Highly-branched-chain polyaniline modified carbon nanotube/thermosetting resin composite material and preparation method thereof

A multi-branched polyaniline and resin composite material technology, which is applied in the field of conductor/polymer composite materials and its preparation, can solve the problem that the excellent performance of carbon nanotubes cannot be fully utilized, the amount of amino-containing pyrene derivatives is high, and it is difficult to adopt Preparation methods and other issues, to achieve high performance, simple and easy method, and improve the effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of multi-branched polyaniline

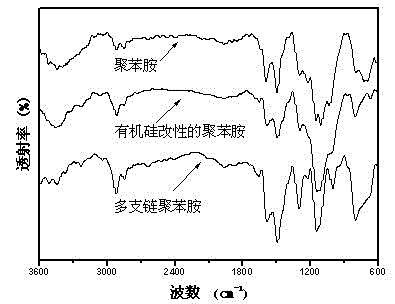

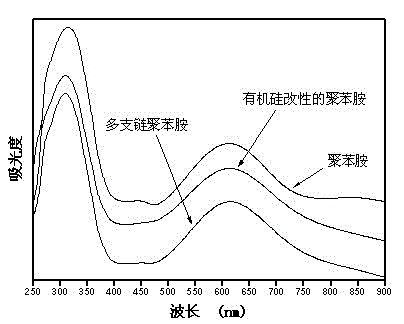

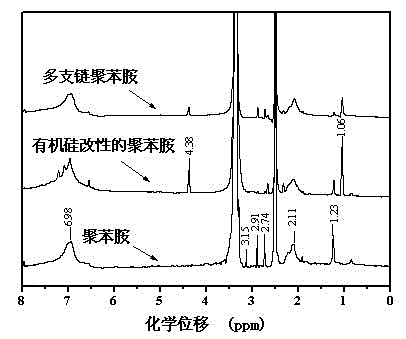

[0035] 0.9g aniline, 1.1g o-toluidine and 1.7g m-aminobenzenesulfonic acid were mixed respectively, and 150mL hydrochloric acid solution (0.2mol / L) was added in the mixture; 2 Under protection and at 0-5°C, mechanically stir for 30 minutes. Subsequently, 100 mL of ammonium persulfate (0.3 mol / L) solution was added dropwise and vigorously stirred. After the dropwise addition, keep warm for 5 hours until the reaction is complete, wash with dilute hydrochloric acid solution, acetone, deionized water, filter with suction, and vacuum dry at 50°C for 24 hours to obtain polyaniline with an intrinsic viscosity of 0.43dL / g. Its infrared spectrum, ultraviolet-visible spectrum, 1 H nuclear magnetic resonance spectrum, scanning electron microscope, X-ray diffraction spectrum, conductivity curve and thermogravimetric curve are respectively as attached figure 1 , 2 , 3, 4, 5, 6 and 7.

[0036] Add 1 g of polyaniline to 90 mL of dime...

Embodiment 2

[0056] 1. Preparation of multi-branched polyaniline

[0057] According to the technical scheme of Example 1, polyaniline with multiple branches was prepared.

[0058] 2. Preparation of multi-branched polyaniline modified carbon nanotubes

[0059] Add 1 g of carbon nanotubes and 0.033 g of polybranched polyaniline into 50 mL of dimethyl sulfoxide, stir at 25 °C and sonicate for 20 min, add 100 mL of methanol to precipitate, filter and wash, and dry in vacuum at 50 °C for 24 Hours, the multi-branched polyaniline-modified carbon nanotubes were obtained. Its X-ray diffraction spectrum and Raman spectrum are as follows Figure 9 , 10 shown.

[0060] 3. Preparation of multi-branched polyaniline modified carbon nanotubes / epoxy resin composites

[0061] Add 0.517g polyaniline-modified carbon nanotubes and 100g epoxy resin (brand E-51) into the flask, stir at 60°C and ultrasonically for 1 hour, vacuum degassing for 30min, add 4g 2- Ethyl-4-methylimidazole, continue to stir for 10...

Embodiment 3

[0063] 1. Preparation of multi-branched polyaniline

[0064] According to the technical scheme of Example 1, polyaniline with multiple branches was prepared.

[0065] 2. Preparation of multi-branched polyaniline modified carbon nanotubes

[0066] Add 1g of carbon nanotubes and 0.05g of polybranched polyaniline into 50mL of dimethyl sulfoxide, stir at 25°C and sonicate for 20min, add 100mL of methanol to precipitate, filter and wash, and dry in vacuum at 50°C After 24 hours, highly branched polyaniline-modified carbon nanotubes were obtained. Its X-ray diffraction spectrum and Raman spectrum are as follows Figure 9 , 10 shown.

[0067] 3. Preparation of multi-branched polyaniline modified carbon nanotubes / epoxy resin composites

[0068]Add 0.525g polyaniline-modified carbon nanotubes and 100g epoxy resin (grade E-51) into the flask, stir at 60°C and ultrasonically for 1 hour, vacuum degassing for 30min, add 4g 2- Ethyl-4-methylimidazole, continue to stir for 10 minutes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com