Ternary composite matrix anode material for molten carbonate fuel cell (MCFC) and preparation method of ternary composite matrix anode material

A molten carbonate and ternary composite technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as hindering large-scale commercialization, affecting battery life, battery short circuit, etc., and achieve large-scale industrial production and preparation The effect of short cycle time and thin coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The ternary composite matrix cathode in this embodiment is obtained through the following steps:

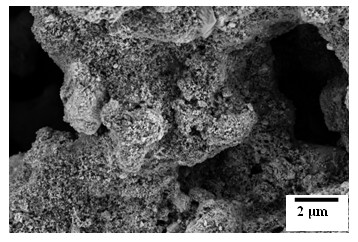

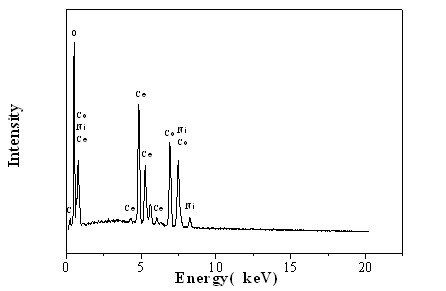

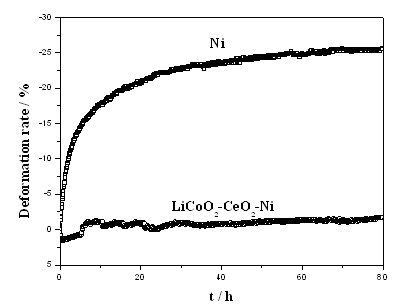

[0035] LiCoO was prepared by using the gel combustion method and controlling the calcination temperature of 650 °C. 2 and CeO 2 Two kinds of nanoparticles. 0.2g LiCoO with a molar ratio of 4:1 2 / CeO 2 The nanoparticle mixture was dispersed in 50 ml of a mixture of isopropanol and ethylene glycol with a volume ratio of 3:1 to make a suspension, and the pH value of the suspension was adjusted to 2.5-3. In the prepared suspension, the porous nickel is used as the cathode, the platinum sheet is used as the anode, the electrode distance is 2.5 cm, the electrophoresis voltage is controlled at 65 volts, and the electrophoresis time is 2 minutes, and the nanoparticle group is modified onto the surface of the porous nickel. Sintered at 650 °C for 1 hour in an inert atmosphere to make porous (nano-LiCoO 2 -CeO 2 )-Ni ternary composite matrix cathode material.

[0036] The su...

Embodiment 2

[0042] The ternary composite matrix cathode in this embodiment is obtained through the following steps:

[0043] LiCoO was prepared by using the gel combustion method and controlling the calcination temperature of 650 °C. 2 and CeO 2 Two kinds of nanoparticles. 0.2g LiCoO with a molar ratio of 3:1 2 / CeO 2 The nanoparticle mixture was dispersed in 50 ml of a mixture of isopropanol and ethylene glycol with a volume ratio of 2:1 to make a suspension, and the pH value of the suspension was adjusted to 2.5-3. In the prepared suspension, the porous nickel is used as the cathode, the platinum sheet is used as the anode, the distance between the electrodes is 2.5 cm, the electrophoresis voltage is controlled at 55 volts, and the electrophoresis time is 2 minutes, and the nanoparticles are modified onto the surface of the porous nickel. Sintered at 650 °C for 1 hour in an inert atmosphere to make porous (nano-LiCoO 2 -CeO 2 )-Ni ternary composite matrix cathode material.

[004...

Embodiment 3

[0047] The ternary composite matrix cathode in this embodiment is obtained through the following steps:

[0048] LiCoO was prepared by using the gel combustion method and controlling the calcination temperature of 650 °C. 2 and CeO 2 Two kinds of nanoparticles. 0.2g LiCoO with a molar ratio of 6:1 2 / CeO 2 The nanoparticle mixture was dispersed in 50 ml of a mixture of isopropanol and ethylene glycol at a volume ratio of 5:1 to make a suspension, and the pH value of the suspension was adjusted to 2.5-3. In the prepared suspension, the porous nickel is used as the cathode, the platinum sheet is used as the anode, the distance between the electrodes is 2.5 cm, the electrophoresis voltage is controlled at 75 volts, and the electrophoresis time is 2 minutes, and the nanoparticle group is modified onto the surface of the porous nickel. Sintered at 650 °C for 1 hour in an inert atmosphere to make porous (nano-LiCoO 2 -CeO 2 )-Ni ternary composite matrix cathode material.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com