Patents

Literature

34results about How to "Meet the shape requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

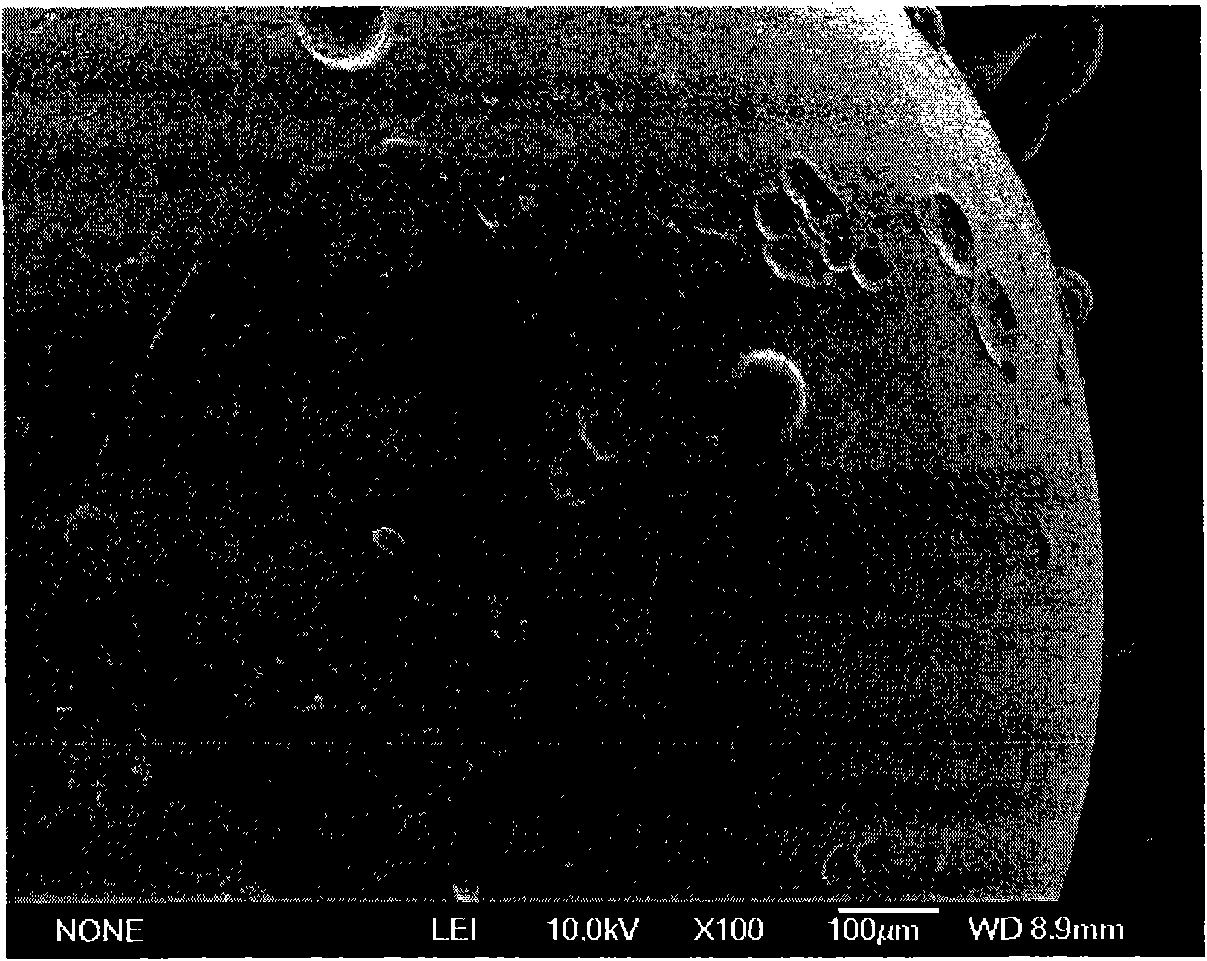

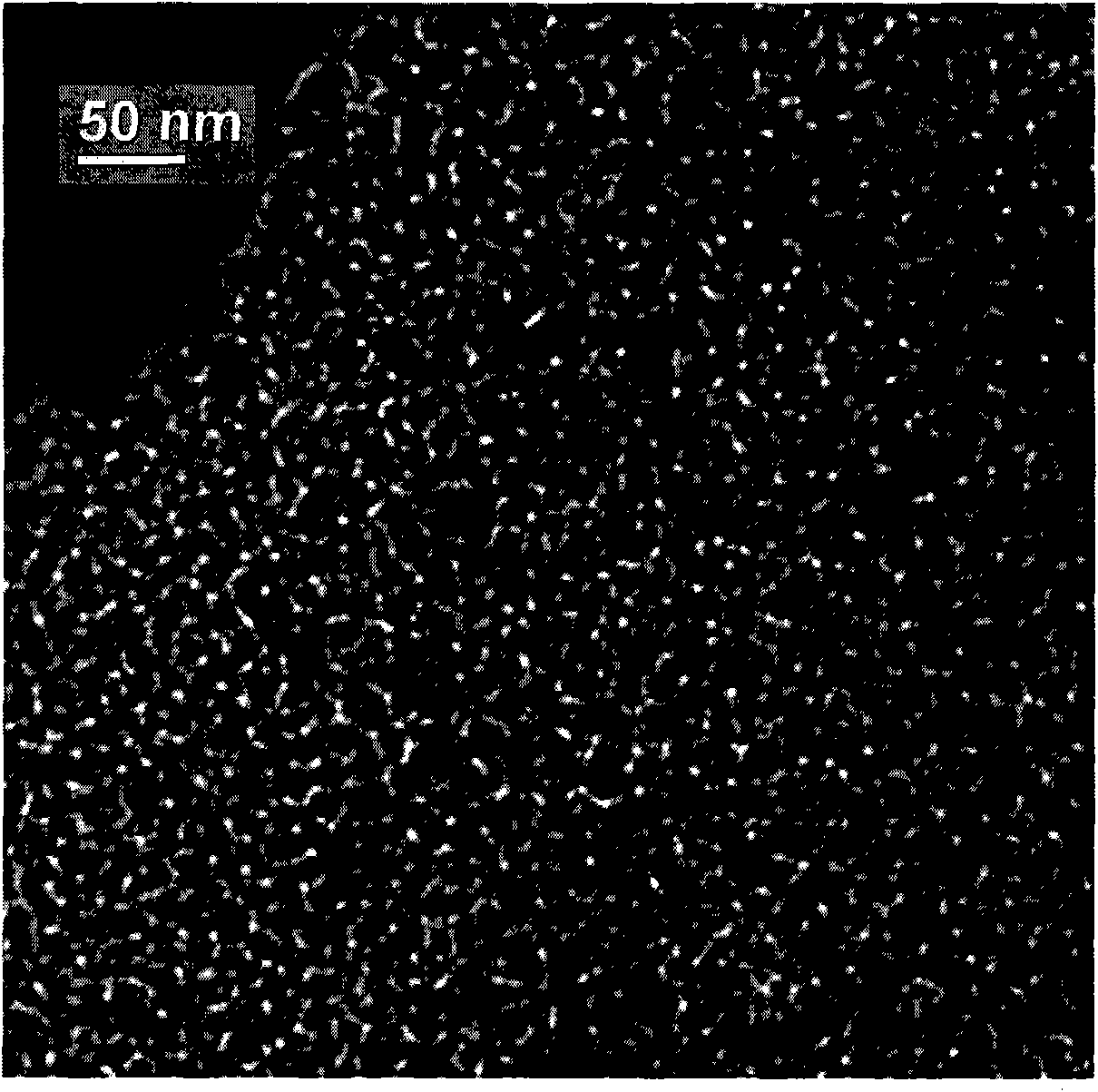

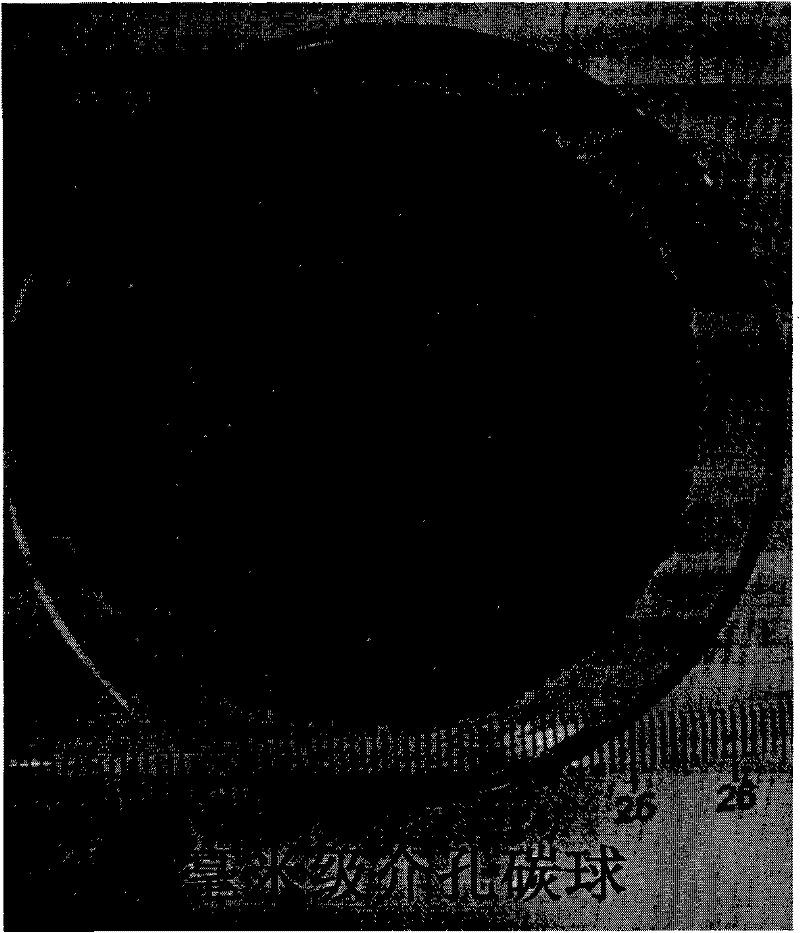

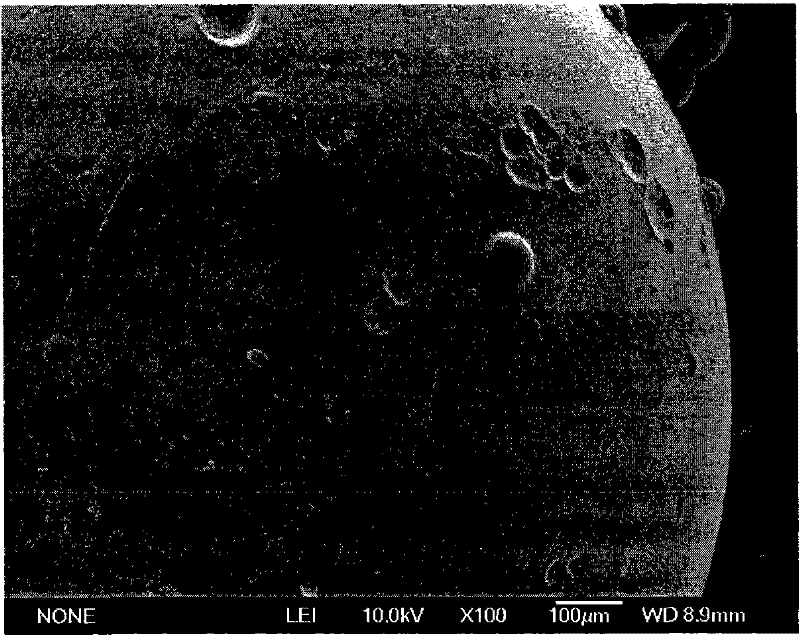

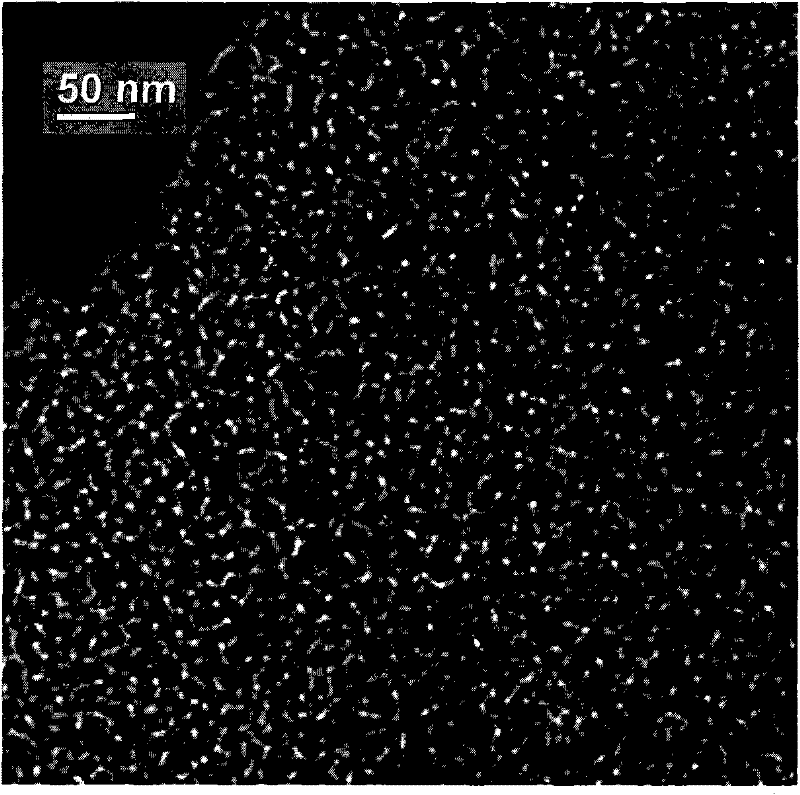

Preparation method and use of millimetre-sized mesoporous carbon spheres

ActiveCN101817519AThe preparation method is simpleEasy to operateNanostructure manufactureParaffin waxFiltration

The invention belongs to the field of inorganic nano material synthesis and particularly relates to a preparation method and use of millimetre-sized mesoporous carbon spheres. The preparation method comprises the following steps of: dissolving resorcinol in ethanol serving as a solvent; adding furfural and ethanol solution of hydrogen chloride, and stirring the mixture at 0 to 15 DEG C for 10 to 120 minutes; adding aqueous solution of hexamethylenetetramine and pore-forming material into the prepared solution to obtain solution of a precursor; adding the prepared solution of the precursor into liquid max containing an emulsifier, and stirring the solution to perform per-polymerization; volatilizing the solvent, filtering the remaining material, and washing and drying the product obtained by filtration; and carbonizing the product to obtain the millimetre-sized mesoporous carbon spheres. The preparation of the millimetre-sized mesoporous carbon spheres of the invention is performed under simple conditions and with easy operation. The millimetre-sized mesoporous carbon spheres prepared by the method have the characteristics of adjustable size, large specific surface area, large pore volume and the like, and can be used as adsorbent for hemoperfusion and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

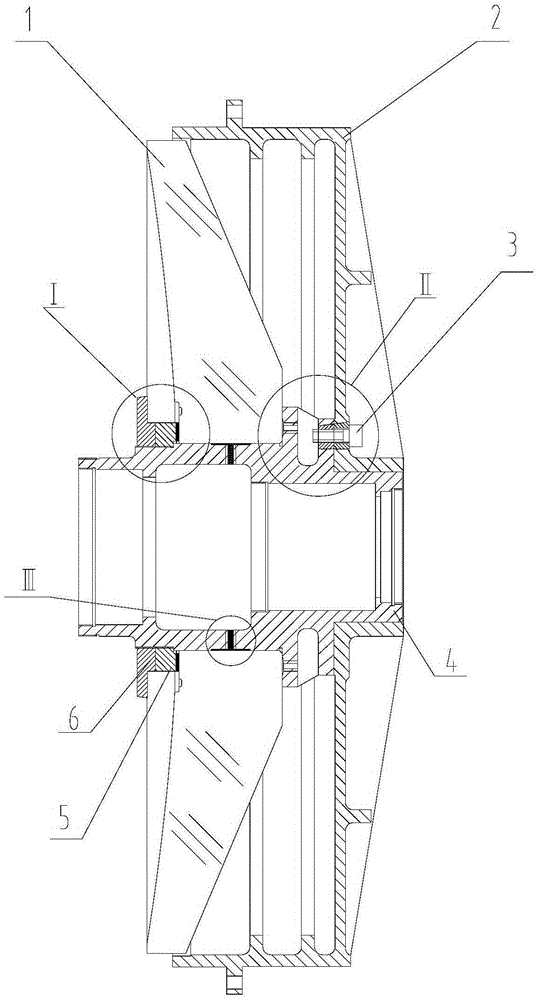

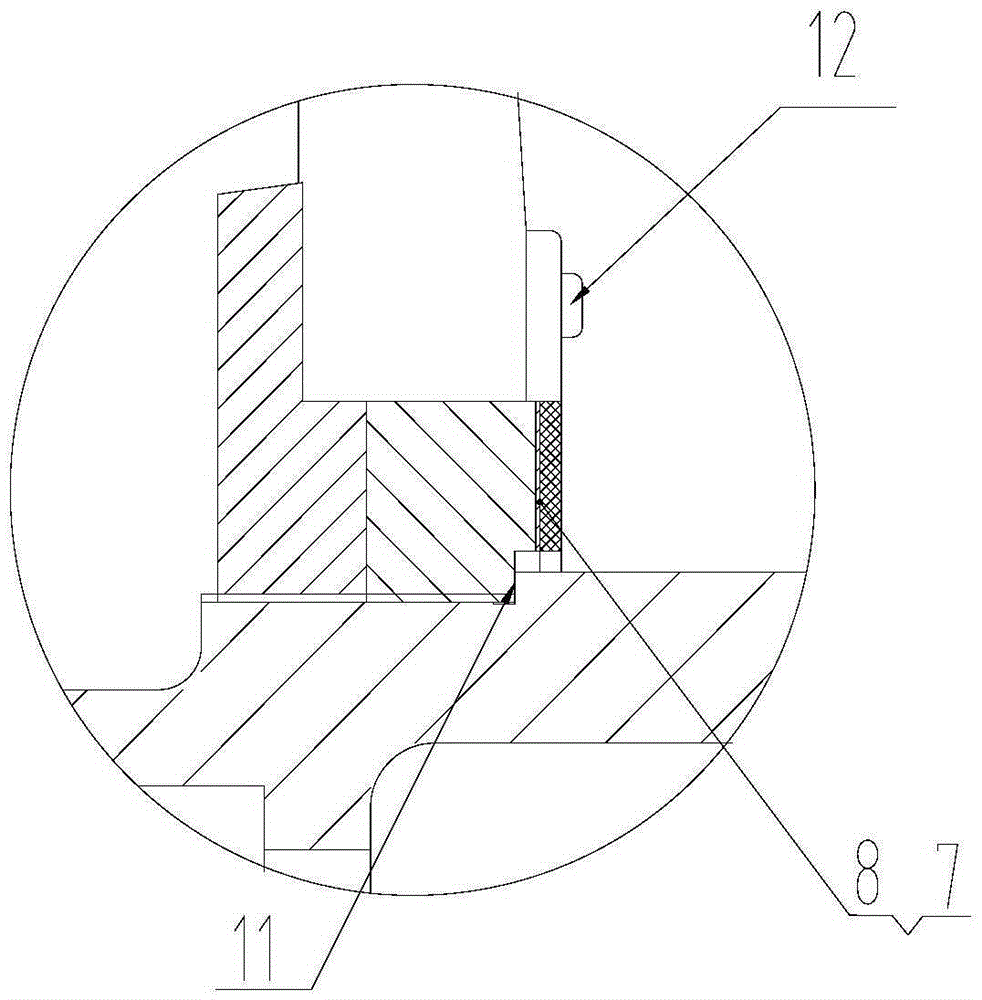

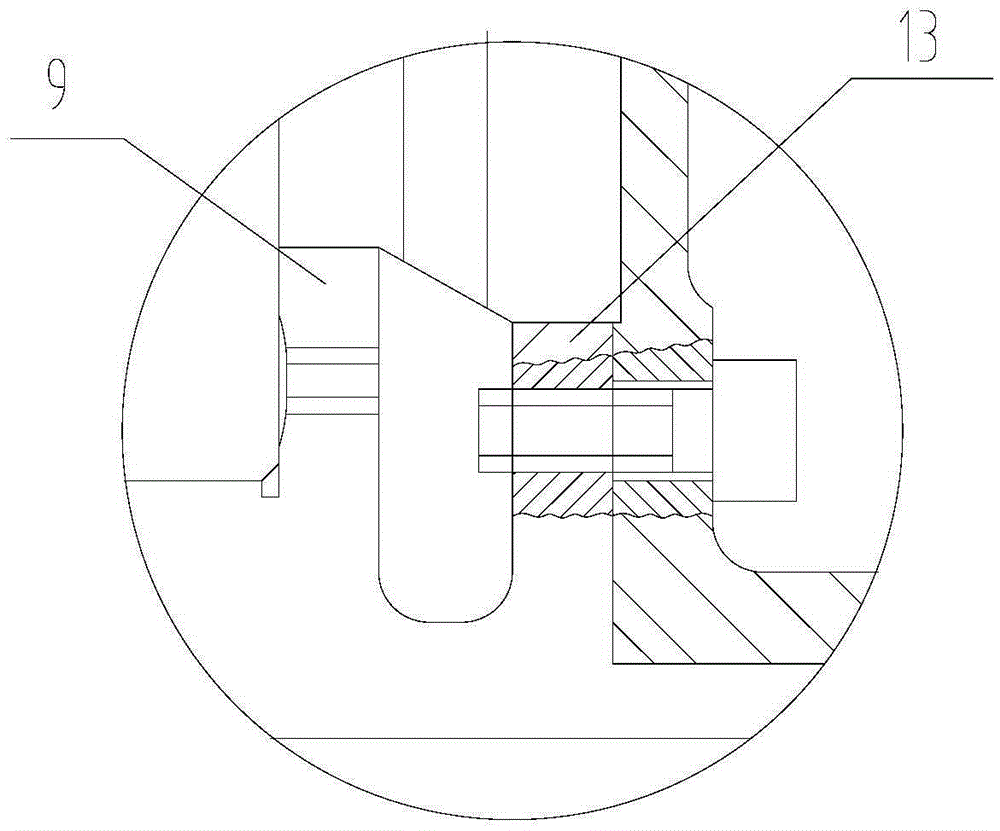

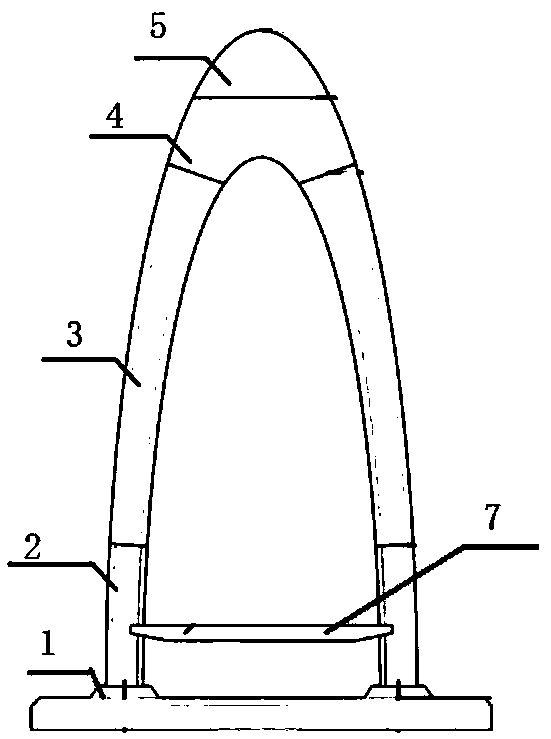

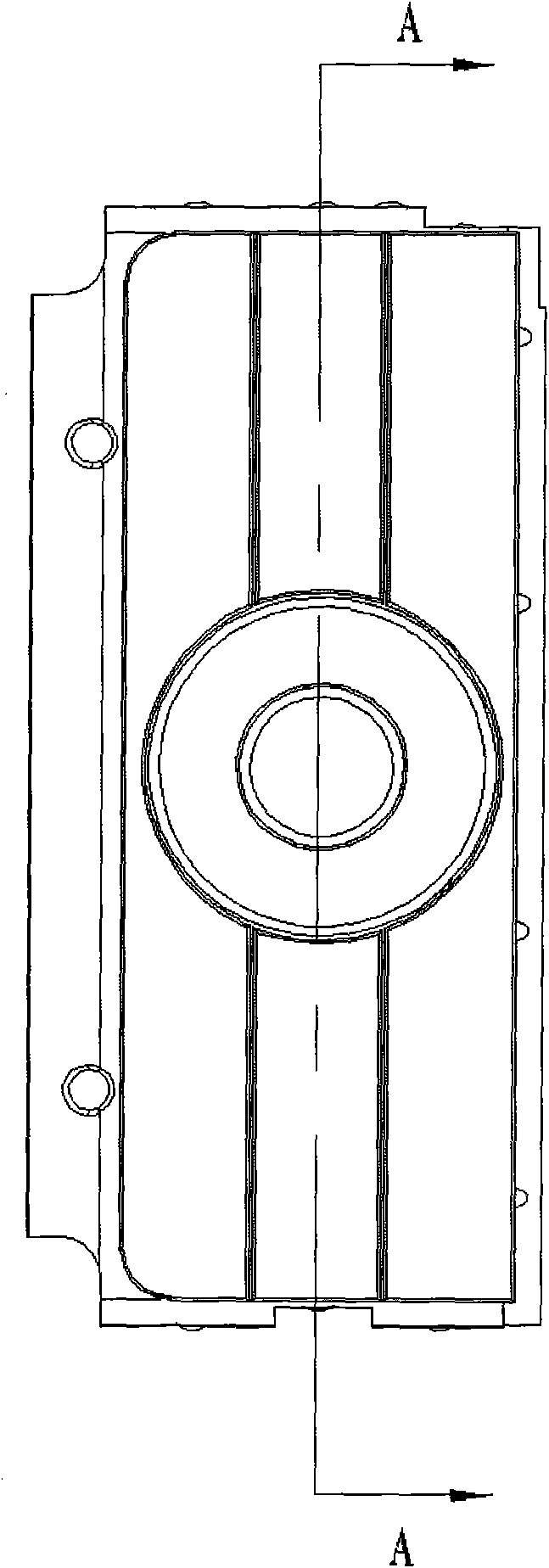

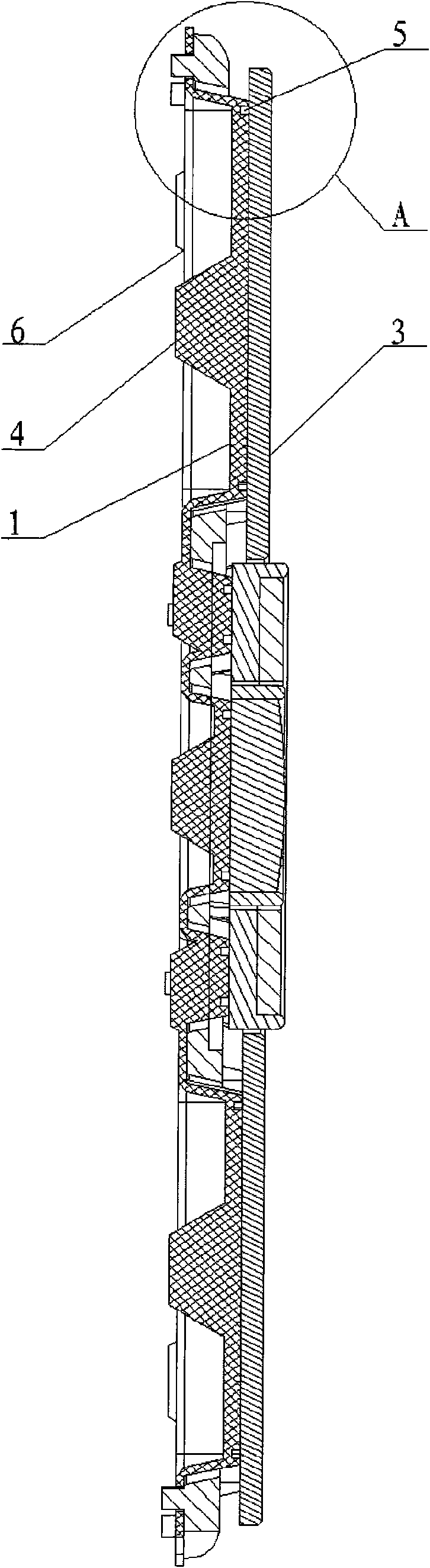

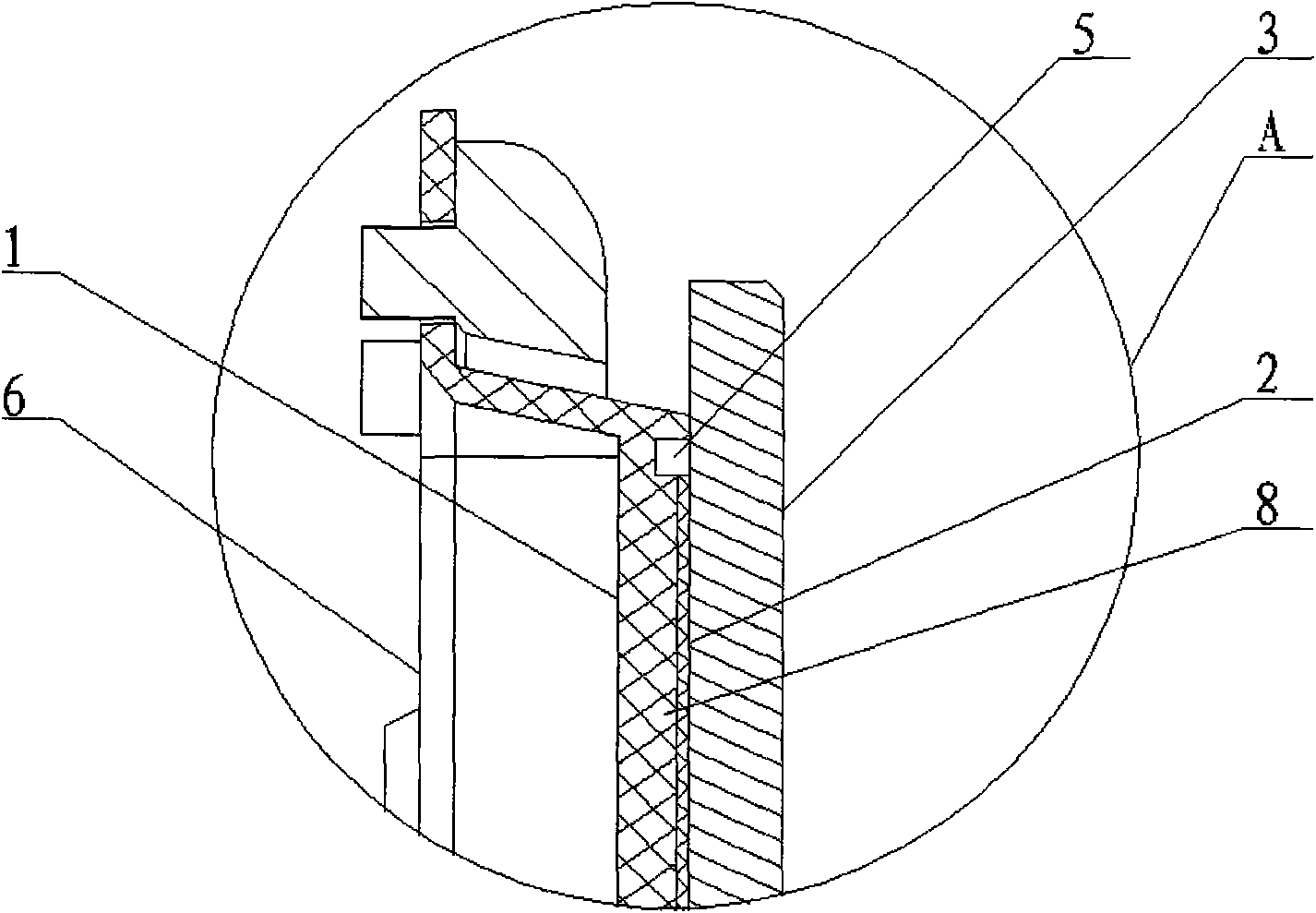

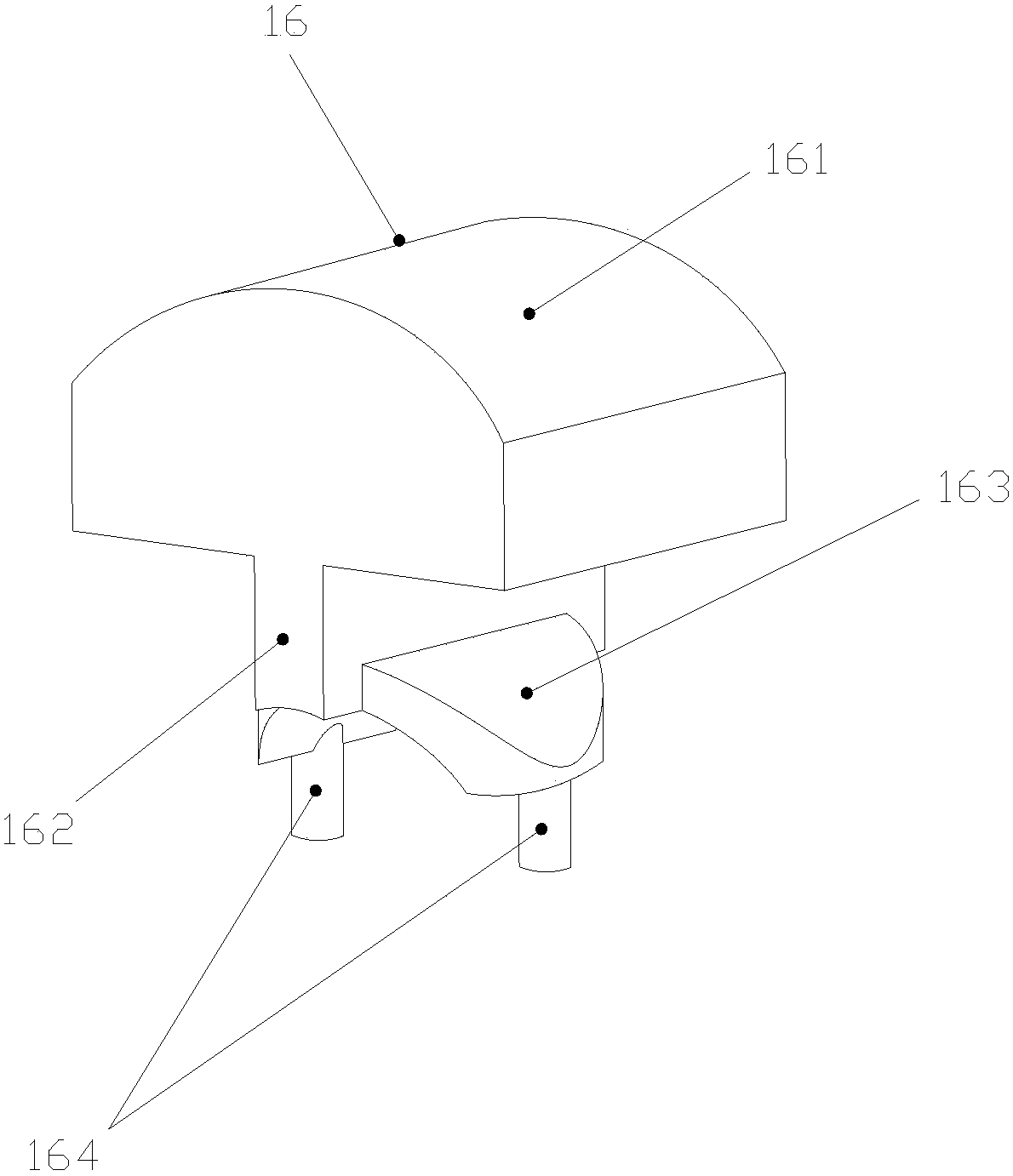

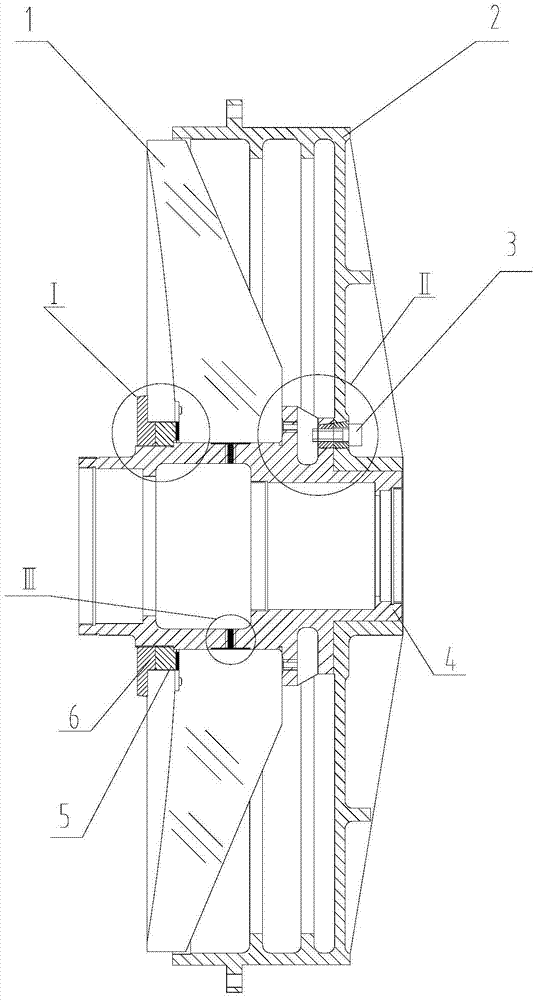

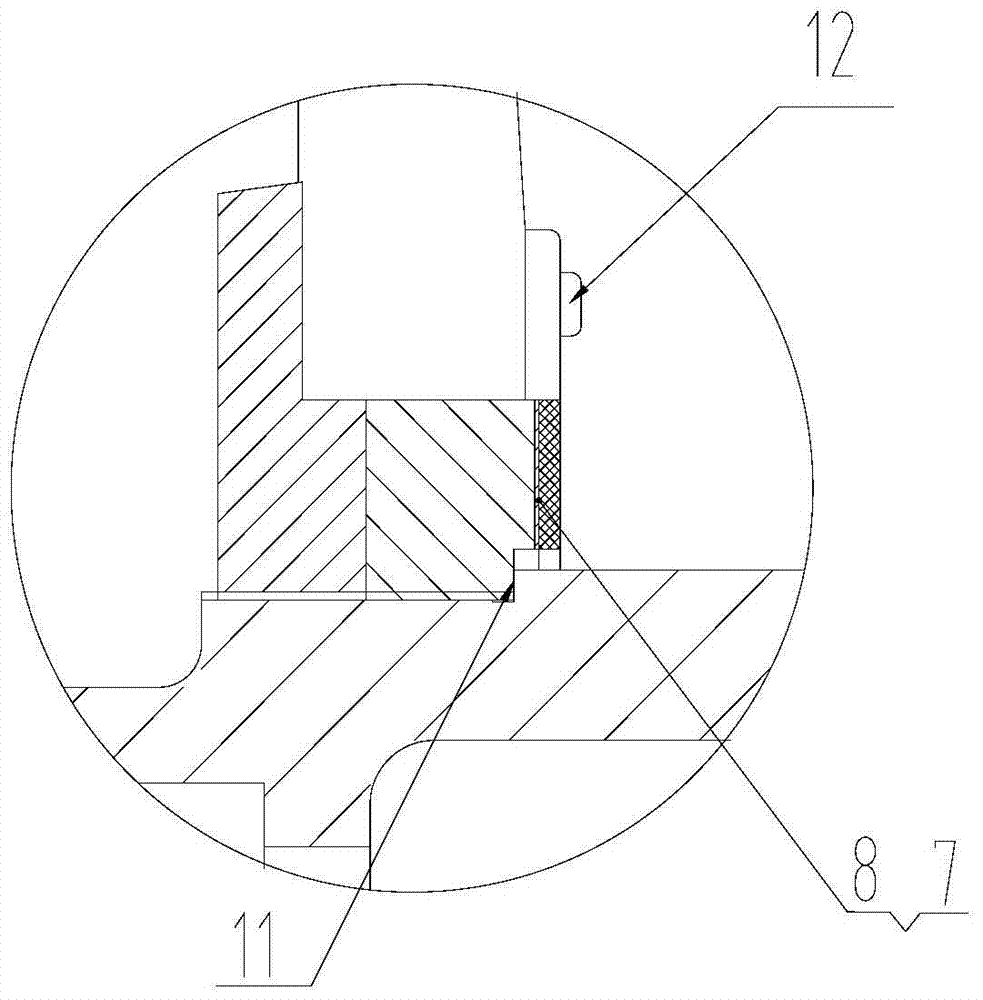

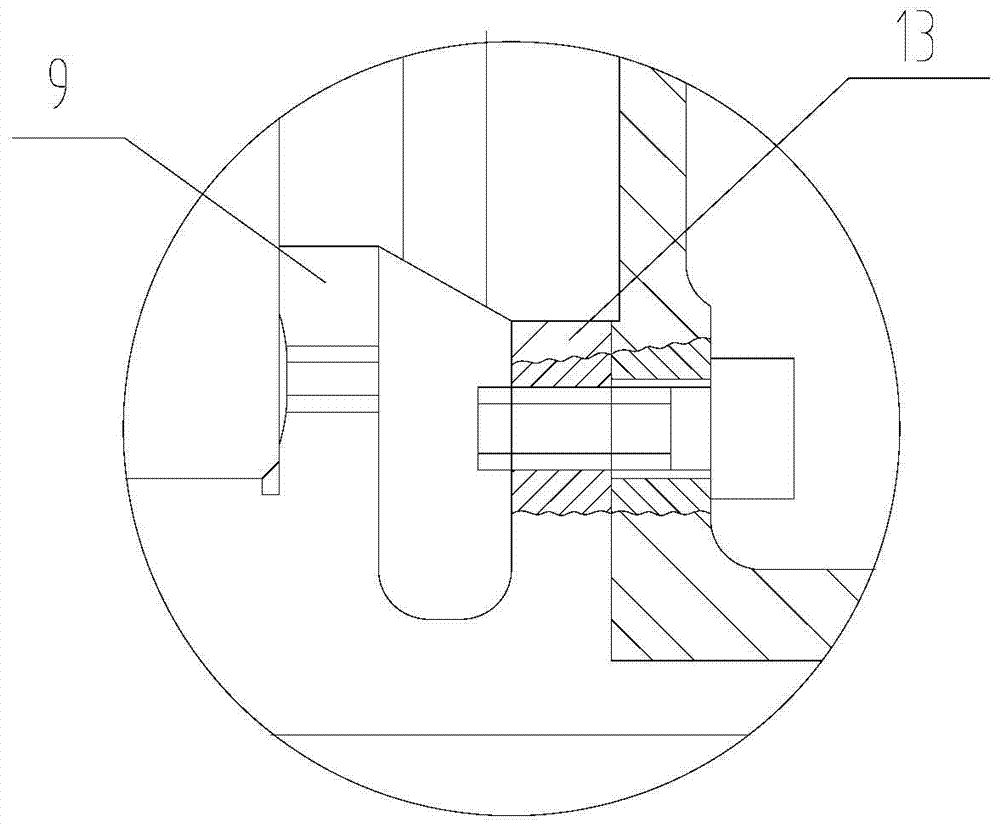

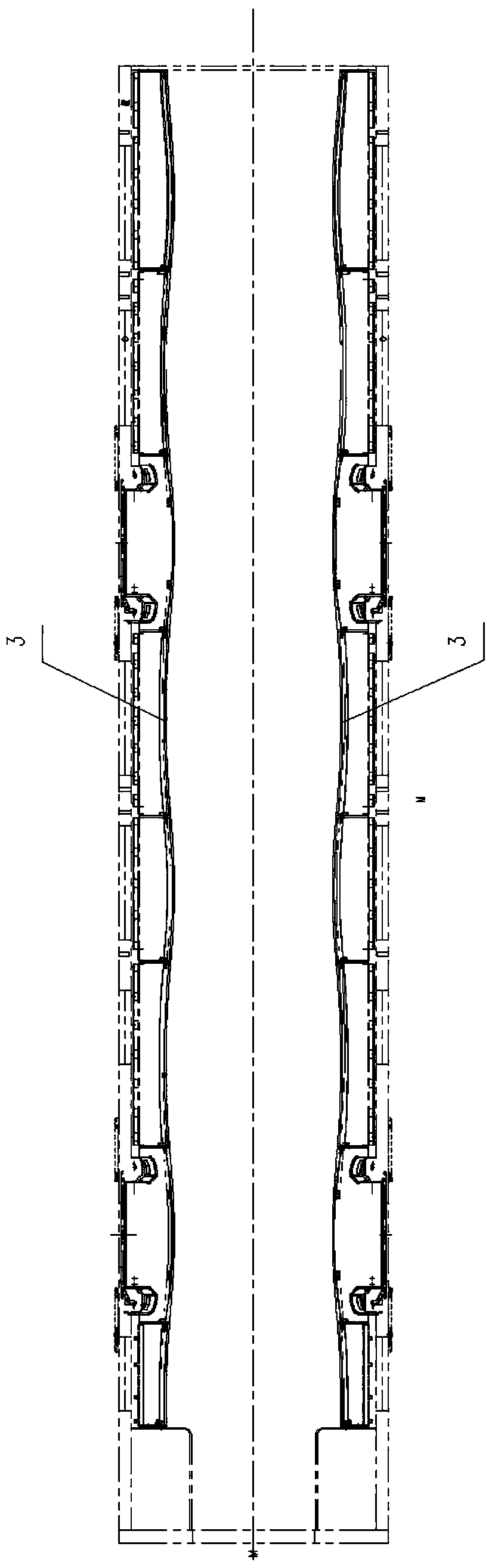

Micro stress supporting structure of satellite-borne space reflector

The invention provides a micro stress supporting structure of a satellite-borne space reflector. The micro stress supporting structure comprises a primary mirror, a primary mirror base and a primary mirror core shaft; the primary mirror is fixedly connected with the primary mirror core shaft; the primary mirror core shaft passes through the center hole of the primary mirror; the small end of the primary mirror abuts against the primary mirror positioning plate of the primary mirror core shaft; a mechanical limiting boss is designed on the primary mirror core shaft; the primary mirror core shaft is provided with a primary mirror rubber pad, a primary mirror metal pad, a first pressing ring and a second pressing ring respectively; the first pressing ring is provided with a boss; after the micro stress supporting structure is installed, the primary mirror rubber pad presses the fixing end surface of the large end of the primary mirror; the boss of the first pressing ring presses the primary mirror metal pad; the non-protruding surface of the first pressing ring presses the mechanical limiting boss; and the second pressing ring presses the first pressing ring. With the micro stress supporting structure provided by the invention adopted, the magnitude of a pressing force to the primary mirror applied by the pressing rings of the primary mirror can be controlled quantitatively and mechanically, and the fastening degree of the primary mirror can be improved, and requirements for the surface shape of the primary mirror after clamping can be satisfied.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

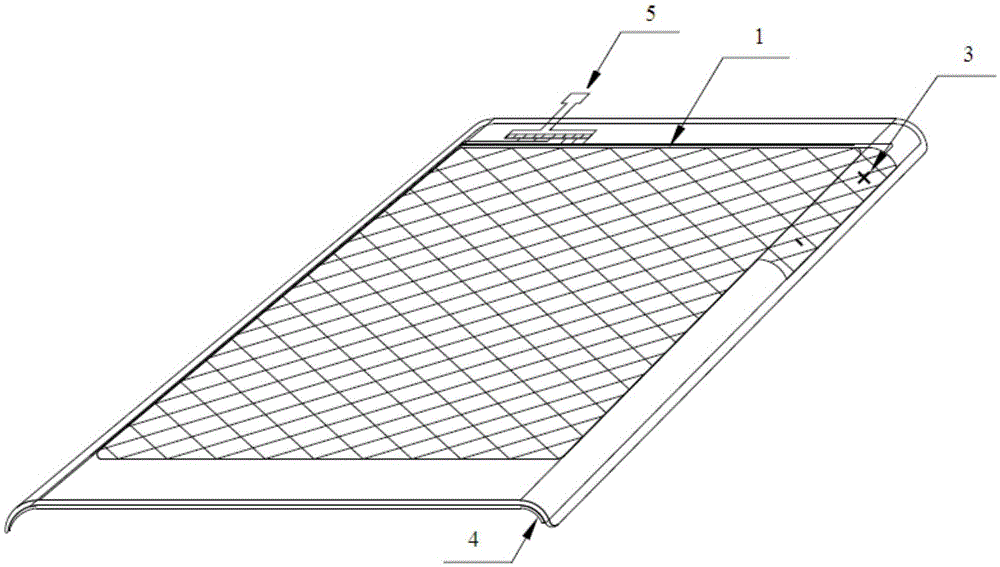

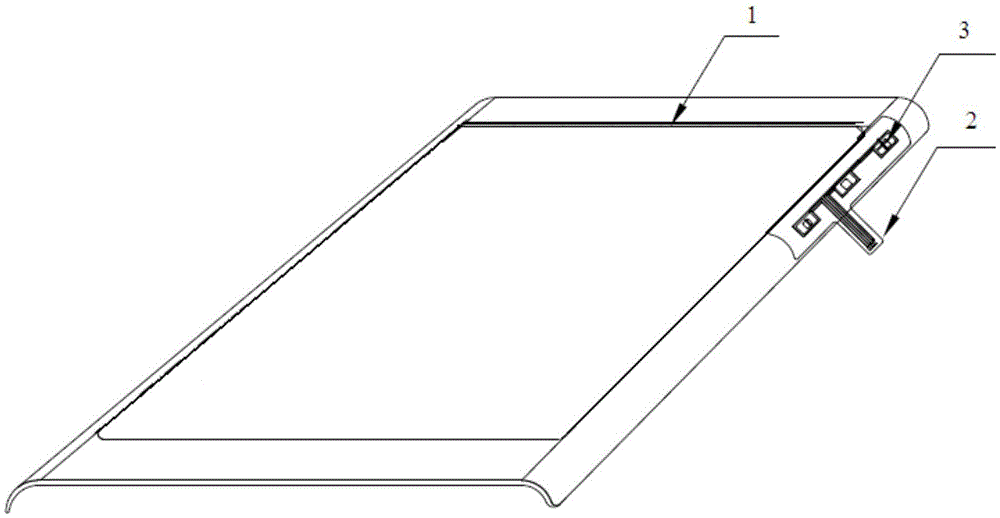

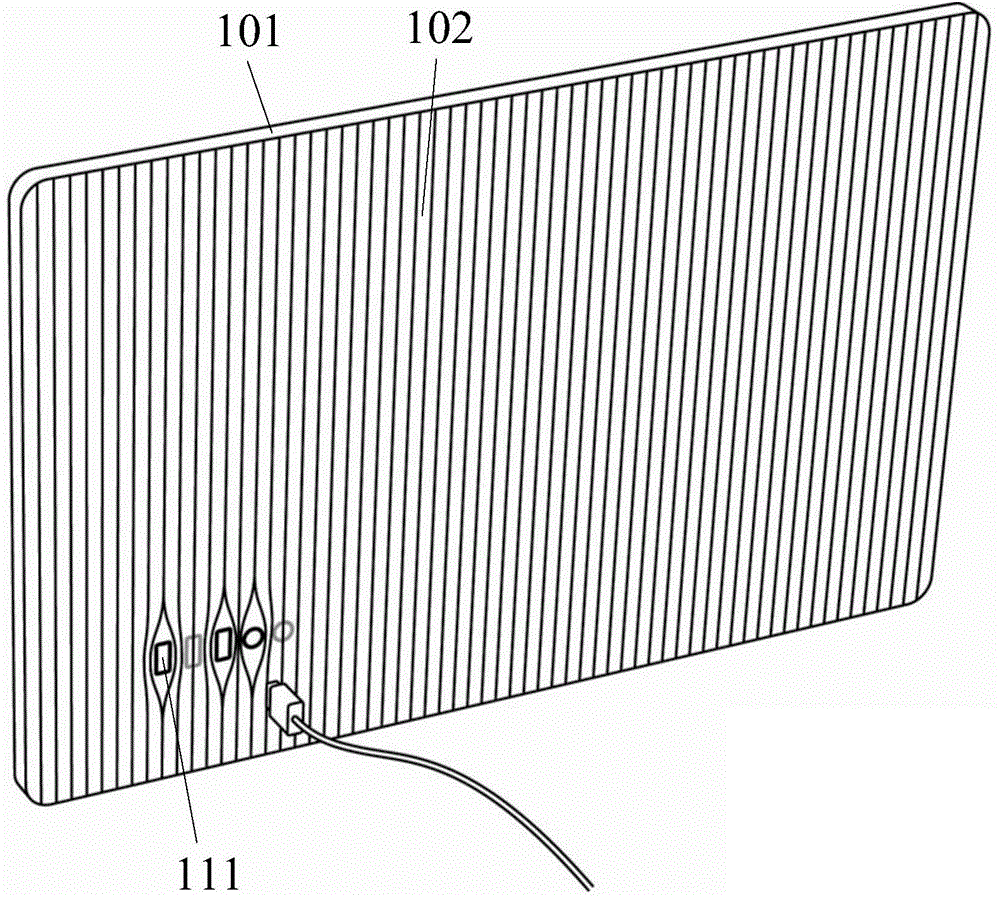

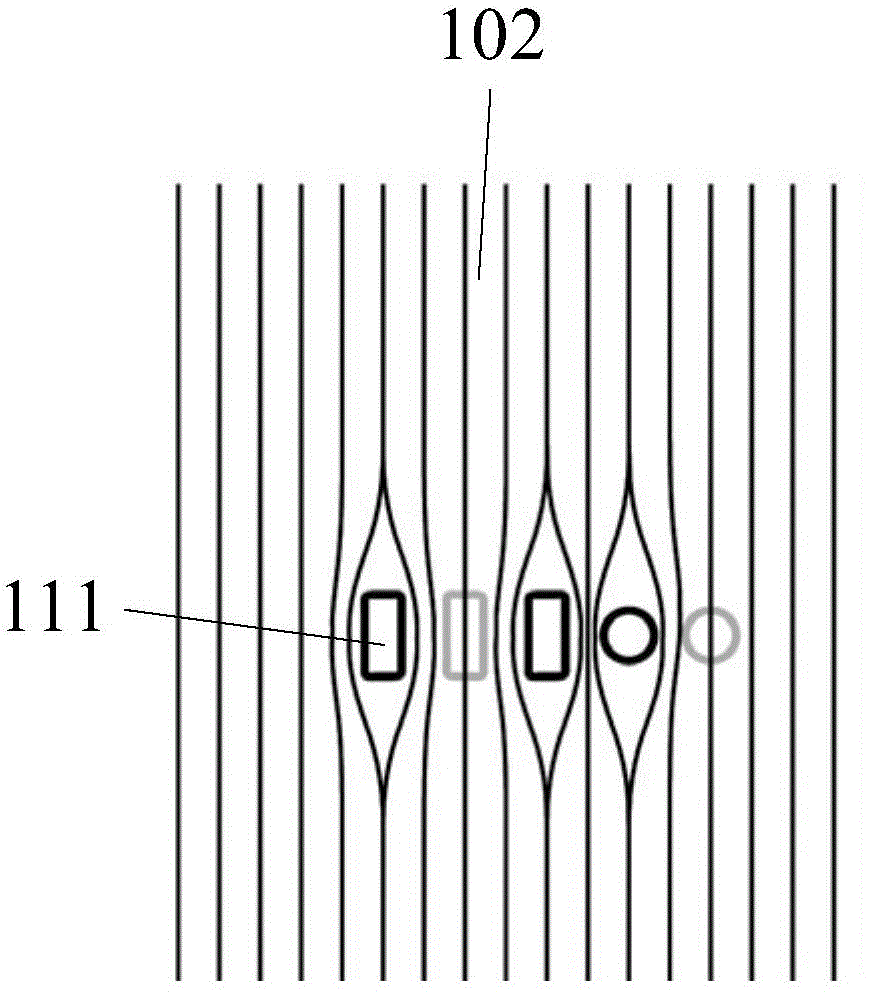

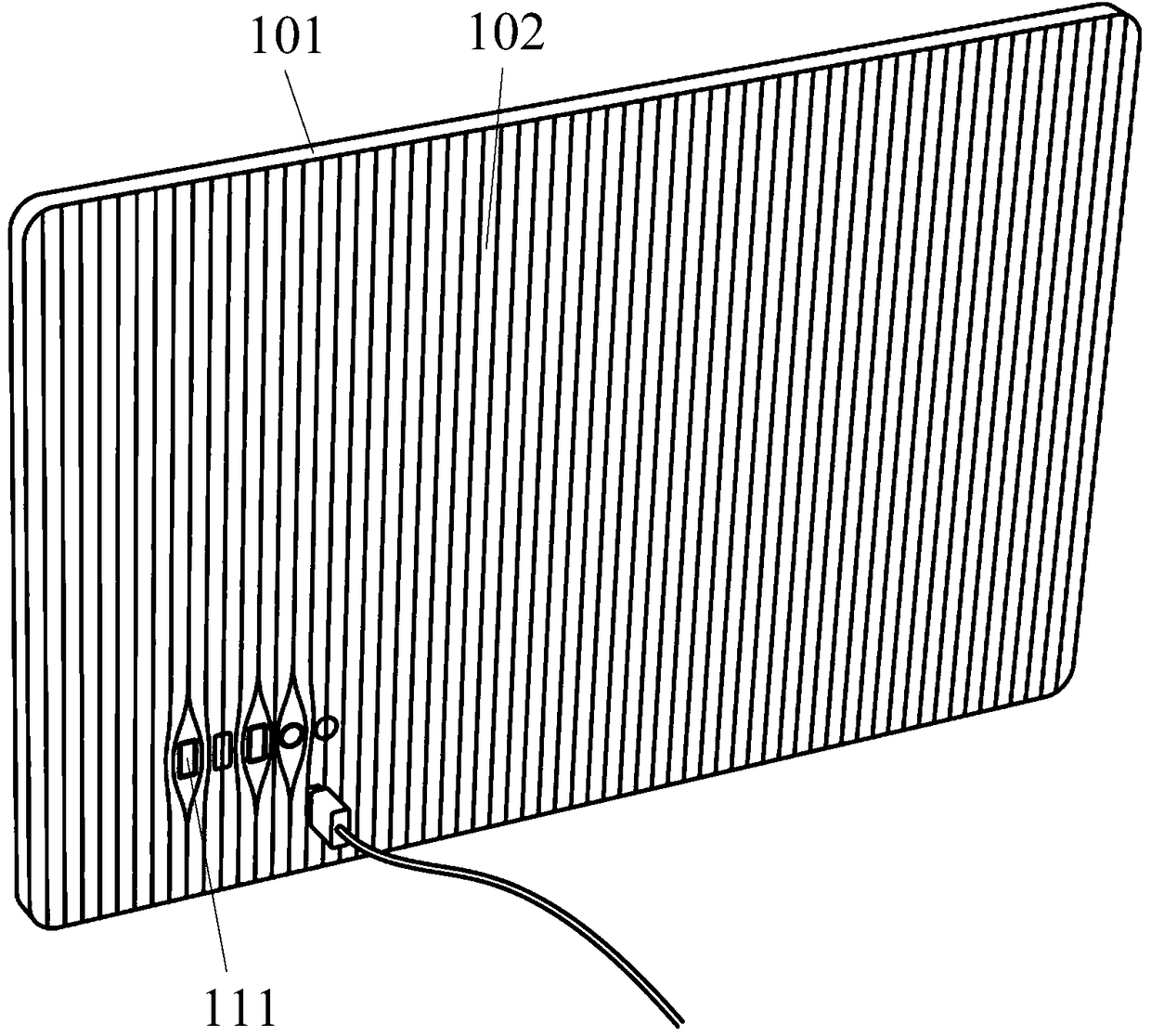

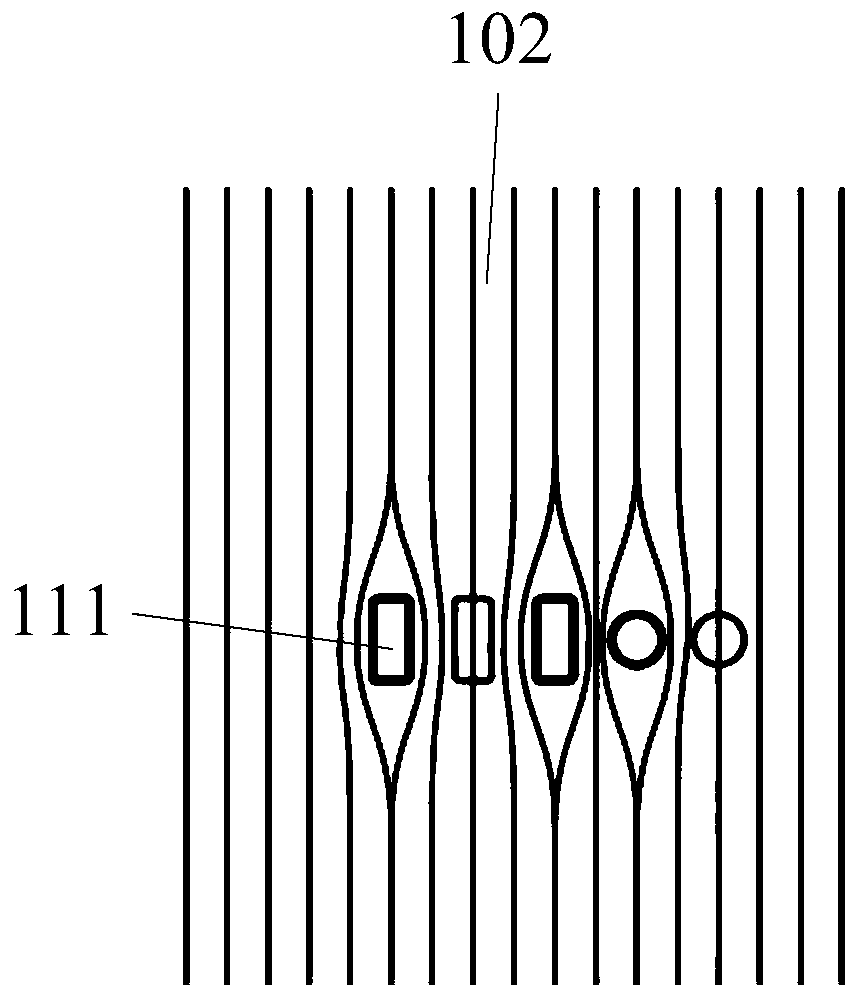

Method for realizing virtual keys on curved side of touch panel

InactiveCN106814902AReduce areaFlexible designInput/output processes for data processingIndiumFlexible circuits

The invention provides a method for realizing virtual keys on a curved side of a touch panel. The method includes preparing a glass sheet consisting of a flat plate part and at least one side with curved plate part, forming a visible region and an icon region of the touch panel on the inner side,containing the curved plate part, of the glass sheet through silk printing; attaching pattern surfaces of a first flexible circuit board which is provided with at least one side having ITO(indium tin oxid) patterns to the curved part of the inner side of the glass sheet, while making the edges of the planar part of the inner side of the glass sheet disconnected or adjacent with the first flexible circuit board, namely making the first flexible circuit board out of attaching to the planar part of the inner side of the glass sheet. The processing of the method is simple; the first flexible circuit board is of small area, and accordingly is quite flexible to use, and can meet more requirements for shapes if it has enough attachment supporting points. There is no electric connection between the first flexible circuit board and a film sensor, so that the method is not limited by structure limitation in the sensor processing.

Owner:LENS TECH CHANGSHA

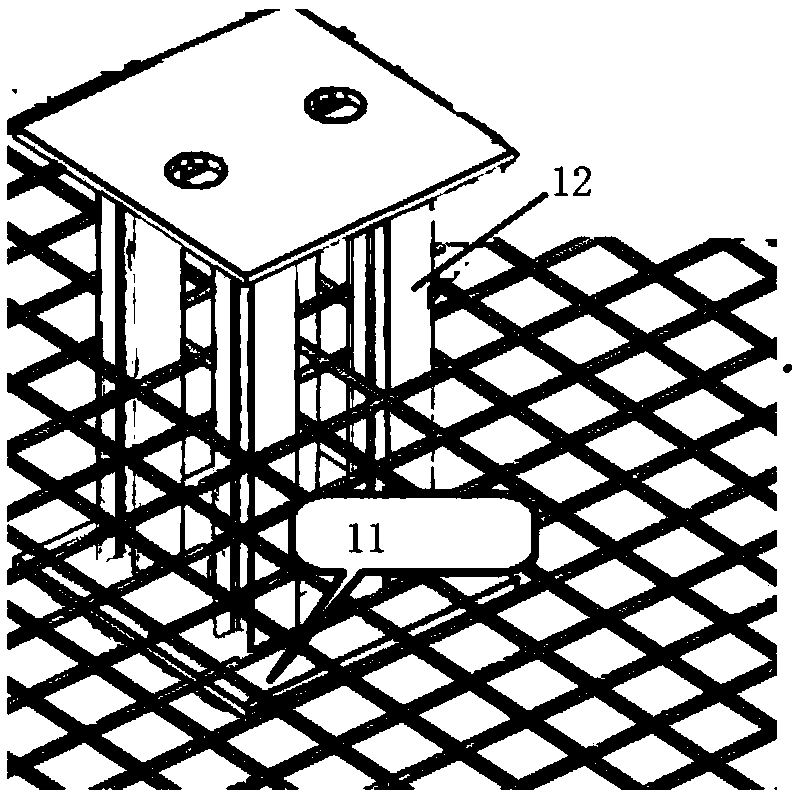

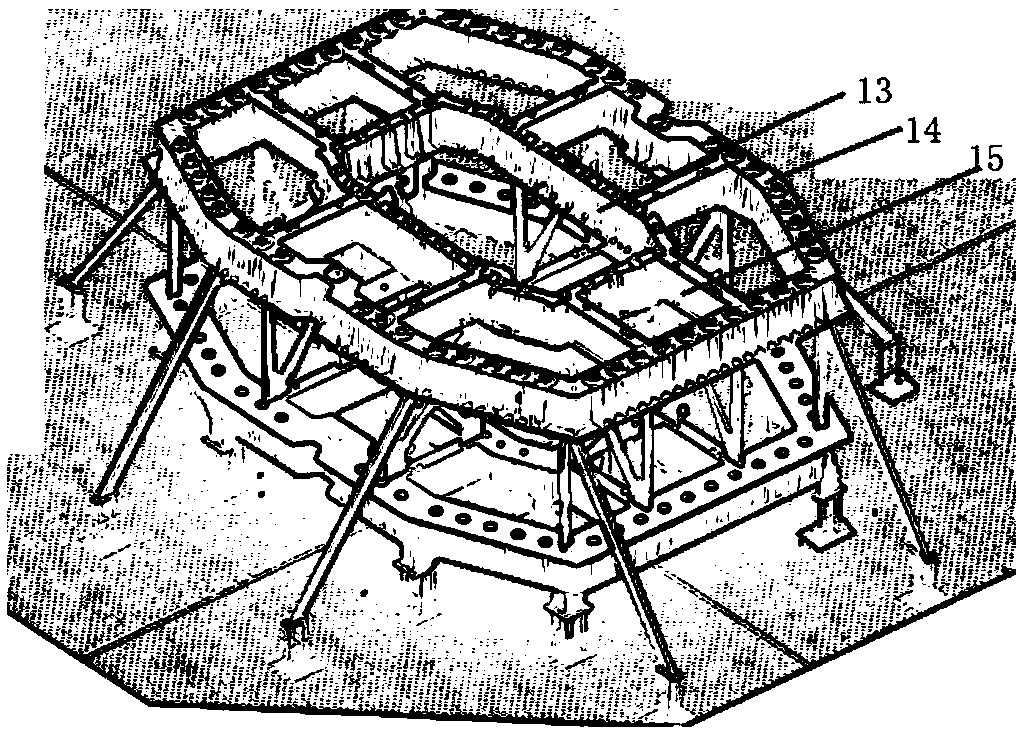

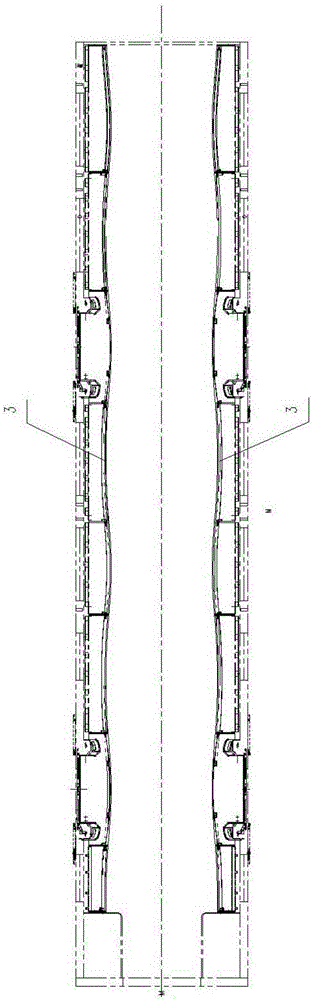

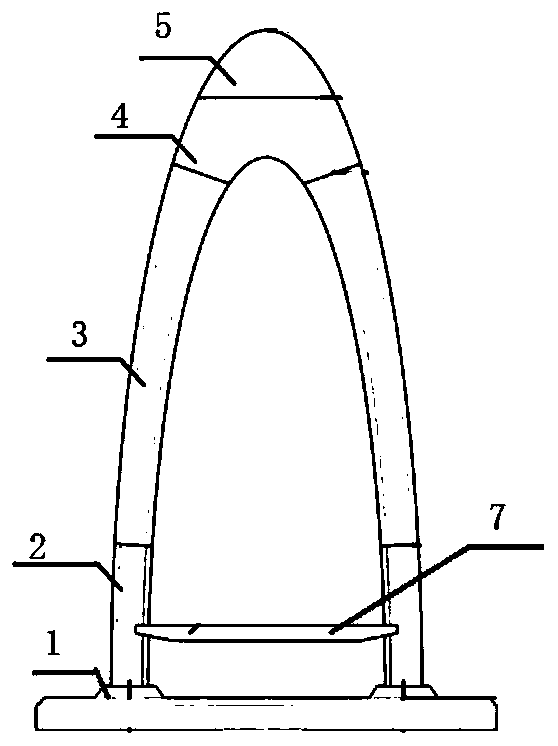

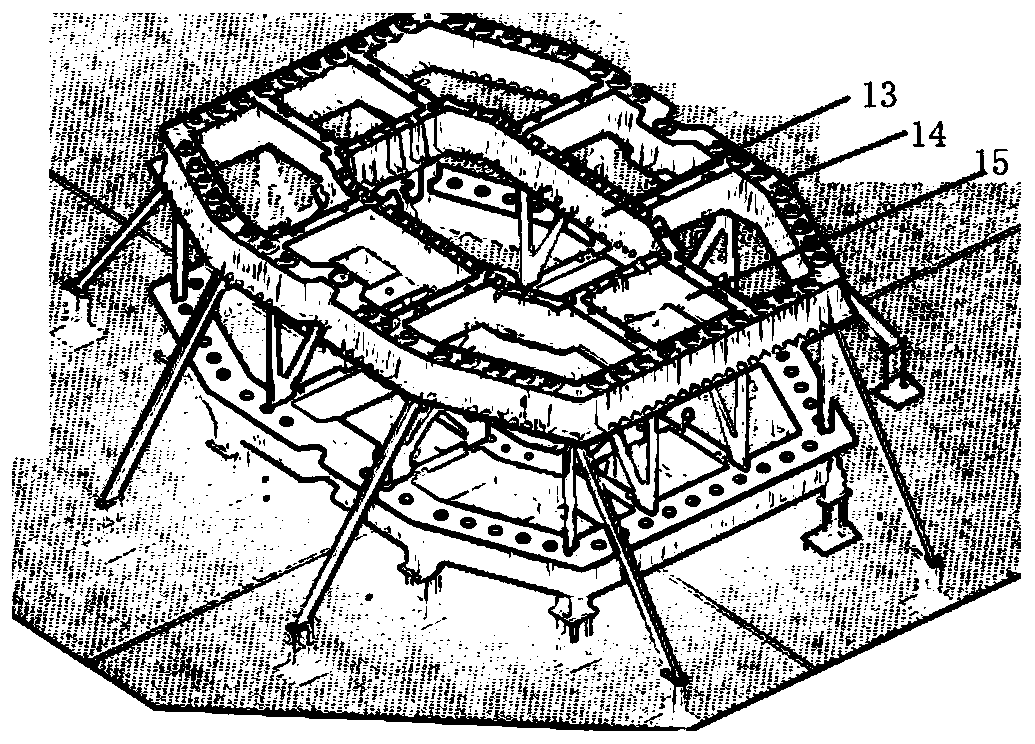

Safe and stable suspension bridge and construction technology thereof

ActiveCN109505225ASimple construction processGuarantee the construction qualitySuspension bridgeBridge erection/assemblyTowerBuilding construction

The invention discloses a safe and stable suspension bridge and a construction technology thereof. The construction technology specifically includes the following steps that 1, firstly, the whole suspension bridge is divided into a steel arch foot bearing platform, a steel mixing joint section, a pure steel structure section, a cross beam section and a tower crown decoration section according tothe different structure composition; 2, embedded parts are set in a designated position, and pouring is conducted on the embedded parts to prepare the steel arch foot bearing platform; 3, the steel mixing joint section is constructed on the steel arch foot bearing platform; 4, after the steel mixing joint section is constructed, the pure steel structure section is constructed; 5, the cross beam section is constructed on the pure steel structure section, and fixation is then conducted; 6, finally, the tower crown decoration section is built and fixed on the upper portion of the cross beam section. On the basis that the construction quality is guaranteed, the construction technology of the bridge is optimized, the whole construction process is relatively simple, the whole construction speedis increased and the construction period is shortened.

Owner:JIANGSU HUNING STEEL MECHANISM

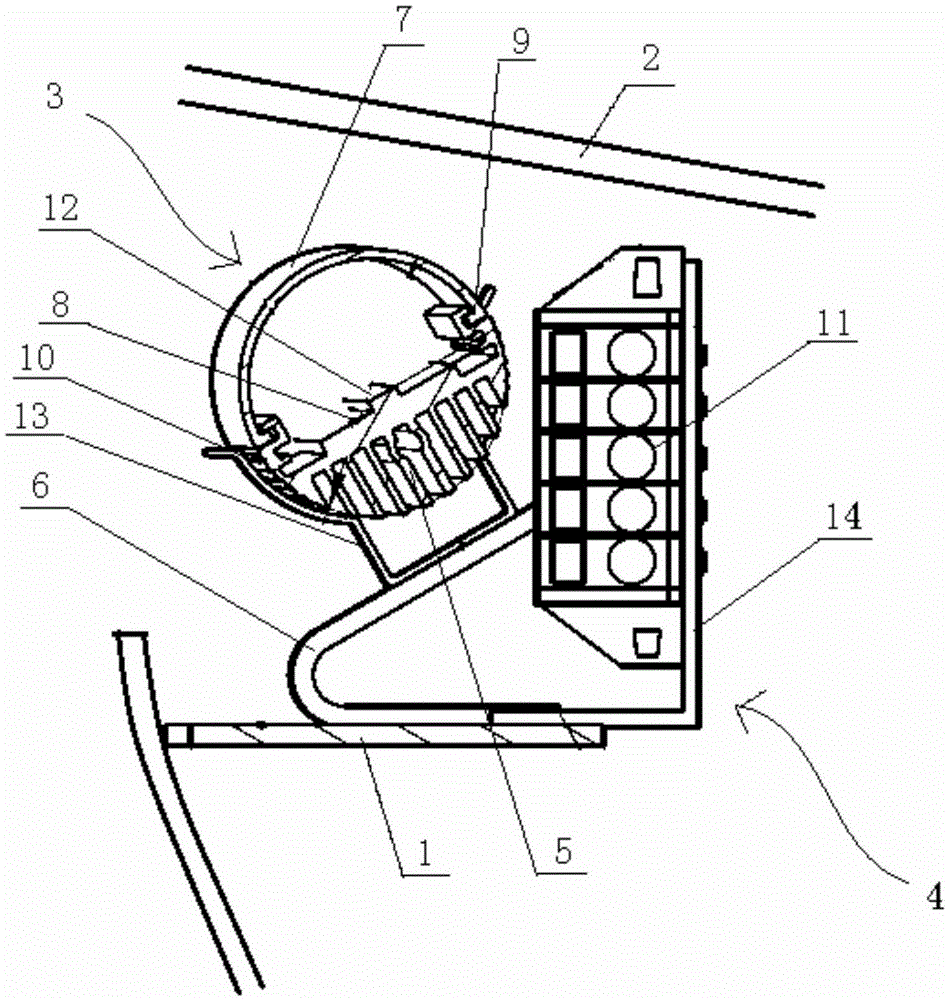

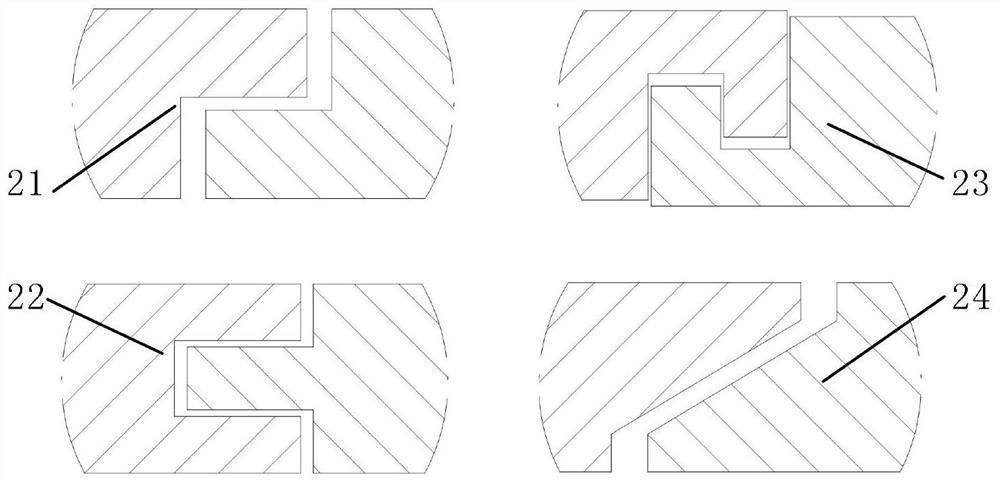

Kay structure and portable mobile terminal

InactiveCN101635211ASolve the yieldSolve the technical problem of poor hand feeling when pressing buttonsElectric switchesTelephone set constructionsCushionElectrical and Electronics engineering

The embodiment of the invention discloses a key structure and a portable mobile terminal, belonging to the technical field of machinery and solving the technical problem of the prior key structure that the yield is lower and the hand touch when pressing the key is not good. The key structure comprises a cushion and a keycap glued on the cushion by glue, wherein one side of the cushion, which is far from the key cap, is provided with an electric conduction base; and an area of the cushion, which is bonded with the keycap and is close to the edge of the keycap, is provided with grooves. The portable mobile terminal comprises a shell and the key structure arranged on the shell. The invention is applied to various electronic devices provided with key structures.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

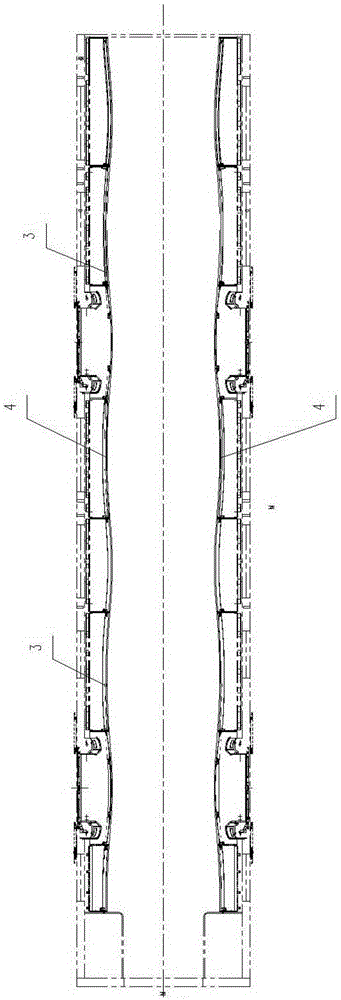

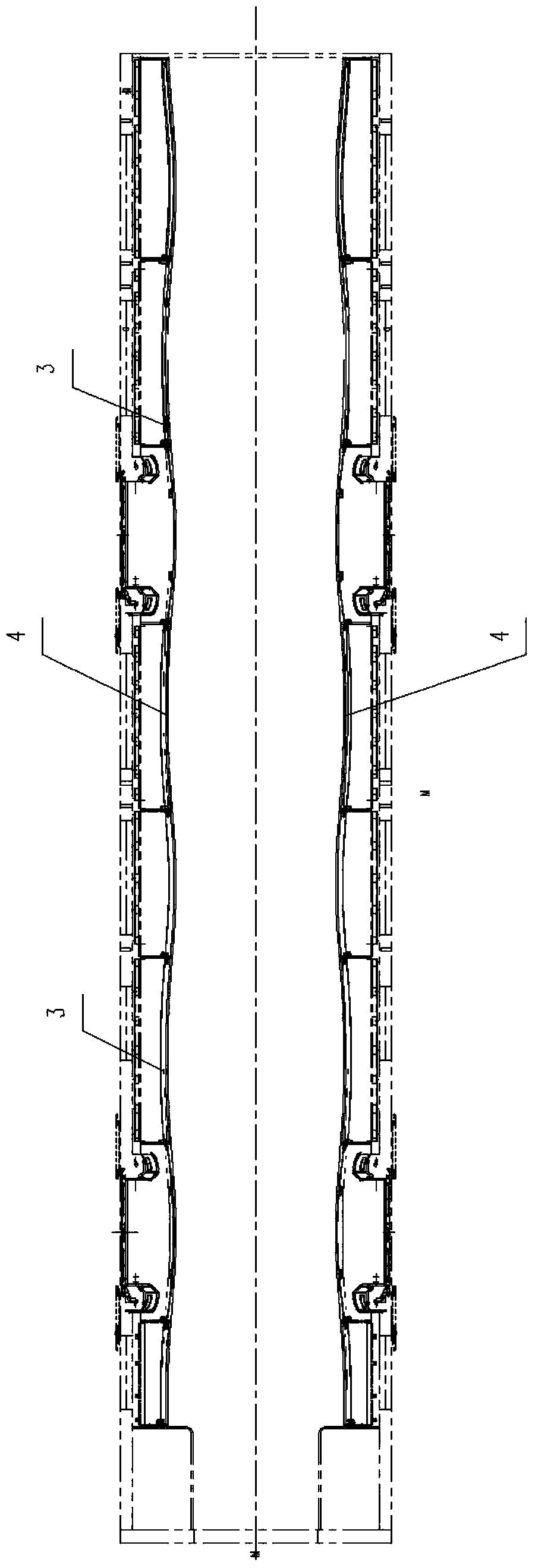

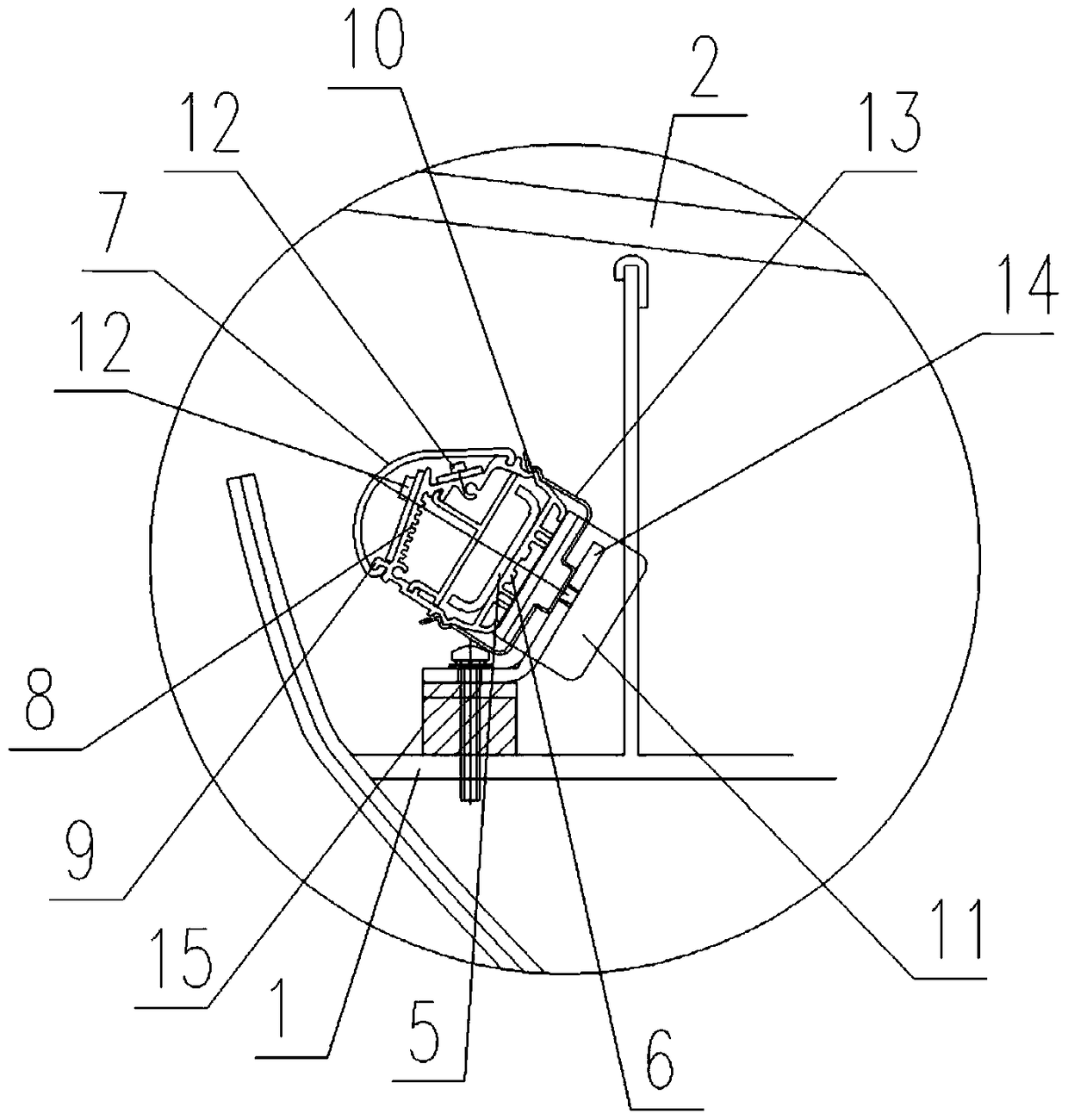

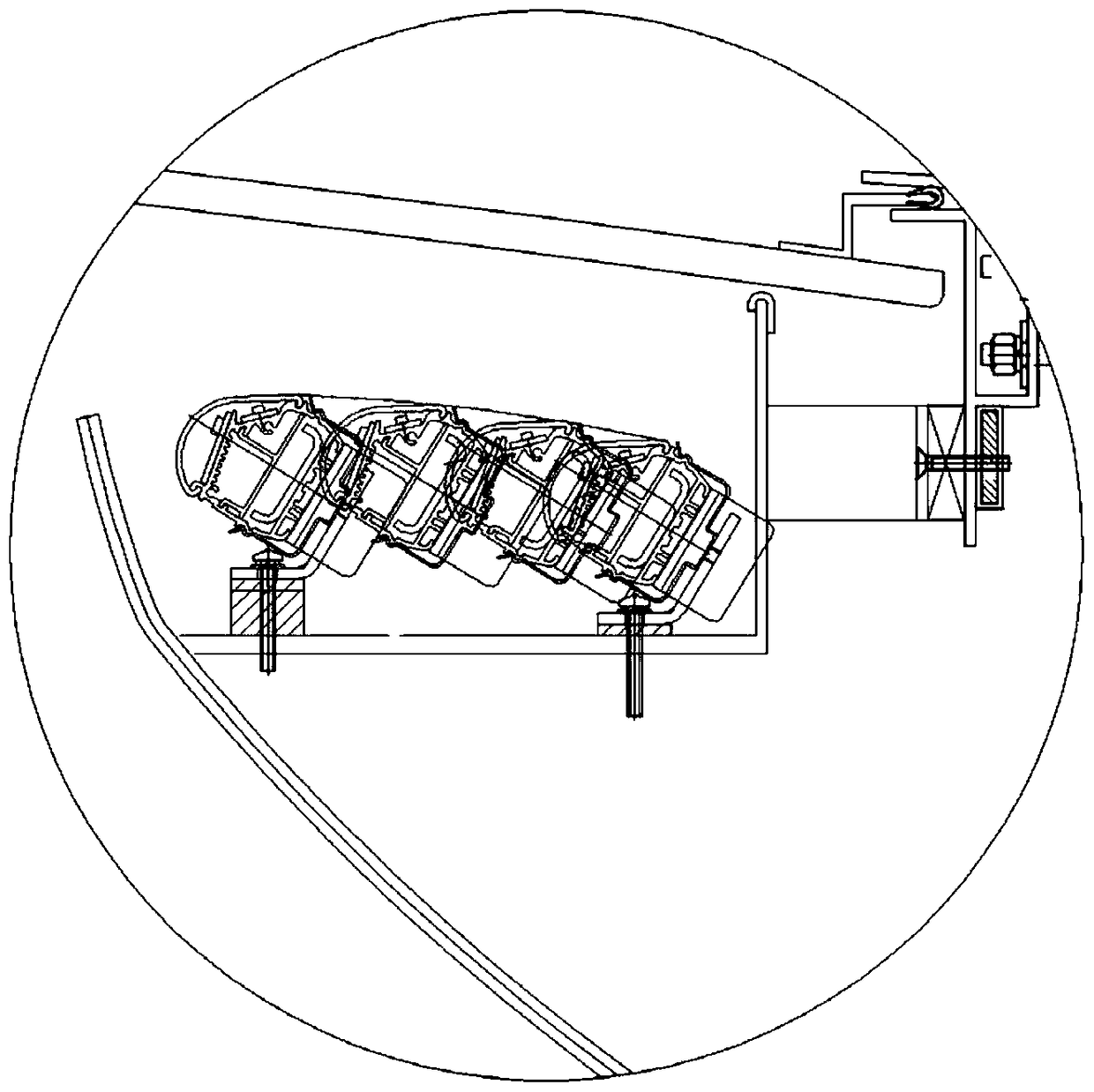

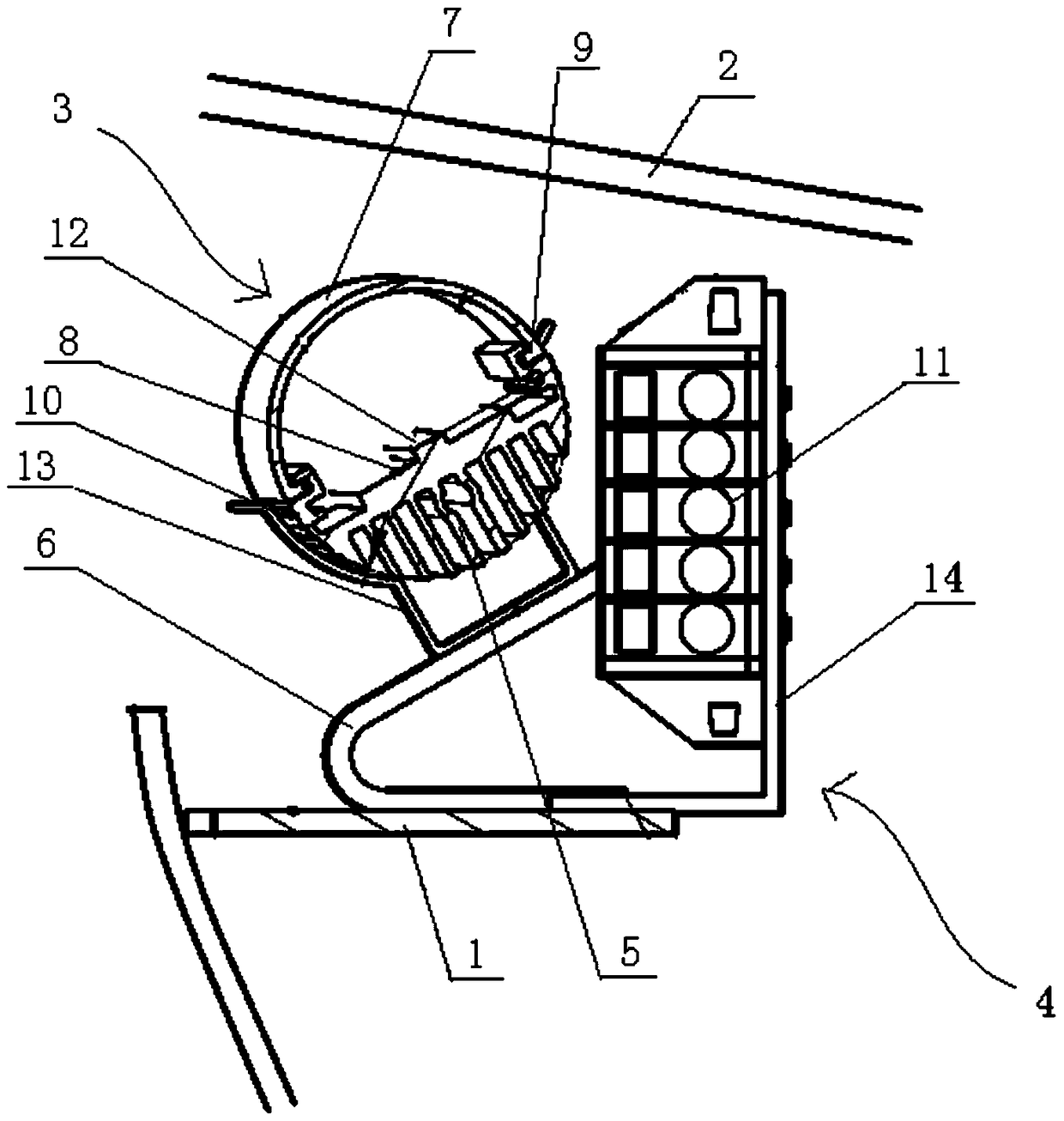

Rail car lighting device

ActiveCN105402677AConducive to heat dissipation of lampsImprove the degree of beautificationElectric circuit arrangementsOptical signallingLight sourceEngineering

A rail car lighting device comprises a plurality of short lamps. The short lamps are spliced into a long lamp matched with a special-shaped interior in shape. Sectional bars are arranged in the short lamps. Light sources are arranged on the sectional bars. The irradiation angles of the included angle between all sections of light sources and the horizontal plane are consistent through sectional bar twisting. The short lamps are spliced into the long lamp matched with the special-shaped interior in shape, and accordingly the requirement for the shape of the lamp is met. The twisted sectional bars are arranged inside, the light source irradiation angles of points of the long lamp are consistent, the requirement for the lighting effect in a carriage of the special-shaped interior is met, and the carriage beautifying degree is further improved.

Owner:CRRC QINGDAO SIFANG CO LTD

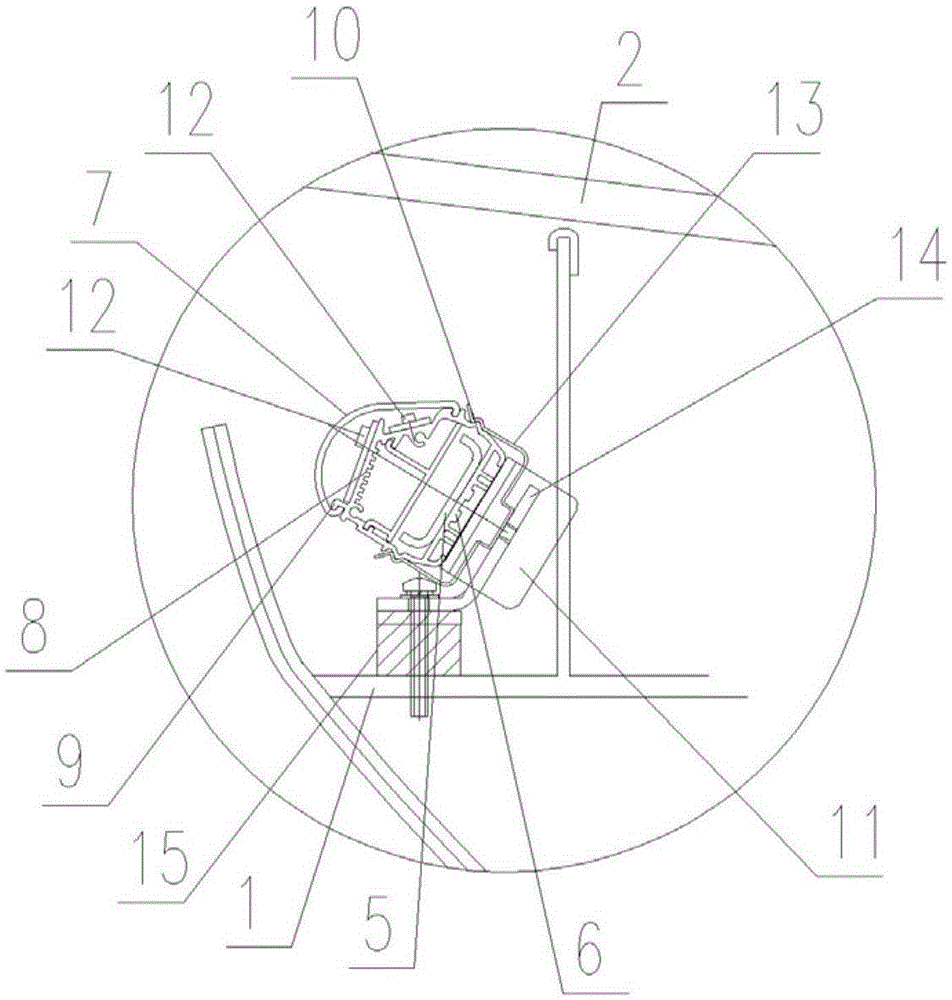

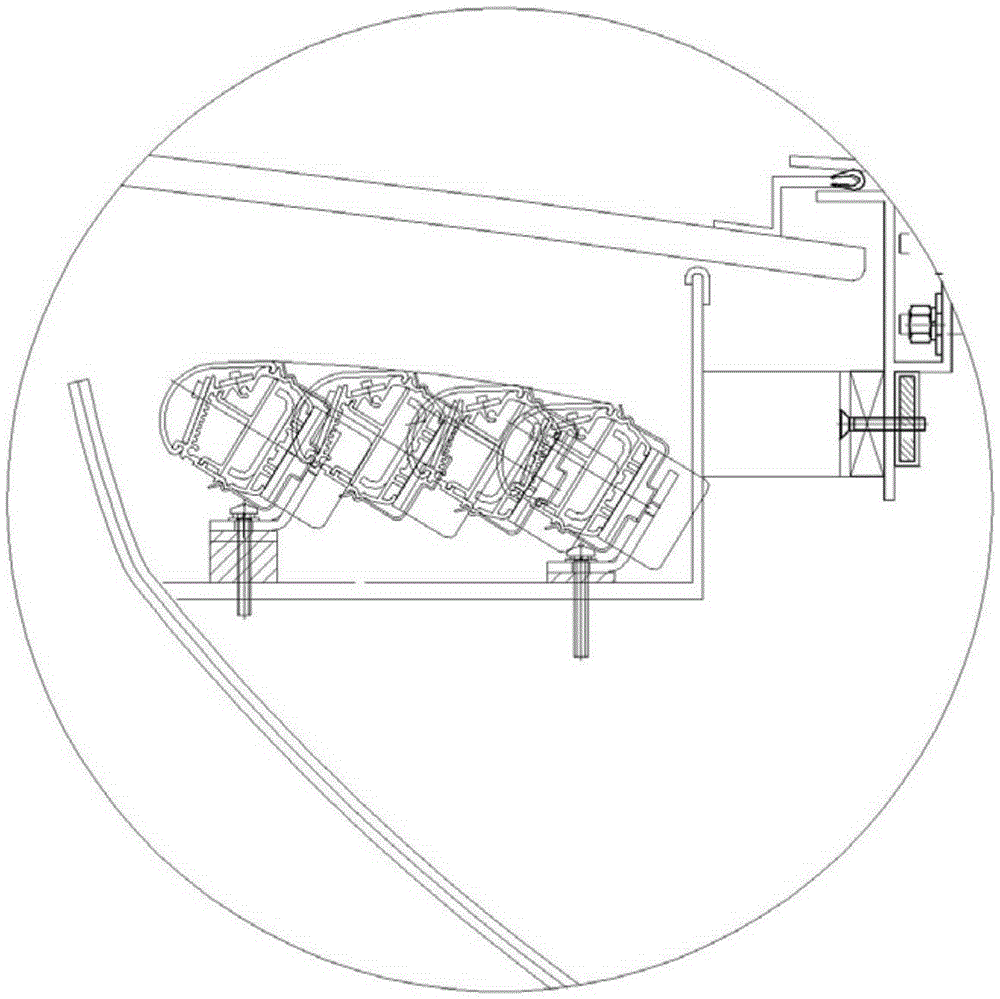

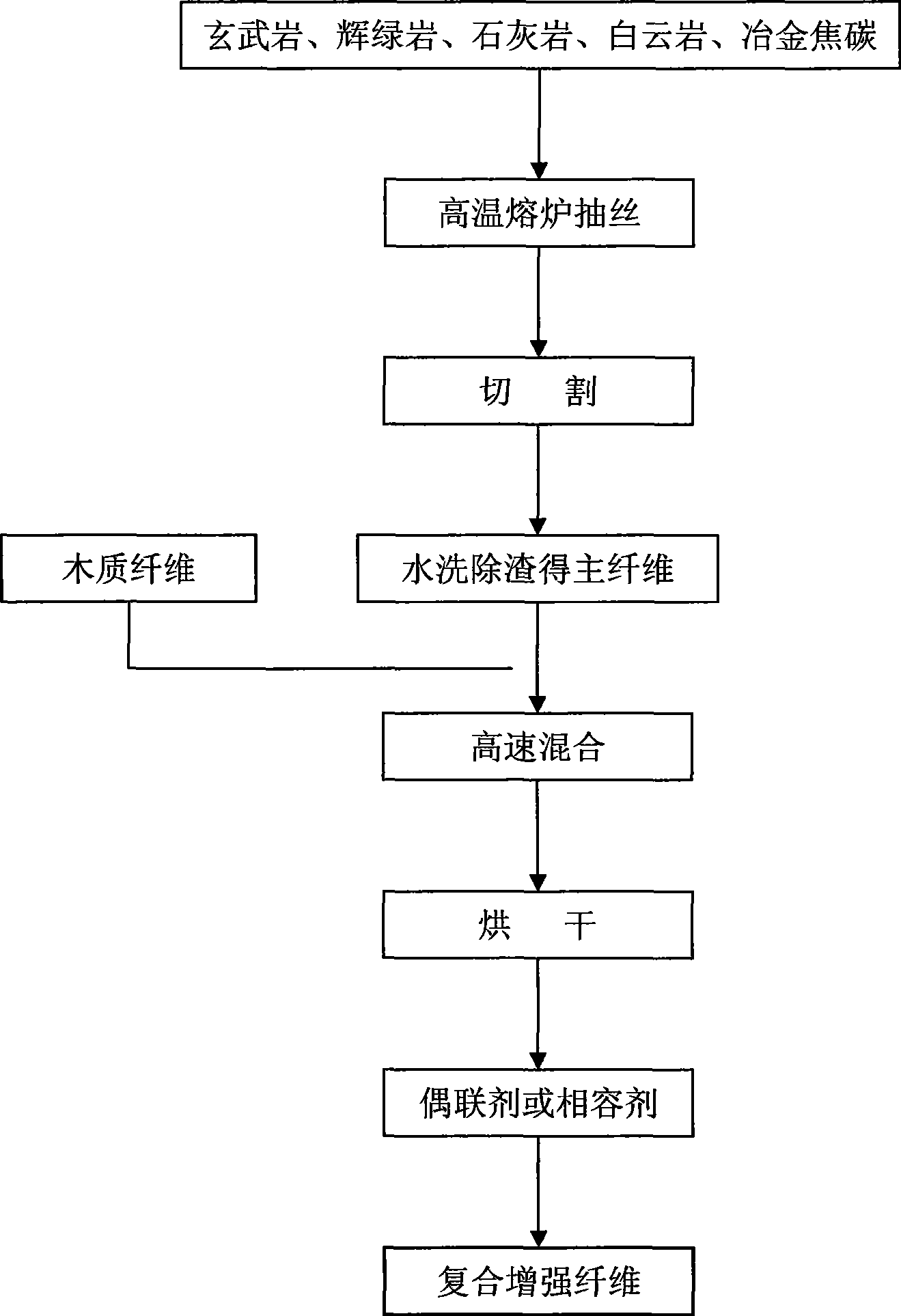

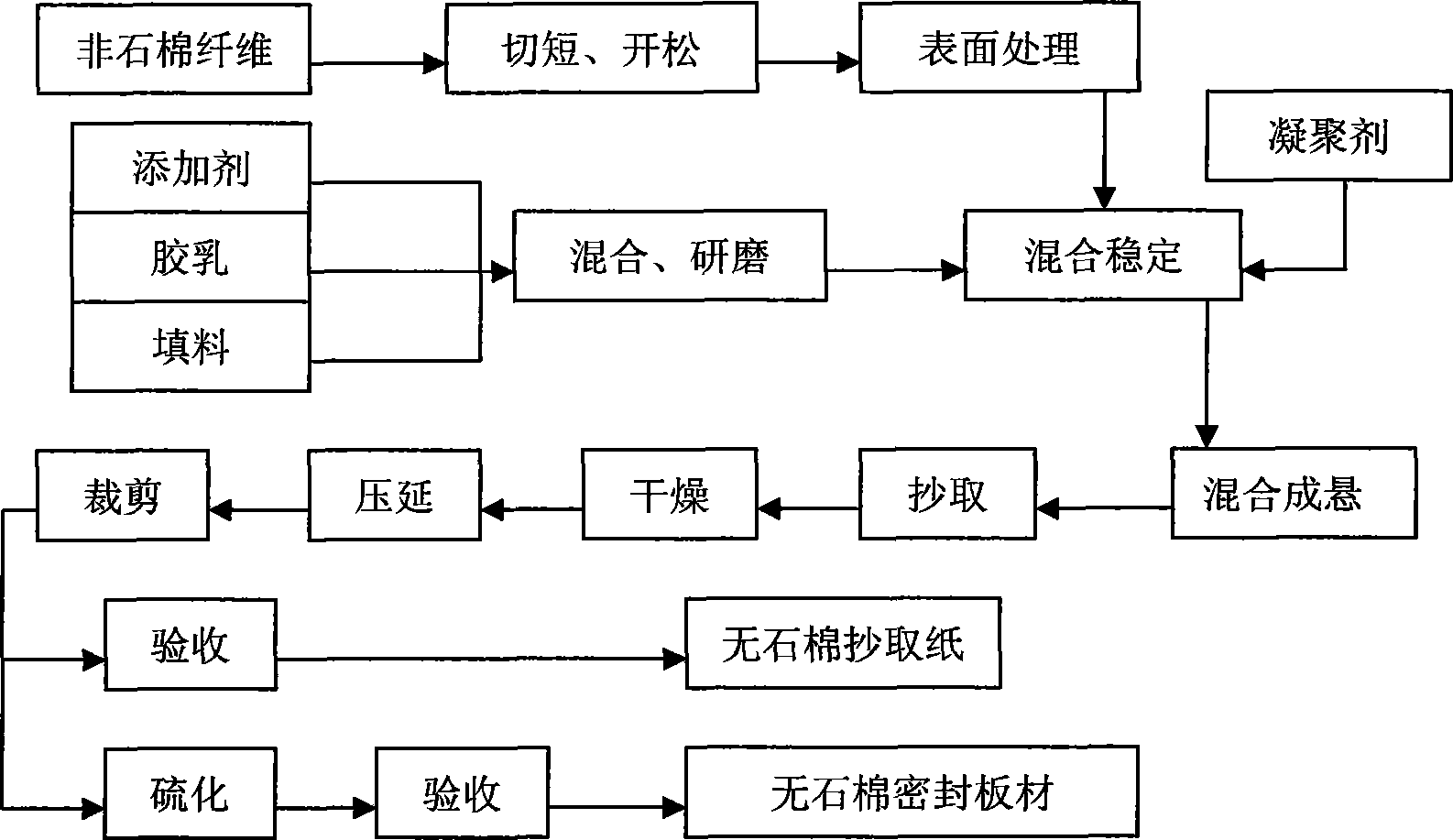

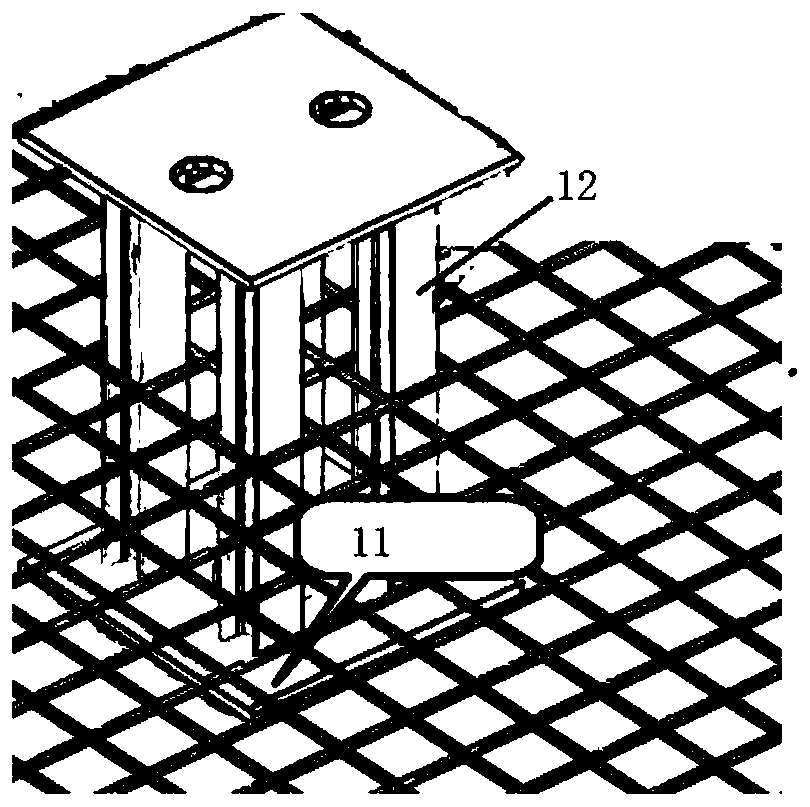

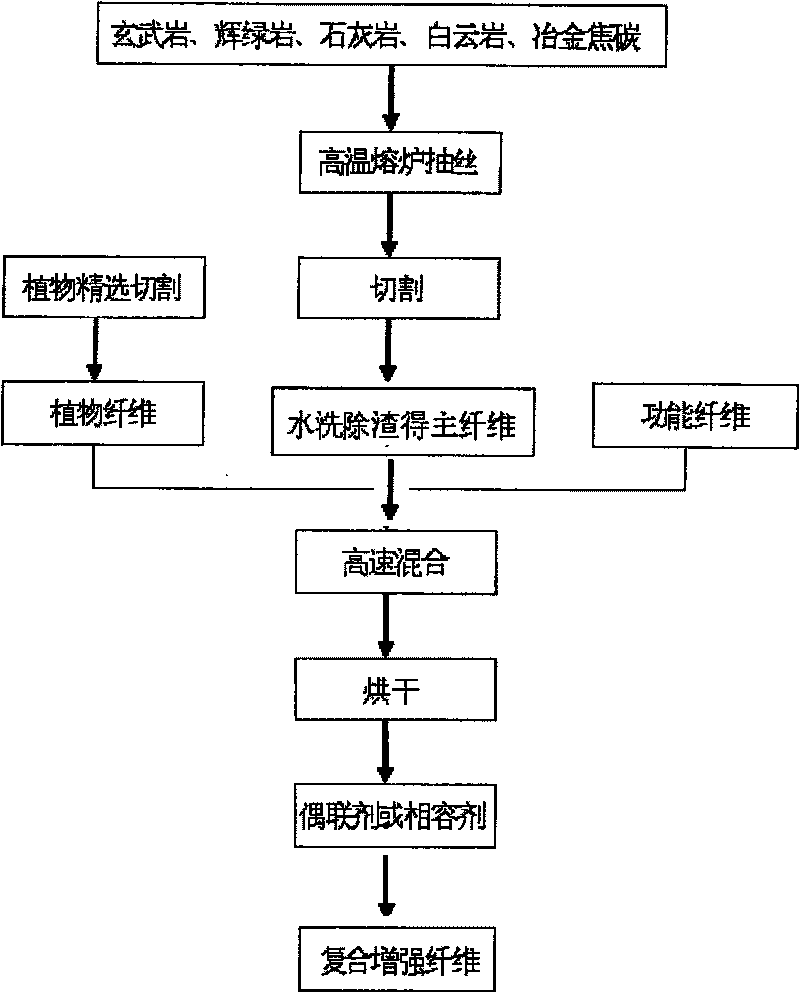

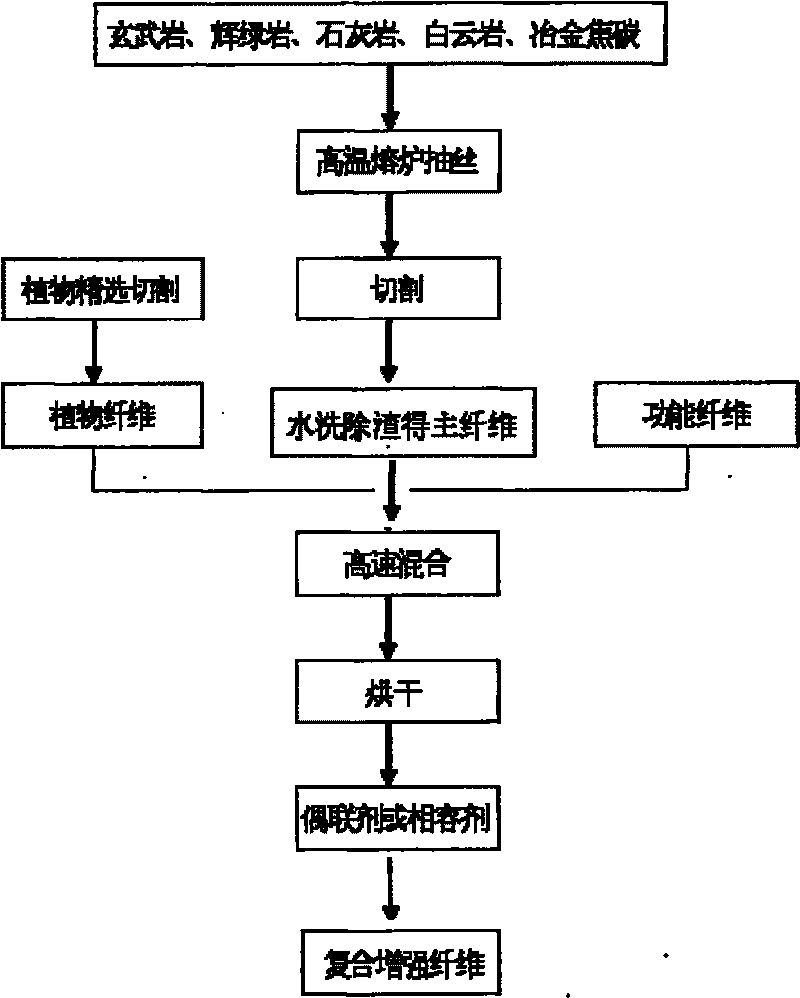

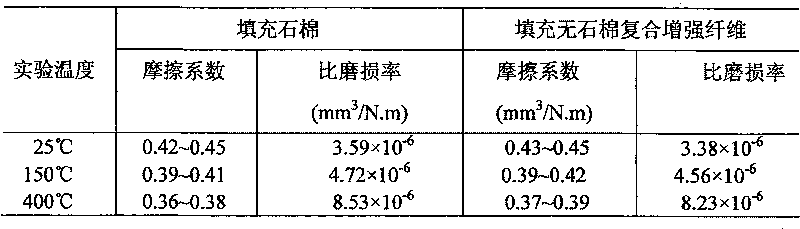

Non-asbestos composite reinforcing fiber for sealing material and technique for producing the same

InactiveCN101412901AAchieve high performanceRealize environmental protectionOther chemical processesFiberDrying time

The invention provides a novel low-cost asbestos-free composite reinforced fiber for a sealing material and a production technology. The fiber is environment-friendly and degradable, has no pollution, and can increase shock resisting strength and tensile resisting strength of the sealing material. The production technology is simple, has low production cost, and is suitable for batch production of the sealing material. The asbestos-free composite reinforced fiber for the sealing material comprises the following raw materials in weight portion: 50 to 90 portions of rock wool or granulated wool, 15 to 30 portions of wood fiber, 2 to 5 portions of coupling agent, and 3 to 5 portions of compatilizer. The preparation technology comprises the following steps: firstly, taking the raw materials in the weight portion; secondly, cutting the rock wool or the granulated wool; thirdly, washing the raw materials by using water through a centrifugal machine to remove dregs and obtain main fiber, and controlling the content of dreg balls at between 0.5 and 1 percent; and fourthly, adding the wood fiber into the main fiber, mixing the mixture at high speed, drying the mixture after the mixing, spraying the coupling agent and the compatilizer in the drying process, and finally obtaining the composite reinforced fiber, wherein the drying temperature is between 105 and 150 DEG C, and the drying time is between 1 and 2 hours.

Owner:韩德忠

Self-etching copper surface bonding agent and preparation method thereof

PendingCN114231982AImprove bindingImprove solubilityInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentOrganic acidCopper salt

The invention discloses a self-etching copper surface bonding agent and a preparation method thereof, and belongs to the technical field of chemicals for printed circuit board production. The bonding agent comprises an oxidizing agent, a nitrogen-containing heterocyclic ring copolymer, a hydroxyl-containing solvent, organic acid and the balance of deionized water, wherein the oxidizing agent is at least one of bivalent copper salt, trivalent iron salt, peroxide and persulfate; the nitrogen-containing heterocyclic ring copolymer is a polymer prepared by free radical copolymerization of a nitrogen-containing heterocyclic ring monomer, an alkyl acrylate monomer and a hydrophilic monomer according to the mass ratio of (20-90): (5-50): (5-15), the hydroxyl-containing solvent is at least one of an alcohol compound and an alcohol ether compound, and the organic acid is organic carboxylic acid. According to the bonding agent, two technologies of chemical micro-etching and chemical bonding are combined, the adhesive force between the copper surface and different photoresist can be effectively improved and kept stable, the change of the copper surface appearance is small, and meanwhile the requirements of fine line processing and high-frequency signal transmission on the copper surface appearance can be met.

Owner:KUNSHAN CITY BANMING ELECTRONICS SCI & TECH

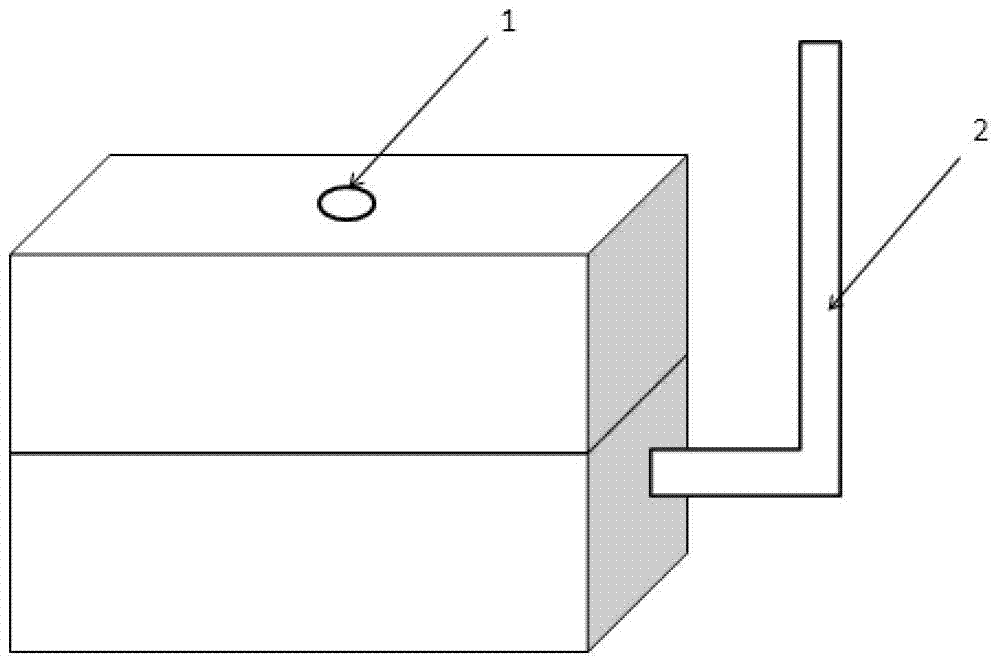

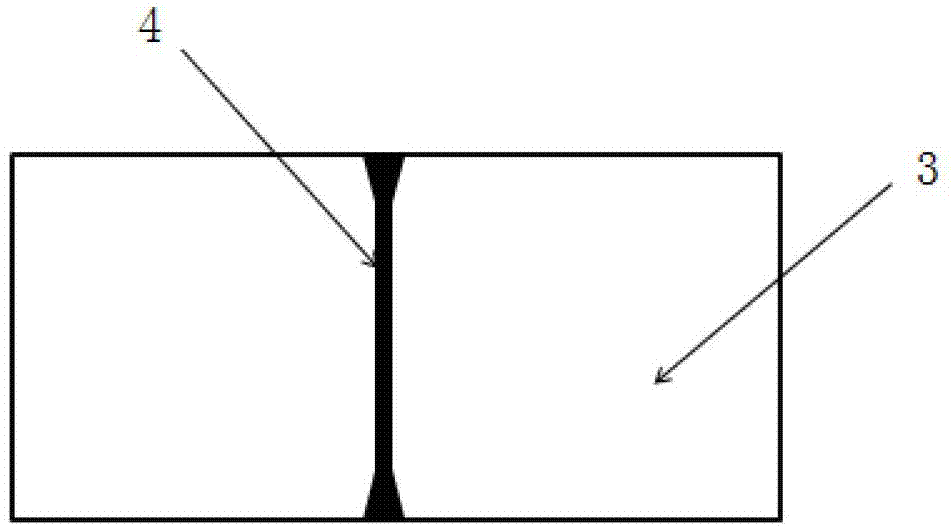

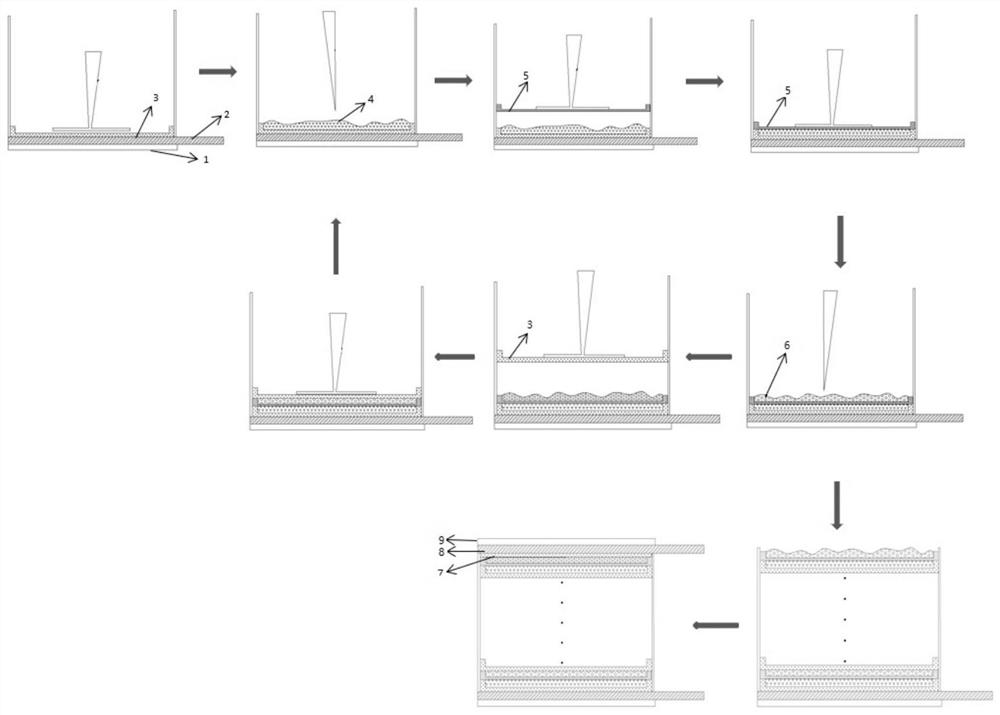

Preparation method of coded aperture for neutron penumbra imaging

ActiveCN102956280AHigh softening pointHigh hardnessX-ray/infra-red processesConversion screensHydrogen chlorideNeutron

The invention discloses a preparation method of a coded aperture for neutron penumbra imaging. The method includes the steps of: firstly drawing a quartz glass tube through a laser tube drawer to obtain a quartz glass tube which satisfies the aperture shape requirement of a penumbra hole; fixing the glass tube in a die and adding smelted liquid heavy metal to the die; after the heavy metal is cooled and solidified, dissolving the quartz glass tube in the metal block through hydrogen chloride solution; and incising the metal block along the middle part to obtain two penumbra holes which contain double-pyramid type thick apertures. The double-pyramid type thick apertures, the diameter change of which can be controlled, are suitable for penumbra hole design of different neutron penumbra imaging technologies. The preparation method is simple in preparation process, and the coded aperture prepared through the method in which a glass tube drawing technology and a metal die cavity forming technology are combined is low in cost and convenient for popularization.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method and use of millimetre-sized mesoporous carbon spheres

ActiveCN101817519BMeet the shape requirementsAdjustable sizeNanostructure manufactureParaffin waxFiltration

The invention belongs to the field of inorganic nano material synthesis and particularly relates to a preparation method and use of millimetre-sized mesoporous carbon spheres. The preparation method comprises the following steps of: dissolving resorcinol in ethanol serving as a solvent; adding furfural and ethanol solution of hydrogen chloride, and stirring the mixture at 0 to 15 DEG C for 10 to 120 minutes; adding aqueous solution of hexamethylenetetramine and pore-forming material into the prepared solution to obtain solution of a precursor; adding the prepared solution of the precursor into liquid max containing an emulsifier, and stirring the solution to perform per-polymerization; volatilizing the solvent, filtering the remaining material, and washing and drying the product obtained by filtration; and carbonizing the product to obtain the millimetre-sized mesoporous carbon spheres. The preparation of the millimetre-sized mesoporous carbon spheres of the invention is performed under simple conditions and with easy operation. The millimetre-sized mesoporous carbon spheres prepared by the method have the characteristics of adjustable size, large specific surface area, large porevolume and the like, and can be used as adsorbent for hemoperfusion and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Novel lighting device

ActiveCN105402676AMeet the shape requirementsImprove cooling effectLighting support devicesVehicle interior lightingEngineeringIrradiation

A novel lighting device comprises a lamp tube part and a lamp body part. The lamp tube part comprises lamp tube sectional bars, and the shape of the lamp tube sectional bars subjected to stretching shaping is matched with the shape of a special-shaped interior. A light source is arranged on the lamp tube sectional bars. By means of twisting and shaping of the lamp tube sectional bars, the irradiation angles of the included angles between all sections of light source and the horizontal plane are consistent. A lamp the same as the special-shaped interior in shape is formed through stretching and twisting of the lamp tube sectional bars, the requirement for the shape of the lamp is met, and heat dissipation of the lamp is facilitated. By means of twisting and shaping of the lamp tube sectional bars, the light source irradiation angles of points of the lamp are consistent, the requirement for the lighting effect in a carriage of the special-shaped interior is met, and the carriage beautifying degree is further improved.

Owner:CRRC QINGDAO SIFANG CO LTD

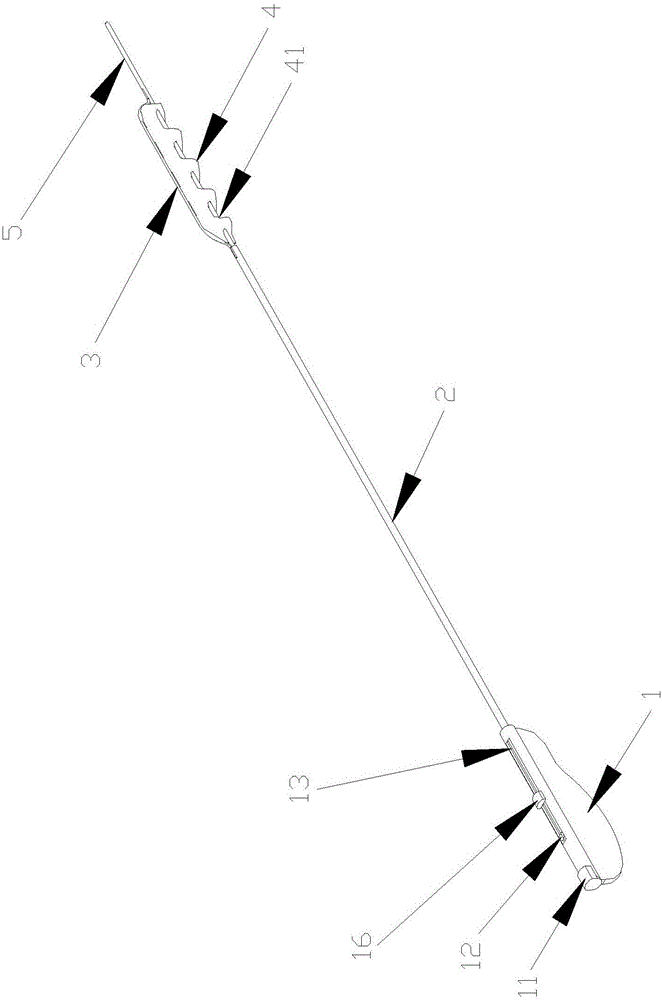

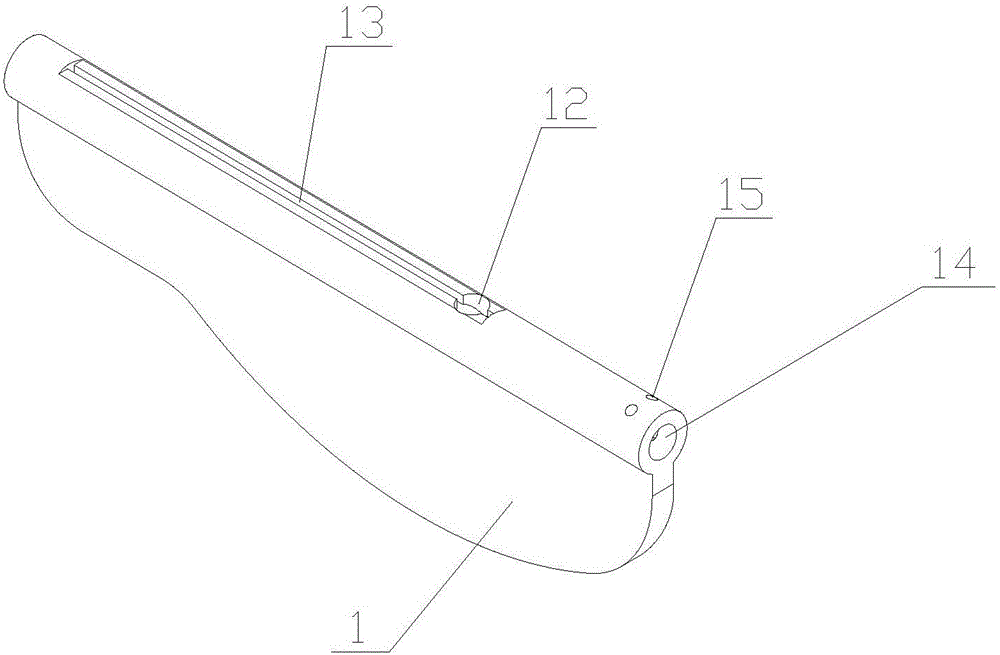

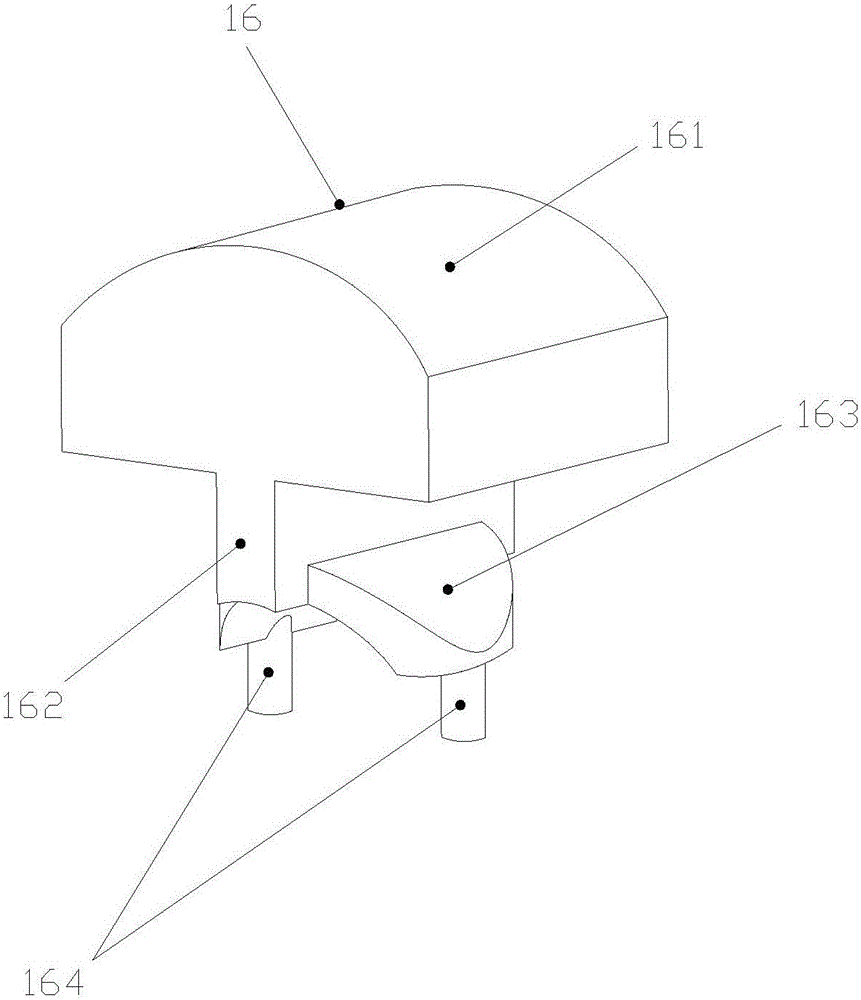

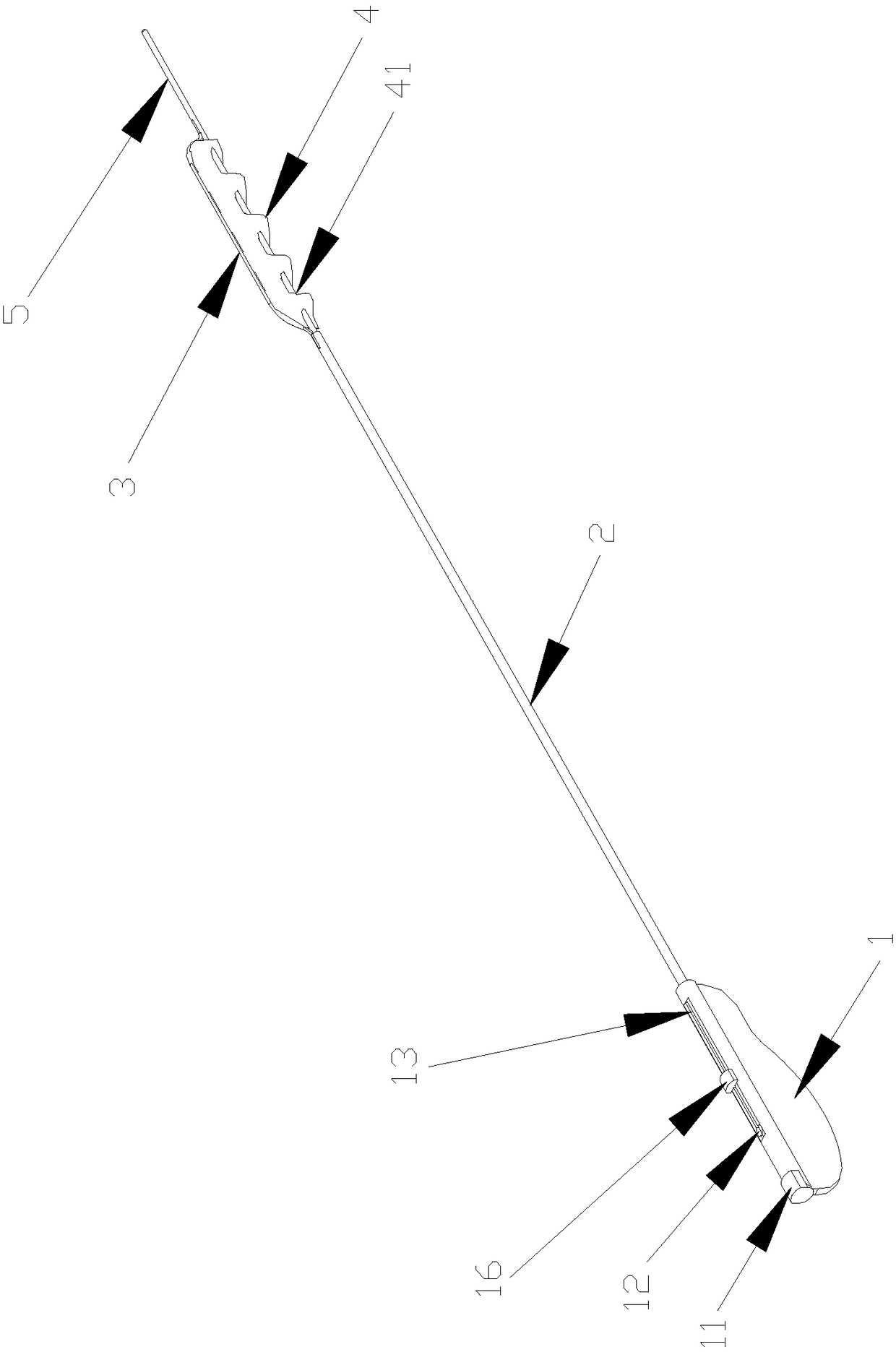

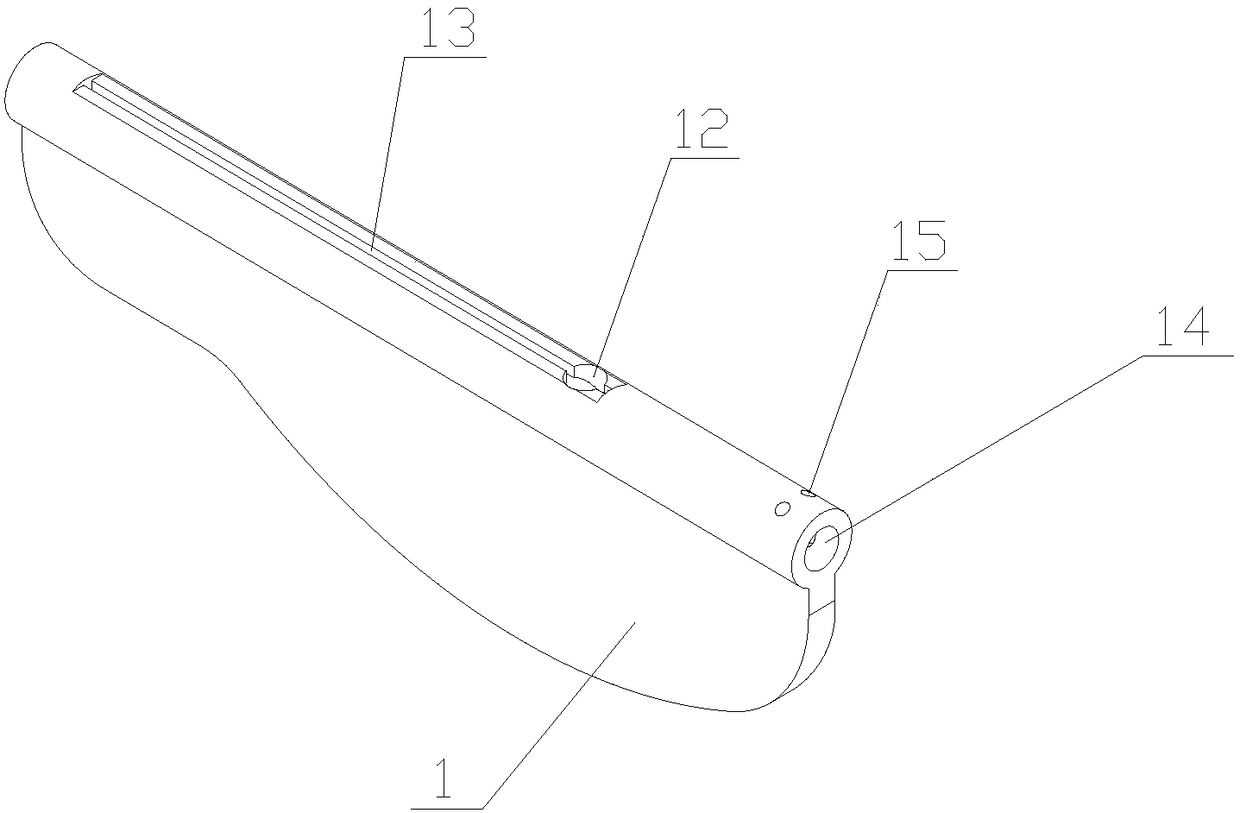

Diaphragm type body cavity blocking equipment

ActiveCN105748127ADoes not cause body cavity wall damageEasy to put inOcculdersEngineeringBody cavity

The invention relates to diaphragm type body cavity blocking equipment which is provided with a handle, a tuba handle, a shaping wire, a film and an inner core; the two ends of the shaping wire are fixed to the far end of the tube handle and the inner core respectively; the shape of the film in the preparation state is that one or more edges are in a linear shape, and other edges are a polygon composed of straight lines or curves, an axially symmetric figure or a face in an irregular shape, one edge, in the linear shape, on the film is provided with a plurality of through holes in the sideline direction, the inner core penetrates through the through holes, the other side edge opposite to the linear-shaped edge of the film wraps and is fixed to the shaping wire, and the position between the shaping wire and the inner core is in a spiral shape under the use state of the film.The shape of a blocking object of the diaphragm type body cavity blocking equipment can be controlled precisely, the blocking object is placed into a body cavity conveniently, completely blocking and one-time taking out of foreign matter can be achieved, and various situations in the operation process can be coped with flexibly.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

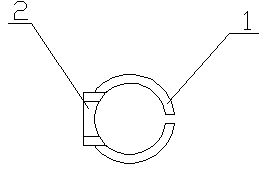

Cable identification ring

InactiveCN103354061ASolve the rotation problemSolving Mobility IssuesSignsPrinting inkElectrical and Electronics engineering

The invention provides a cable identification ring which has a C-shaped section. An identification area is formed in the identification ring; a character filled with printing ink is arranged on the identification area; the character is a concave character or a convex character; the identification area is one or more of the outer surface of the identification ring, a protruding platform on the outer surface of the identification ring, and a downwards concave platform on the outer surface of the identification ring; a bulge is formed on the edge of the identification ring; a lower recess is formed in the other side which corresponds to the bulge. The C-shaped section is directly matched with the shape of a cable, so that the cable is prevented from being extruded through the identification ring; due to matching between the edge bulge and the small recess among lantern rings, the problem that the identifier rotates and moves is solved, the identification character is clear due to the concave or convex character, and the identification ring is difficult to wear.

Owner:卓开富

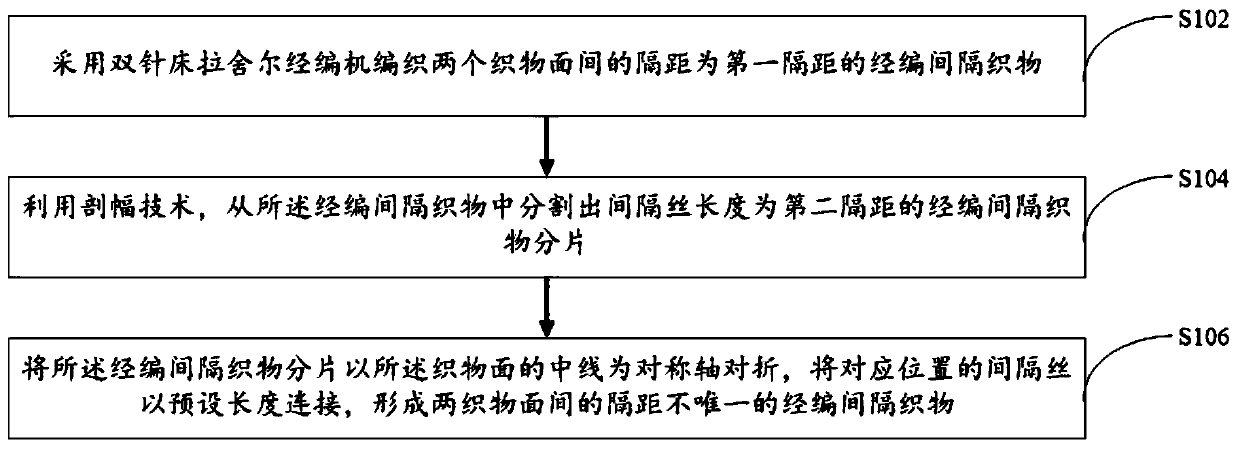

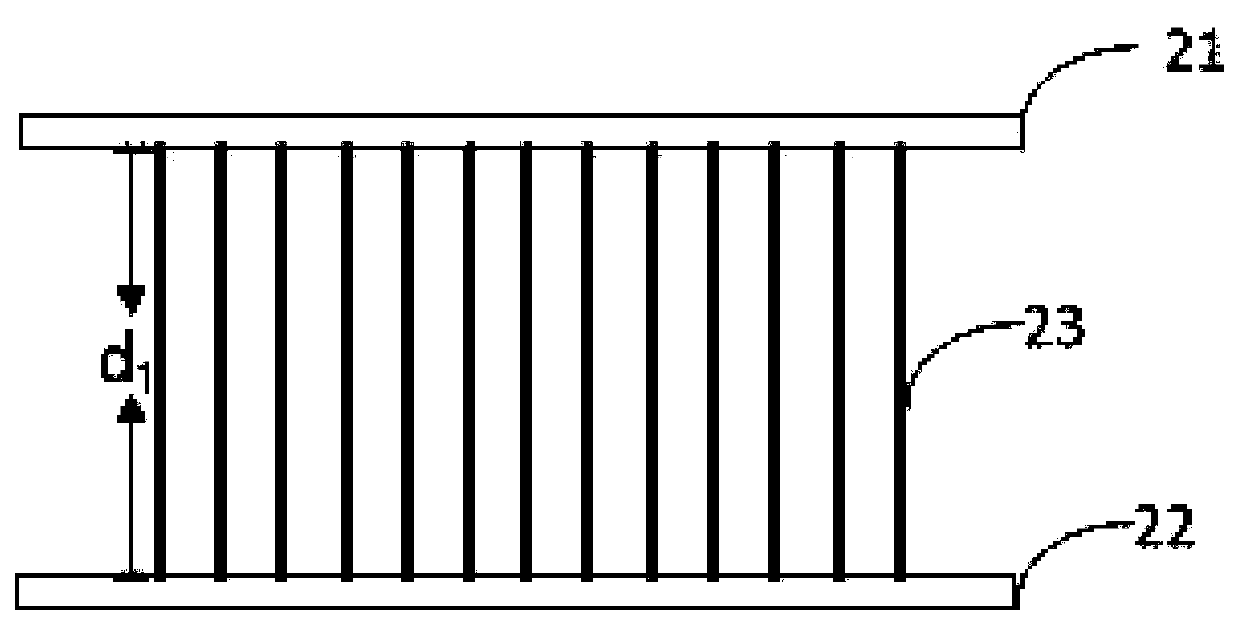

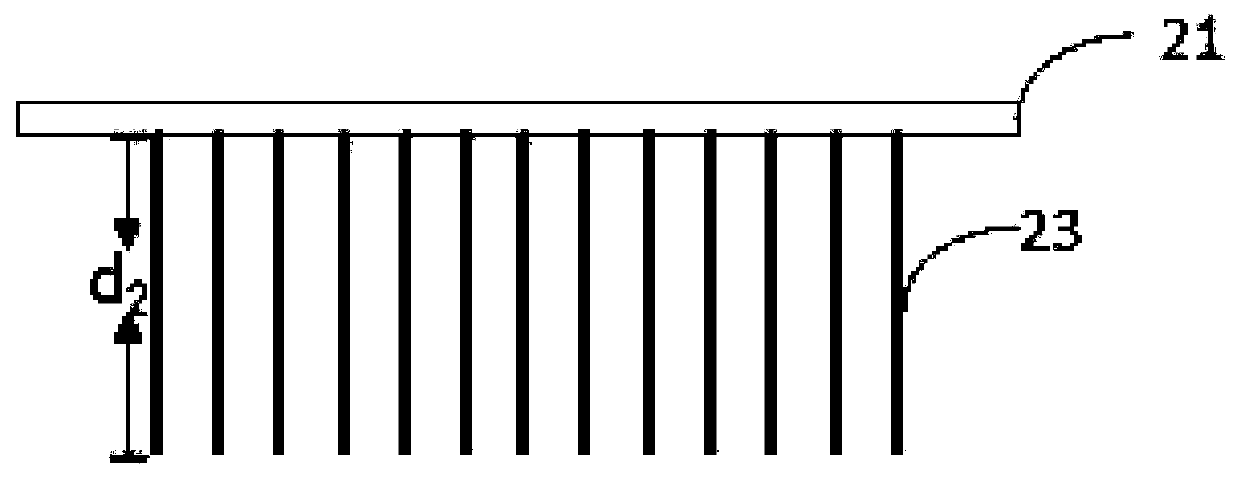

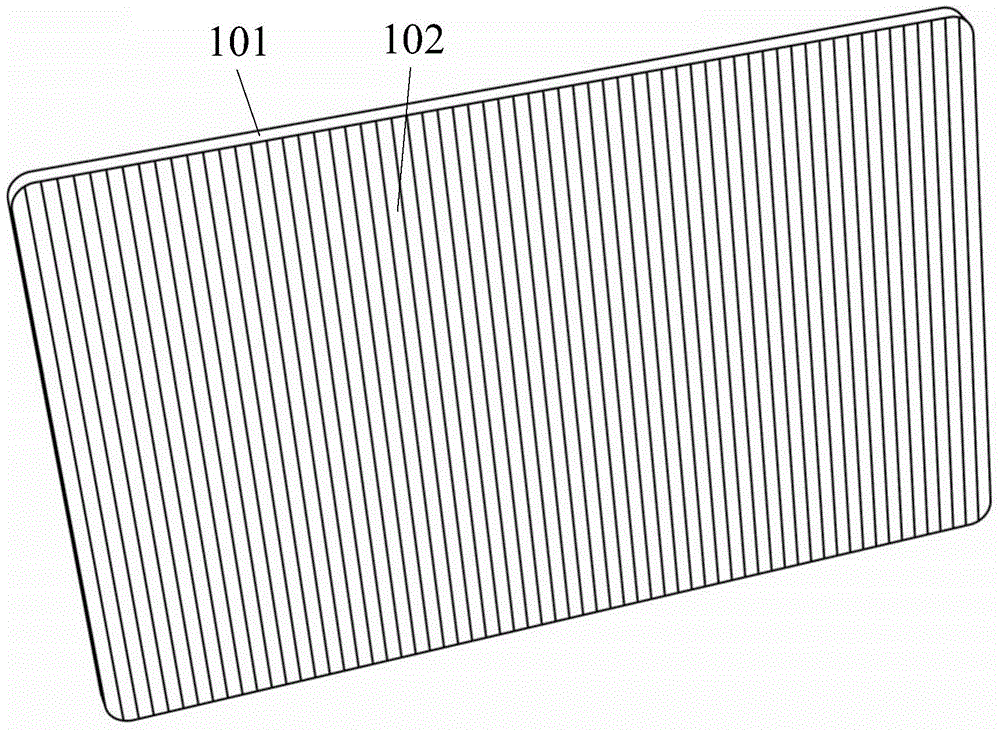

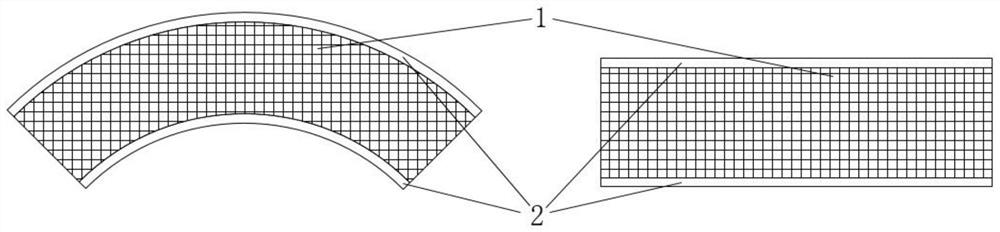

Clearance-variable warp-knitted spacer fabric and preparation method thereof

InactiveCN110777474AMeet the shape requirementsWarp knittingMechanical engineeringComposite material

An embodiment of the invention provides clearance-variable warp-knitted spacer fabric and a preparation method thereof. The preparation method includes: adopting a double-needle bed Raschel warp knitting machine to knit warp-knitted spacer fabric with clearance between fabric faces as a first clearance; utilizing slitting technology to divide the warp-knitted spacer fabric into a warp-knitted spacer fabric fragment with spacer thread length being a second clearance, wherein the second clearance is smaller than or equal to the first clearance, and a fabric face is included in the warp-knitted spacer fabric fragment; folding the warp-knitted spacer fabric fragment by taking a central line of the fabric face as symmetric axis, and connecting spacer threads at corresponding positions by presetlength to form the warp-knitted spacer fabric with a clearance between two fabric faces not being unique. By the method, the clearance-variable warp-knitted spacer fabric with the clearance between the fabric faces not being unique can be prepared, and limitation that a clearance between two fabric faces of warp-knitted spacer fabric is unique in conventional technical schemes is overcome.

Owner:JIANGNAN UNIV

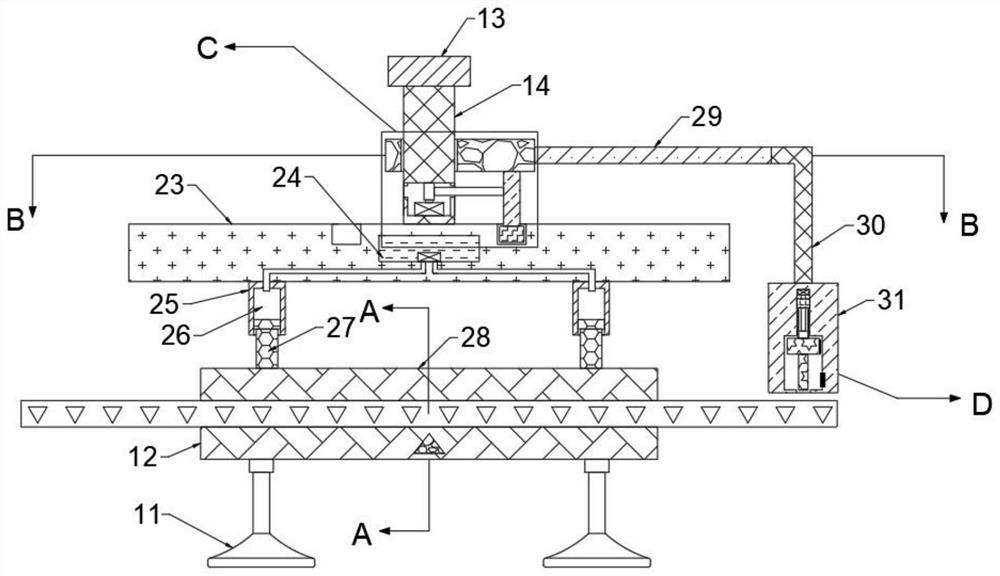

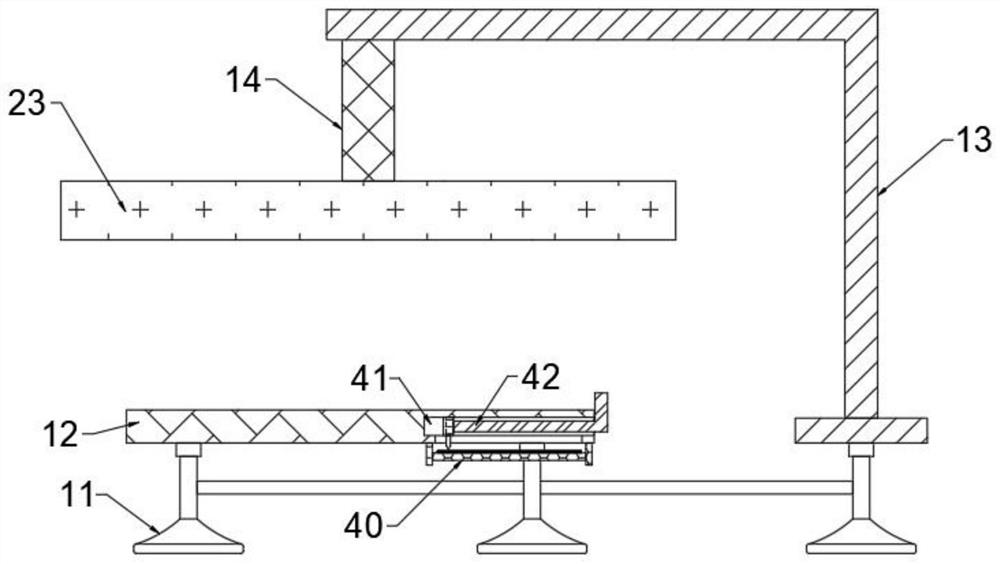

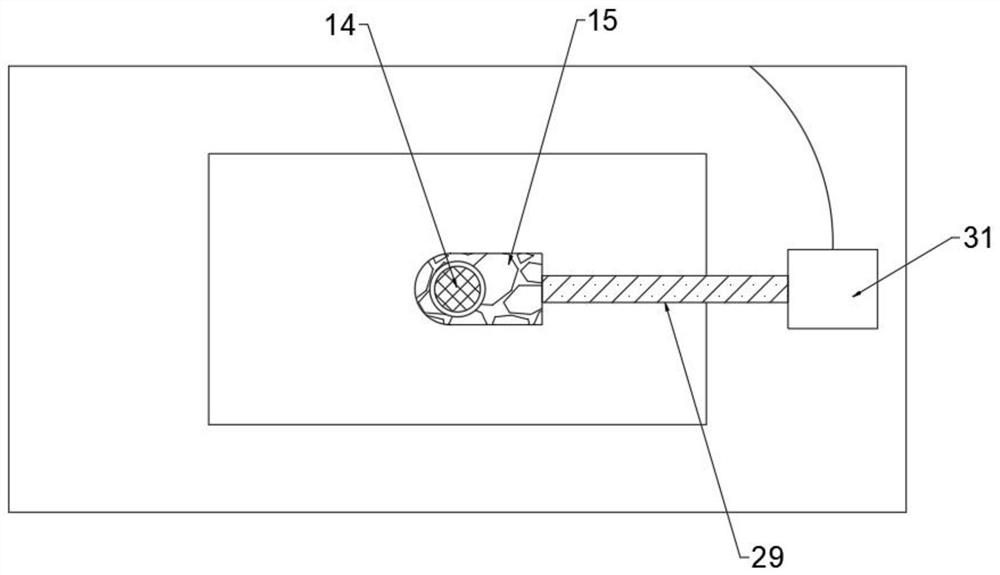

Ecological board cutting equipment

InactiveCN113815048ASame arcMeet the shape requirementsCircular sawsSawing componentsAgricultural scienceEngineering

The invention discloses ecological board cutting equipment, and relates to the related field of cutting. The ecological board cutting equipment comprises a base, a placing plate is fixedly arranged at the upper end of the base, a measuring mechanism is arranged in the placing plate, an ecological board can be placed at the upper end of the placing plate, a supporting rod is fixedly arranged at the upper end of the base, the supporting rod is arranged at the rear end of the placing plate, and a power cylinder is fixedly arranged on the supporting rod. According to the ecological board cutting equipment, by arranging the measuring mechanism, people can be assisted in accurately finding the center position of the ecological board when fixing the ecological board, so that the radians of the ecological board can be the same when the two ends are cut, arc-shaped cutting can be performed on the two ends of the ecological board by arranging arc-shaped cutting, the requirement of people for the appearance of the cutting equipment is met, meanwhile, manual assistance is not needed during cutting, and errors caused by manual errors are reduced.

Owner:高紫燕

Electronic device

ActiveCN105451482AComplete shape and structureEasy to useCasings/cabinets/drawers detailsVeinEngineering

The invention discloses an electronic device comprising a framework, M electronic elements, and an elastic cover body with veins, wherein the M is a positive integer. The M electronic elements are fixed to the framework supporting the elastic cover body. The framework and the elastic cover body define a space in which the electronic elements are received. The first electronic element of the M electronic elements is provided with an interface for being connected with another electronic device. The elastic cover body is provided with an opening portion disposed at a position, corresponding to the interface, on the elastic cover body. The vein visual effect of the opening portion matches that of the elastic cover body. When the electronic device is used, the elastic cover body can be switched among various deformation states in order to open and close the opening portion and further to expose and conceal the interface, thereby satisfying usage and achieving a complete profile structure. The invention also provides another electronic device. The fixed portion of the another electronic device can be also concealed and exposed by switching the deformation states of the elastic cover body so as to satisfy usage and achieve a complete profile structure.

Owner:LENOVO (BEIJING) CO LTD

A safe and stable suspension bridge and its construction technology

ActiveCN109505225BSimple construction processGuarantee the construction qualitySuspension bridgeBridge erection/assemblyArchitectural engineeringStructural composition

The invention discloses a safe and stable suspension bridge and a construction technology thereof. The construction technology specifically includes the following steps that 1, firstly, the whole suspension bridge is divided into a steel arch foot bearing platform, a steel mixing joint section, a pure steel structure section, a cross beam section and a tower crown decoration section according tothe different structure composition; 2, embedded parts are set in a designated position, and pouring is conducted on the embedded parts to prepare the steel arch foot bearing platform; 3, the steel mixing joint section is constructed on the steel arch foot bearing platform; 4, after the steel mixing joint section is constructed, the pure steel structure section is constructed; 5, the cross beam section is constructed on the pure steel structure section, and fixation is then conducted; 6, finally, the tower crown decoration section is built and fixed on the upper portion of the cross beam section. On the basis that the construction quality is guaranteed, the construction technology of the bridge is optimized, the whole construction process is relatively simple, the whole construction speedis increased and the construction period is shortened.

Owner:JIANGSU HUNING STEEL MECHANISM

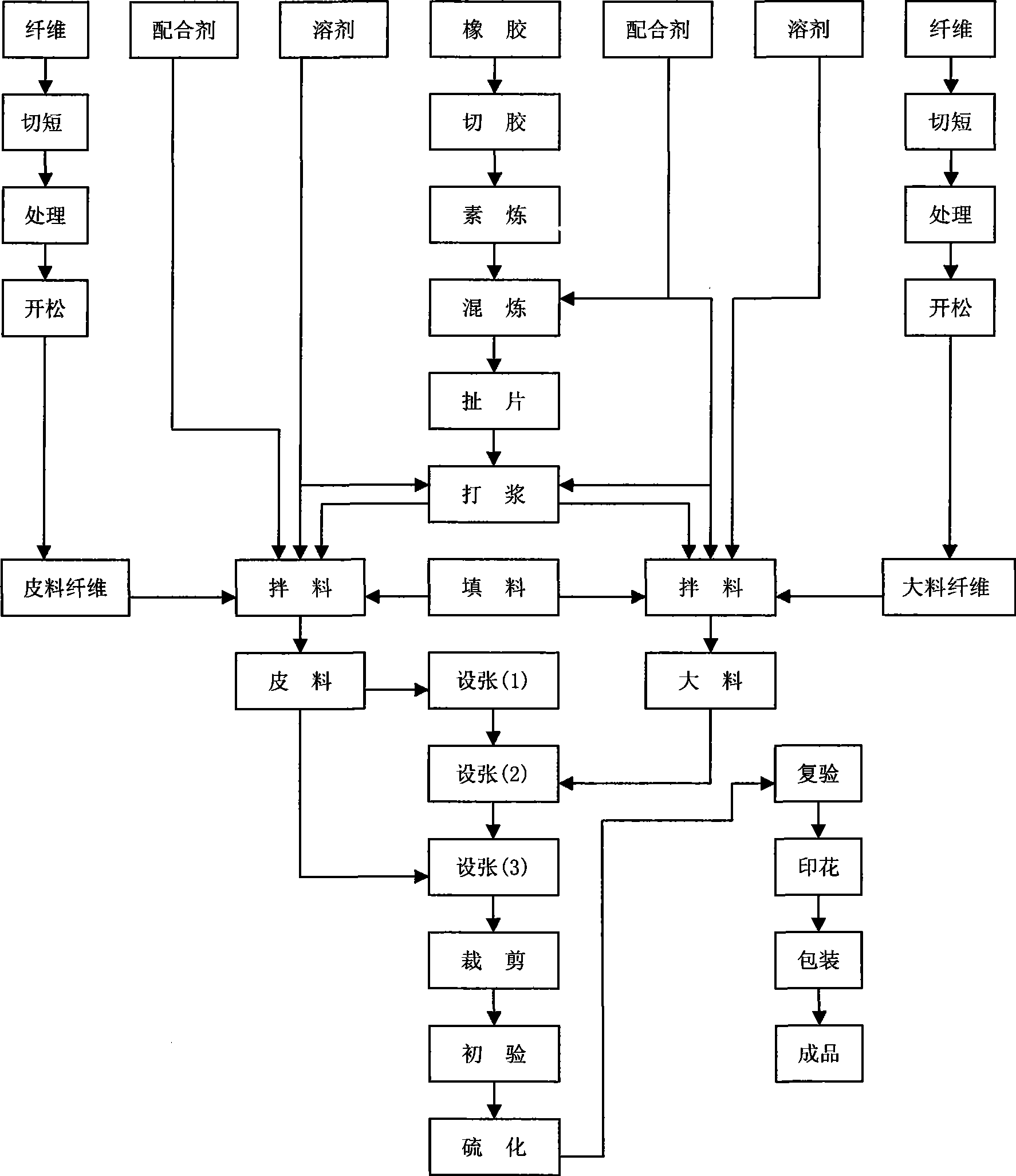

Asbestos-free composite enhancement fibre for friction material and producing technique thereof

InactiveCN101235153BNo pollution in the processEase of mass productionOther chemical processesFiberSlag

The invention provides a new non-asbestos composite reinforced fiber of friction material with low cost and a relative production method, wherein the fiber is environment-friendly, degradable and non-pollution, which can improve the impact strength of friction material. When in use at high temperature, the friction factor is stable with low abrasion. The production method is simple, cheap and suitable for producing friction material. The non-asbestos composite reinforced fiber for friction material contains mine rock wool or gravel-shaped wool of 50-80 parts by weight, fibrilia of 2-10 parts by weight, wood fiber of 3-8 parts by weight, mica powder or ceramic powder of 2-20 parts by weight, and coupling agent or compatibilizer of 1-5 parts by weight. The production method comprises preparing the materials, cutting mine rock wool or gravel-shaped wool, washing via centrifugal machine, removing slag to obtain main fiber, controlling the slag content lower than 0.5-1%, adding fibrilia, wood fiber and mica powder or ceramic powder to be mixed at high speed, drying and spraying coupling agent or compatibilizer, while the drying temperature is 105 to 150 DEG C and the drying time is 1-2h, to obtain composite reinforced fiber.

Owner:韩德忠

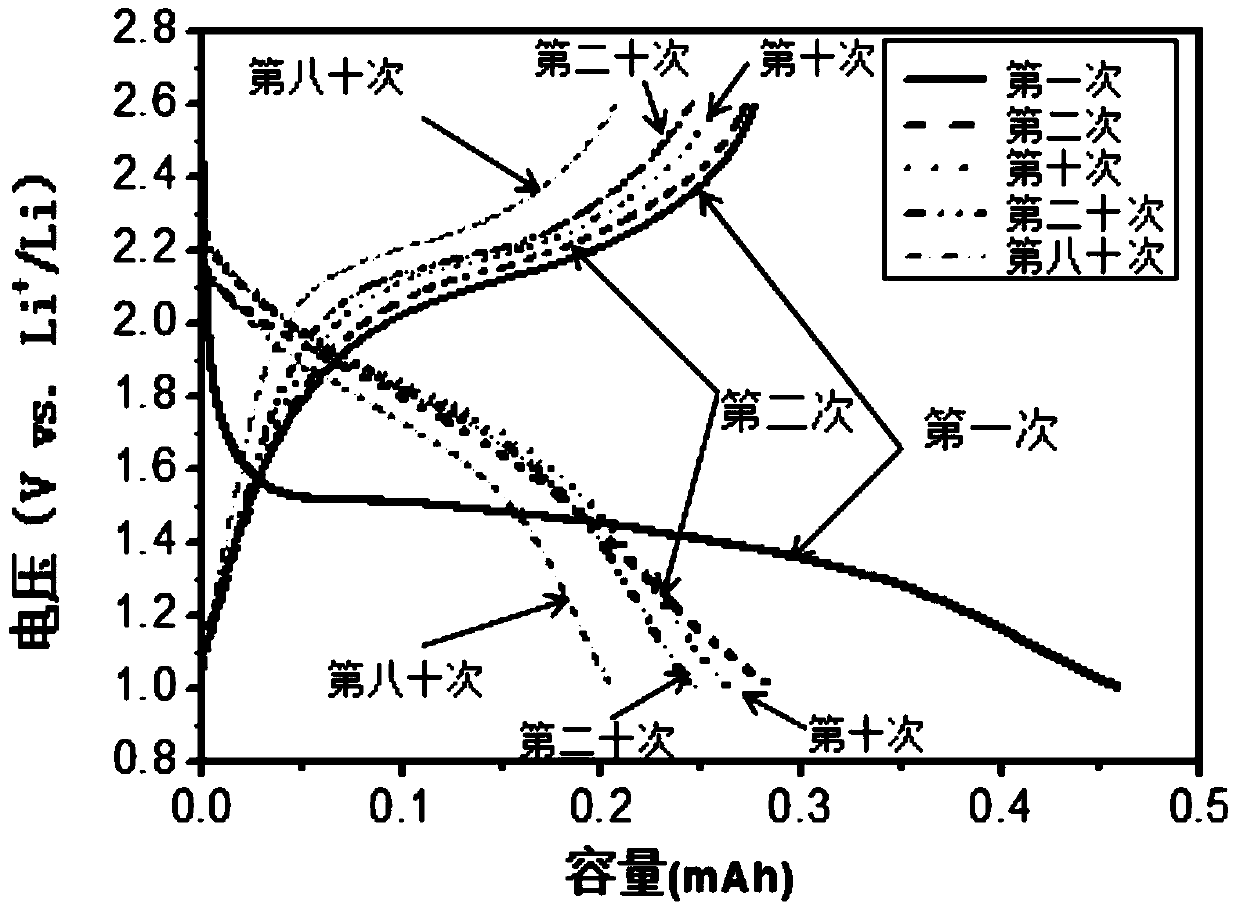

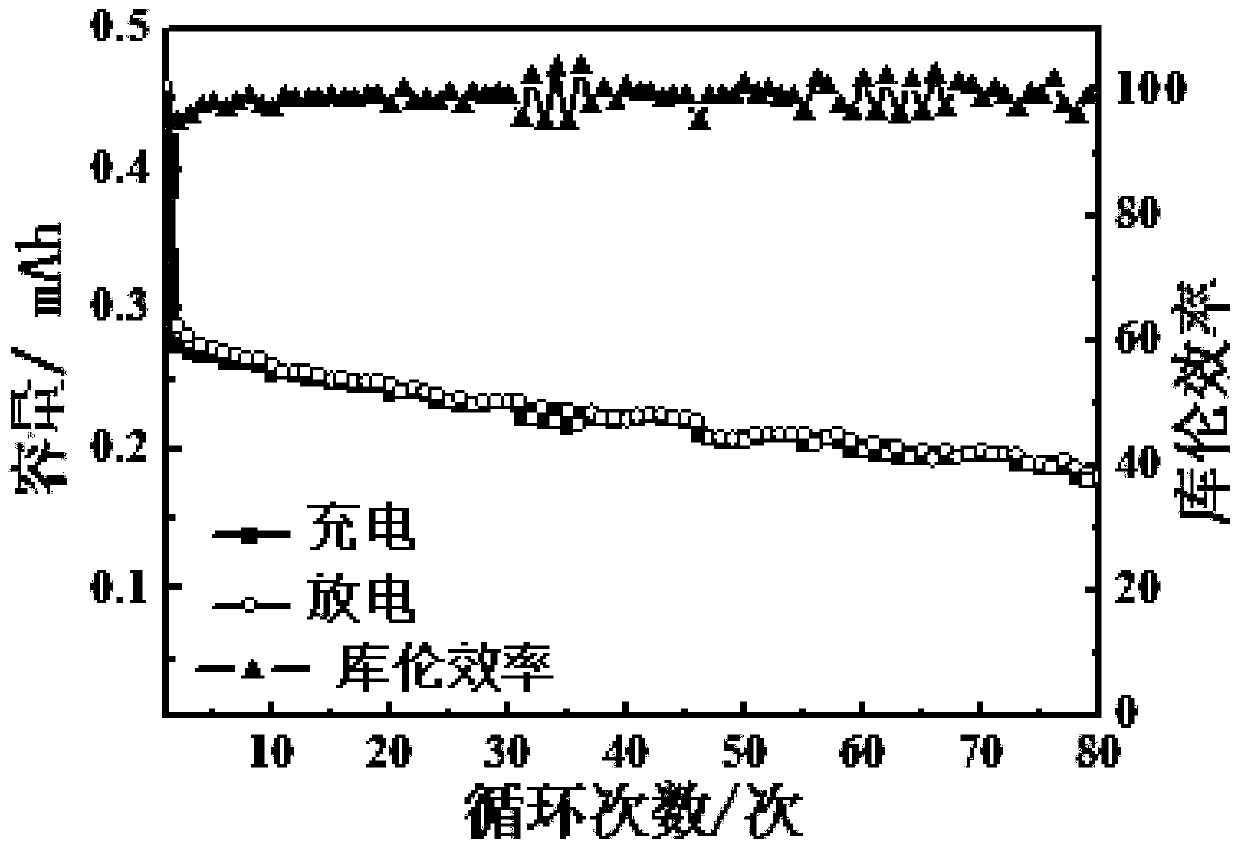

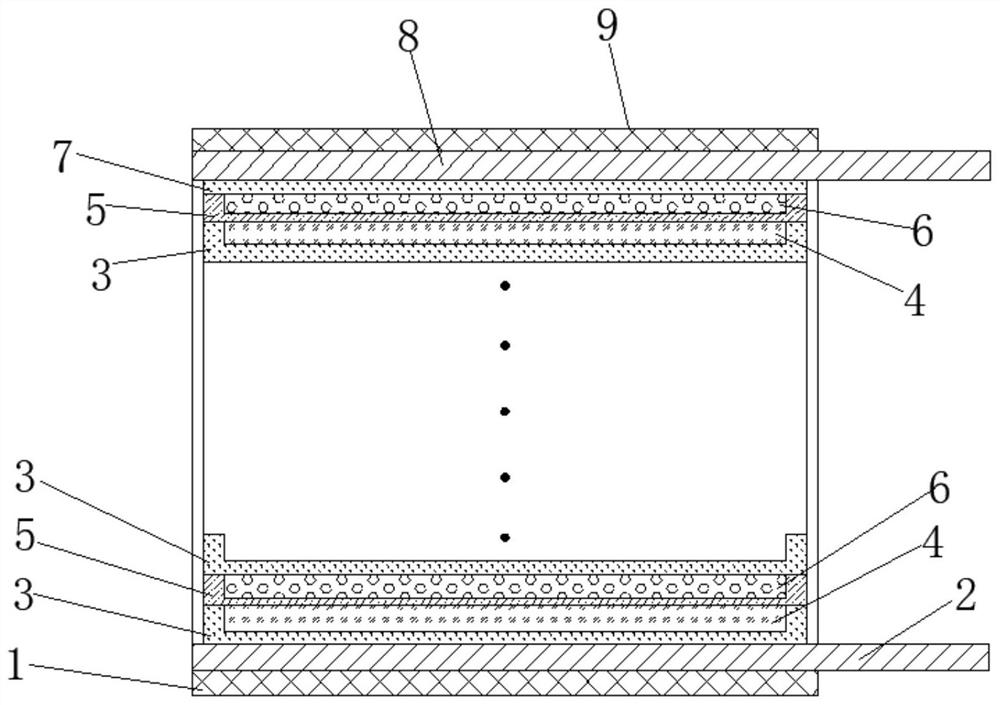

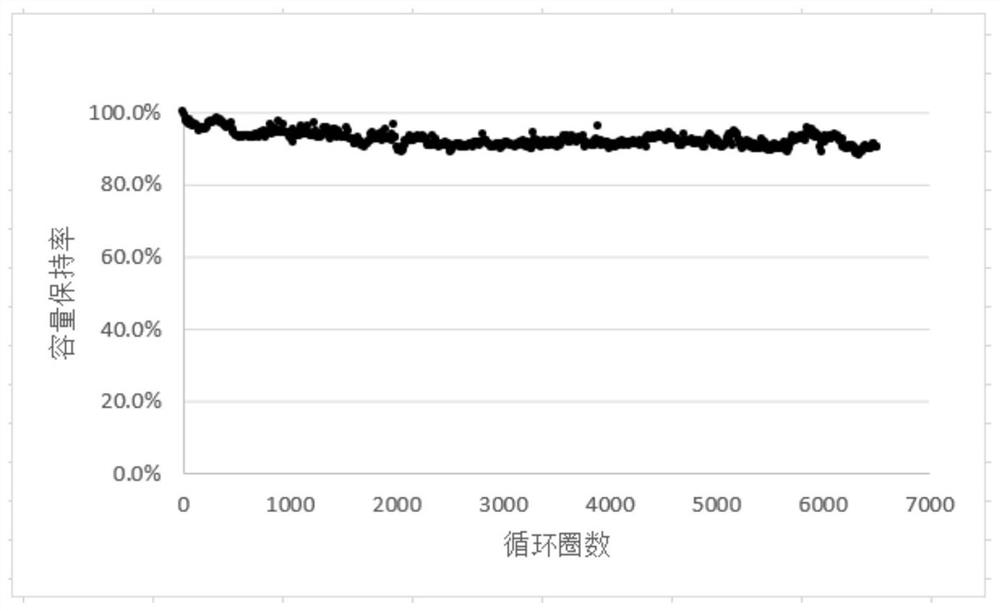

An all-solid-state lithium-sulfur battery

ActiveCN106876783BImprove Coulombic efficiencyImprove cycle lifeSecondary cellsNon-aqueous electrolyte accumulator electrodesAll solid stateLithium–sulfur battery

The invention discloses an all-solid-state lithium-sulfur battery, comprising a sulfur positive electrode, a lithium or lithium alloy negative electrode, and a lithiated sulfonic acid polymer solid electrolyte diaphragm; the solid electrolyte diaphragm is located between the sulfur positive electrode and the lithium or lithium alloy negative electrode; the sulfur positive electrode Including sulfur-containing active material, conductive agent and lithiated sulfonic acid polymer; sulfur positive electrode, lithiated sulfonic acid polymer solid electrolyte, lithium or lithium alloy negative electrode are sequentially stacked and assembled to form a battery. The room temperature ionic conductivity of the lithiated sulfonic acid polymer solid electrolyte is >10 ‑5 S / cm, no complex lithium salt is required, the preparation method is simple, and the room temperature ionic conductivity of the lithiated sulfonic acid polymer solid electrolyte is better than that of general inorganic-organic composite solid electrolytes. The polymer emulsion is used to prepare the sulfur positive electrode sheet, and an efficient "sulfur / carbon / solid electrolyte" interface is built inside the electrode to improve the activity of the sulfur electrode and obtain a battery with excellent performance; and the existing electrode sheet coating process and equipment, which is conducive to large-scale production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

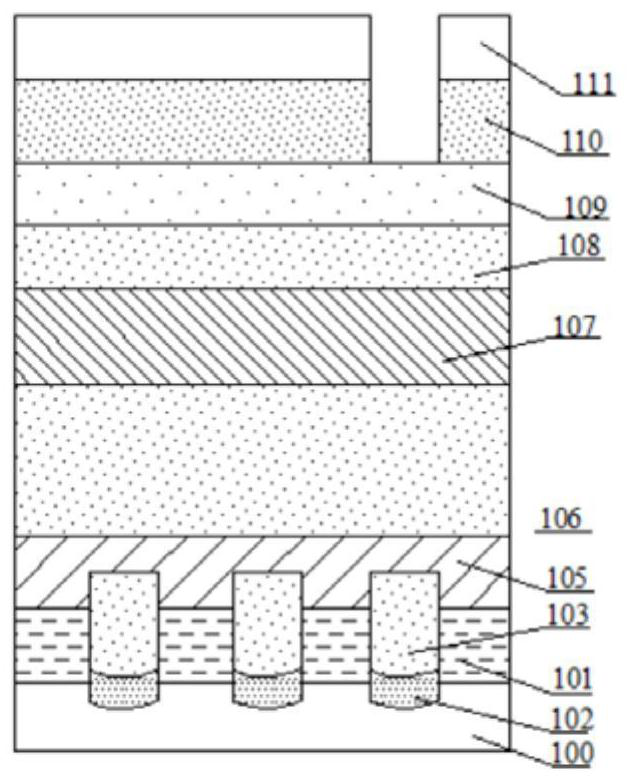

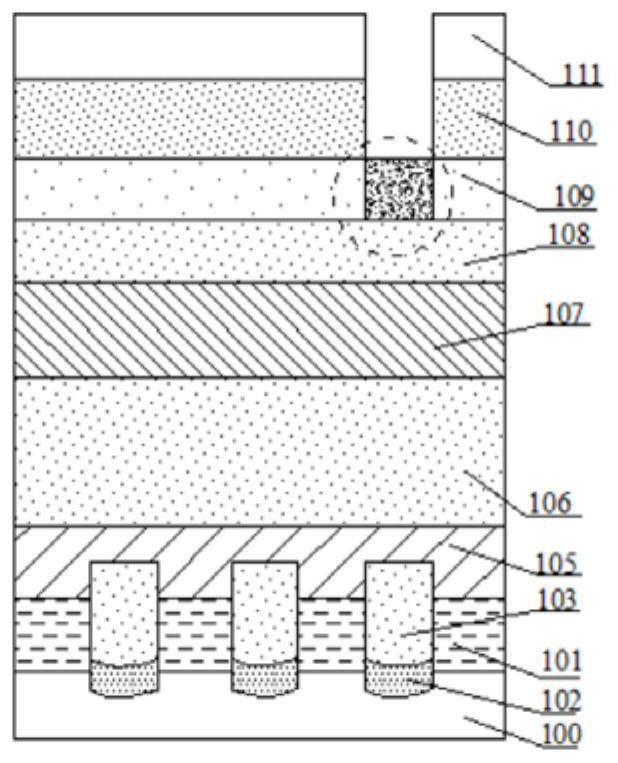

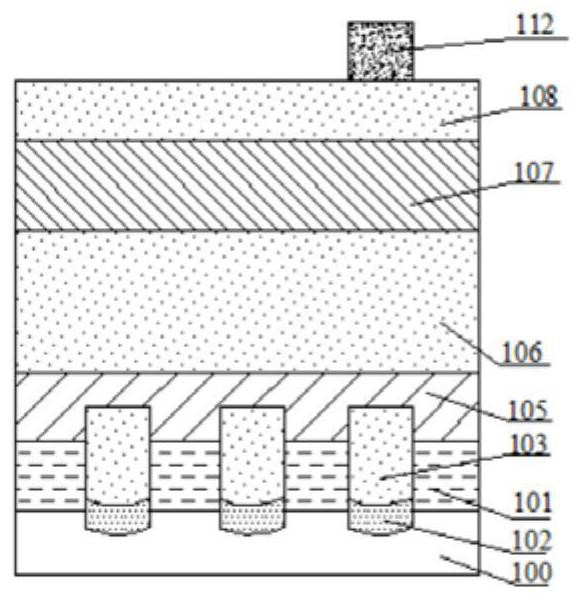

Semiconductor structure and forming method thereof

PendingCN114141623AGuaranteed dimensional stabilityImprove electrical performanceSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentSemiconductor structureElectrical performance

The invention discloses a semiconductor structure and a forming method thereof, and the method comprises the steps: providing a substrate which comprises a substrate, a gate structure located on the substrate, source and drain doping layers located at the two sides of the gate structure, and interlayer dielectric layers which are located at the two sides of the gate structure and cover the source and drain doping layers; a mask layer is formed on the gate structure and the interlayer dielectric layer, a first opening is formed in the mask layer, and the first opening corresponds to the source-drain doping layer, extends in the extending direction of the gate structure and is continuous; forming a sacrificial layer, wherein the sacrificial layer fills a part of the first opening; and etching the interlayer dielectric layer corresponding to the first opening which is not filled by the sacrificial layer to form a first groove exposing the source-drain doping layer. According to the method, the electrical performance of the device is improved, the process is simplified, and the cost is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

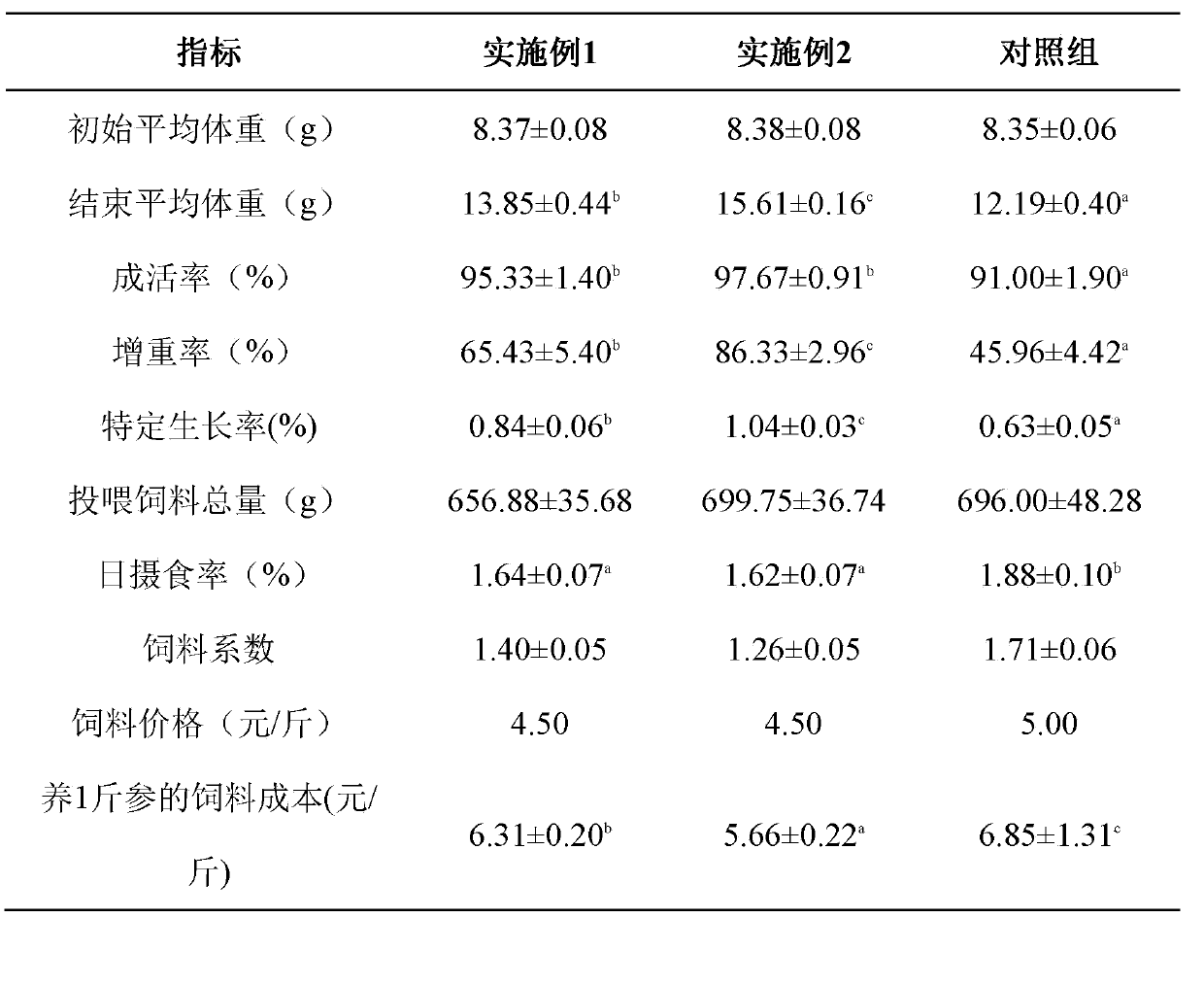

Full-balanced powder forage for adult stichopus japonicus

The invention discloses a full-balanced powder forage for adult stichopus japonicas. The full-balanced powder forage comprises compounds of protein, starch, grease, composite vitamin, composite mineral, bacteria, algae and Chinese herbal medicine. The ratio of the compounds is designed based on physiological characteristics and nutritional requirements of adult stichopus japonicus; the ratio is scientific and reasonable, and meets growth requirements of stichopus japonicus; the powder forage is developed based on characteristics of greenhouse cultivation of stichopus japonicus; it is confirmed by feeding that absorptivity is high, and digestive efficiency is excellent. The Chinese herbal medicine and the bacteria are added specially, so that the full-balanced powder forage has significant effects on improvement of physical condition of adult stichopus japonicus, and morbidity in cultivation is low. Single-celled algae and macrophytic algae are added into the full-balanced powder forage according to feeding characteristics of stichopus japonicus, so that the full-balanced powder forage is popular with stichopus japonicus, and growth speed of stichopus japonicus fast.

Owner:QINGDAO QIHAO NUTRITION TECH

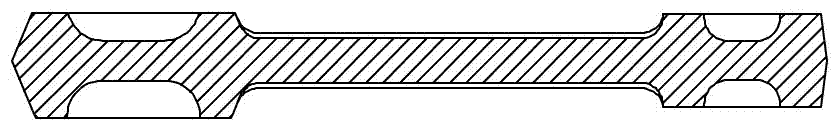

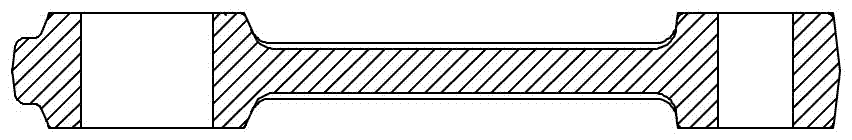

Precise forging method for engineering machine connecting rod

InactiveCN107234199ASave materialLow costMetal-working apparatusMaterial consumptionMaterials science

The invention discloses a precise forging method for an engineering machine connecting rod, and relates to the technical field of connecting rod precise forging and manufacturing. The method comprises the following steps that A, blank heating is conducted, and the temperature ranges from 1,180 DEG C to 1,200 DEG C; B, a blank is arranged in a die cavity inner drawing-out rod part of a rod part drawing-out die and then placed in a die cavity of a first forge die, and a forge piece rough blank is obtained; C, the forge piece rough blank is placed in a die cavity of a second forge die to be forged, and a forge piece is obtained; D, the forge piece is subjected to edge cutting, burr grinding and shot blasting treatment; and E, the forge piece is placed in a die cavity of a correction fine press forge die to be corrected and subjected to fine press, the temperature ranges from 500 DEG C to 700 DEG C, and precise forging of the engineering machine connecting rod is finished. Compared with the prior art, the problems that during existing engineering machine connecting rod forging, the machining allowance is large, and material consumption is large can be solved.

Owner:河池桂嘉知识产权服务有限公司

A diaphragm type body cavity occlusion device

ActiveCN105748127BDoes not cause body cavity wall damageEasy to put inOcculdersEngineeringForeign body

The invention relates to diaphragm type body cavity blocking equipment which is provided with a handle, a tuba handle, a shaping wire, a film and an inner core; the two ends of the shaping wire are fixed to the far end of the tube handle and the inner core respectively; the shape of the film in the preparation state is that one or more edges are in a linear shape, and other edges are a polygon composed of straight lines or curves, an axially symmetric figure or a face in an irregular shape, one edge, in the linear shape, on the film is provided with a plurality of through holes in the sideline direction, the inner core penetrates through the through holes, the other side edge opposite to the linear-shaped edge of the film wraps and is fixed to the shaping wire, and the position between the shaping wire and the inner core is in a spiral shape under the use state of the film.The shape of a blocking object of the diaphragm type body cavity blocking equipment can be controlled precisely, the blocking object is placed into a body cavity conveniently, completely blocking and one-time taking out of foreign matter can be achieved, and various situations in the operation process can be coped with flexibly.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Lighting device for rail vehicles

ActiveCN105402677BImprove the degree of beautificationMeet the shape requirementsVehicle interior lightingElectric circuit arrangementsEffect lightEngineering

Owner:CRRC QINGDAO SIFANG CO LTD

Electronic equipment

ActiveCN105451482BComplete shape and structureMeet the shape requirementsCasings/cabinets/drawers detailsVeinEngineering

The invention discloses an electronic device comprising a framework, M electronic elements, and an elastic cover body with veins, wherein the M is a positive integer. The M electronic elements are fixed to the framework supporting the elastic cover body. The framework and the elastic cover body define a space in which the electronic elements are received. The first electronic element of the M electronic elements is provided with an interface for being connected with another electronic device. The elastic cover body is provided with an opening portion disposed at a position, corresponding to the interface, on the elastic cover body. The vein visual effect of the opening portion matches that of the elastic cover body. When the electronic device is used, the elastic cover body can be switched among various deformation states in order to open and close the opening portion and further to expose and conceal the interface, thereby satisfying usage and achieving a complete profile structure. The invention also provides another electronic device. The fixed portion of the another electronic device can be also concealed and exposed by switching the deformation states of the elastic cover body so as to satisfy usage and achieve a complete profile structure.

Owner:LENOVO (BEIJING) LTD

A micro-stress support structure for a space-borne space mirror

A micro-stress supporting structure of a space-borne space mirror provided by the present invention includes a primary mirror, a primary mirror seat, and a primary mirror core shaft. The primary mirror is fixedly connected with the primary mirror mandrel, the primary mirror mandrel passes through the primary mirror central hole, and the small end of the primary mirror is close to the primary mirror positioning plate of the primary mirror mandrel. A mechanical limit boss is designed on the main mirror mandrel, and a main mirror rubber pad, a main mirror metal pad, a first pressure ring and a second pressure ring are sequentially installed on the main mirror mandrel. The first pressure ring has a boss. After the installation is completed, the rubber pad of the primary mirror is pressed against the fixed end surface of the large end of the primary mirror, the boss of the first pressure ring is pressed against the metal pad of the primary mirror, the non-convex surface of the first pressure ring is pressed against the mechanical limit boss, and the second The pressure ring tightly presses the first pressure ring. The support structure provided by the present invention can mechanically and quantitatively control the pressing force of the primary mirror pressure ring on the primary mirror, which can not only improve the fixing and fastening degree of the primary mirror, but also meet the surface shape requirements of the primary mirror after clamping .

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

A new lighting device

ActiveCN105402676BMeet the shape requirementsImprove cooling effectLighting support devicesVehicle interior lightingEffect lightEngineering

Owner:CRRC QINGDAO SIFANG CO LTD

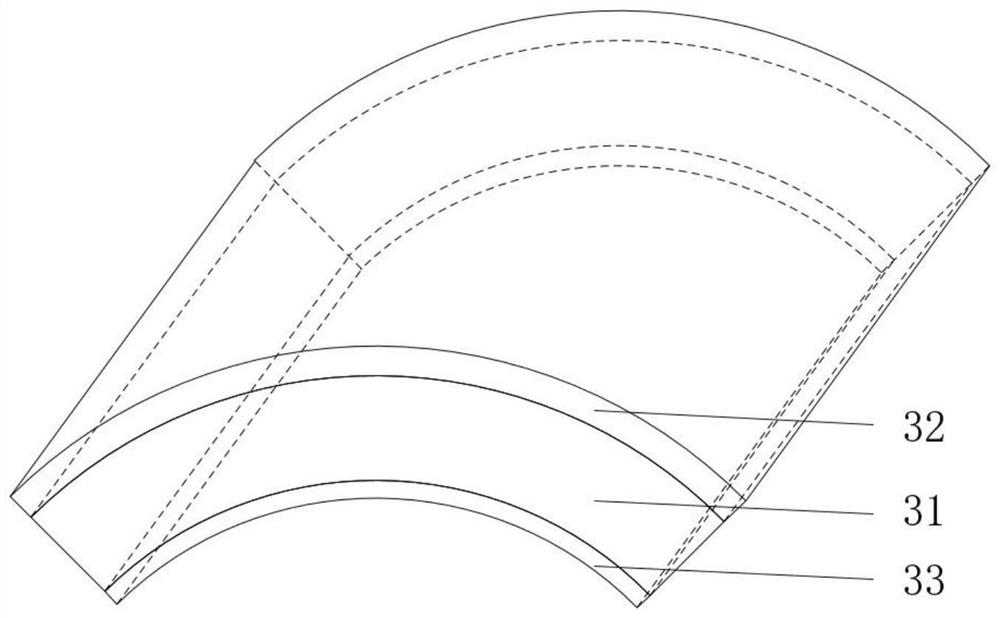

Sandwich structure based on carbon foam as well as preparation method and maintenance method of sandwich structure

ActiveCN113771445AStable structureExtended service lifeSynthetic resin layered productsLaminationMoisture resistanceAsphalt

The invention discloses a sandwich structure based on carbon foam as well as a preparation method and maintenance method of the sandwich structure The sandwich structure comprises a carbon foam sandwich and a panel, wherein the carbon foam sandwich is composed of one or more of resin-based carbon foam, coal-based carbon foam and asphalt-based carbon foam. The carbon foam sandwich has the advantages of thermoelectric conduction property, tailorability, large modulus, high strength, impact resistance, good processability, stable physical and chemical properties, flame retardance, no toxicity, moisture resistance, wave absorption, capability of being compounded with various functional materials and the like; the carbon foam sandwich can be matched with the panel made of different materials according to requirements, so that the sandwich structure with outstanding key functions and excellent comprehensive performance can be formed under different environments; and the sandwich structure can be widely applied to military and civil fields such as aerospace, automobiles and ships, composite material manufacturing, buildings, safety protection and the like.

Owner:BEIHANG UNIV

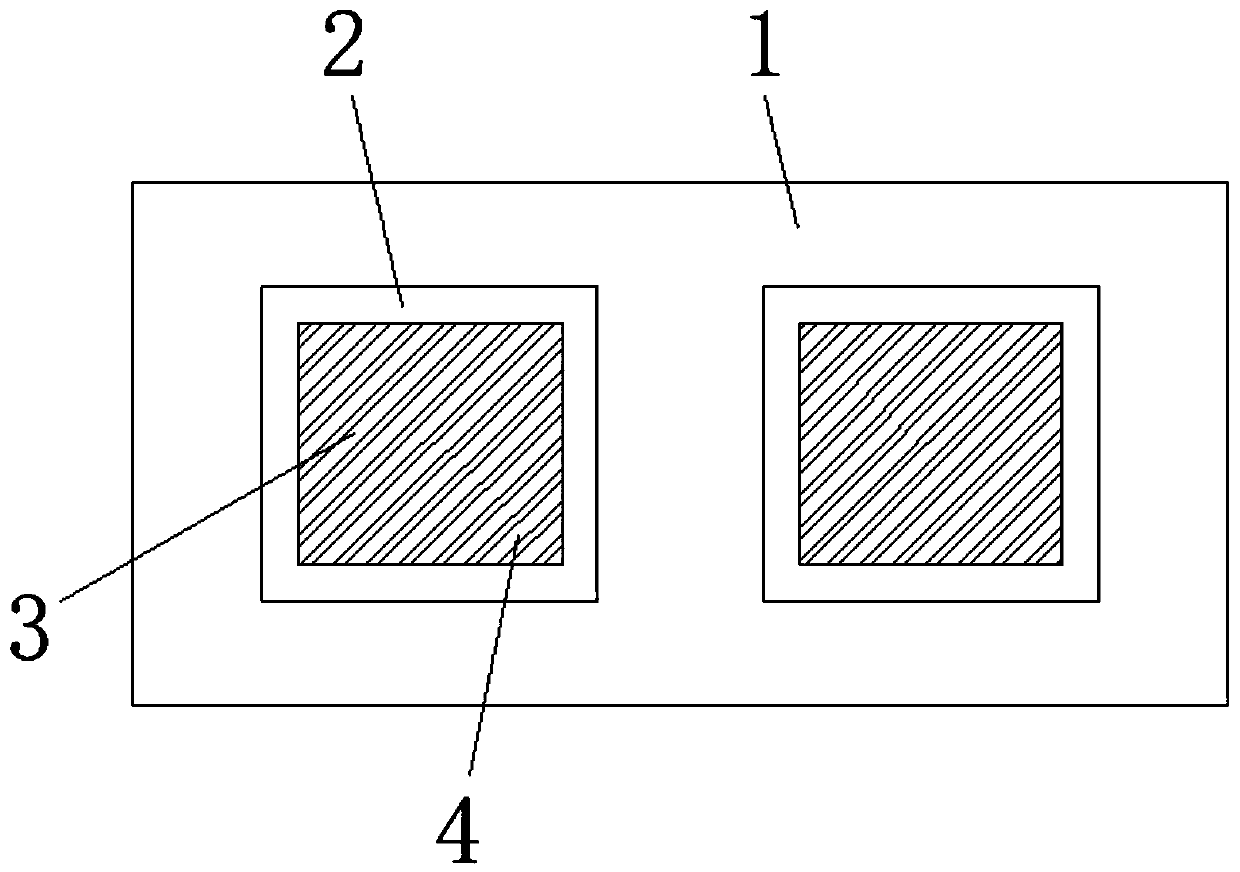

Plastic electrode and preparation method thereof, and aqueous sodium-ion battery and preparation method thereof

ActiveCN113161511BIncreased production flexibilityShort manufacturing processElectrode rolling/calenderingFinal product manufactureElectrolytic agentElectrical battery

The invention discloses a plastic electrode and its preparation method, as well as a water-based sodium ion battery and its preparation method. The preparation method of the plastic electrode includes: mixing electrolyte salt and deionized water into an electrolyte solution; adding a surfactant and a moisturizing agent into the electrolyte solution , mix into a uniform solvent matrix; add the conductive material into the solvent matrix, and disperse the conductive material evenly in the solvent matrix; add positive / negative active materials and binders; A water-based sodium-ion battery plastic electrode paste with a three-dimensional network structure formed by cross-linking of the binder. The plastic electrode of the present invention is a stable mixture of active material and electrolyte, the electrolyte is locked in the plastic electrode, the ion diffusion path is reduced when the battery is charged and discharged, the ionic impedance and electronic impedance are greatly reduced, and it is beneficial to large-scale output; the preparation and operation of the electrode of the present invention The battery assembly is completed synchronously, and the liquid injection process is omitted, which simplifies the battery preparation process.

Owner:太仓中科赛诺新能源科技有限公司

Preparation method of metal-assisted two-dimensional material nanobelt

InactiveCN110203881AMeet specificationsMeet the shape requirementsSpecific nanostructure formationPhotoresistMetal

The invention discloses a preparation method of a metal-assisted two-dimensional material nanobelt. The preparation method involves preparation materials including an insulating substrate, a substratesurrounding frame, a two-dimensional nano material and a photoresist. The preparation method comprises the following specific steps that 1, the substrate surrounding frame is selected according to the required specification and shape, then the substrate surrounding frame is placed on the upper surface of the insulating substrate, and finally the two-dimensional nano material is placed on the inner side of the substrate surrounding frame until the two-dimensional nano material completely covers the insulating substrate on the inner side of the substrate surrounding frame; 2, metal is placed ina liquid for dissolving metal and then stirred; when the specification and the shape are customized on the transferred nano material, and surrounding frames of different specifications and in different shapes are prefabricated so that it can be ensured that the prepared nanobelt meets the specification and shape requirements, and deviations are avoided.

Owner:HUAIYIN TEACHERS COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com