Patents

Literature

85results about How to "Achieve high performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Star-shaped comb type butadiene/phenylethylene block copolymers and preparation method thereof

ActiveCN101456938AThe synthetic route is simpleAchieve high performanceMaterial synthesisMacromolecule

The invention belongs to the technical field of polymer material synthesis and preparation, relating to a star-shaped comb butadiene / styrene segmented copolymer, which is characterized in that the copolymer has the following structure: An-C, wherein A is the butadiene / styrene segmented copolymer, C is star-shaped seed tree coupler residue which is an epoxidation liquid star-shaped copolymer, n is branching degree which is larger or equal to 3, the number average molecular weight of the star-shaped comb segmented copolymer An-C is 5*10<4>-50*10<4>, the number average molecular weight of the segmented copolymer A is 1*10<4>-15*10<4>, the content of styrene is 55 percent to 85 percent (weight percent, same below), the content of butadiene is 15 percent to 45 percent, the content of 1, 2-structure is less than 30 percent (weight percent, which is counted by 100 percent of the total amount of monomer butadiene). The synthesis has the effect and benefit of simplifying the synthetic route of the star-shaped comb butadiene / styrene segmented copolymer, which can be widely applied to the preparation of the star-shaped comb butadiene / styrene segmented copolymer.

Owner:DALIAN UNIV OF TECH

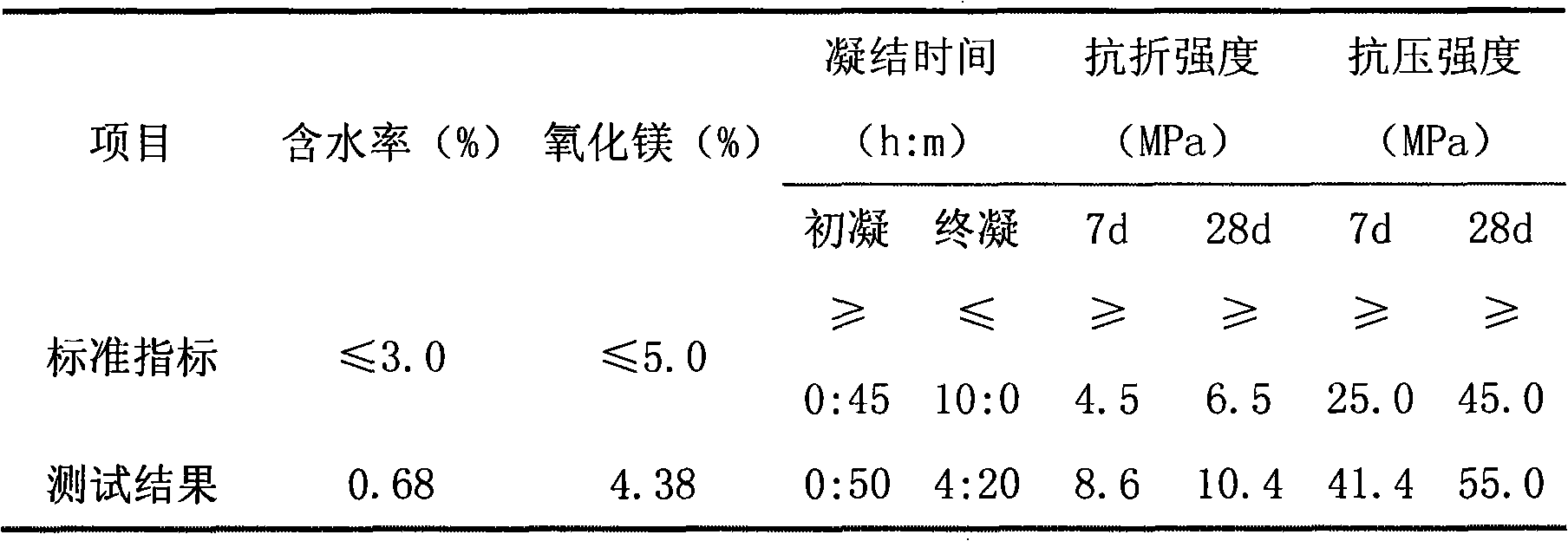

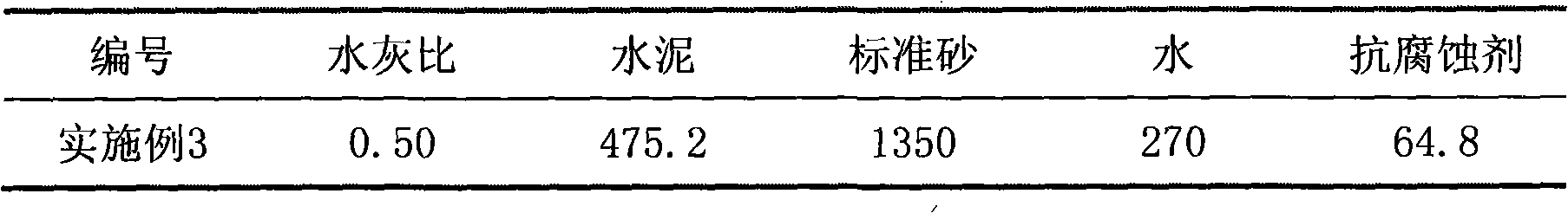

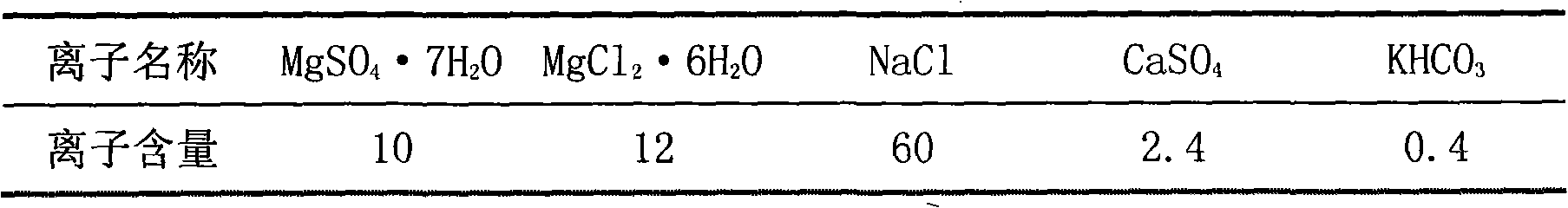

Concrete corrosion resistant additive for sea construction

InactiveCN101337787AAchieve high performanceImprove corrosion resistanceSolid waste managementCrack resistanceHazardous substance

The invention relates to a concrete corrosion proof additive for maritime work. The concrete corrosion proof additive is characterized in that the concrete corrosion-proof additive is prepared with the following components by weight: 40 to 80 percent of a sulfoaluminate micro-expanding agent, 0.1 to 2.0 percent of synthetic fiber, 1 to 10 percent of anticorrosive composition, 10 to 40 percent of fleur, and 0 to 12 percent of a water reducer. In the invention, the sulfoaluminate micro-expanding agent, the synthetic fiber, the anticorrosive composition, the fleur, the water reducer and so on are matched and compounded properly, thus forming the mutual superimposed effect. In this way, the crack resistance and the impermeability of concrete can be significantly improved; and chloride ions, vitriol and other hazardous substance can be effectively prevented from entering the concrete, thus preventing seawater and hazardous substance contained in seawater from eroding the concrete, protecting steel bars from being eroded, and improving the service life of concrete structure in maritime work.

Owner:南京派尼尔科技实业有限公司

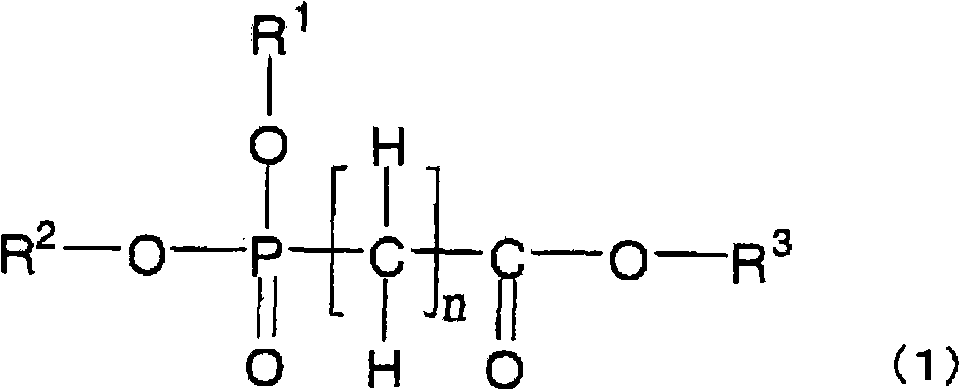

Nonaqueous electrolyte solution and nonaqueous electrolyte battery

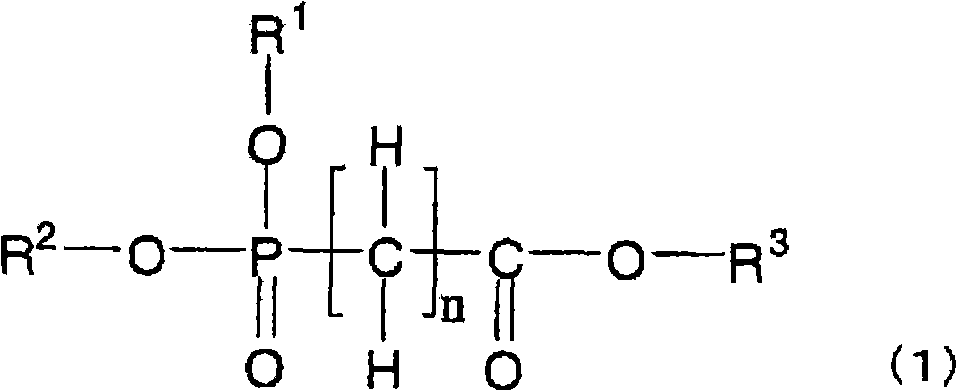

Disclosed is a nonaqueous electrolyte solution which enables to obtain a battery with high capacity which generates only a small amount of gas, while being excellent in storage characteristics and cycle characteristics. This nonaqueous electrolyte solution contains an electrolyte and a nonaqueous solvent dissolving the electrolyte, and further contains a compound represented by the general formula (1) below in an amount of not less than 0.001% by volume but less than 1% by volume in the nonaqueous solvent. Alternatively, the nonaqueous electrolyte solution contains the compound represented by the general formula (1) below in an amount of not less than 0.001% by volume but less than 5% by volume in the nonaqueous solvent, and further contains at least one compound selected from the group consisting of cyclic carbonate compounds having a carbon-carbon unsaturated bond, cyclic carbonate compounds having a fluorine atom, monofluorophosphates and difluorophosphates. In the general formula (1), R<1>-R<3> independently represent an alkyl group having 1-12 carbon atoms which may be substituted by a halogen atom; and n represents an integer of 0-6.

Owner:MITSUBISHI CHEM CORP

Method for preparing meso-scale flaky vermiculite and heat-resistant polymer heat insulation composite membrane

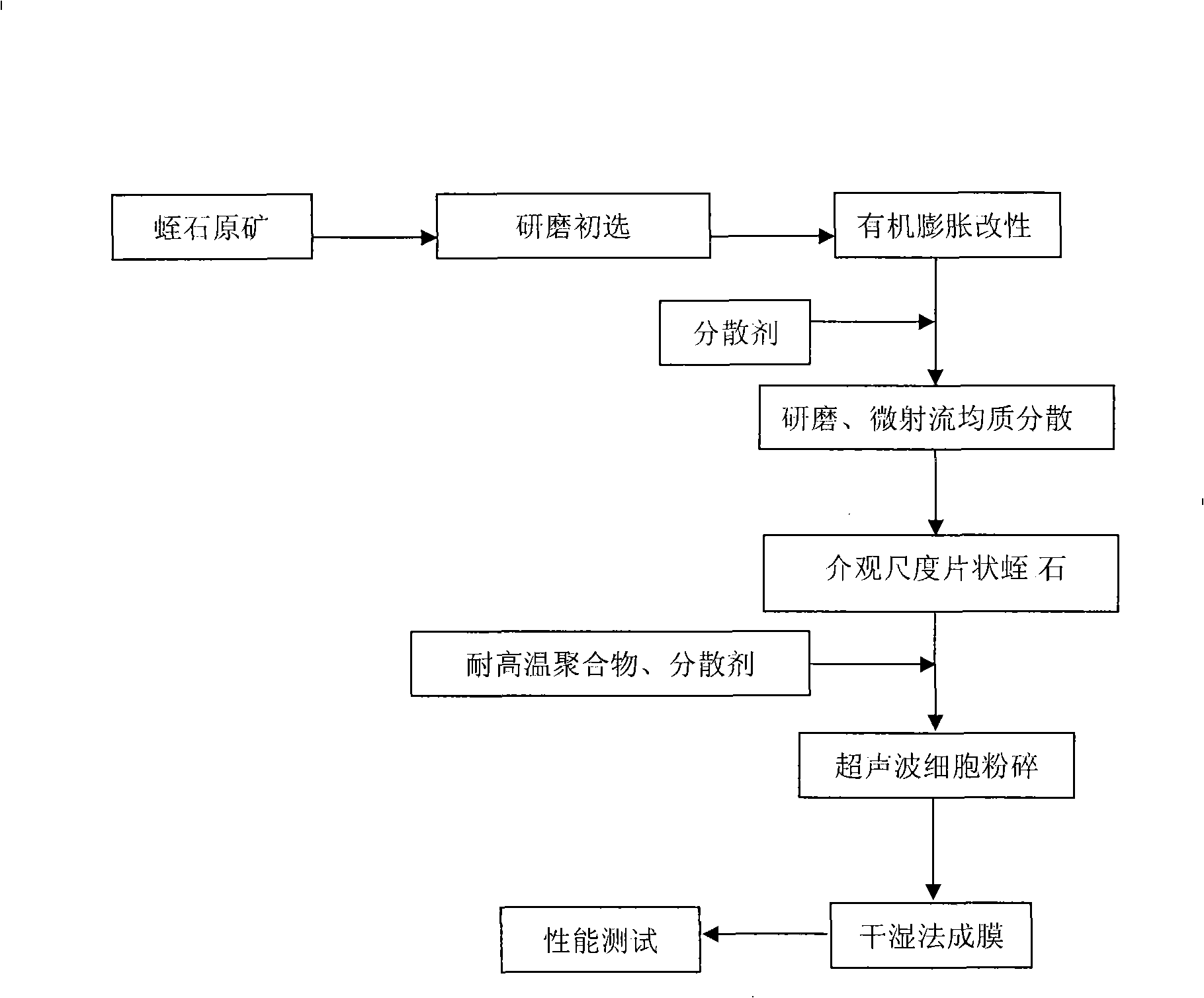

The invention provides a method for preparing mesoscale flaky vermiculite and high temperature polymer thermal insulation composite membrane. The invention adopts a technical proposal that primary mineral of vermiculite are ground to choose the part of vermiculite with a grain diameter less than 10 mu m; quaternary alkylammonium salt compound with a carbon chain of between 12 and 36 is used to modify the chosen vermiculite by organic expansion; a dispersing agent, grinding and a high-pressure homogenizer are adopted to treat the mesoscale flaky vermiculite; inorganic flaky vermiculite microcrystals are dispersed in organic high molecular polymer materials by using high temperature resistance polymer materials of poly(aryl ether sulfone) and poly(phthalazinone ether sulfone ketone) as continuous phrases and by methods of ultrasonic cell disruption, etc., and are formed into membranes by dry and wet methods. The products made by the method have extremely low heat conductivity, and excellent thermal insulation performance. Meanwhile, the composite membrane can be tightly covered on the surfaces of polysulfonamide and other fiber fabrics to improve the fireproof and thermal insulation properties, particularly the thermal insulation property of the fiber fabrics, can be used to make fire-protection clothing for safe access to fire ground or used as surface material for combat uniform.

Owner:DONGHUA UNIV

A high performance photoluminescent material and a production method therefor

A photoluminescent material is formed by curing a blend of a transparent base material and a photoluminescent pigment component, wherein the viscosity of the transparent base material is 1 Pa.s(20 DEG C.) or more and is added in an amount of 7 to 95 wt %. Luminescence performance is further improved by taking in consideration the relation between the internal structure of a molding and its luminescence performance, thereby achieving a luminescence of predetermined brightness for an extended period of time.

Owner:DOPPEL

Camera lens, camera module and terminal

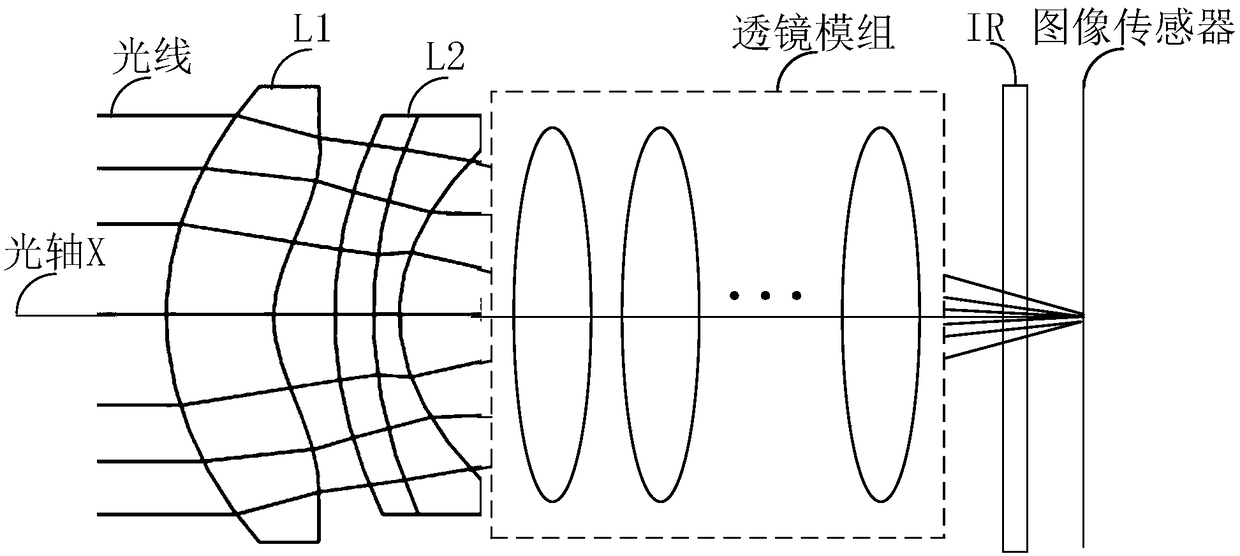

ActiveCN109031592AImprove image qualityMeet miniaturization needsTelevision system detailsColor television detailsCamera lensSize increase

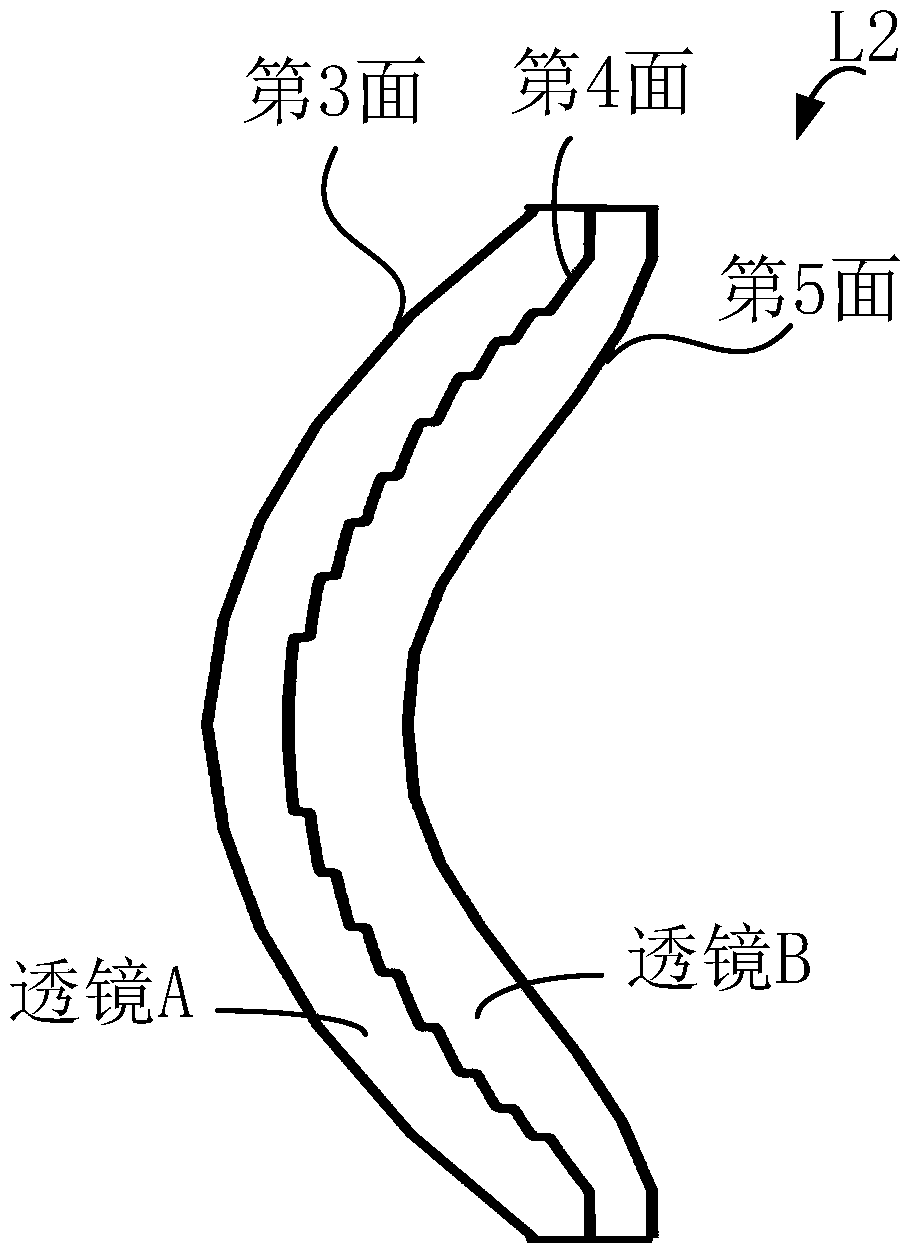

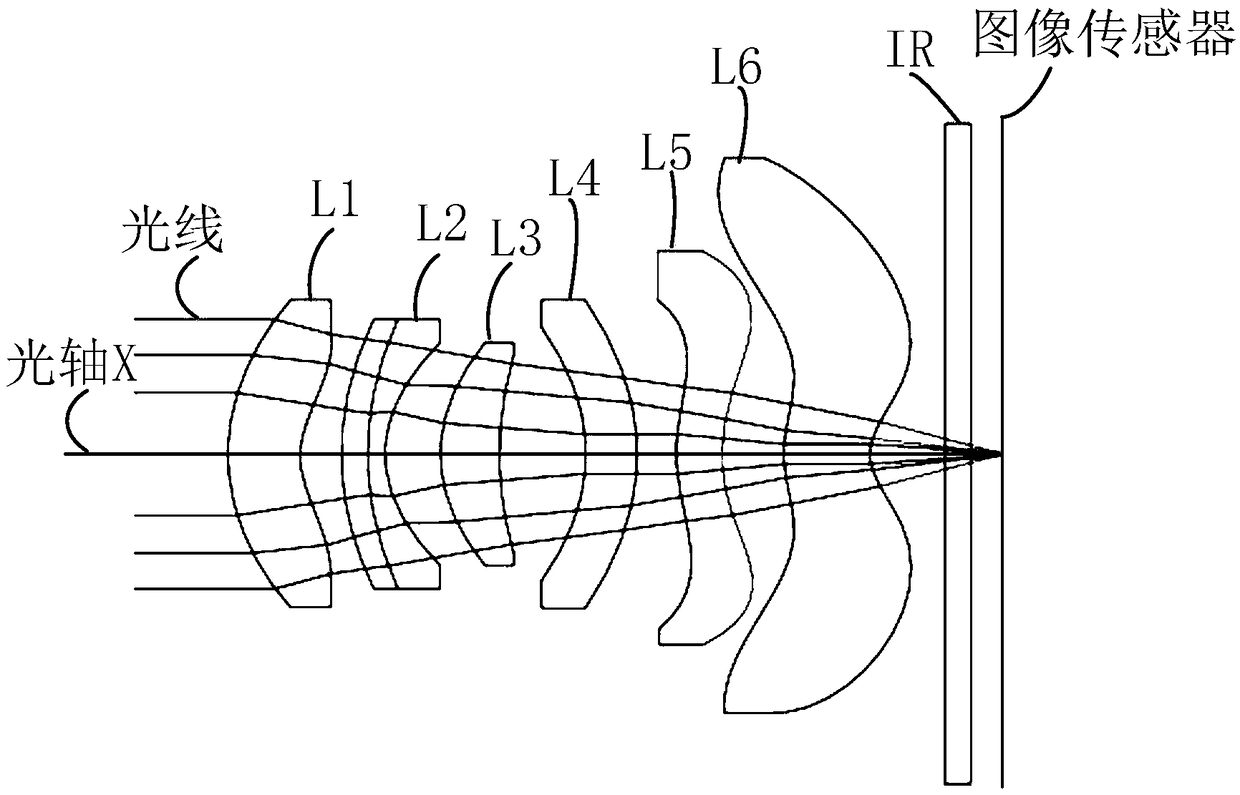

The application provides a camera lens, a camera module, and a terminal. The camera lens includes a first lens, a diffractive optical element, and a lens module along an optical axis from the object surface to the image surface; the surface of the first lens facing the object surface is a convex surface at the optical axis, and the surface facing the image surface is a concave surface, having a positive focal power; the diffractive optical element has a positive focal power and includes a surface facing the object surface, a surface facing the image surface, and a diffractive surface between the two surfaces, the surface facing the object surface is a convex surface at the optical axis, and the surface facing the image surface is a concave surface at the optical axis; the lens module includes N lenses, at least one of the surface facing the object surface and the surface facing the image surface of each of the N lenses is an aspheric surface, and the lens module has a positive focal power. The camera lens provided by the application can meet the requirements of miniaturization and high image quality, and meet the demand for size increase of the image sensor.

Owner:HUAWEI TECH CO LTD

Starlike high impact polystyrene and preparation method thereof

InactiveCN101899135AThe synthetic route is simpleAchieve high performancePolymer scienceEthylene Homopolymers

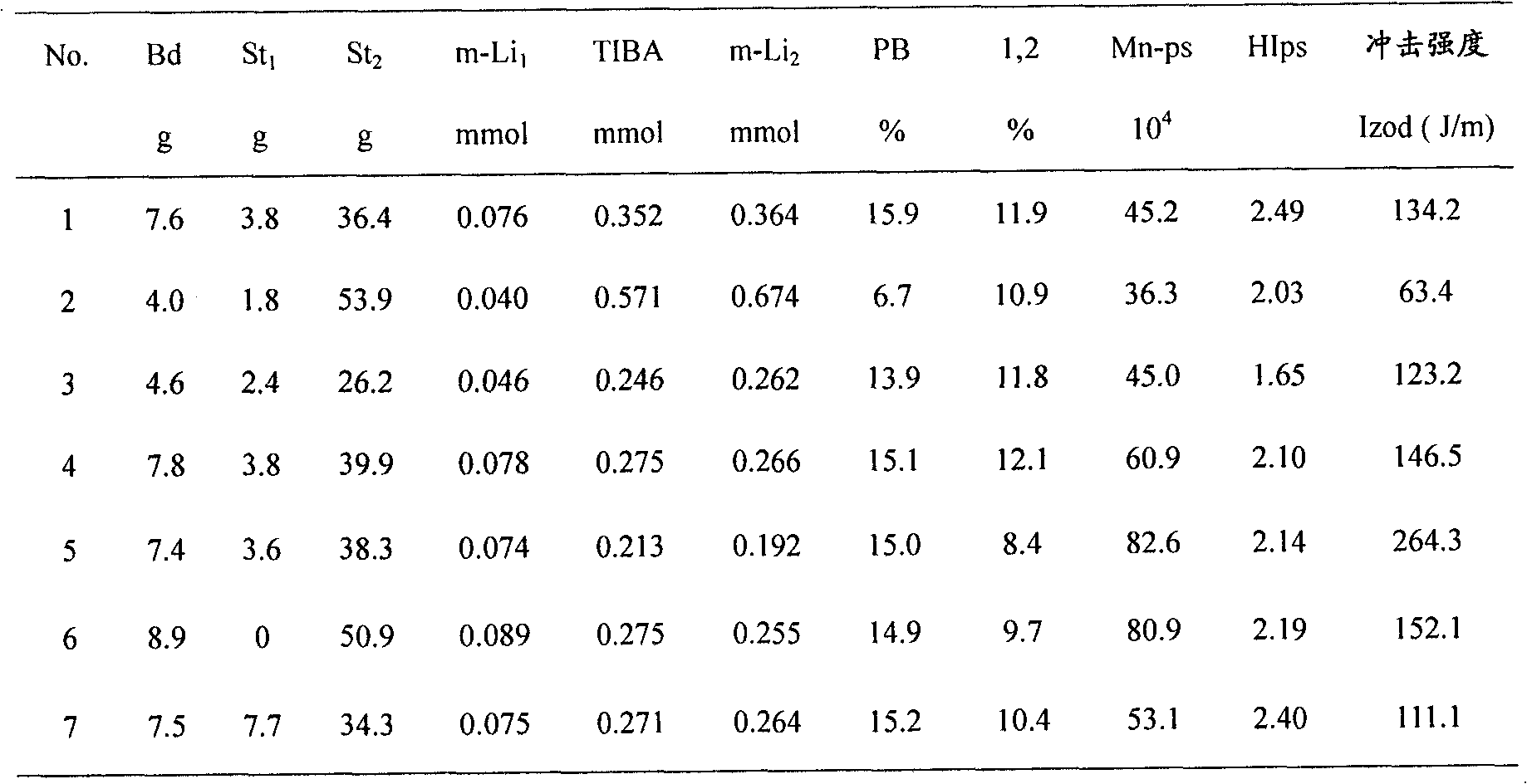

The invention discloses a starlike high impact polystyrene and a preparation method thereof. The polymer is an in-situ composition of a starlike butadiene / styrene block copolymer with the structure shown in (SBC-PS)n-C and a starlike styrene homopolymer with the structure shown in (PS)n-C, wherein SBC is a butadiene / styrol copolymer block, PS is styrene homopolymer block, C is polyfunctional alkyllithium initiator residue, and n is the functionality of the polyfunctional alkyllithium initiator, which is larger than 3; the starlike high impact polystyrene comprises the following components by weight percent: 70-95% of styrene, 5-30% of butadiene, 10-60% of (SBC-PS)n-C, and 90-40% of (PS)n-C. The starlike high impact polystyrene prepared by the invention has excellent impact resistance, and the star structure also endows excellent processability to the materials.

Owner:DALIAN UNIV OF TECH

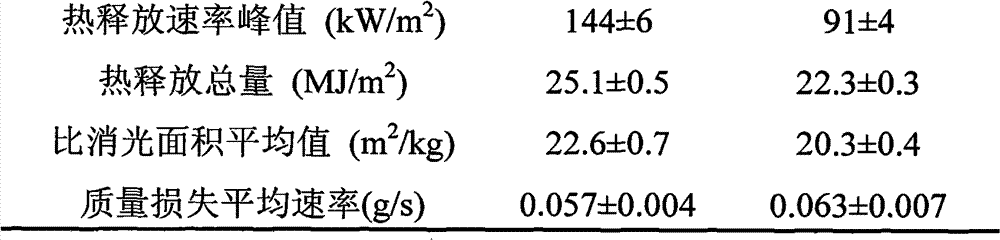

Flame-retardant cotton fiber and preparation method thereof

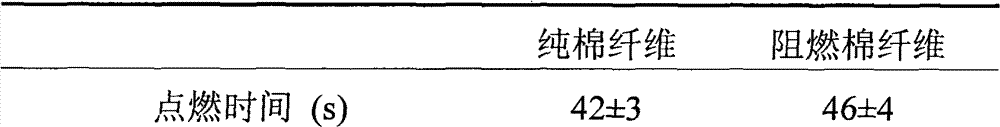

The invention discloses a flame-retardant cotton fiber and a preparation method thereof. An intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating contains an intumescent flame retardant, polyvinyl alcohol and montmorillonoid. The intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating is prepared by adopting the following step of: carrying out layer-by-layer self-assembly on a polyvinyl alcohol aqueous solution with the intumescent flame retardant and montmorillonoid suspension liquid dispersed in water to obtain the intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating. The flame-retardant cotton fiber is obtained by treating the intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating. According to the flame-retardant cotton fiber and the preparation method thereof, the intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating is prepared by the adoption of a layer-by-layer self-assembly technology; and through the synergistic flame-retardant effect of the intumescent flame retardant and montmorillonoid, the flame retardance of cotton fibers is improved, so that the usage amount of the flame retardant for cotton fabrics is reduced, therefore the cost of flame-retardant cotton fibers is lowered.

Owner:TAIZHOU UNIV

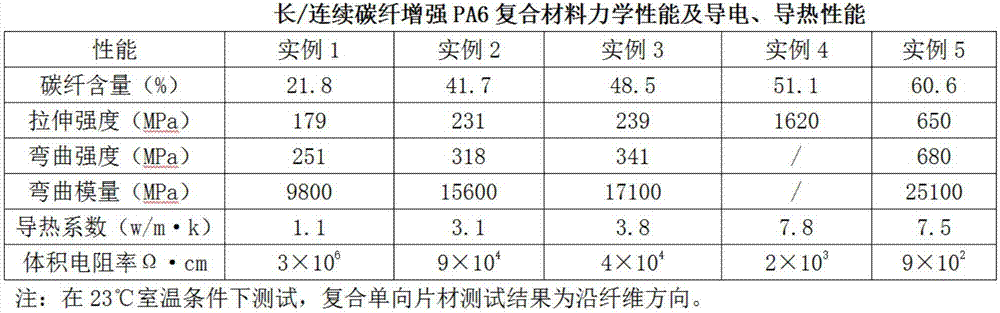

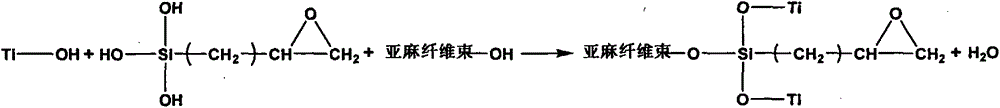

Continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and preparation method thereof

InactiveCN106939124AImprove conductivityHigh thermal conductivityHeat-exchange elementsFiberCarbon fibers

The invention relates to a continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and a preparation method thereof. The composite comprises, by weight, (1) 100 parts of PA6 resin, (2) 0.2 to 1 part of an anti-oxidant, (3) 0.2 to 1.2 parts of a flow promoter, (4) 2 to 10 parts of a flexibilizer and (5) 1 to 5 parts of a compatilizer. The preparation method comprises the following steps: premixing the above components according to a certain ratio, carrying out melting and mixing via a double / single-screw set and then extruding the obtained mixture into a die head for flow splitting and impregnation so as to prepare the continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity. Compared with conventional staple carbon fiber-reinforced PA6 composites, the continuous carbon fiber-reinforced PA6 composite prepared by using a special impregnation process in the invention has greatly improved mechanical properties since the length retention rate of carbon fibers in a PA6 carrier is high or continuous and has substantially improved electrical conductivity and thermal conductivity due to a continuous network structure, so the application range of the composite is greatly broadened.

Owner:浙江胜钢新材料有限公司

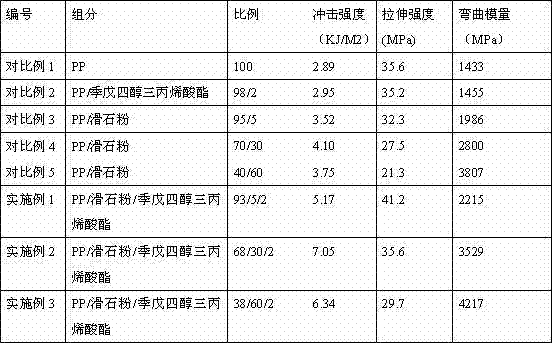

Strengthening and toughening polypropylene composite and preparation method thereof

ActiveCN102516655AEnhanced Interfacial InteractionAchieve high performancePolypropylene compositesPolymer science

The invention discloses a strengthening and toughening polypropylene composite, which comprises, by weight, 35 to 94 parts of polypropylene, 0.5 to 5 parts of polyfunctional monomer, 5 to 60 parts of inorganic filler and 0.2 to 4 parts of polypropylene universal antioxidant and processing agent. A preparation method of the strengthening and toughening polypropylene composite includes: mixing all components evenly, adding the components in a screw extruder to perform melt mixing reaction, extruding and prilling to obtain the strengthening and toughening polypropylene composite. In-situ graft reaction occurs in a melt mixing process through double bond of the polyfunctional monomer and polypropylene, simultaneously C=O bond of the polyfunctional monomer and hydroxy on the surface of the filler form hydrogen bond, interfacial interaction between the filler and a matrix is enhanced, thereby achieving high performance of the polypropylene composite. The obtained polypropylene composite not only has good toughness and rigidity, but also can restrain degradation of the polypropylene.

Owner:KINGFA SCI & TECH CO LTD +2

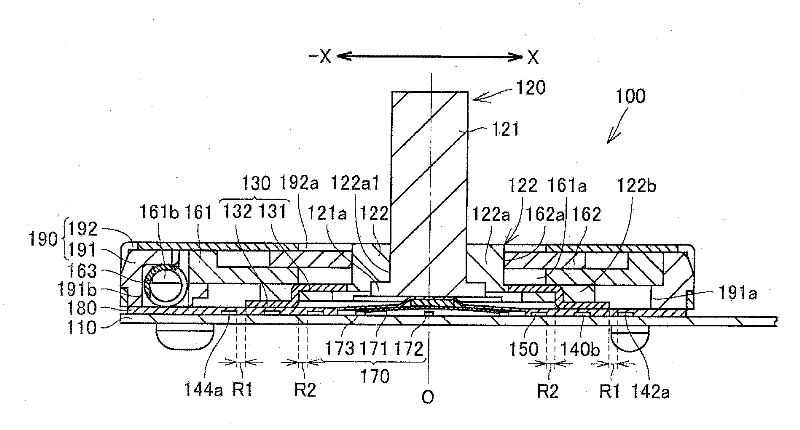

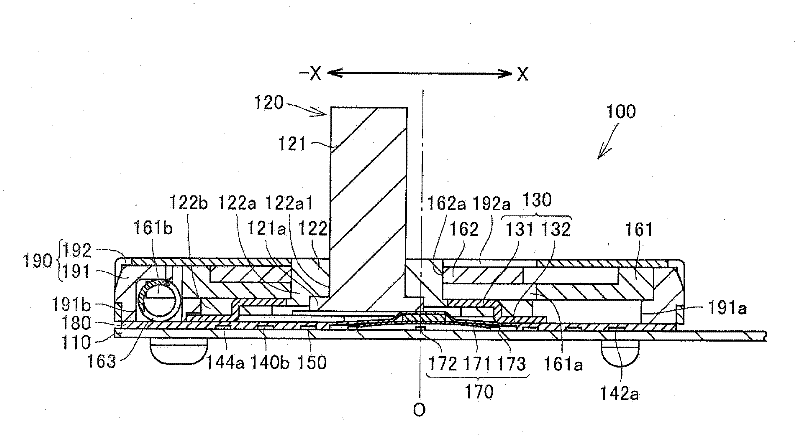

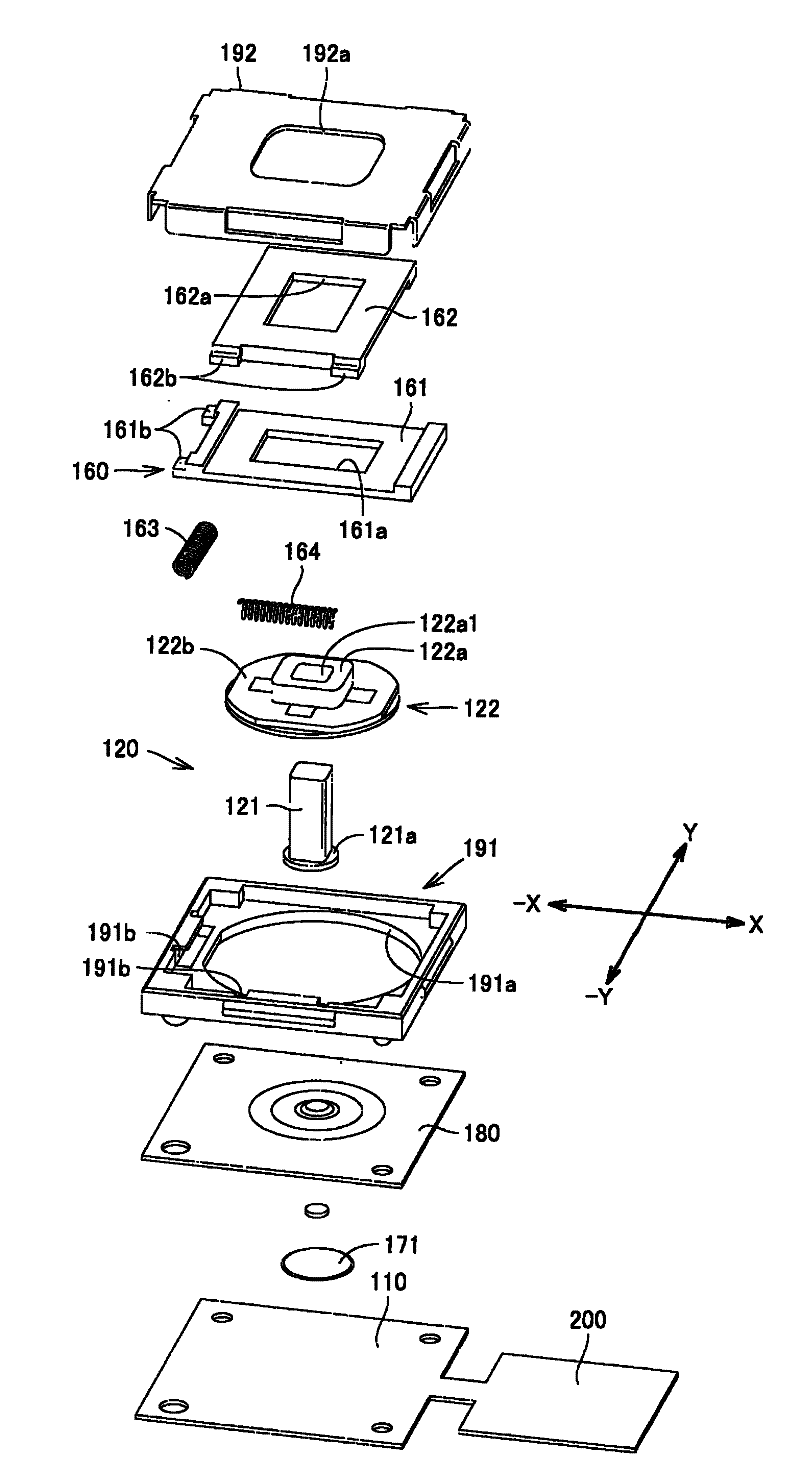

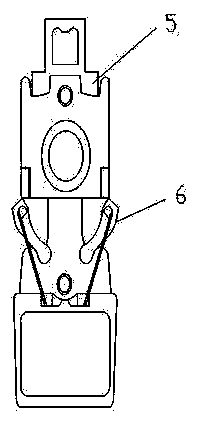

Multidirectional input device

InactiveCN102402312AAchieve high performanceElectronic switchingElectric switchesCapacitancePeripheral

The invention provides a multidirectional input device capable of reducing power consumption in a sleep mode period. A multidirectional input device PD includes an input unit 100 and a capacitance detection IC 200. The input unit 100 includes an operation body 120, a metal piece 130 movable in multiple directions, and various electrodes 141a to 144a, 140b and 150 disposed on a surface of an insulating substrate 110. The capacitance detection IC 200 detects the presence or absence of movement of the operation body 120 through measurement of capacitance between the metal piece 130 and the detection electrode 140b, while it detects a movement direction of the operation body 120 through measurements of capacitances between the metal piece 130 and the respective detection electrodes 141a to 144a. A distance R1 and a distance R2 are substantially the same, where R1 is a planar distance between an outer circumference of an outer peripheral area 132 of the metal piece 130 and inner circumferences of the detection electrodes 141a to 144a at an initial position, and R2 is a planar distance between an inner circumference of the outer peripheral area 132 and an outer circumference of the GND electrode 150.

Owner:HOSIDEN CORP

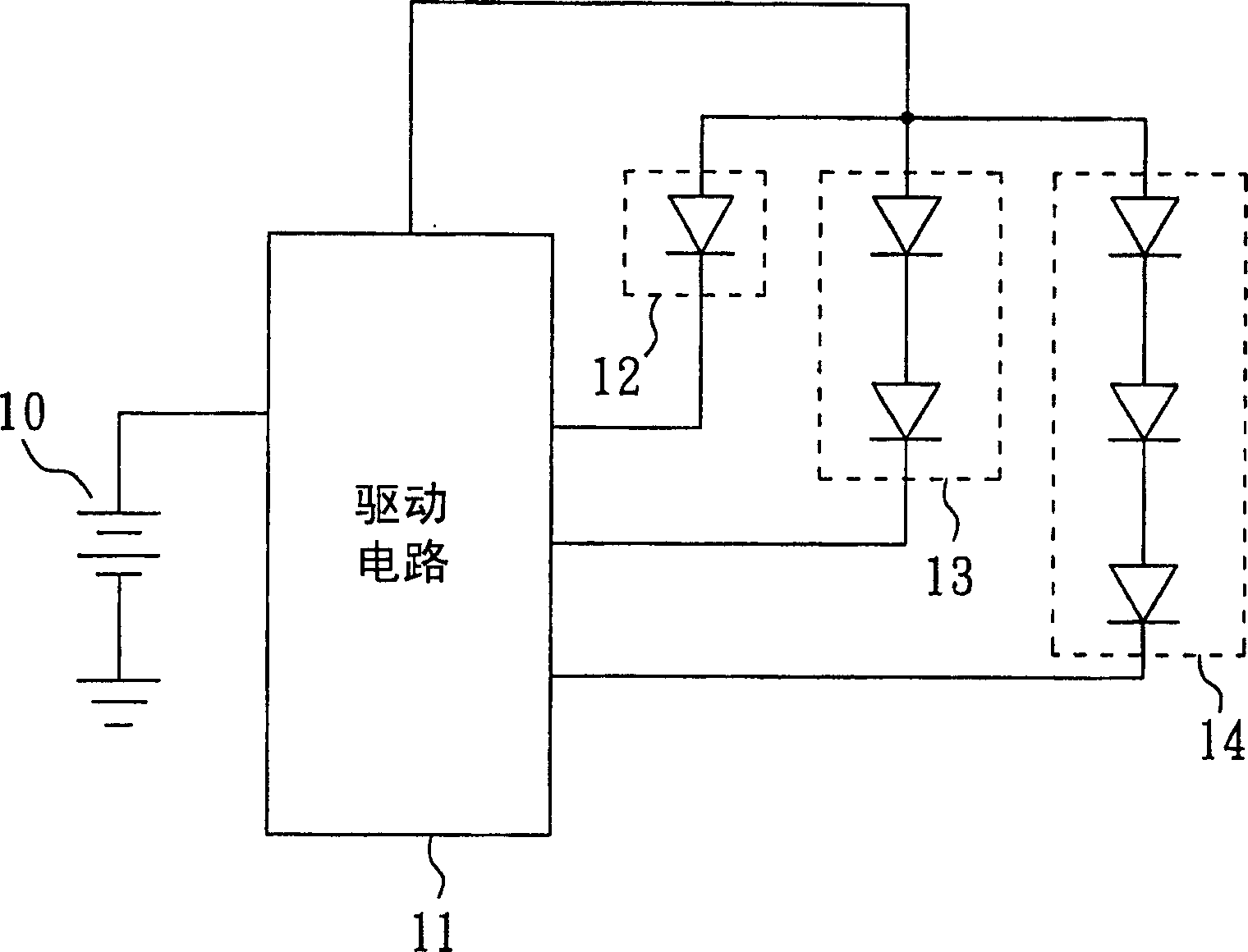

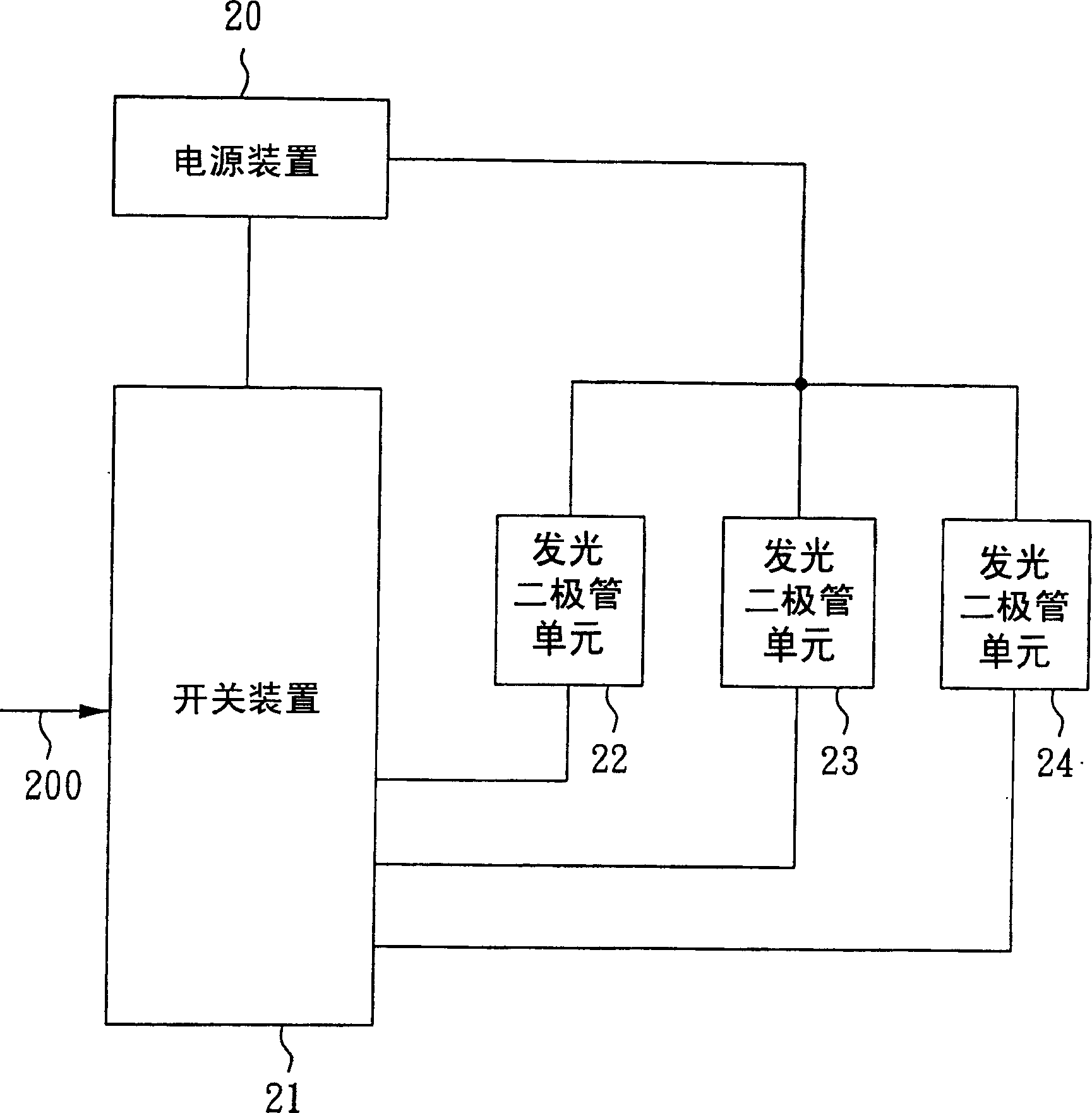

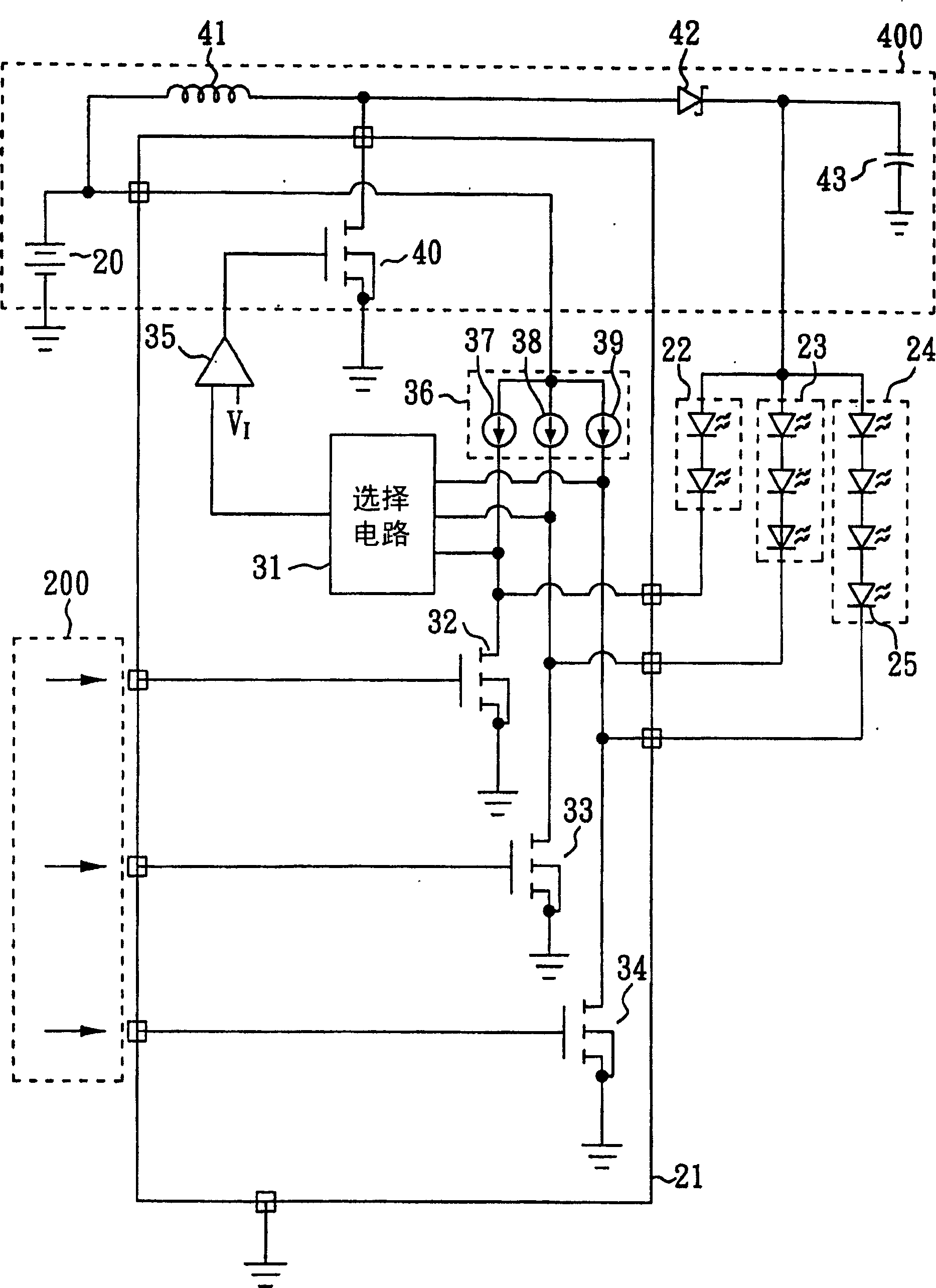

Parallel-connected type light-emitting diode driving device

InactiveCN1766963AAvoid wasting powerAchieve high performanceStatic indicating devicesElectricityEngineering

The invention relates to a parallel light-emitting diode driver which comprises a switch, a power and a plurality of groups of light-emitting diode units, wherein it uses the switch to parallel the plurality of groups of light-emitting diode units so that the power can provide the electricity to the light-emitting diode.

Owner:雅捷科技股份有限公司

Production process for rapidly achieving galvanization and polyvinyl fluoride (PVF) paint coating of tubular products

InactiveCN102534741AImprove surface qualityFast Galvanizing EfficiencyCellsLiquid surface applicatorsElectrogalvanizationPower flow

The invention relates to a production process for rapidly achieving galvanization and polyvinyl fluoride (PVF) paint coating of tubular products, which belongs to the technical field of metal plating coating processes. The production process for rapidly achieving the galvanization and the PVF paint coating of the tubular products enables a plurality of tubes to move parallelly, achieves process integration of galvanization PVF paint coating, achieves high-speed electrogalvanization and PVF coating surface processing, and simultaneously meets organic combination of trivalent chromium galvanization passivation and trivalent chromium PVF paint with the speed as high as 20m / min. Surface quality of produced tubular products is excellent, galvanization efficiency is high, yield is improved, and production cost is reduced. Key technical problems that an existing electroplating device has poor environment protection, tightness and product operation stability, large current can generate heat during electroplating, and the like are solved. When the process is utilized, tubes do not generate electric sparks during continuous galvanization operation, the plating is free of burns and rough black phenomena. Besides, due to large current density, high galvanization efficiency and fast electroplating speed in galvanization, the production purposes of high efficiency and low cost are achieved.

Owner:COOPER STANDARD JINGDA JINGZHOU AUTOMOBILE FITTINGS

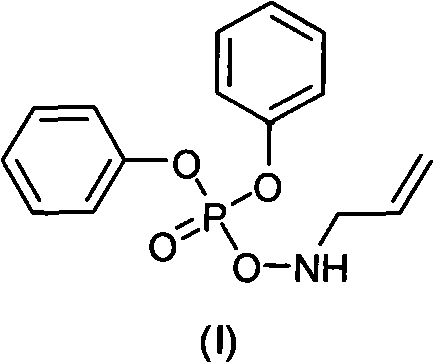

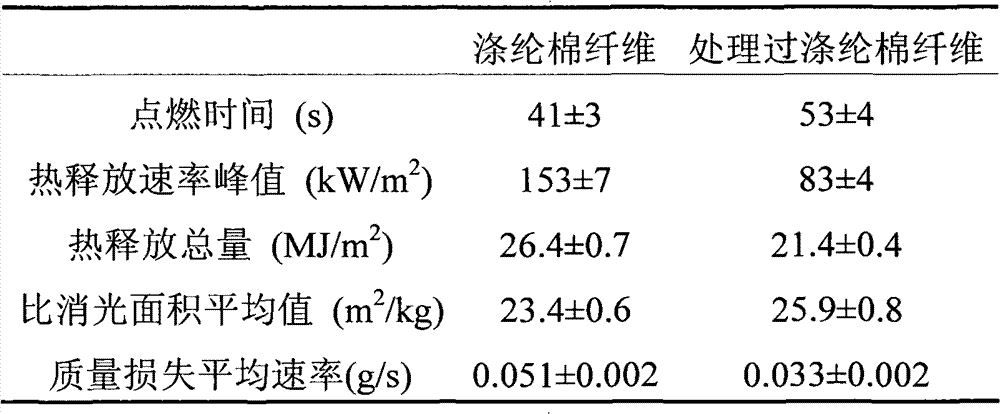

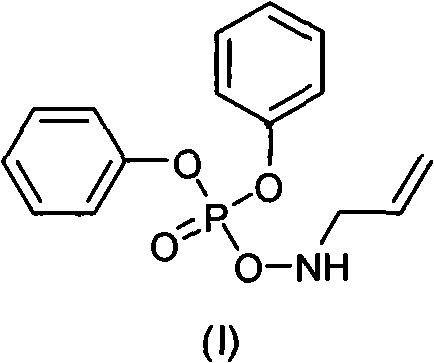

Flame-retardant coating and preparation method and application thereof

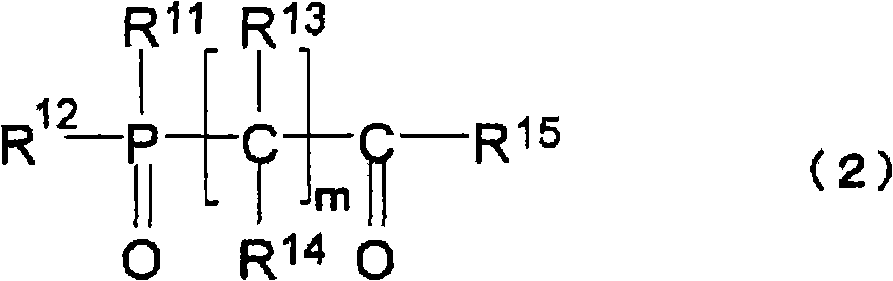

ActiveCN102926202AFlame retardantIntumescent flame retardantGroup 5/15 element organic compoundsFibre treatmentPolymer scienceOxide composite

The invention discloses an intumescent flame-retardant modified polyacrylamide / graphene oxide composite coating, a preparation method and application thereof. The structure of an intumescent flame retardant is represented by a formula (I). The intumescent flame retardant is prepared by adopting the following step of: making diphenyl chlorophosphate react with acrylamine or acrylamine hydrochloride to obtain the intumescent flame retardant. The intumescent flame retardant is copolymerized with acrylamine monomer to obtain intumescent flame-retardant modified polyacrylamide. According to the invention, the intumescent flame-retardant modified polyacrylamide / graphene oxide composite coating is prepared through the adoption of a layer-by-layer self-assembly technology; and through the synergistic flame-retardant effect of the intumescent flame retardant and graphene oxide, the flame retardance of the composite coating is improved, so that the usage amount of the flame retardant coating on textile materials is reduced, therefore the cost of flame-retardant textiles is lowered.

Owner:SAIYANG SEALING ELEMENT ZHEJIANG

Polypropylene compound for automobile fender and preparation method thereof

The invention discloses a polypropylene compound for automobile fenders and a preparation method thereof. The polypropylene compound for automobile fenders comprises 89-19 wt% of polypropylene, 5-40 wt% of a flexibilizer, 1-5 wt% of polar monomer grafted olefin polymer, 0-2 wt% of a heat stabilizer, 0-2 wt% of a processing auxiliary agent, 0-2 wt% of a light stabilizer, and 5-30 wt% of talcum powder. The preparation method comprises the following steps: melting, mixing and dispersing polypropylene, the flexibilizer, polar monomer grafted olefin polymer, the heat stabilizer, the processing auxiliary agent, and the light stabilizer in a double screw extruder, feeding the talcum powder from a side feeding port into the double screw extruder, setting the temperature of each section of the extruder at 180-240 DEG C, and performing extrusion granulation. The material provided by the invention has the characteristics of low modulus, high impact, and excellent aging resistance, meets the requirements of low modulus, high impact, and aging resistance for automobile fenders, and realizes high performance of automobile fender materials.

Owner:SHANGHAI KINGFA SCI & TECH +1

Preparation method of ultrahigh molecular weight polyethylene composite material

The invention relates to a preparation method of a polyethylene composite material with ultrahigh molecular weight. The method is characterized by comprising the steps of: selecting two olefin polymerization catalysts, wherein one is an ultra-high molecular weight polyethylene catalyst capable of producing ultrahigh molecular weight polyethylene, and the other is a low molecular weight catalyst capable of producing low molecular weight polyethylene; using POSS molecules with hydroxyl and acrylate isobutyl on the surfaces as carriers, loading the low molecular weight catalyst on the POSS molecules, and conducting a polymerization reaction to obtain low molecular weight polyethylene; and then loading the ultrahigh molecular weight polyethylene catalyst on the POSS molecules, adding a cocatalyst, introducing ethylene, and conducting a polymerization reaction to obtain an ultrahigh molecular weight / POSS / low molecular polyethylene blended nano composite material. The preparation method provided by the invention has advantages of simple process, high efficiency and low energy consumption, and can prepare UHMWPE / low molecular weight polyethylene / POSS nano composite material with uniformly mixed molecular scale by in situ polymerization.

Owner:NINGBO UNIV

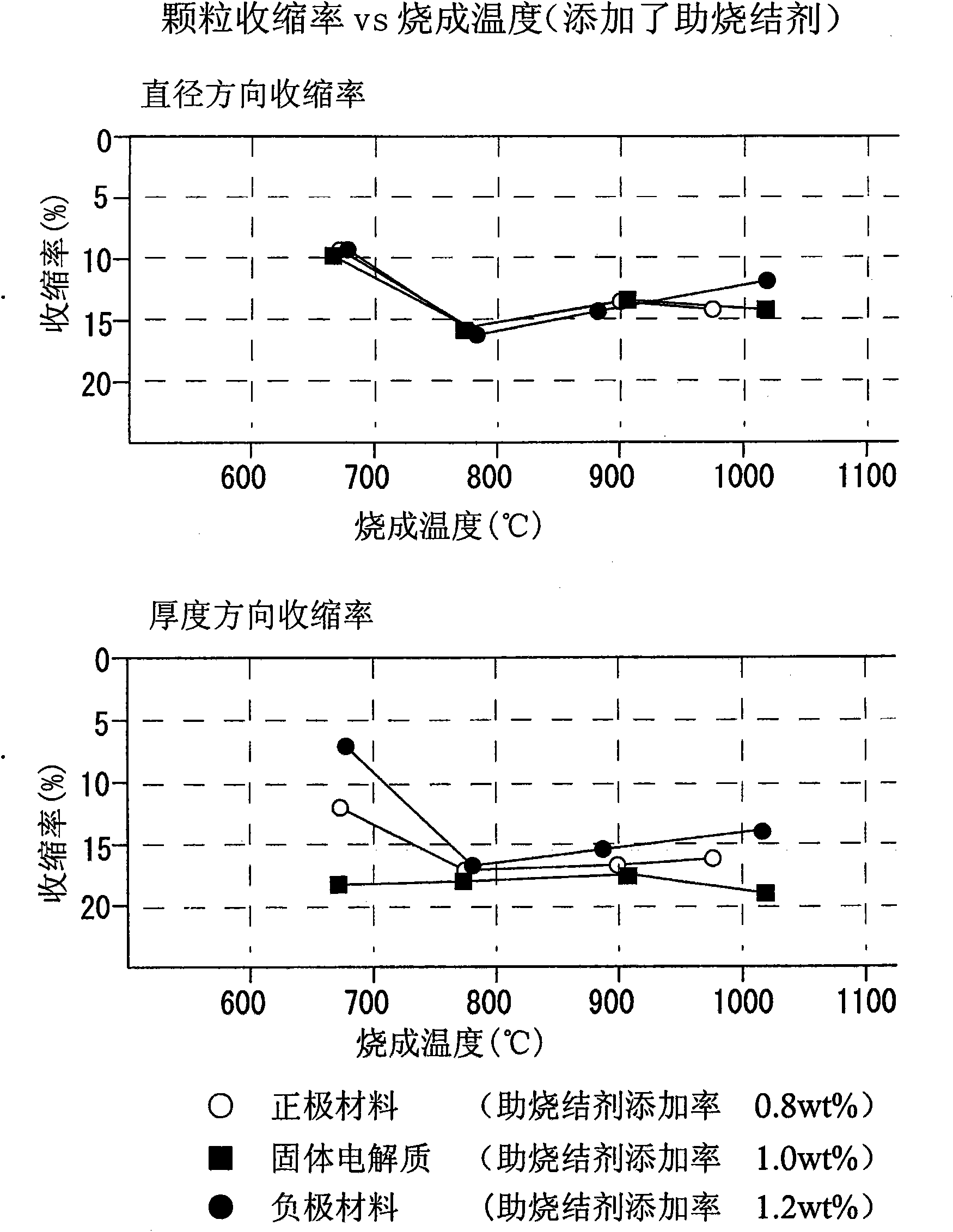

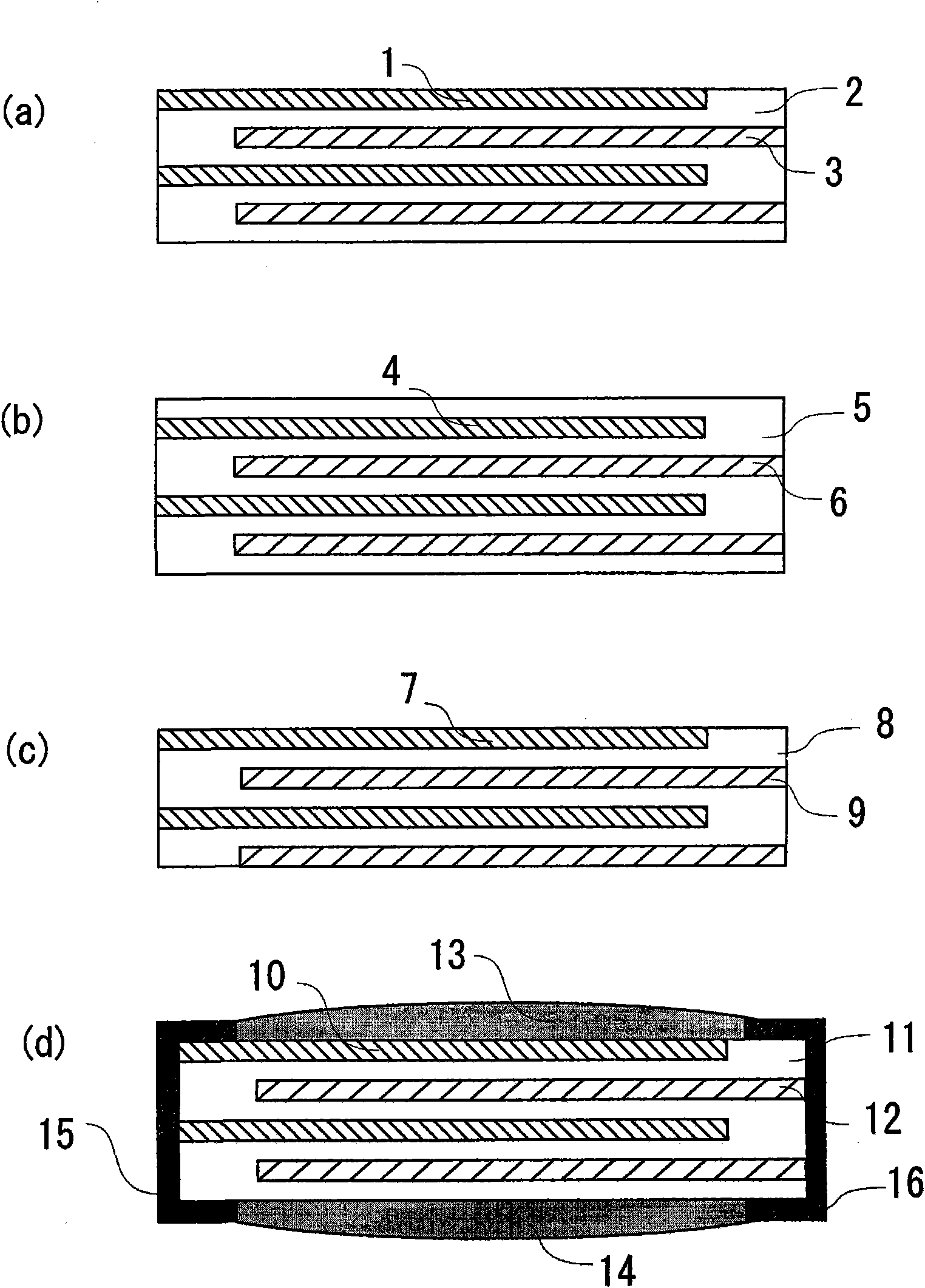

Lithium ion rechargeable battery and process for poducing the rechargeable battery

ActiveCN101904040AAvoid delaminationReduce electricity costsElectrode thermal treatmentFinal product manufactureLithiumThermal expansion

Owner:NAMICS CORPORATION

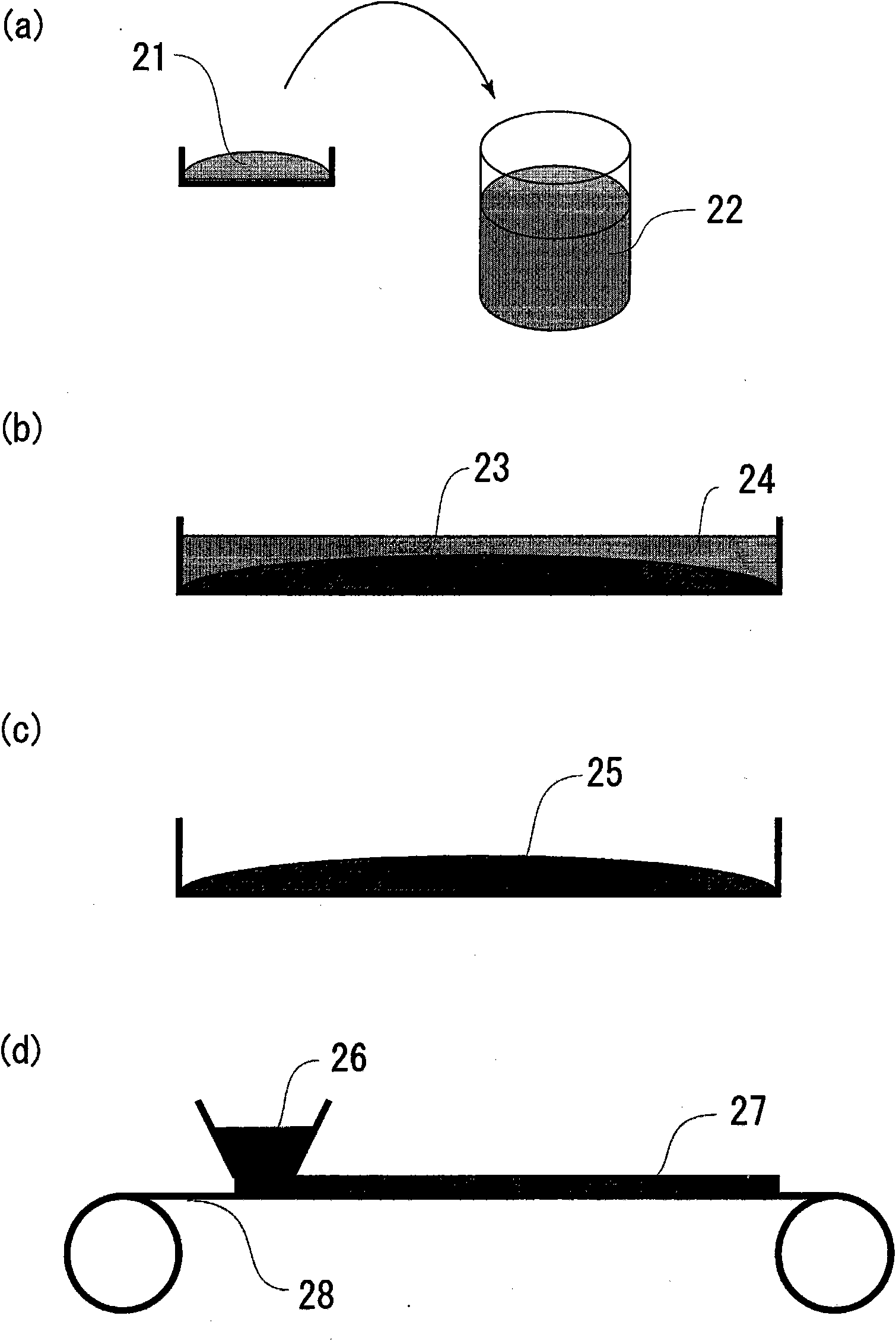

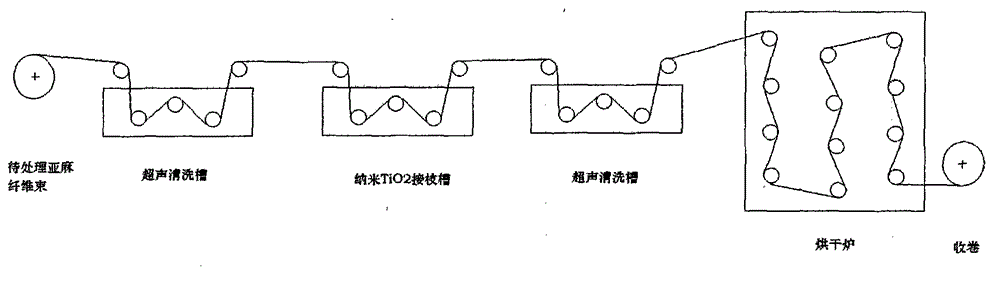

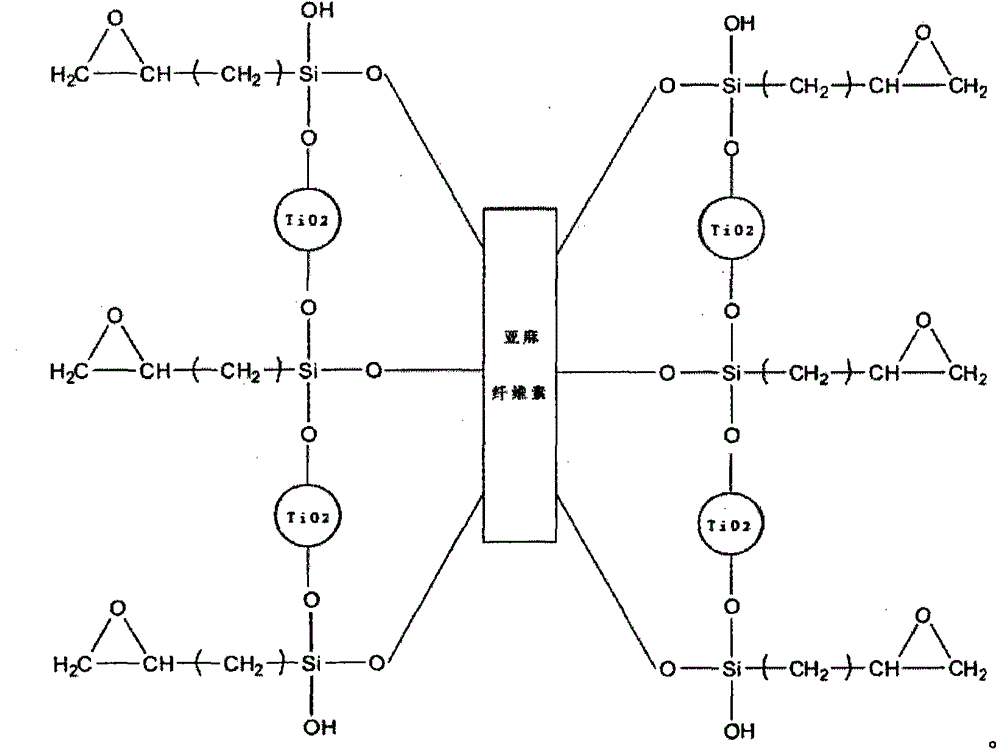

Continuous flax fiber bundle surface grafted with nano titanium dioxide as well as preparation method thereof

ActiveCN104562636AImprove monofilament tensile strengthImprove interfacial adhesionVegetal fibresPigment treatment with organosilicon compoundsEpoxyDistilled water

The invention provides a continuous flax fiber bundle surface grafted with nano titanium dioxide as well as a preparation method thereof. The preparation method of the continuous flax fiber bundle comprises the following steps: firstly ultrasonically cleaning the continuous flax fiber bundle by distilled water; then, dipping the bundle into a suspension of nano titanium dioxide and a silane coupling agent and ultrasonically cleaning the continuous flax fiber bundle again by distilled water after a certain action time; and finally drying and coiling the treated continuous flax fiber bundle. According to the continuous flax fiber bundle treated by virtue of the method, the tensile performance of the continuous flax fiber bundle as well as the interface bond behavior with epoxy resin can be remarkably improved. High performance of a flax fiber reinforced resin-based composite material is realized by virtue of the method.

Owner:HARBIN INST OF TECH

Continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material and preparation thereof

The invention relates to a continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material and a preparation thereof. The continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material comprises the components in parts by weight: (1) 100 parts of polypropylene, (2) 0.1-1 parts of an antioxidant, (3) 0.2-2 parts of a flow promoter, and (5) 1-5 parts of a compatilizer; after being premixed according to a certain proportion, the components are melted, mixed and extruded into a hanger-shaped mold head by a double / single-screw machine unit to be shunted; finally, the components enter an S-shaped mold head to sufficiently soak carbon fibers so as to prepare the continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material. Compared with the traditional carbon fiber reinforced PP composite material, the continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material provided by the invention has the advantages that the mechanical property of the continuous carbon fiber reinforced composite material prepared by using a special soaking process is greatly improved because the length retention rate of carbon fibers in a PP carrier is very high or the carbon fibers are continuous in the PP carrier; on the basis of a continuous network structure, the electricity-conductive and heat-conductive performances of the continuous carbon fiber reinforced composite material are also greatly improved.

Owner:浙江胜钢新材料有限公司

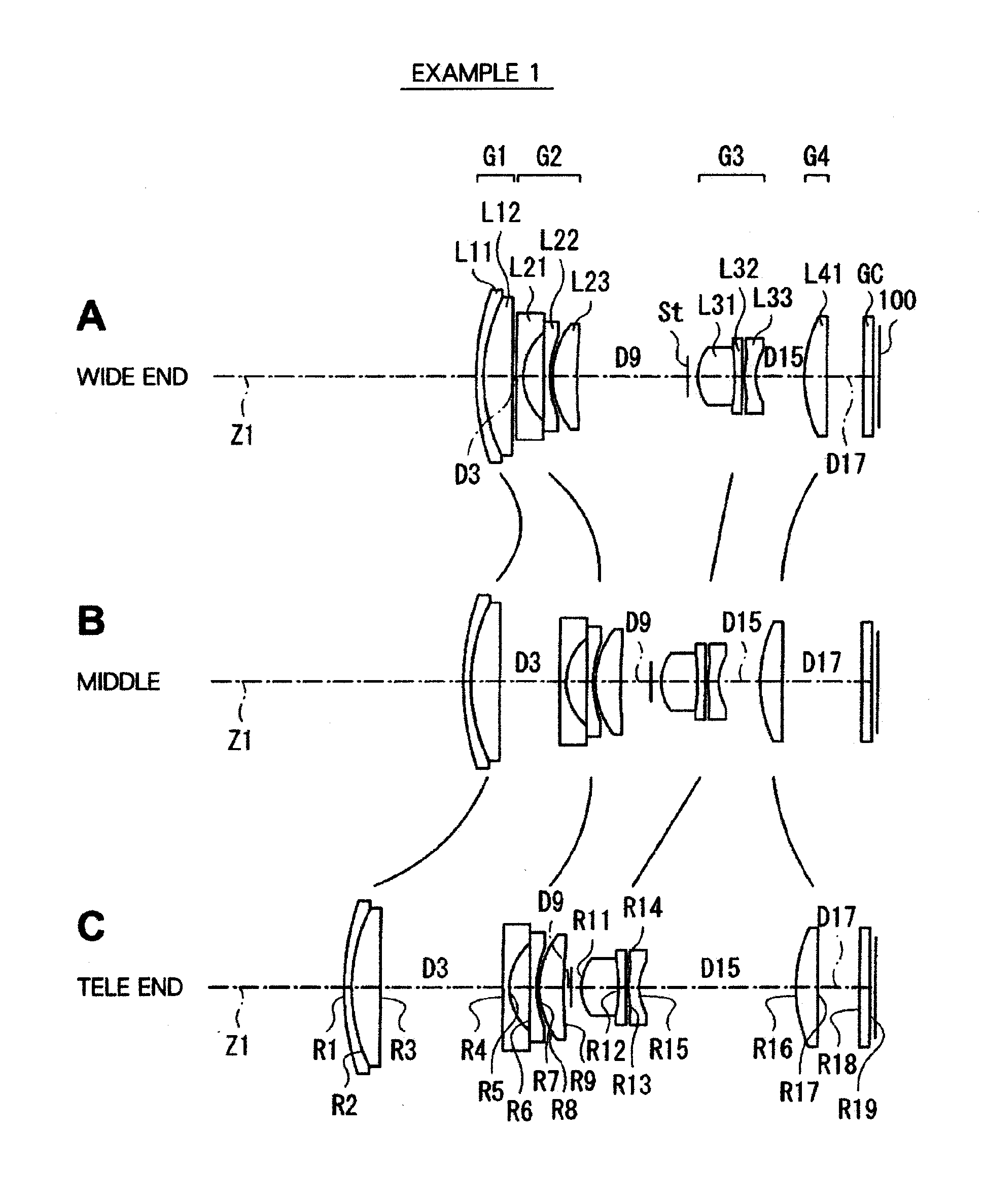

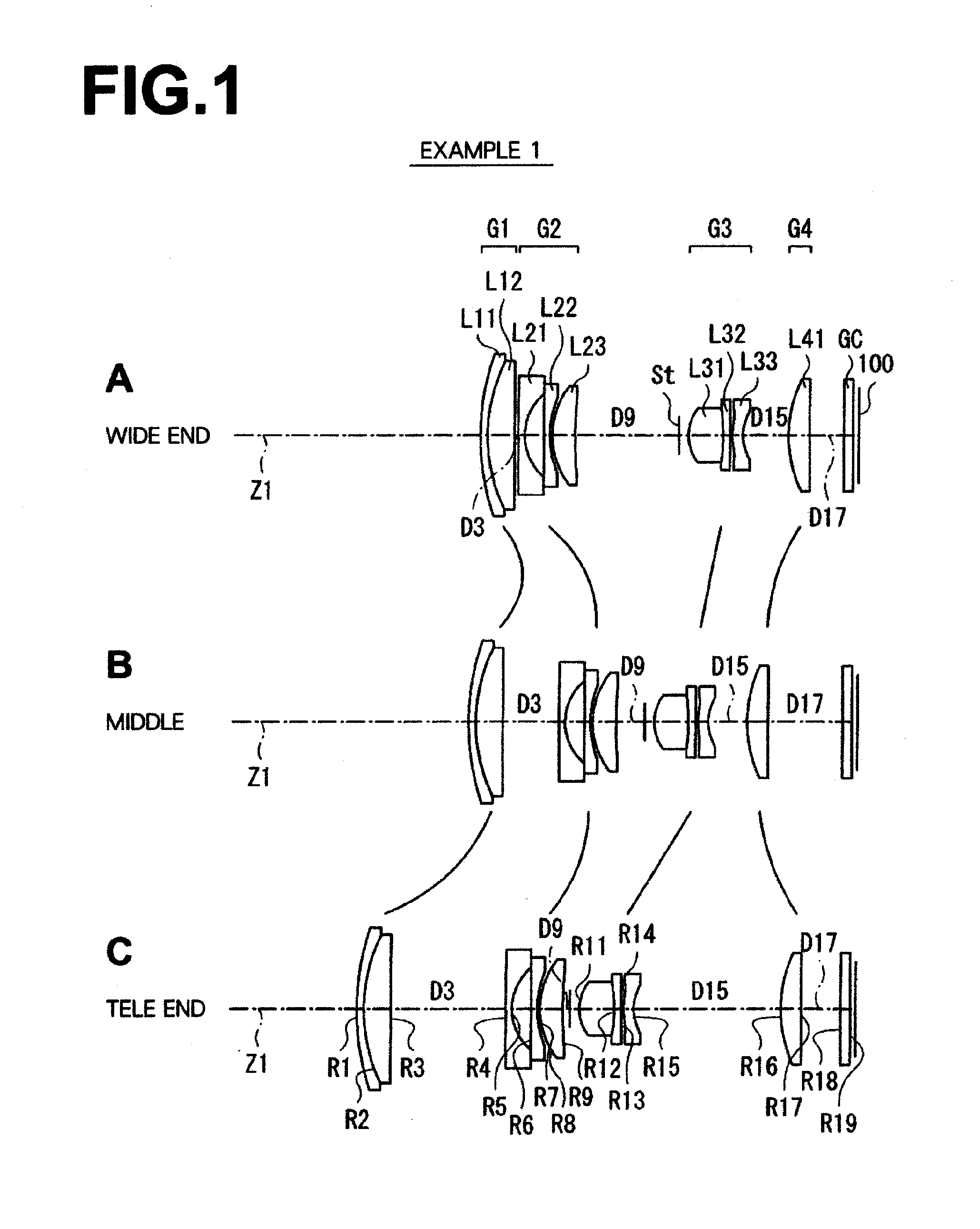

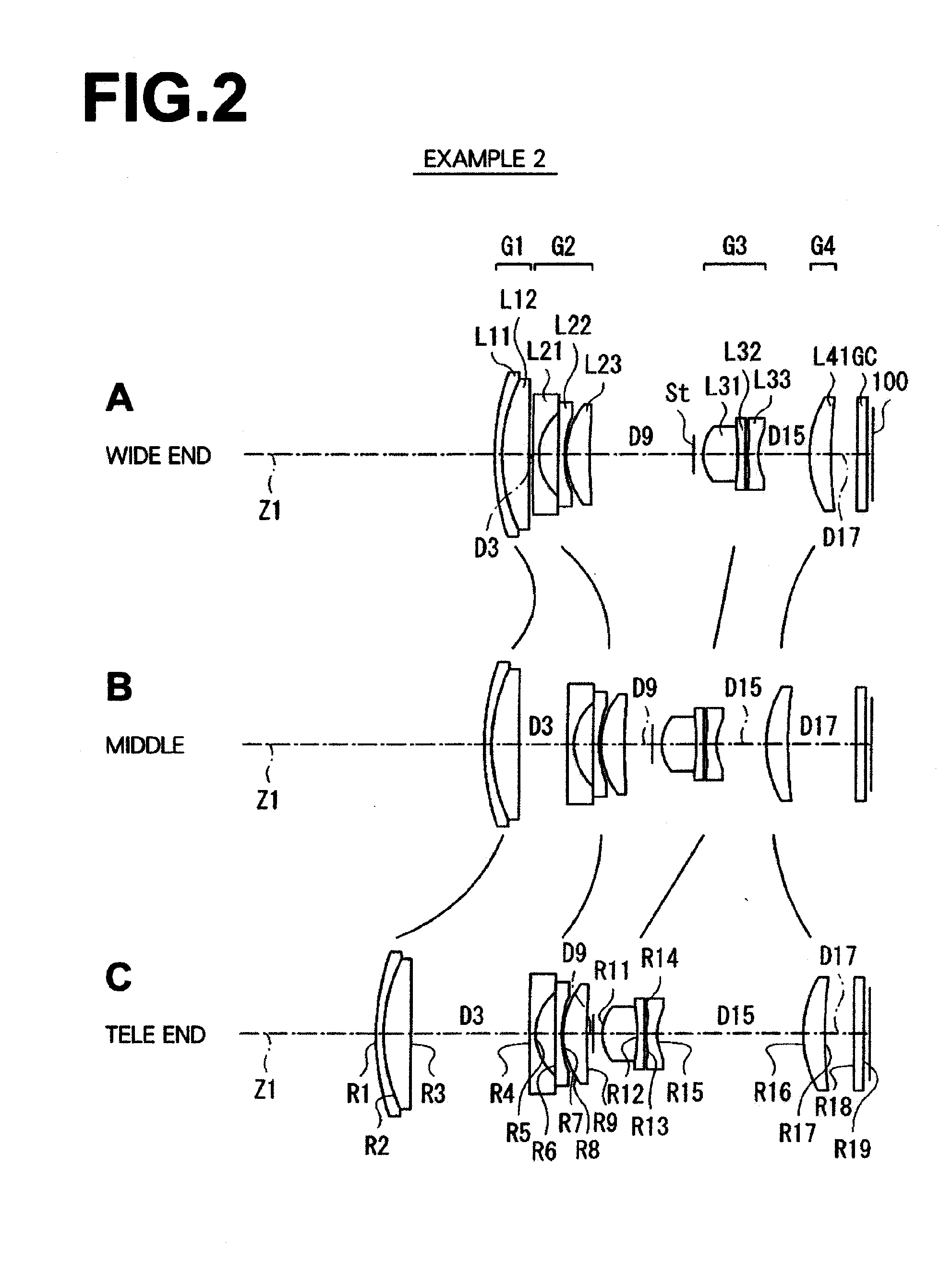

Zoom lens and imaging apparatus

InactiveUS20110194016A1Small aberration fluctuationHigh zoom ratioTelevision system detailsTelevision system scanning detailsCamera lensMagnification

First lens-group is composed of a negative lens and a positive lens. When magnification is changed from wide end to tele end, a distance between first lens-group and second lens-group increases, and a distance between second lens-group and third lens-group decreases. Specifically, first lens-group moves toward the object side, second lens-group moves along a path convex toward the image side, third lens-group monotonously moves only toward the object side, and fourth lens-group moves along a path convex toward the object side. Further, the following formulas are satisfied:0.3<X1 / ft<0.5 (1); and5.0<f1 / fw<7.0 (2),where X1: the amount of movement of first lens-group when magnification is changed from wide end to tele end, ft: the focal length of the entire system at tele end, f1: a combined focal length of first lens-group, and fw: the focal length of the entire system at wide end.

Owner:FUJIFILM CORP

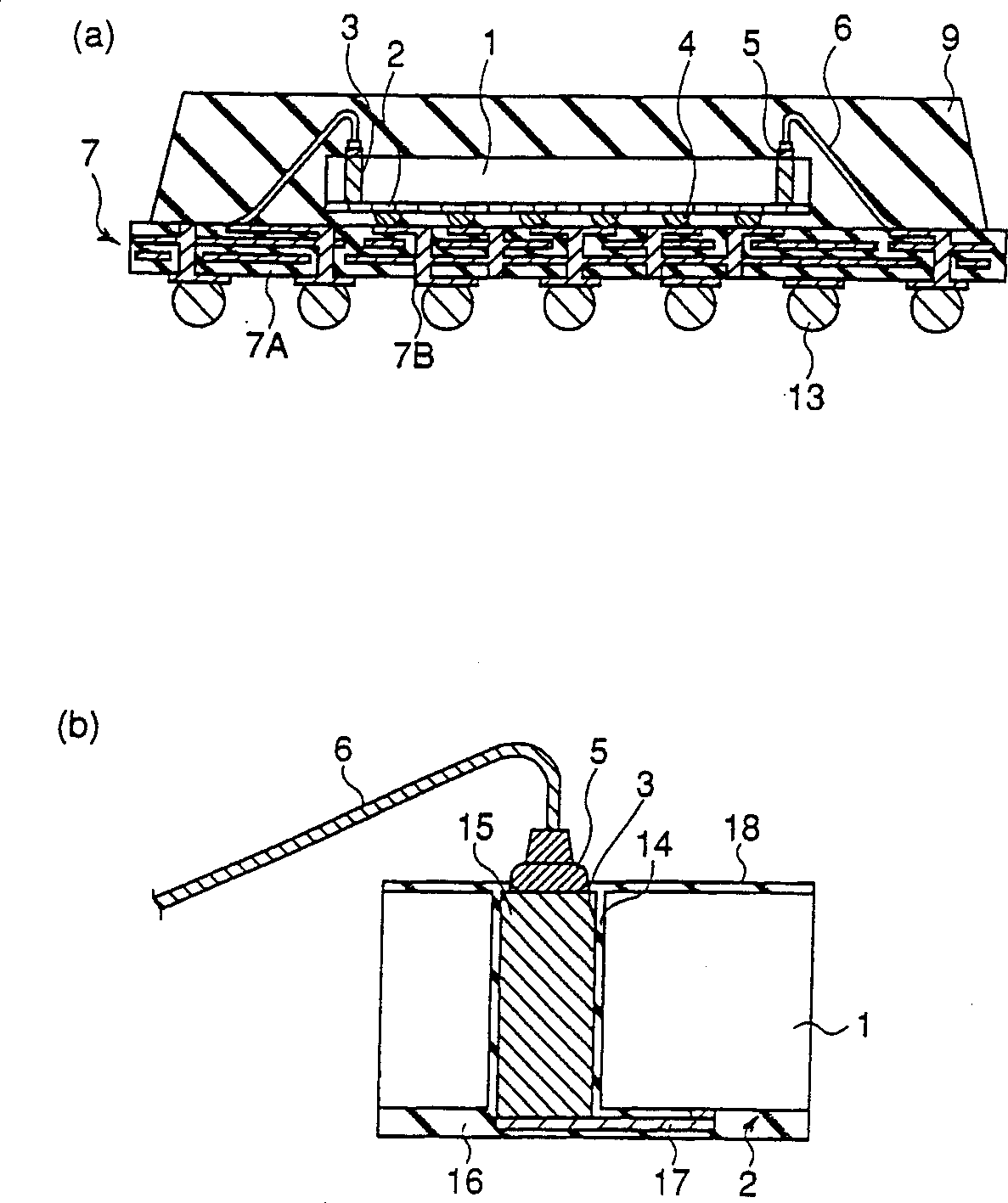

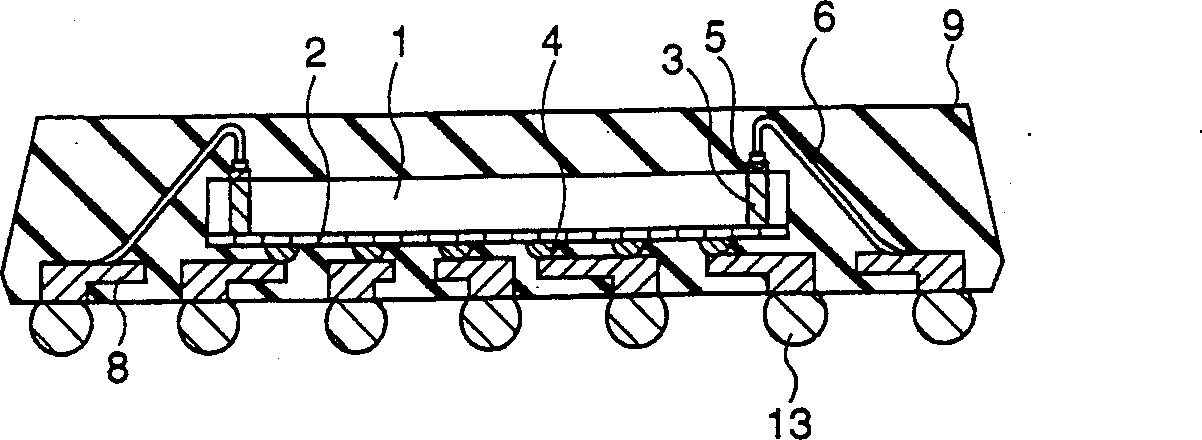

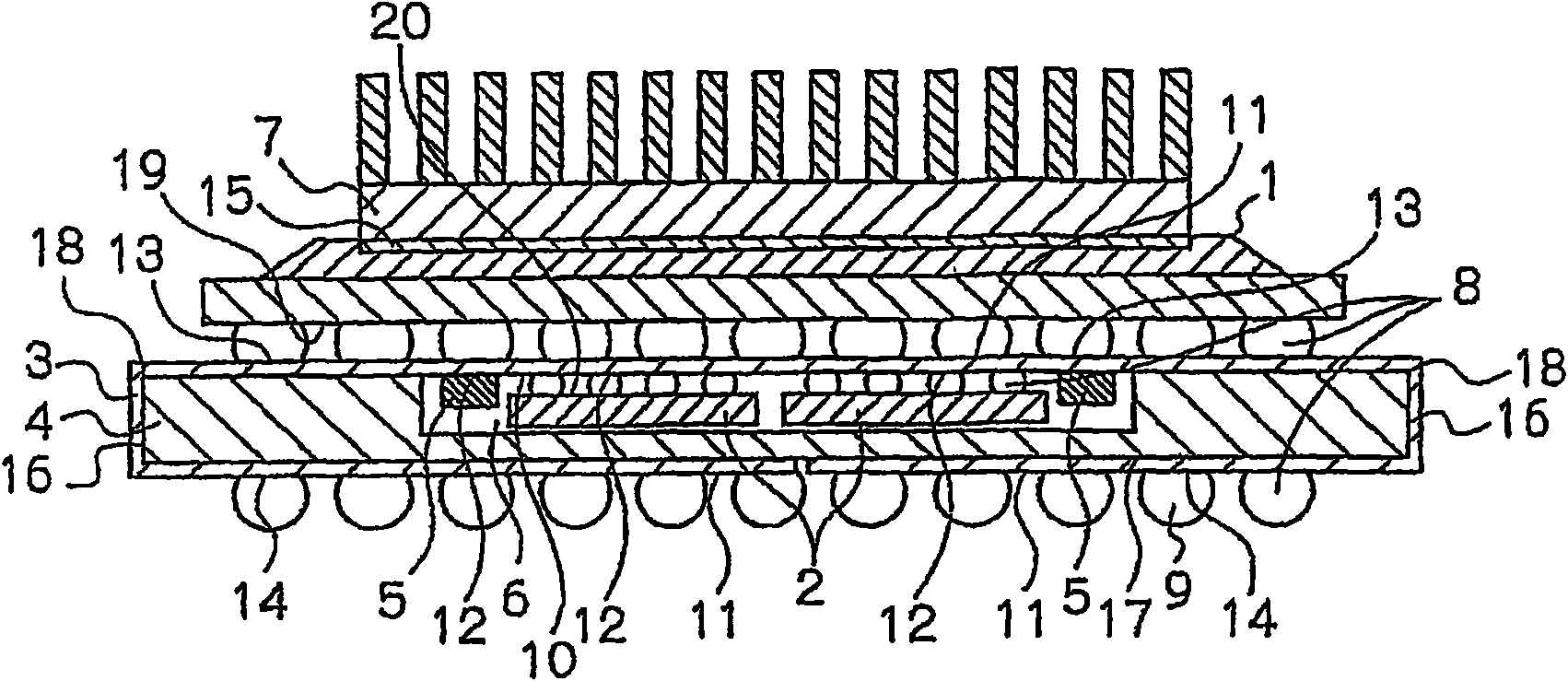

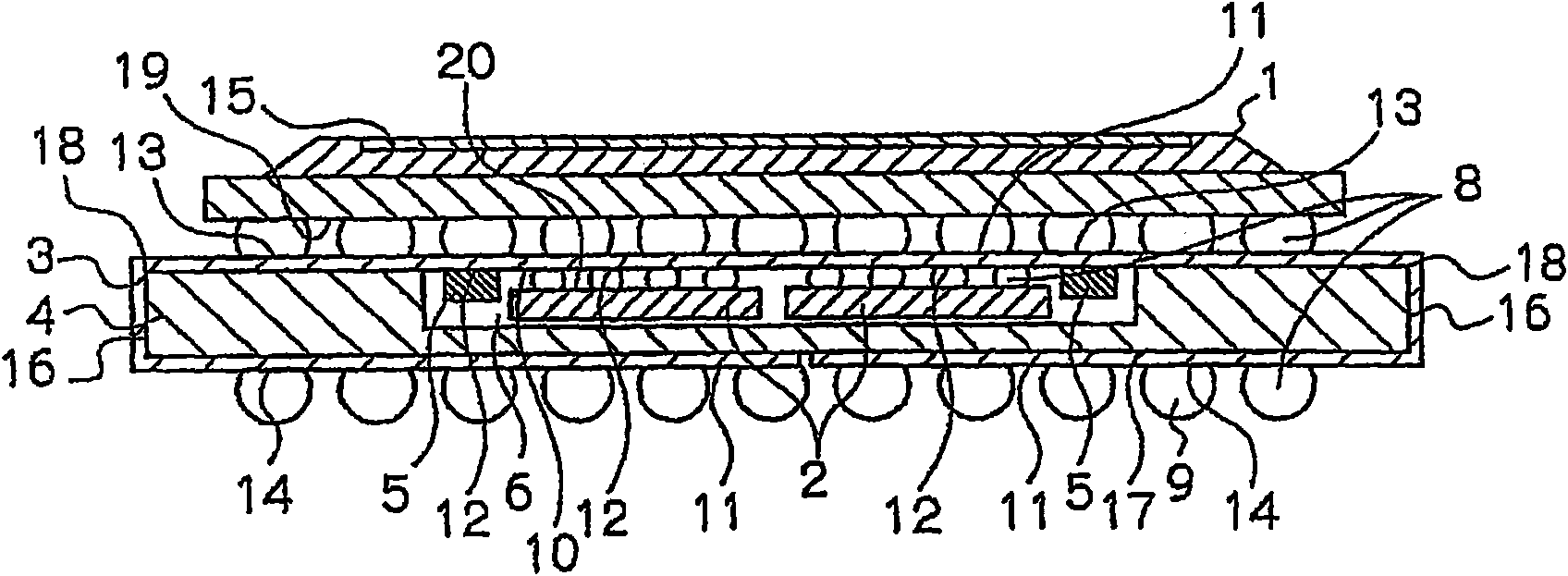

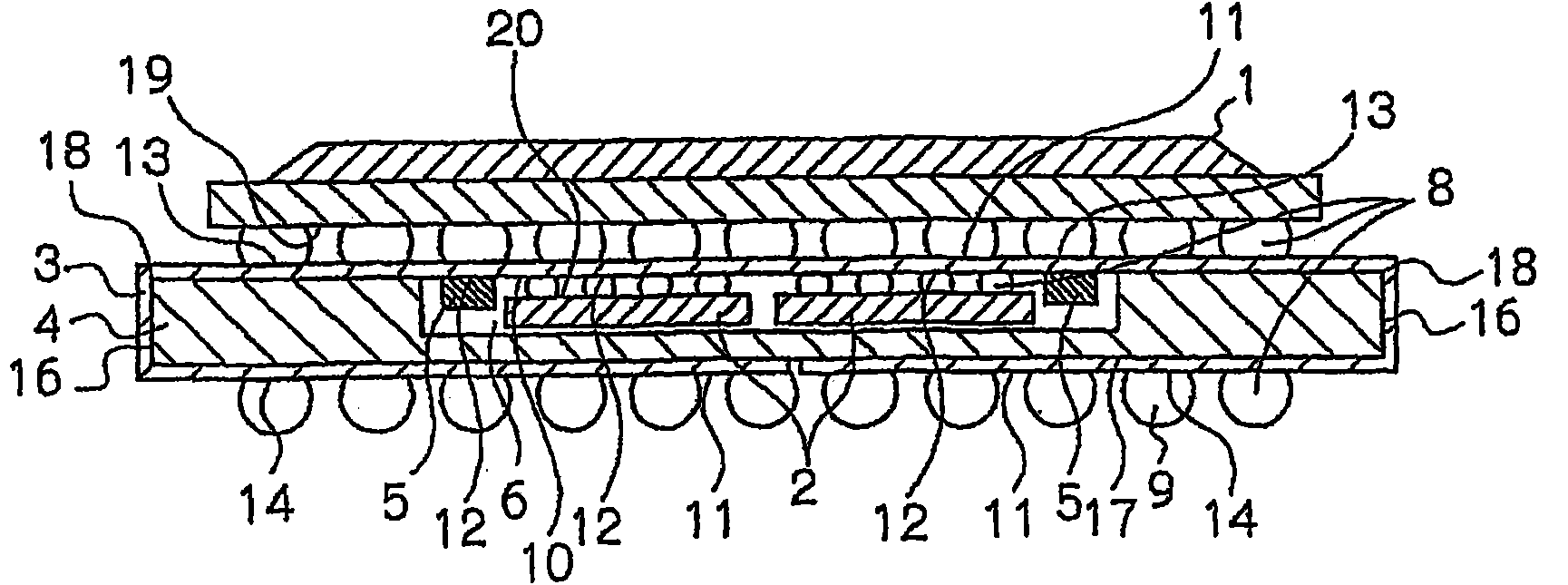

Semiconductor device

InactiveCN1359154AAdd configuration locationIncrease the number of connection terminalsSemiconductor/solid-state device detailsSolid-state devicesPhysicsSemiconductor chip

Owner:KK TOSHIBA

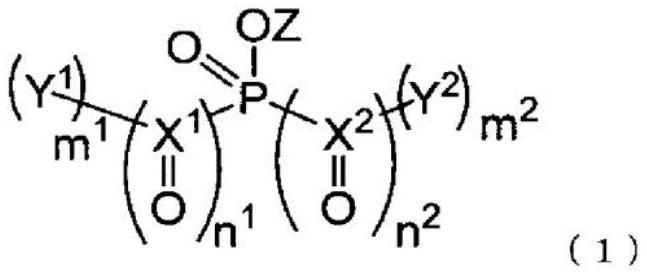

Nonaqueous electrolyte solution and electricity storage device using same

PendingCN111788733AMiniaturizationAchieve high performanceSilicon organic compoundsGroup 5/15 element organic compoundsElectrolytic agentPhysical chemistry

A nonaqueous electrolyte solution which contains an electrolyte, a nonaqueous solvent and a compound represented by formula (1) are provided. (In the formula (1), each of X1 and X2 independently represents C, S or P; each of n1 and n2 independently represents 1 in cases where X1 and X2 are C or P, or represents 2 in cases where X1 and X2 are S; n1 is 1 or 2; n2 is 1 or 2; each Y1 and Y2 independently represents an optionally substituted hydrocarbon group or an -OW group (wherein W represents an optionally substituted hydrocarbon); m1 is 1 or 2; m2 is 1 or 2; and Z represents an optionally substituted hydrocarbon group, an -SiV3 group (wherein V represents an optionally substituted hydrocarbon group), an organic onium or a metal element.)

Owner:MITSUBISHI CHEM CORP +1

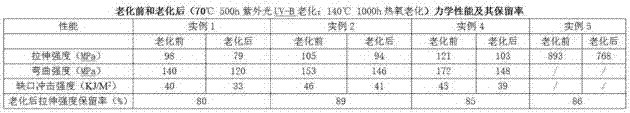

High-weatherability high-flow glass fiber dipping polyolefin formula and preparation method thereof

The invention relates to a high-weatherability high-flow glass fiber dipping polyolefin formula and a preparation method thereof. The high-weatherability high-flow glass fiber dipping polyolefin formula comprises the following components by mass part: 1) 100 parts of polyolefin; 2) 0.5-2 parts of an anti-ultraviolet aging auxiliary agent; 3) 0.5-2 parts of an anti-oxidant; 4) 0.2-2 parts of a flow promoter; 5) 2-10 parts of a flexibilizer; and 6) 1-5 parts of a compatilizer. The components are pre-mixed according to certain proportion, the components are fusion through a double / single screw extruder, then mixed and extruded to a die head for shunting and dipping, and the high-weatherability high-flow glass fiber dipping polyolefin can be prepared. The high-weatherability high-flow glass fiber dipping polyolefin has the advantages that a hyper branched tail end active function group and glass fiber are combined, interface combination capability between polyene resin and glass fiber are enhanced, and the mechanical properties are increased.

Owner:浙江胜钢新材料有限公司

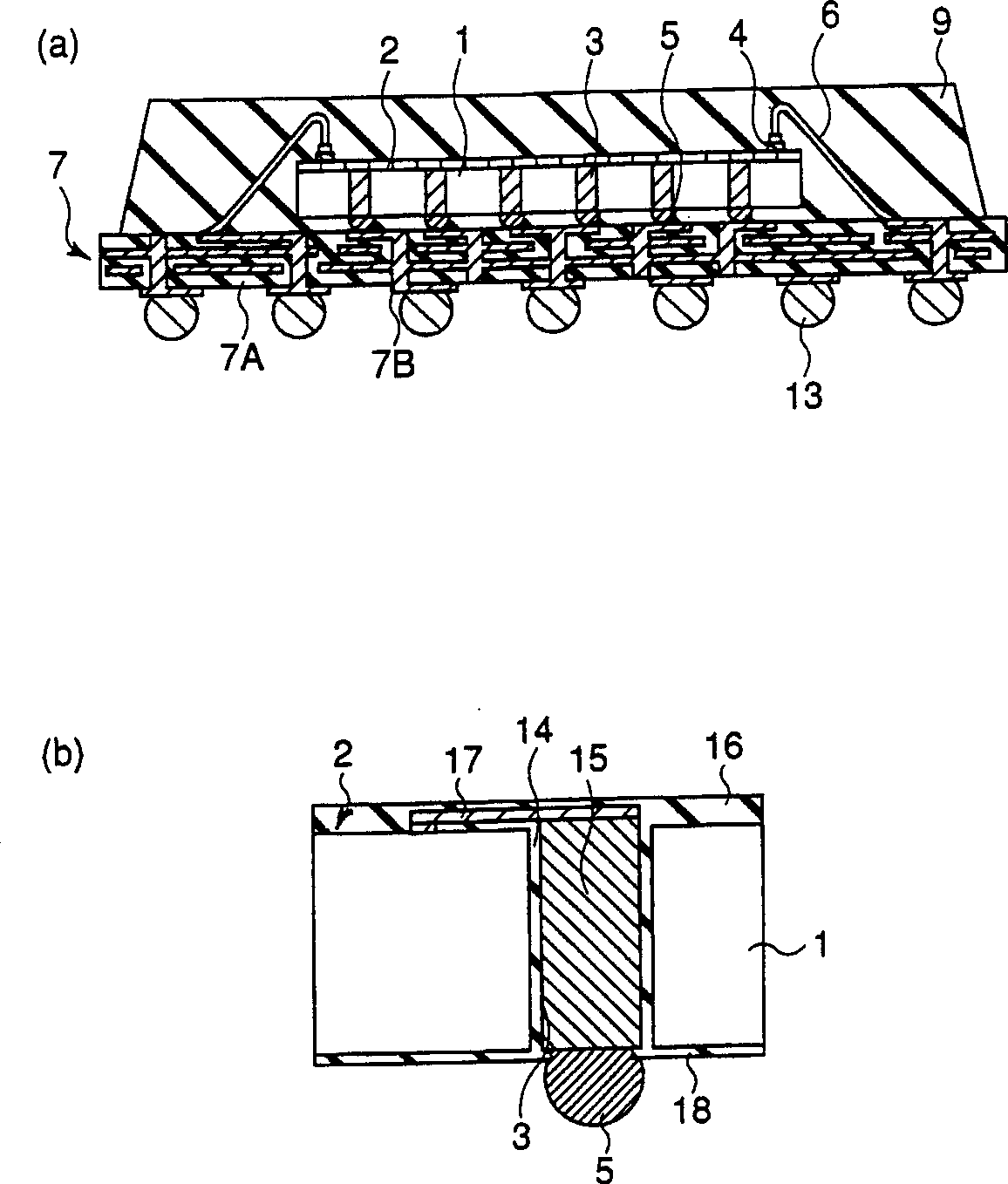

Semiconductor device, semiconductor device manufacturing method, printed circuit board and electronic device

InactiveCN101960591AStable jobImprove flatnessSemiconductor/solid-state device detailsSolid-state devicesFlexible circuitsEngineering

Provided is a semiconductor device which includes a flexible circuit board whereupon a first external electrode is arranged on a first surface and second and third external electrodes are arranged on a second surface; a plurality of memory devices and passive components; a supporting body having a groove on one surface; and an arithmetic processor device. The memory devices and the passive components are connected to the first external electrode, the one surface of the supporting body is bonded on the first surface of the flexible circuit board so that a groove stores the memory devices and the passive components. The flexible circuit board is bent along the periphery of the supporting body, and wraps the side surfaces and the other surface of the supporting body. On the flexible circuit board, the second external electrode is arranged on the second surface which faces the first external electrode, and the third external electrode is arranged on the second surface which is bent to the other surface of the supporting body. The arithmetic processor device is connected to the second external electrode, and a bump is formed on the third external electrode.

Owner:NEC CORP +1

Liquefied consolidated soil and preparation method thereof

The invention belongs to the field of comprehensive utilization of solid wastes, and particularly relates to liquefied consolidated soil and a preparation method thereof. According to the liquefied consolidated soil, soil is used as a main raw material, a cementing material, a dispersing agent, an additive and water in a certain proportion are added, a vibration stirring technology is adopted, aggregate is made to be uniform in macro and micro, a large-flow-state and pumpable liquefied consolidated material is formed, the strength, density and expansion degree are adjustable, and the liquefied consolidated soil is suitable for backfilling of fertilizer grooves, pipe culverts, cavities and abutment backs and reinforcing of building foundations, road subgrade filling, and riverway, lake and coastline embankment reinforcement, seepage prevention and the like. The problems of narrow space, non-uniform compaction of special-shaped end faces, improper non-excavation cavity backfilling and non-uniform mixing of the flow-state solidified soil by using the traditional mixing equipment are solved, and the liquefied consolidated soil has the advantages of no vibration, self compaction, high strength, anti-permeability, seismic resistance, stable volume and environmental protection.

Owner:河南绿岩工程科技有限公司

Polylactic acid composition and preparation method thereof

The invention belongs to the technical field of processing and preparation of a macromolecular material and particularly relates to a polylactic acid composition and a preparation method thereof. Thepolylactic acid composition comprises the following components in parts by weight: 100 parts of polylactic acid, 1 to 15 parts of reduced nanometer carbon oxide material / organic salt microsphere composite powder and 0.02 to 0.30 part of a hydrolysis-resistant agent. The reduced nanometer carbon oxide material / organic salt microsphere composite powder has high compatibility with the polylactic acid, so that the reduced nanometer carbon oxide material is dispersed in the polylactic acid well, the mechanical property of the polylactic acid is improved, and the crystallization property, the processing property, the biodegradability, the heat stability and the like are effectively improved; meanwhile, high electricity-conducing and heat-conducting properties are achieved and the application range of the polylactic acid is enlarged. In the polylactic acid composition prepared by the method, the preparation process is simple and the operation process is easy to implement.

Owner:QINGDAO UNIV OF SCI & TECH

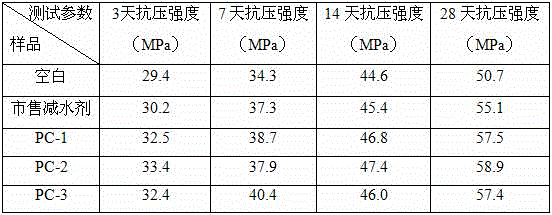

Polycarboxylate high-efficiency water reducer and preparation method thereof

The invention discloses a polycarboxylate high-efficiency water reducer and a preparation method thereof. The preparation method comprises the following steps of at normal temperature, dropwise adding components B, C into a component A, cooling to room temperature after dropwise adding the components, and adjusting the pH value to obtain the polycarboxylate high-efficiency water reducer, wherein the component A is obtained by mixing and stirring polyoxyethylene ether, polyethylene glycol and water and then adding a tin or acid catalyst and hydrogen peroxide; the component B is obtained by mixing acrylic acid, a reducing agent and water; and the component C is obtained by mixing sodium methallyl sulfonate, an initiator and water. The water reducer disclosed by the invention is of a multi-arm branch structure with sufficient arm lengths, so that a steric-hinerance effect can be sufficiently developed, the water reduction performance is high, and the working performance of concrete is improved; and the method disclosed by the invention is mild in reaction condition, simple in technology, few in side reactions, safe, environmentally-friendly, low in energy consumption and low in production cost.

Owner:HUNAN UNIV

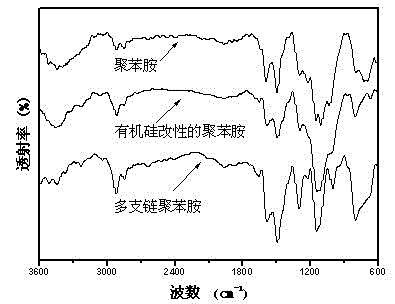

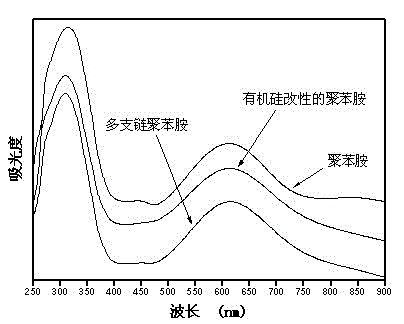

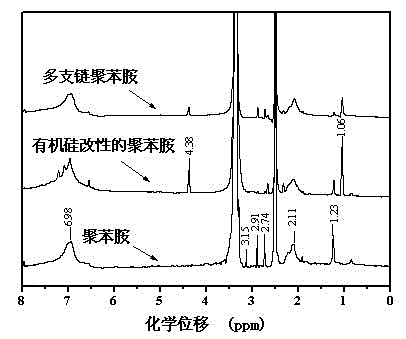

Highly-branched-chain polyaniline modified carbon nanotube/thermosetting resin composite material and preparation method thereof

InactiveCN102875975ARealize decentralized controlControl Dielectric PropertiesMolten stateModified carbon

The invention discloses a highly-branched-chain polyaniline modified carbon nanotube / thermosetting resin composite material and a preparation method thereof. The preparation method comprises the following steps of: dissolving polyaniline in dimethyl sulfoxide, and dropwise adding trialkoxysilane containing epoxide group and hydrochloric acid in dimethyl sulfoxide to obtain organosilicone modified polyaniline; dissolving obtained organosilicone modified polyaniline in dimethyl sulfoxide, and then adding deionized water and hydrochloric acid into dimethyl sulfoxide to obtain highly-branched-chain polyaniline; adding highly-branched-chain polyaniline and carbon nanotubes into the carbon nanotube, and performing suction filter and washing on highly-branched-chain polyaniline and the carbon nanotubes which are settled in methyl alcohol, thus obtaining highly-branched-chain polyaniline modified carbon nanotubes which are mixed with thermocuring resin at a molten state; and curing the carbon nanotubes and the resin to obtain the highly-branched-chain polyaniline modified carbon nanotube / thermosetting resin composite material which has the characteristics of high dielectric constant and low dielectric loss. A conducting layer of the highly-branched-chain polyaniline wraps the surfaces of the carbon nanotubes, and the decentralized control on the carbon nanotubes and the control on dielectric properties of the composite material can be realized by adjusting the content of the surface wrapping layer. The preparation method is easy to implement and suitable for large-scale application.

Owner:SUZHOU UNIV +1

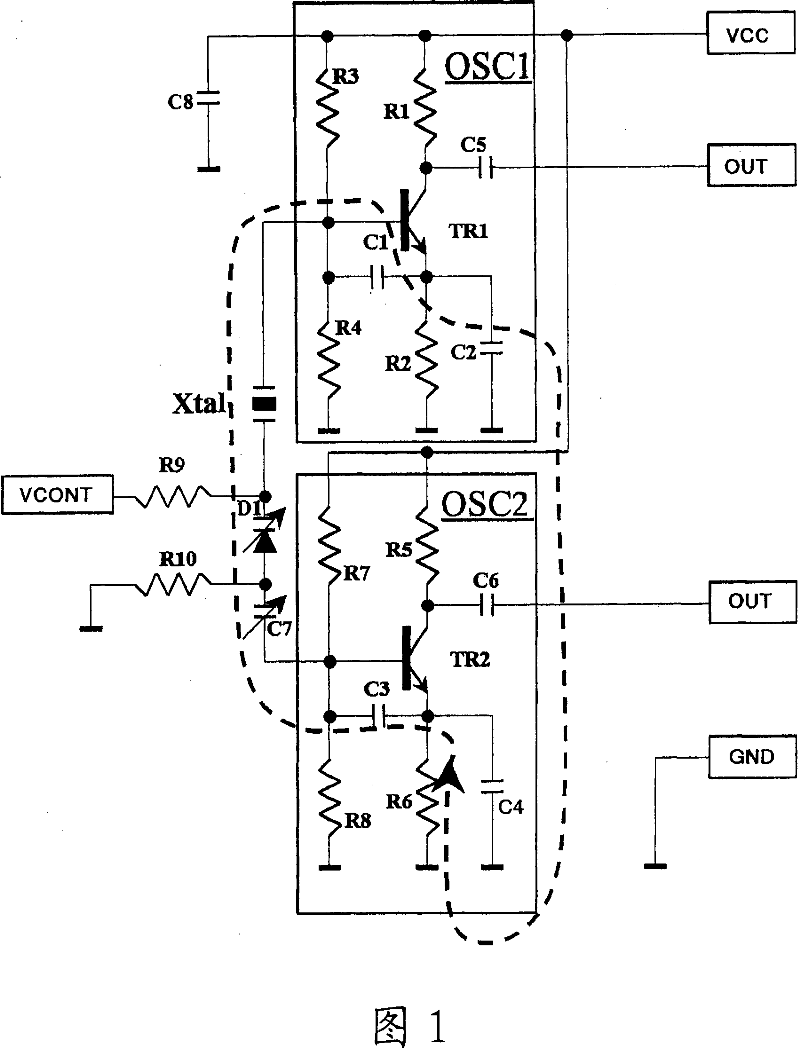

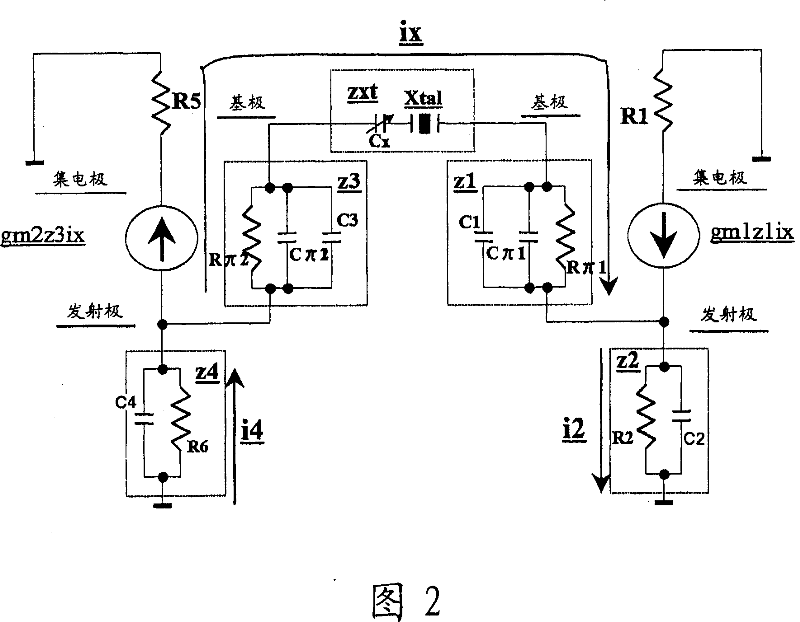

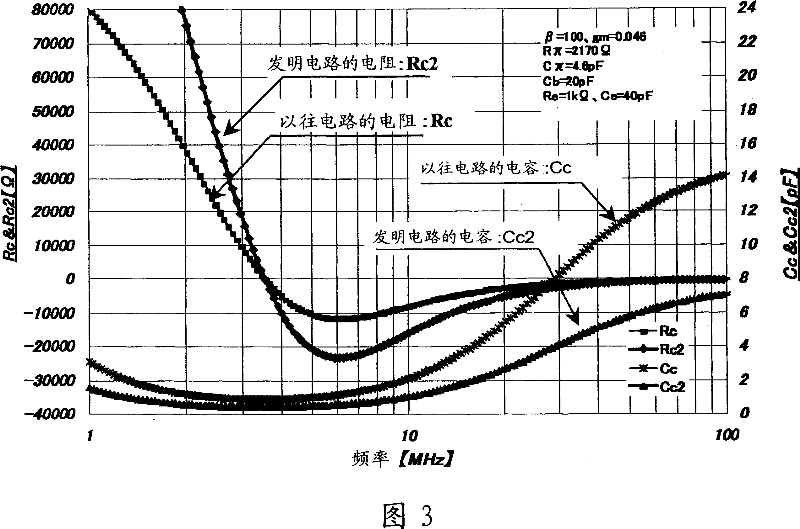

Piezoelectric oscillator

InactiveCN101040433AHigh performanceAchieve high performanceOscillations generatorsDifferential amplifierQuantum electrodynamics

Conventionally, in order to remove in-phase external noise, such as power supply noise and the like, related to a crystal oscillator, one oscillation output is obtained from one oscillator, and then two oscillation outputs, the phases of which are different from each other by 180 degrees, are obtained from that one oscillation output by use of a differential amplifier. However, it was impossible to remove in-phase noise occurring in the oscillator. According to the present invention, a piezoelectric oscillator comprises a piezoelectric vibrator, and first and second oscillator circuits. An input terminal of the first oscillator circuit is connected to one terminal of the piezoelectric vibrator, while an input terminal of the second oscillator circuit is connected to the other terminal of the piezoelectric vibrator. It is arranged that the first and second oscillator circuits provide oscillation outputs whose phases are different from each other by 180 degrees.

Owner:TOYO TSUSHINKI

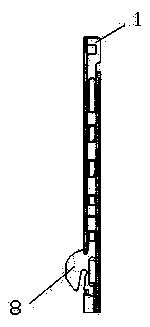

Novel height-adjusting device

InactiveCN107933491APrevent slipping outSolve complex structuresBelt anchoring devicesEngineeringMechanical engineering

The invention discloses a buckle device with a safety belt multi-gear height adjusting function. The buckle device comprises a plate body, chutes, lock catches and a lock pin. Side protecting plates are arranged on the two sides of the plate body, and the adjusting lock catches are arranged in the middles of the side protecting plates at intervals. Triangular grooves are formed in the edges of thelock catches, and the tensile strength of the lock catches is improved. The chutes are formed in the inner sides of the side protecting plates, and sliding blocks are provided with the round-head long lock pins capable of automatically stretching out and drawing back through control by springs. The sliding blocks slide in the chutes, when the lock pins slide to the lock catches, the lock pins automatically drop into the lock catches, clamping is achieved, and certain height adjusting is completed. According to the buckle device, through multiple improved design of plates, the sliding blocks and the chutes, the body weight is greatly reduced, and the lightweight requirement is met; through the structure of the double-row lock catches, clamping is stable and firm, and positioning clamping pieces at the two ends are prevented from slipping out; the potential safety hazard is eliminated, the extreme value reaches, the problem that the structure of an existing height-adjusting device is complex is solved, and the high performance is achieved; and mounting and fixing are conducted through wing clamps, the universality is high, and a novel height-adjusting device is suitable for variousvehicle types.

Owner:YIXING AOHUA AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com