Non-asbestos composite reinforcing fiber for sealing material and technique for producing the same

A technology of composite reinforcement and sealing materials, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of weak tensile strength, poor mixing, poor dispersion, etc., and achieve high impact strength, simple process, The effect of high tortuosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

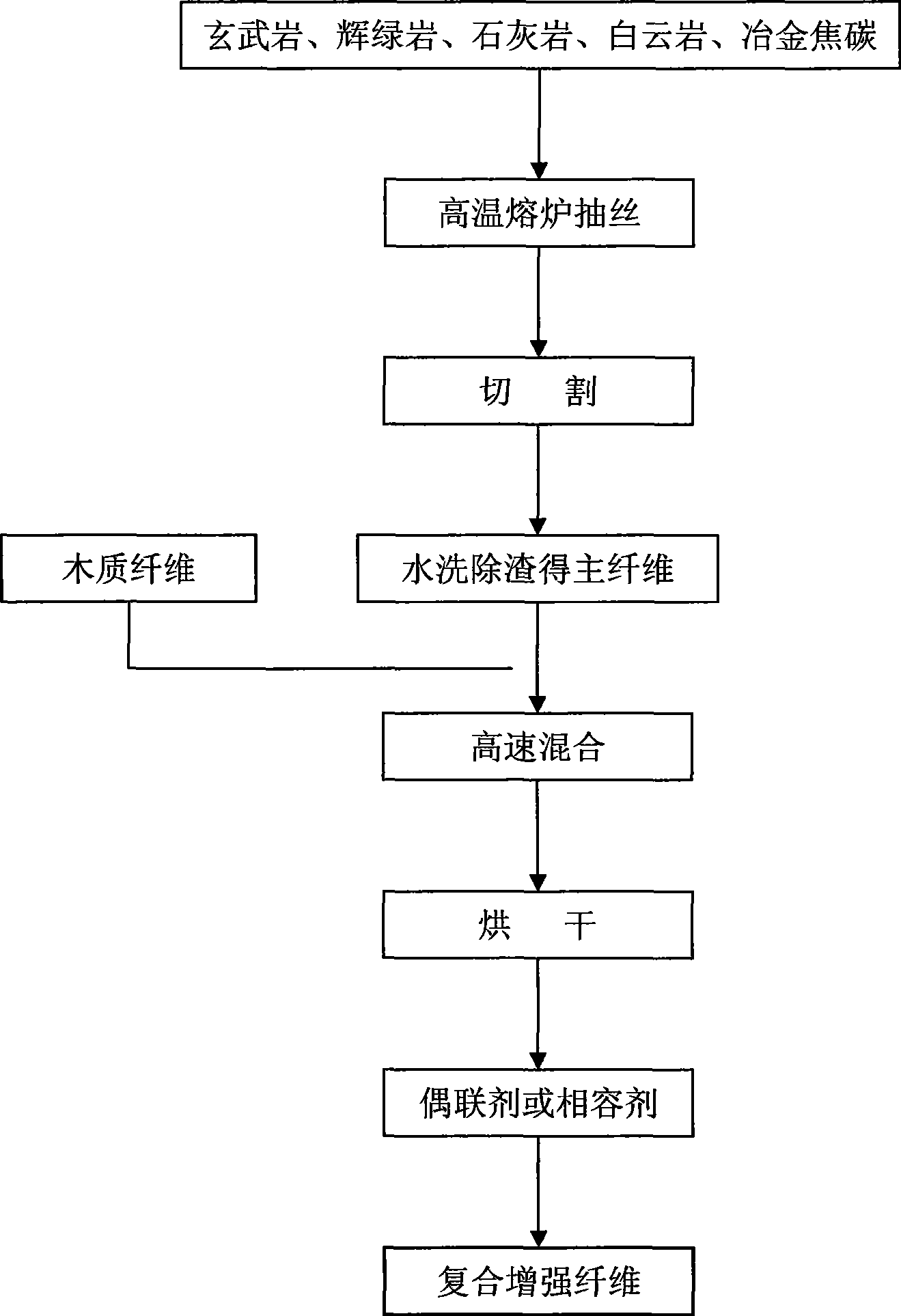

[0027] Raw mineral rock wool or granular wool can be purchased or prepared from the market. The preparation process:

[0028] 200kg of basalt, 600kg of diabase, 110kg of limestone, 80kg of dolomite, and 20kg of metallurgical coke are selected as the main materials, which are spun through a high-temperature furnace over 1000°C and subjected to surface treatment. The fibers produced by high-temperature melting are cut to a length of 10-20mm, and then washed with water and slag removed by a centrifuge to control the content of fiber slag balls at 0.5%-1%, and then made into main fibers.

[0029] The preparation process is as figure 1 Shown, take 800kg of the prepared main fiber, 200kg of selected plant fiber and wood fiber, and cut the wood fiber to 8-15mm in advance, mix the raw materials evenly in a high-speed mixer at 2000-2500 rpm, form a mixed fiber, and enter the drum type Carry out mixing and drying in the drying machine, spray 30kg of silica gel coupling agent, 50kg of n...

Embodiment 2

[0031] The main fiber preparation method used is the same as in Example 1. Get 600kg of main fiber and 300kg of wood fiber. The wood fiber is pre-cut to 8-15mm, and it is mixed evenly in a high-speed mixer at 2000-2500 rpm to form a mixed fiber. Mix and dry in the dryer, spray 20kg of silane coupling agent and 30kg of nitrile rubber powder into the process of mixing and drying, dry at 110°C, and dry for 2 hours to obtain the composite reinforced fiber of the present invention. The obtained fibers are then cut to the required specifications, and the obtained fibers should be packaged waterproofly.

Embodiment 3

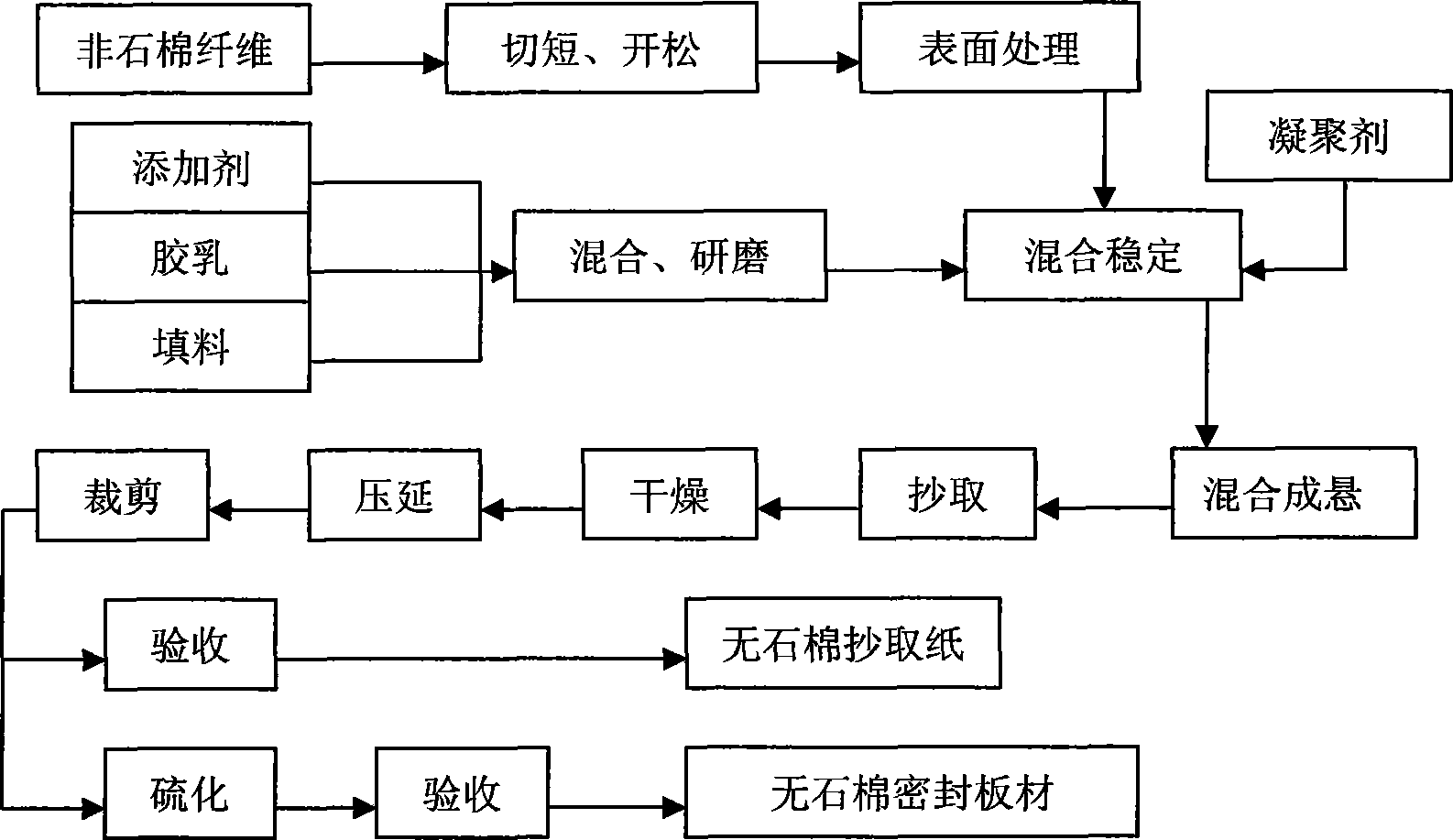

[0033] Commercially available mineral rock wool or granular cotton is cut according to specifications, then washed with water and slag removed by a centrifuge, and the content of fiber slag balls is controlled at 0.5%-1% to obtain the main fiber.

[0034] Take 800kg of the main fiber and 250kg of wood fiber. The wood fiber is pre-cut to 8-15mm, and it is mixed evenly in a high-speed mixer at 2000-2500 rpm to form a mixed fiber, which is mixed and dried in a drum dryer. In the process of mixing and drying, 40kg of silane coupling agent and 40kg of nitrile rubber powder are sprayed, the drying temperature is 140°C, and the drying time is 1.2 hours to obtain the composite reinforced fiber of the present invention, and the prepared fiber is cut to the desired size. Specifications are required, and the obtained fibers should be packed in waterproof packaging.

[0035] The impact strength of the sealing material using the above-mentioned composite reinforced fiber is greater than 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com