MOF (metal-organic framework) derived gas separation membrane as well as preparation method and application thereof

A gas separation membrane and reaction technology, applied in separation methods, gas treatment, semi-permeable membrane separation, etc., can solve the problems of polymer membrane separation performance limited separation coefficient and permeation, limited application, high cost, etc., to achieve good results Recyclable ability, excellent capture ability, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

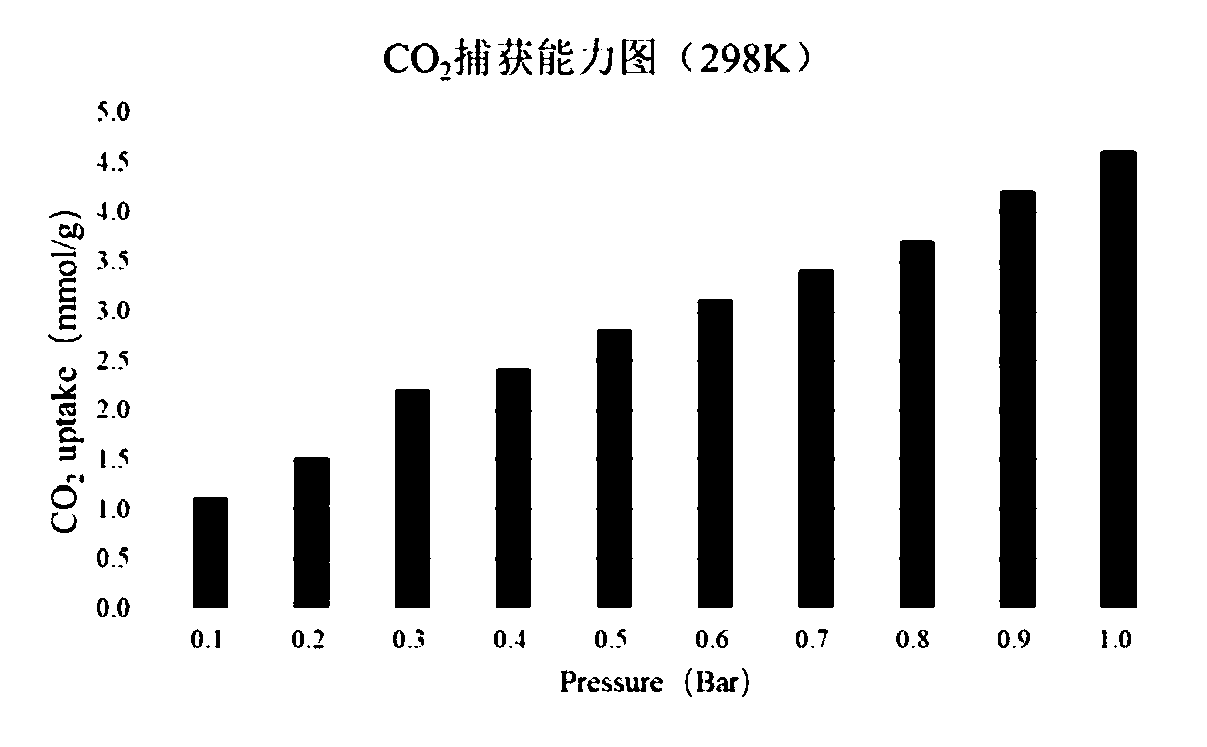

[0033] (1) Weigh 0.37gH 3 BTC solution and 0.75gAl(NO 3 ) 3 ·9H 2 O, dissolved in 10 mL of deionized water, adjusted the pH of the system to 1.9 to 2.0, and added 0.21 mL of methanol solution to obtain a mixed solution. After cleaning with ionized water, bright yellow MIL-100Al powder was obtained;

[0034] (2) Weigh 0.46 g of dried MIL-100Al powder and 0.94 g of triblock copolymer (poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide)) (Pluronic F- 127Sigma-Aldrich) was dissolved in 5 mL of absolute ethanol at room temperature and under ultrasonic conditions, then 0.1 mL of 37% wt HCl solution was added, and ultrasonically mixed for 24 h at room temperature; After cooling and washing with deionized water, a solid mixture was obtained after drying under vacuum at 80 °C for 24 h; the mixture was heated at 700 °C under N 2 Carbonized at high temperature for 3 h under protection, washed and dried with water and HCl after cooling, to obtain clean MIL-100Al porous carb...

Embodiment 2

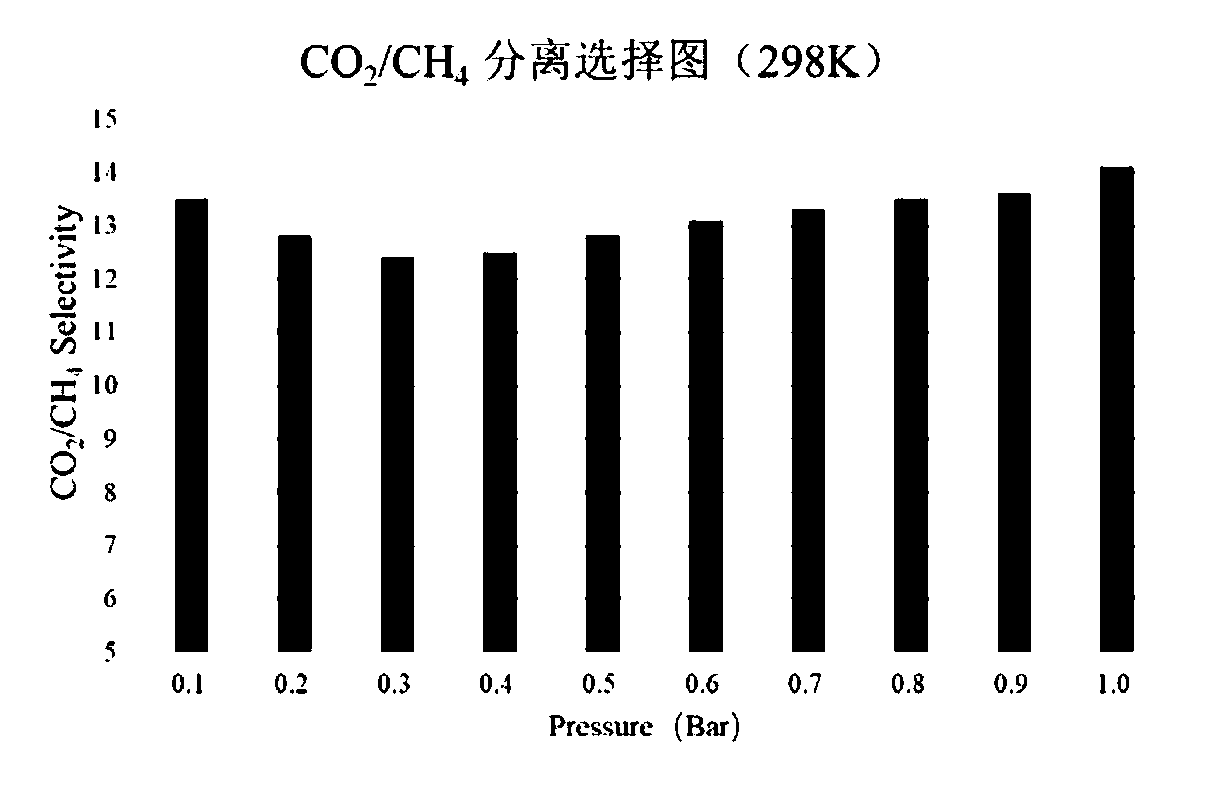

[0037] Keeping other conditions the same, heat the mixture from step 2 at 600 °C, N 2 The MIL-100Al porous carbon material obtained by carbonization at high temperature under protection for 3h is used to prepare gas separation membranes under the same test conditions. CO at 1Bar, 298K 2 The loading is 4.4 mmol / g; and for CO 2 and CH 4 The separation selectivity is good, reaching 13.7 at 1Bar and 298K.

Embodiment 3

[0039] Keeping other conditions the same, heat the mixture from step 2 at 800 °C, N 2 The MIL-100Al porous carbon material obtained by carbonization at high temperature under protection for 3h is used to prepare gas separation membranes under the same test conditions. CO at 1Bar, 298K 2 The loading is 4.3 mmol / g; and for CO 2 and CH 4 The separation selectivity is good, reaching 13.7 at 1Bar and 298K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com