Semiconductor device

A semiconductor and device technology, applied in the field of high-performance semiconductor devices, can solve problems such as voltage drop of semiconductor chips that cannot be solved, and achieve the effect of increasing the number of connection terminals, reducing voltage drop, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

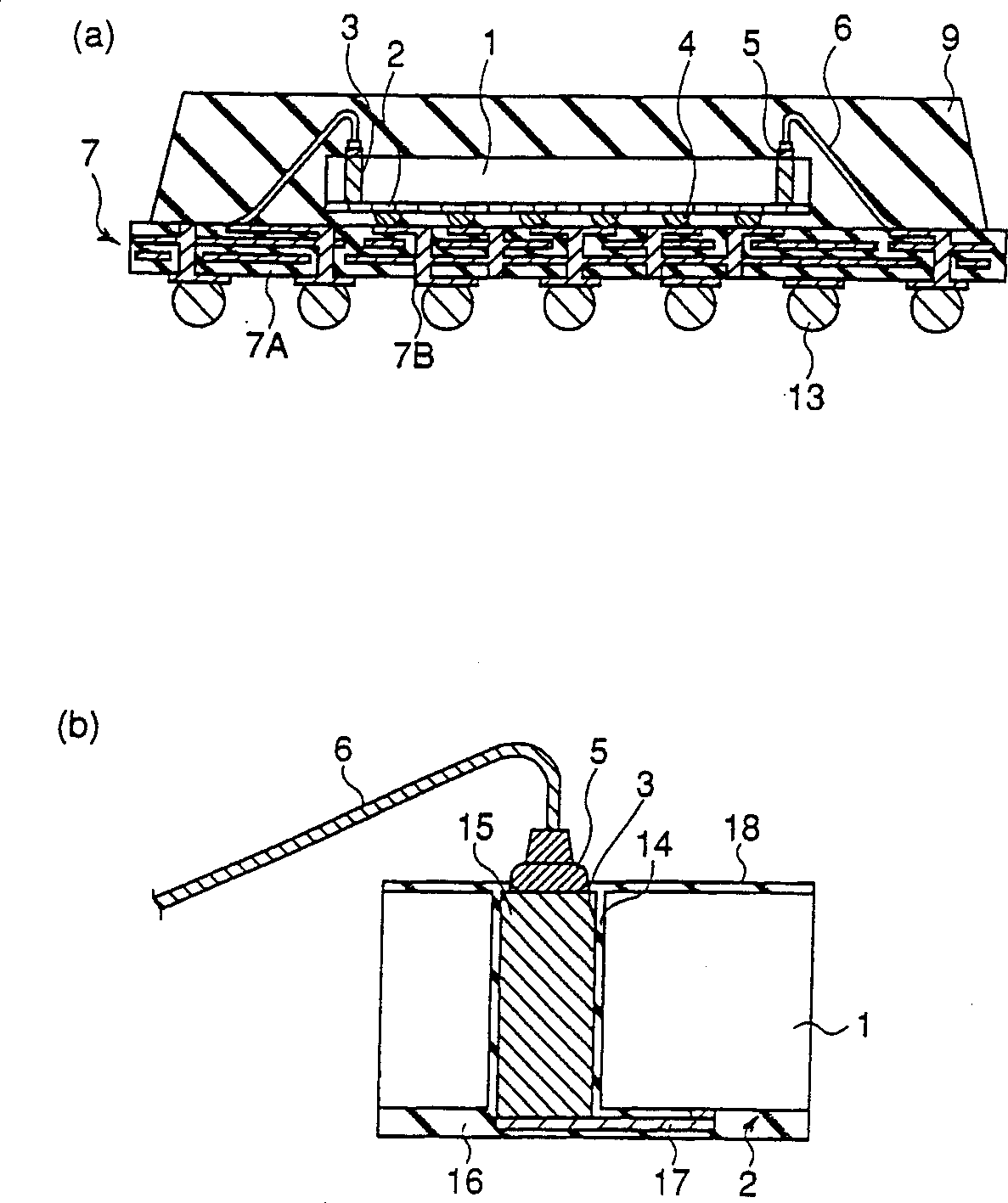

[0080] [First Embodiment]

[0081] figure 1 (a) and (b) respectively illustrate the semiconductor device of the first embodiment of the present invention, (a) is a schematic cross-sectional view, and (b) is a partial enlarged view of (a). As shown in Figure (a), the semiconductor chip 1 is mounted with the formation surface 2 of the semiconductor element (internal circuit) facing the wiring board 7 (face down). The formation surface 2 of the semiconductor element is formed by dispersing connection terminals (conductive bumps) 4 over the entire area (for example, in an array), and is electrically connected to the wiring layer 7B of the wiring board 7 via the connection terminals 4. The wiring board 7 has wiring layers (multilayer wiring) 7B formed on both sides and inside of an insulating substrate 7A made of resin or the like, respectively, and the wiring layer is arranged on the stern corresponding to the bump 4 on the mounting side of the semiconductor chip 1 . The wiring laye...

Example

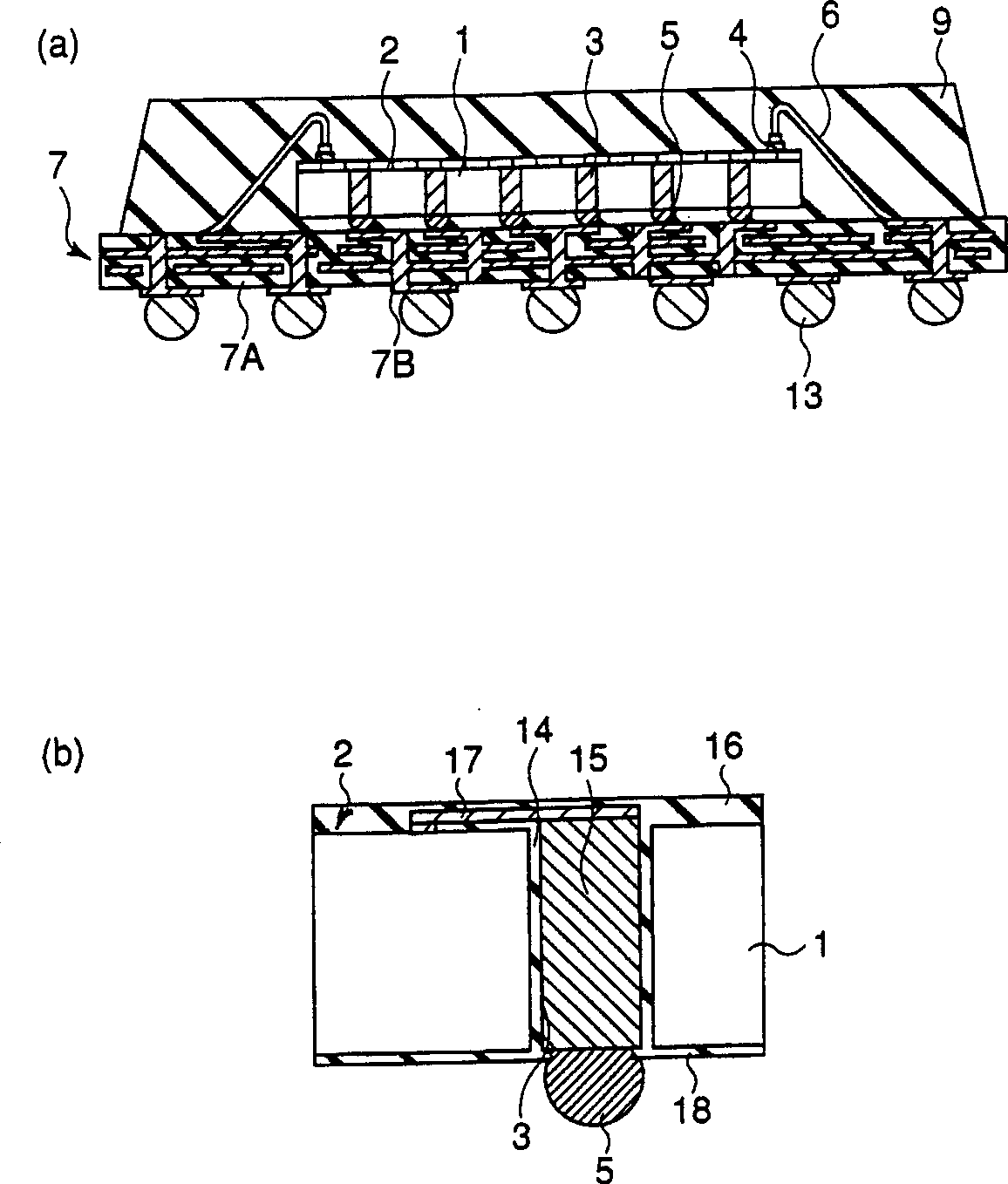

[0087] [Second embodiment]

[0088] figure 2 (a) and (b) respectively illustrate the semiconductor device of the second embodiment of the present invention, (a) is a schematic cross-sectional view, and (b) is a partially enlarged view of (a). In the second embodiment, the semiconductor chip 1 is mounted with the back surface of the semiconductor element forming surface 2 facing the wiring board 7 (face upward). The through holes 3 in which the conductive member 15 is embedded are dispersedly arranged throughout the semiconductor chip 1, and connection terminals (conductive bumps) 5 formed on the back surface of the chip 1 through the through holes 3 are used to connect to the wiring board 7. A connecting terminal (bump) 4 similar to a general semiconductor device is formed on the outer periphery of the semiconductor element forming surface 2 of the semiconductor chip 1, and the connecting terminal 4 is electrically connected to the wiring layer 7B of the wiring board 7 via wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com