Polycarboxylate high-efficiency water reducer and preparation method thereof

A high-efficiency water reducer and polycarboxylic acid technology, applied in the field of polycarboxylate high-efficiency water reducer and its preparation, can solve the problems of insufficient steric hindrance and electrostatic repulsion, high polymerization temperature, self-polymerization reaction, etc., to achieve Increase market share and share, improve work performance, and improve the effect of steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

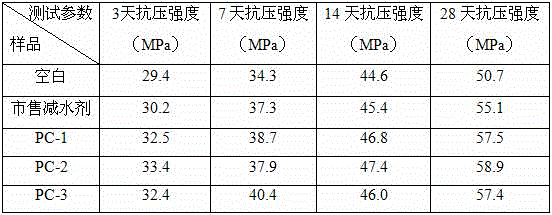

[0037] The preparation method of the polycarboxylate high-efficiency water reducer in this embodiment is as follows:

[0038]Put 120g of TPEG-2400, 10g of PEG-200 and 50g of water in a four-necked flask and mix and stir, then add 0.1g of dibutyltin dilaurate, 1.2g of p-toluenesulfonic acid and 34g of hydrogen peroxide to obtain component A; g acrylic acid, 1.02g Vc and 10g water are mixed to obtain component B; 0.384g sodium methacrylate sulfonate, 0.3g ammonium persulfate and 20g water are mixed to obtain component C; Parts B and C were dripped into component A at a rate of 2 mL / min, cooled to room temperature after the drop was completed, and adjusted to pH 7 with NaOH aqueous solution to obtain a polycarboxylic acid superplasticizer, which was designated as PC-1.

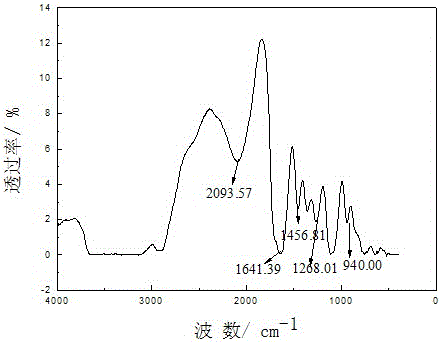

[0039] Depend on figure 1 It can be seen that in the infrared spectrum of the polycarboxylic acid superplasticizer PC-1 obtained in this embodiment, 2093.57cm -1 at -CO-CN 2 The stretching vibration peak at -,...

Embodiment 2

[0042] The preparation method of the polycarboxylate high-efficiency water reducer in this embodiment is as follows:

[0043] Put 108g of TPEG-2400, 10g of PEG-200 and 72g of water into a four-necked flask and mix and stir, then add 0.2g of dibutyltin dilaurate, 1.2g of p-toluenesulfonic acid and 20.4g of hydrogen peroxide to obtain component A; Mix 10.8g acrylic acid, 3.7g sodium bisulfite and 10g water to get component B; mix 0.67g sodium methacrylate, 0.1g ammonium persulfate and 15g water to get component C; The pump first drips component B into component A at a rate of 1mL / min, after component B has been added dropwise for 0.5h, then drips component C into component A at a rate of 1mL / min, and the addition is complete After cooling to normal temperature, adjust the pH value to 7 with NaOH aqueous solution to obtain polycarboxylate superplasticizer, which is denoted as PC-2.

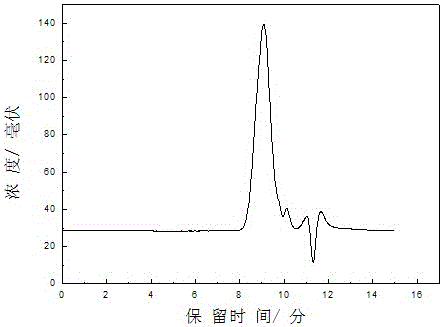

[0044] After testing, the PC-2 obtained in this example conforms to the structural characteristi...

Embodiment 3

[0046] The preparation method of the polycarboxylate high-efficiency water reducer in this embodiment is as follows:

[0047] Put 120g of TPEG-2400, 10g of PEG-200 and 50g of water in a four-necked flask and mix and stir, then add 0.1g of dibutyltin dilaurate and 1.2g of p-toluenesulfonic acid to obtain component A; mix 21.6g of acrylic acid and Mix 10g of water to obtain component B; mix 0.67g of sodium methacrylate, 0.19g of ammonium persulfate and 20g of water to obtain component C; at 45°C, use a peristaltic pump to simultaneously Add dropwise to component A at a rate of 2 mL / min, cool to room temperature after dropwise addition, and adjust the pH value to 7 with NaOH aqueous solution to obtain a polycarboxylate superplasticizer, denoted as PC-3.

[0048] After testing, the PC-3 obtained in this example conforms to the structural characteristics of the general molecular structure formula of the polycarboxylate superplasticizer described in the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com