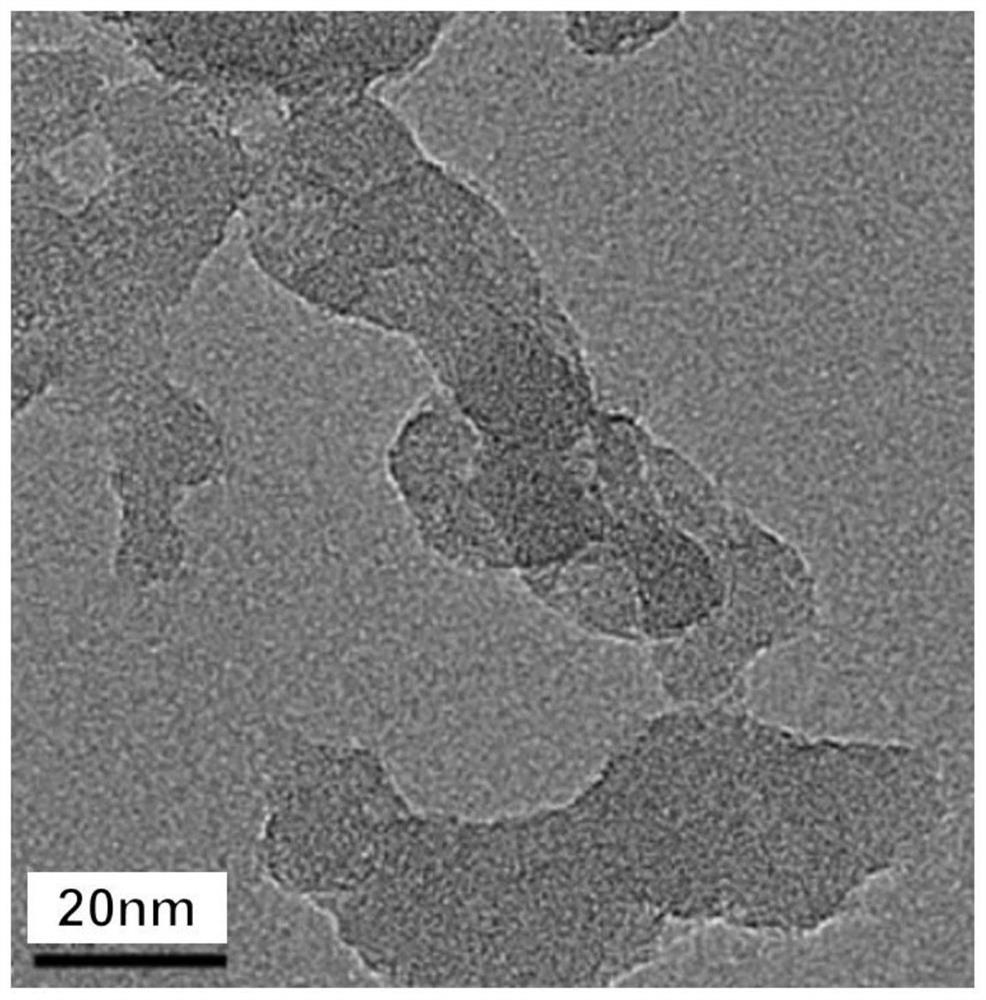

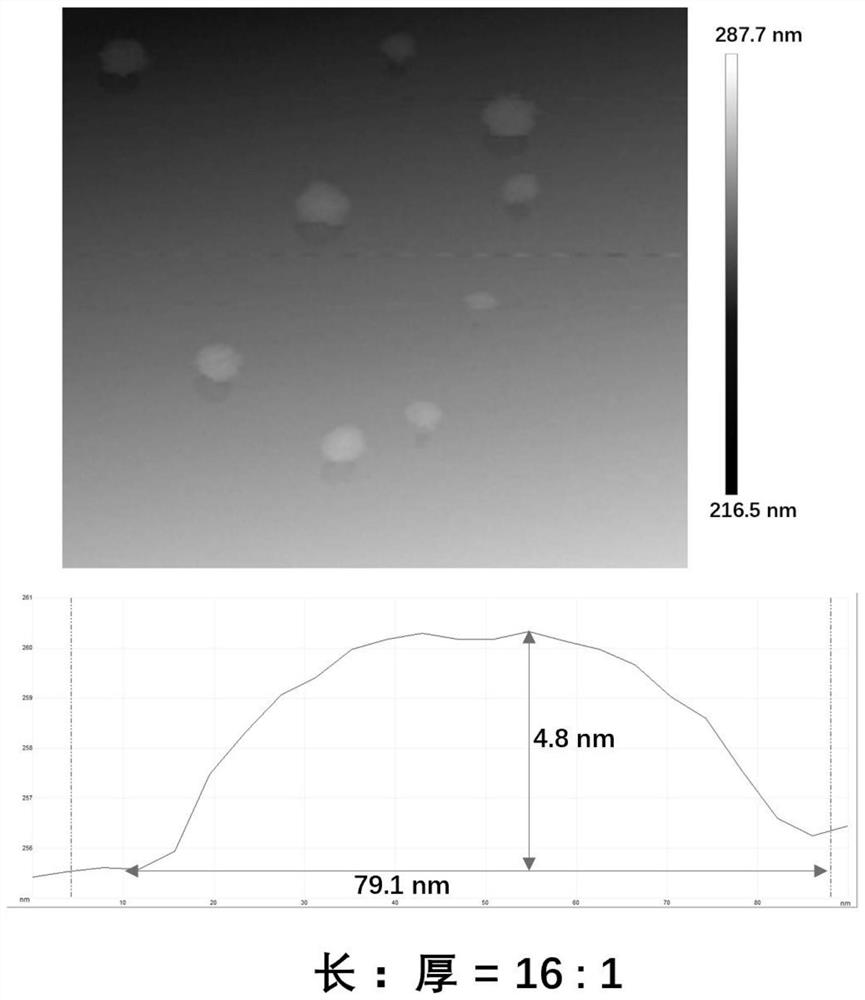

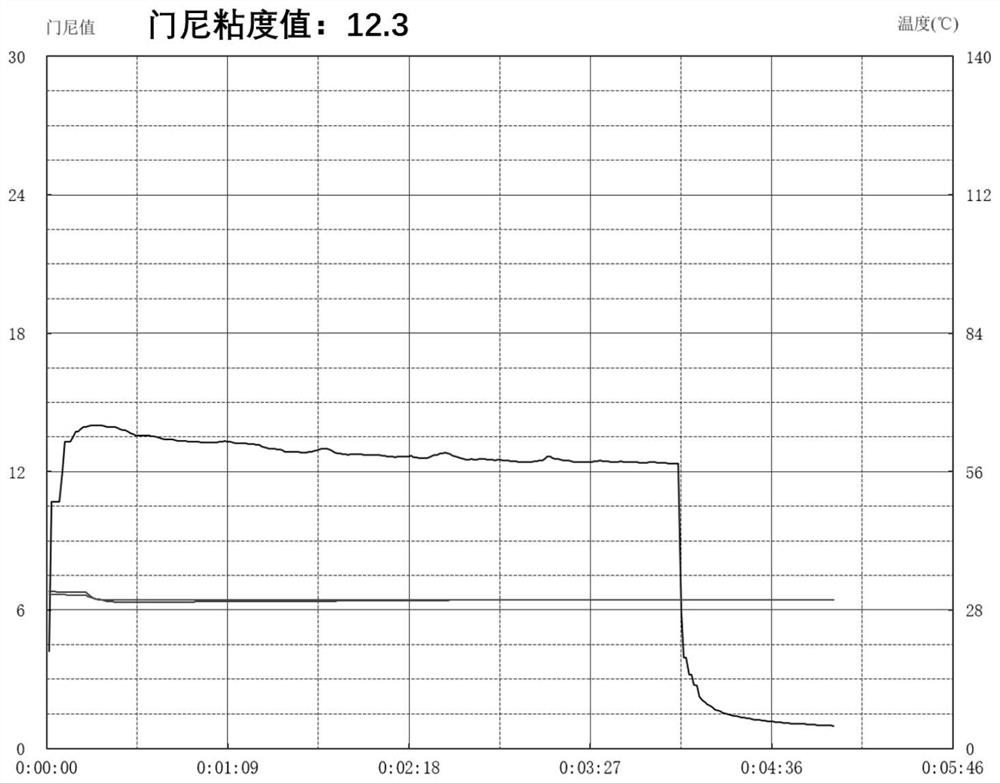

Modified fumed silica with flattened structure and high tap density as well as preparation method and application of modified fumed silica

ActiveCN113105758ALarge specific surface areaHigh reinforcement propertiesPigment treatment with organosilicon compoundsPigment physical treatmentPolymer scienceFumed silica

The invention provides modified fumed silica with a flat structure and high tap density as well as a preparation method and application of the modified fumed silica. By utilizing a rotary vacuum reaction kettle, under the action of a structured modification additive and the gravity action of the fumed silica in the rotary process, the fumed silica is directionally gathered to form a flat structure, so that the tap density of the modified fumed silica is improved, and the fumed silica is endowed with good low-thickening characteristic; the viscosity in a rubber compound of the rubber is reduced; and meanwhile, the porous structure of the fumed silica can be kept, it is ensured that the fumed silica has the high specific surface area, and the high reinforcing characteristic of the fumed silica in rubber is achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of hydrogel gauze capable of preventing blood adhesion

ActiveCN114045681AMaintain porous structureAir permeability effectPharmaceutical delivery mechanismAbsorbent padsPolymer scienceMeth-

The invention provides hydrogel gauze capable of preventing blood adhesion, and belongs to the technical field of biochemical engineering. The preparation method of the hydrogel gauze comprises the following steps: S1, adding a monomer and hydroxyl silicone oil into a solvent, and fully stirring and emulsifying to obtain a uniform emulsified solution; and adding a photoinitiator and N-aminoethyl-3-aminopropyl methyl dimethoxy silane, and fully stirring and mixing, so as to obtain a gel precursor solution, wherein the monomer is composed of a first monomer and a second monomer, the first monomer comprises acrylamide, and the second monomer comprises a silane coupling agent containing double bonds; S2, soaking gauze in the gel precursor solution, and enabling the soaked gauze to be subjected to light curing treatment to prepare the hydrogel gauze capable of preventing blood adhesion. The hydrogel gauze retains the softness and air permeability of original gauze, and meanwhile has a good anti-adhesion effect on solutions such as water, protein and blood.

Owner:GUANGZHOU UNIVERSITY

Composite photothermal conversion material based on shaddock peel as well as preparation and application of composite photothermal conversion material

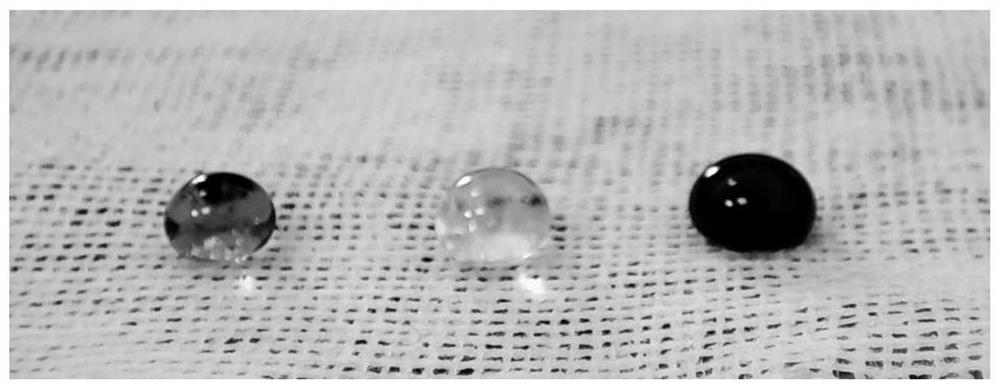

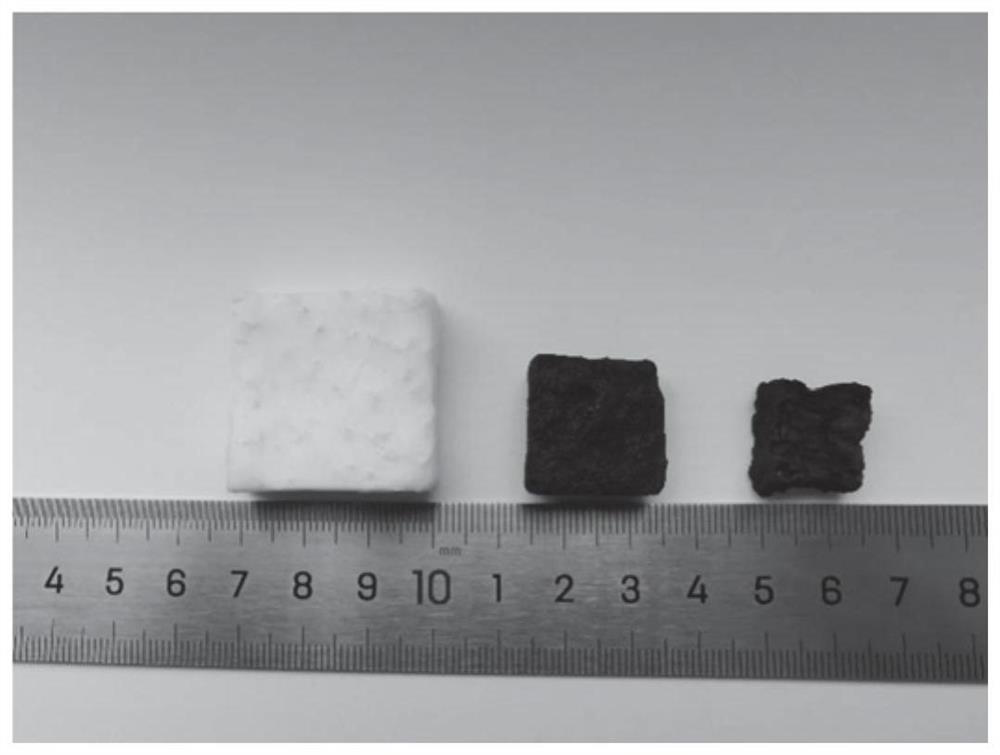

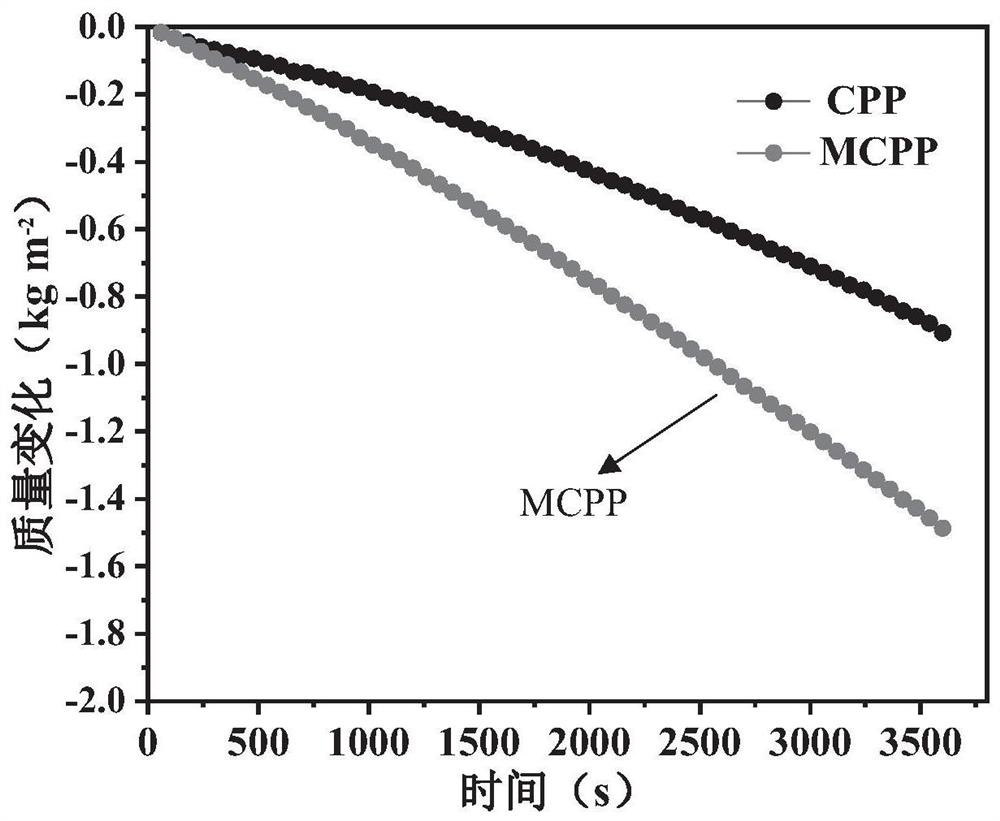

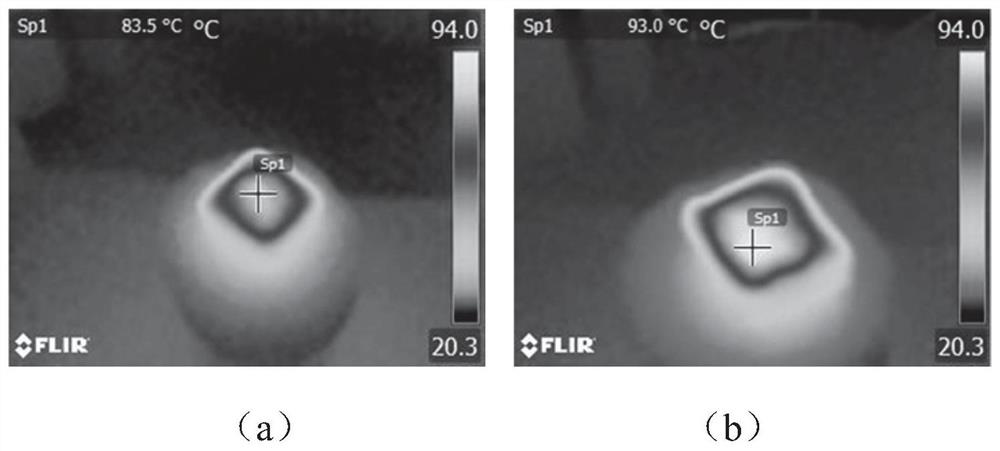

ActiveCN113247980AImprove use valueWide variety of sourcesGeneral water supply conservationSeawater treatmentPhotothermal conversionCarbonization

The invention belongs to the technical field of solar photo-thermal conversion, and discloses a composite photo-thermal conversion material based on shaddock peel and preparation and application of the composite photo-thermal conversion material. The method comprises the following steps of: (1) removing yellow outer skins of shaddock peels to obtain white shaddock sacs; and (2) soaking the shaddock sacs in an aqueous solution of manganese carbonate, and carrying out adsorption treatment, drying and carbonization treatment to obtain the composite photo-thermal conversion material based on shaddock peel. The method disclosed by the invention is simple, wide in raw material source and low in cost, and meanwhile, the prepared composite photo-thermal conversion material based on shaddock peel is good in photo-thermal conversion effect and excellent in salt-resistant effect. The composite photo-thermal conversion material based on shaddock peel is used for the field of solar seawater desalination and the field of purification of printing and dyeing wastewater and / or heavy metal ion wastewater, and the purification effect is good.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for enhancing mechanical property of electrospun fibrous membrane

ActiveCN114086320AImprove mechanical propertiesMaintain porous structureFilament/thread formingCoatingsFiberPolymer science

The invention belongs to the technical field of nano material preparation, and particularly relates to a method for enhancing the mechanical property of an electrospun fibrous membrane by adding a bonding layer, which is characterized in that a low-volatility solvent is added in a bonding layer spinning solution, and the receiving distance is reduced in the electrostatic spinning process, so that the mechanical property of the electrospun fibrous membrane is enhanced. Due to the low-volatility solvent, the fibers still have certain fluidity when reaching the receiving plate, and are adhered to the compact layer interfibrous membrane under the action of gravity; in addition, the contact parts of the bonding layer and other layers are also adhered, so that the fiber layers are tighter; and finally, the non-woven layer is bound on the bonding layer to form the electrospun fiber membrane with a three-layer structure. The method is easy to operate, high in controllability and good in reinforcing effect, and the porous structure on the surface of the electrospun fiber membrane can be kept; and the porosity of the adhesive layer and the cocrystallization degree during stretching can be adjusted only by adjusting the receiving distance and the content of the low-volatility solvent. The mechanical property of the electrospun fibrous membrane is greatly improved under the condition that the structure is not damaged, so that the electrospun fibrous membrane with the thickness of 200 mu m can bear tension greater than 32 N.

Owner:WUXI ZHONGKE GUANGYUAN BIOMATERIALS

A kind of catalytic oxidation catalyst and preparation method thereof

ActiveCN109621976BHigh catalytic activityImprove catalytic stabilityWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention discloses a catalytic oxidation catalyst and a preparation method thereof. The catalytic oxidation catalyst is based on the weight of the catalyst, and its composition includes: the content of clay is 20%-50%, the content of activated carbon is 20%-55%, and the content of ferromanganese slag is 10%-45% , the rare earth content is 0.2%-5%. The preparation method comprises: mixing clay, activated carbon, ferromanganese slag, and rare earth sources, molding, drying, and high-temperature roasting in an oxygen-free atmosphere. The catalytic oxidation catalyst not only turns waste catalysts into valuables, but also has good activity and stability, and is especially suitable for the catalytic oxidation process of wastewater ozone.

Owner:中科粤能净(山东)新材料有限公司

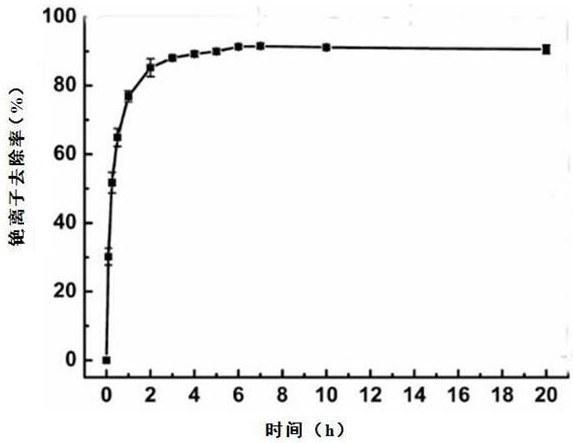

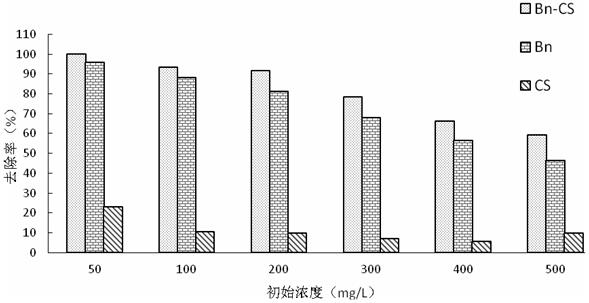

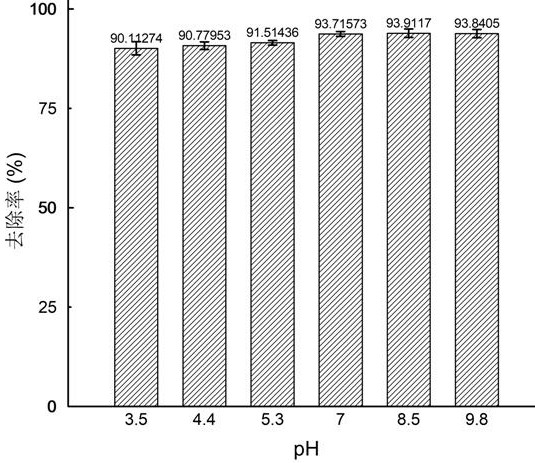

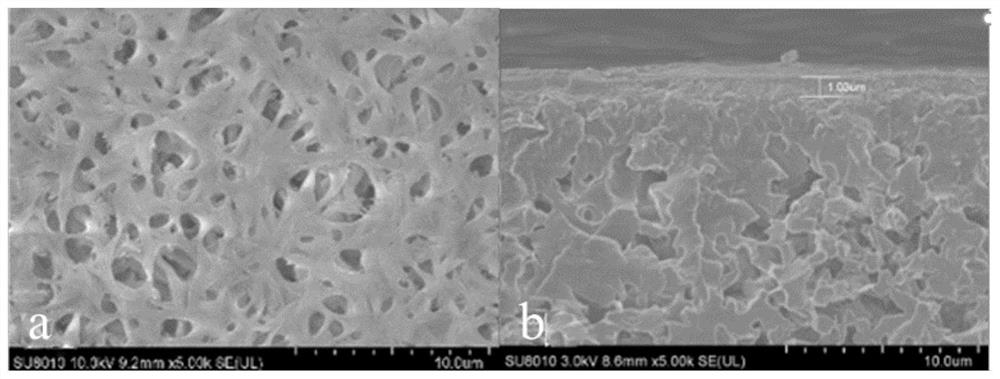

A method for removing cesium ions based on bentonite-chitosan composite microspheres

ActiveCN108428486BImprove adsorption capacityLarge adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesMicrospherePhysical chemistry

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

A kind of preparation method of lithium-sulfur battery

ActiveCN105529490BGrowth inhibitionLarge specific surface areaMaterial nanotechnologyFinal product manufactureMass ratioLithium–sulfur battery

The invention relates to a preparation method of a lithium-sulfur battery, which is characterized by comprising: in parts by mass, consisting of the following raw material composition: 7-10 parts of steady-state lithium powder, 3-8 parts of carbon material and solvent. In the present invention, a mixture of stable lithium powder and vertically arrayed carbon nanotubes (VACNT) and mesoporous carbon is specially selected as the carbon material in the negative electrode to prepare the negative electrode mixed slurry according to the mass ratio of 10:1. The use of the binder in the slurry makes the lithium-sulfur battery negative electrode material have more excellent performance. At the same time, with the optimally selected positive electrode material, the battery prepared by the preparation method of the present invention shows a small impedance, which can effectively weaken the shuttle effect and dendrite growth in the continuous charge and discharge process, and shows a better cycle than conventional metal lithium foil. performance and rate performance.

Owner:驰特(佛山)新能源科技有限公司

MOF derived gas separation membrane and its preparation method and application

The invention discloses a MOF-derived gas separation membrane and its preparation method and application. The preparation method of the MOF-derived gas separation membrane is as follows: H 3 BTC and Al(NO 3 ) 3 9H 2 Dissolve O in deionized water, adjust the pH of the system to 1.9-2.0, and add additives, the reaction is complete to obtain MIL-100Al and tri-block copolymer Dissolve in alcohol at room temperature and under ultrasonic conditions, and then add 37%wt hydrochloric acid solution In the process, ultrasonically mix at room temperature for 24 hours, and then copolymerize at 100°C to 120°C for 24 hours. After the reaction is complete, a solid mixture is obtained, which is carbonized at a high temperature to obtain a MIL‑100Al porous carbon material, which is then dissolved in NMP solution, mixed and stirred A clear and uniform viscous solution was obtained, which was then casted to obtain a MOF-derived gas separation membrane. The prepared membrane structure is rich in micropores, and the CO 2 Excellent capture ability, and CO 2 and CH 4 It has good separation selectivity and good recycling ability, which provides a valuable reference for the application of MOF derived materials in the field of membrane materials.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of modified alumina carrier, palladium catalyst and preparation method thereof

ActiveCN109967132BHigh mechanical strengthStable structureMaterial nanotechnologyCatalyst carriersPtru catalystPalladium catalyst

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

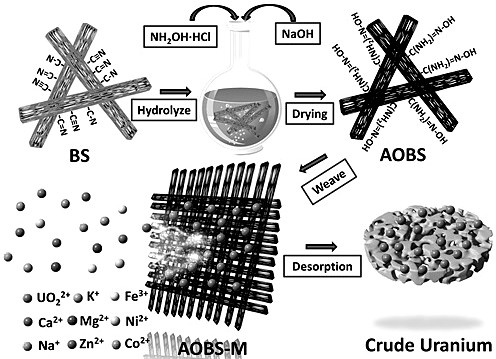

A weavable seawater uranium extraction adsorption material and its flexible control preparation method

ActiveCN113231038BLower synthesis costEasy to operateOther chemical processesSeawater treatmentMineralogyEnvironmental chemistry

A weavable seawater uranium extraction material and its flexible control preparation method relate to the technical field of adsorption materials, in particular a weavable seawater uranium extraction material and its flexible control preparation method. After sonicating bamboo strips with acetone, ethanol, and deionized water, select H 2 o 2 As a solvent, hydrothermal method is used to carry out hydroxylation treatment on it, and finally NH 2 Amidoximation reaction was carried out in alkaline solution of OH·HCl to prepare amidoximated bamboo strips. The method is simple in preparation and operation, low in cost, and can be built into a macroscopic large-area shaped adsorption material. In addition, the oxime nitrogen, amino nitrogen and oxime oxygen in the amidoxime functional group can be chemically coordinated with uranyl ions, which can effectively improve the selectivity of bamboo sticks to uranyl ions and achieve the effect of specifically capturing uranyl ions.

Owner:HARBIN ENG UNIV

A kind of modified fly ash with surface coating SIO2 and its preparation method and application

ActiveCN104403401BProtect the porous structureGood heat insulationSolid waste managementCoatingsPolymer scienceThermal insulation

Owner:SHAANXI UNIV OF TECH

A kind of nanoporous film capacitor electrode material and preparation method thereof

InactiveCN106098415BMaintain porous structureImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureChemical platingFilm material

The invention provides an electrode material of a nanometer porous film capacitor and a preparation method thereof. The method comprises the following steps of: taking nanometer porous gold as a substrate material, putting the nanometer porous gold into a plating solution with nickel nitrate as a main component, and loading nickel on a nanometer porous gold surface by using a chemical plating method; and keeping the nanometer porous gold loaded with the nickel in the air for a certain time. The nanometer porous gold is taken as a substrate, and the metal Ni is modified on the surface of the nanometer porous gold by the interface chemical plating method. The Ni is contacted with oxygen in the air to form NiO, and a nanometer porous nickel oxide film material is obtained. SEM and EDS tests show that the prepared NiO material keeps the porous structure of the substrate and improves the electrical conductivity and ion conductivity of the electrode material. The prepared porous nickel oxide is good super capacitor electrode material with exploitation potential.

Owner:YILI NORMAL UNIV

A kind of lithium-sulfur battery negative electrode material and preparation method thereof

ActiveCN105514396BGrowth inhibitionLarge specific surface areaFinal product manufactureNon-aqueous electrolyte accumulator electrodesLithium–sulfur batteryCarbon nanotube

Owner:东莞市技领科技有限公司

A kind of high tap density modified fumed silica with flat structure and its preparation method and application

ActiveCN113105758BLarge specific surface areaHigh reinforcement propertiesPigment treatment with organosilicon compoundsPigment physical treatmentPolymer scienceSilicon oxide

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Lithium sulfur battery electrode material and method for manufacturing lithium sulfur battery by using same

ActiveCN106865495AGrowth inhibitionLarge specific surface areaMaterial nanotechnologyFinal product manufactureMass ratioCarbon nanotube

The invention relates to a lithium sulfur battery electrode material and a method for manufacturing a lithium sulfur battery by using the electrode material. A negative electrode material includes the following raw materials, by mass, 5-10 parts of stable lithium powder, 3-7 parts of carbon materials, I part of a binder, and a solvent. The stable lithium powder and the carbon materials which are mixture of carbon nano balls, carbon nano tubes, and mesoporous carbons according to the mass ratio of 5:2:1 are used to prepare negative mixed slurry, and then the kithium sulfur battery negative electrode material has excellent performance. The battery manufactured by the method is small in impedance, can effectively weaken the shuttle effect and dendritic growth in a continuous charging / discharging process, and has more excellent circulation performance and rate performance than metal lithium foils.

Owner:宁夏和兴碳基材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com