Method for realizing virtual keys on curved side of touch panel

A touch panel and bending technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of high scrap rate of touch panel and complicated overall steps, so as to improve the process yield, The effect of flexible design and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

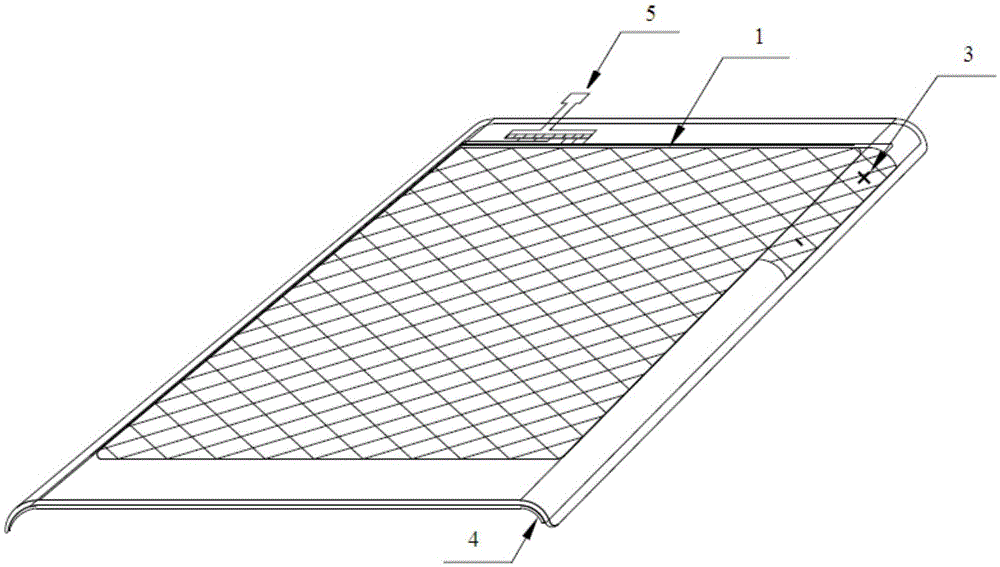

Embodiment 1

[0027] The invention provides a method for realizing virtual keys on the curved side of a touch panel, which includes preparing a glass plate including a flat part and at least one side of which is a curved panel part, and forming a touch screen on the inner side of the glass plate including the curved panel part. The visible area and the icon area of the control panel; the pattern surface of the first flexible circuit board containing at least one indium tin oxide pattern is pasted on the curved surface part inside the glass plate, and the boundary of the plane part inside the glass plate is in contact with the The first flexible circuit board is separated or adjacent, that is, the first flexible circuit board will not be pasted to the plane portion inside the glass plate. The specific structure of the product obtained is shown in Figure 2, wherein the specific process steps used are as follows.

[0028] Making curved glass panels: use the hot bending process to make the le...

Embodiment 2

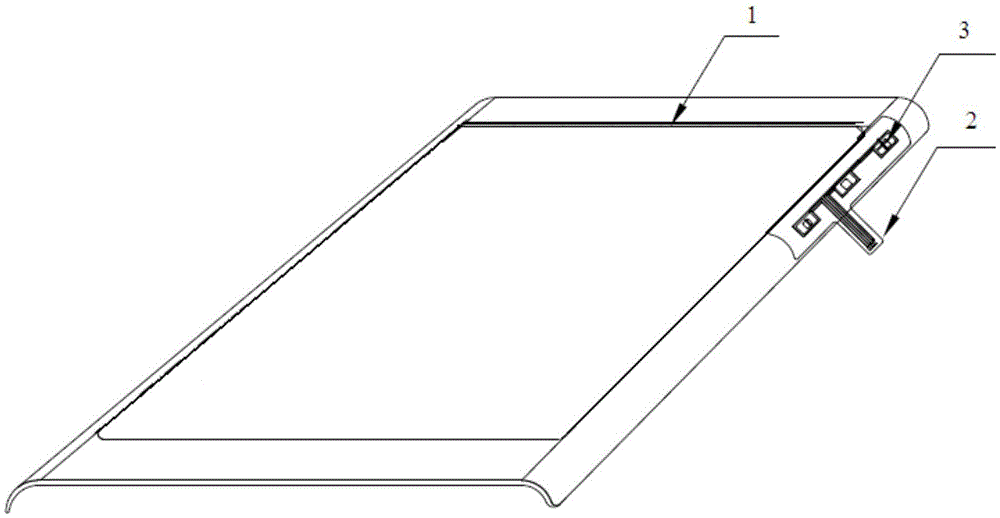

[0033]The invention provides a method for realizing virtual keys on the curved side of a touch panel, which includes preparing a glass plate including a flat part and at least one side of which is a curved panel part, and forming a touch screen on the inner side of the glass plate including the curved panel part. The visible area and the icon area of the control panel; the pattern surface of the first flexible circuit board containing at least one indium tin oxide pattern is pasted on the curved surface part inside the glass plate, and the boundary of the plane part inside the glass plate is in contact with the The first flexible circuit board is separated or adjacent, that is, the first flexible circuit board will not be pasted on the plane part inside the glass plate; and a film sensor is pasted in the visible area of the plane part inside the glass plate A second flexible circuit board bonded to the film sensor is also arranged on the plane part inside the glass plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com