Continuous flax fiber bundle surface grafted with nano titanium dioxide as well as preparation method thereof

A nano-titanium dioxide and flax fiber technology, applied in fiber treatment, plant fiber, fibrous filler, etc., can solve the problems of ignoring the properties of polymers and not considering the interaction, so as to achieve high performance and improve interface bonding Performance, the effect of improving the tensile strength of monofilament

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

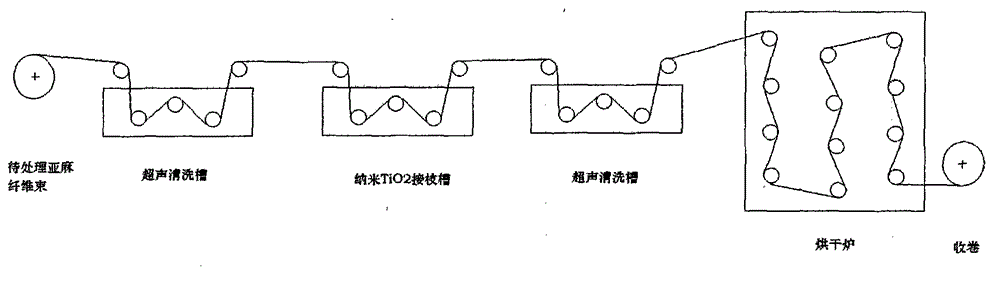

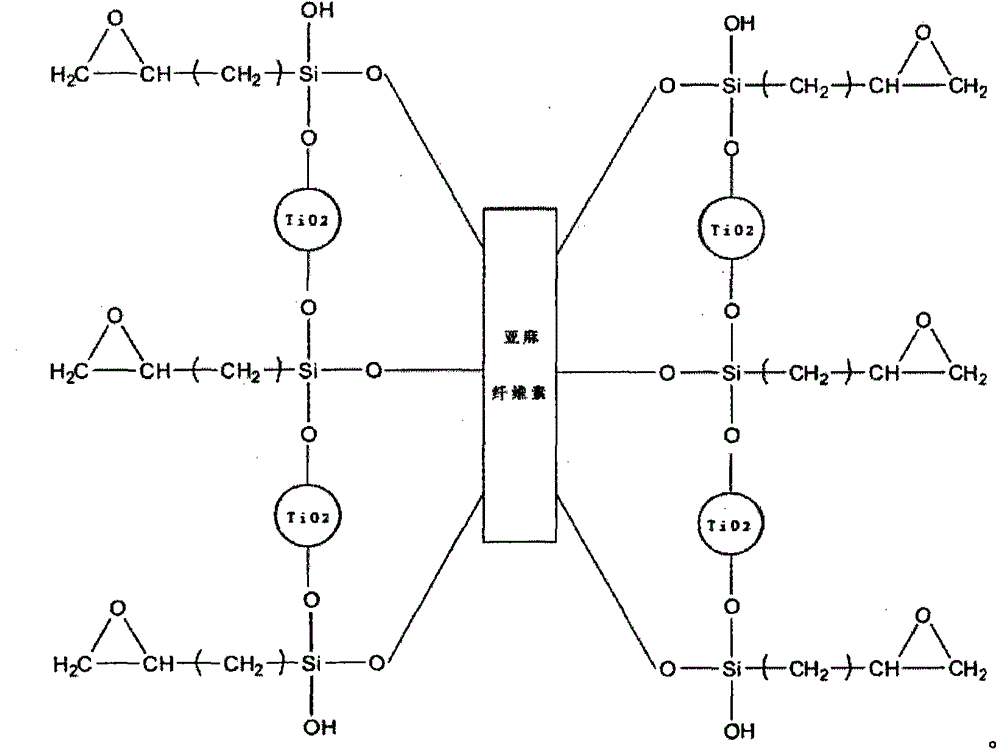

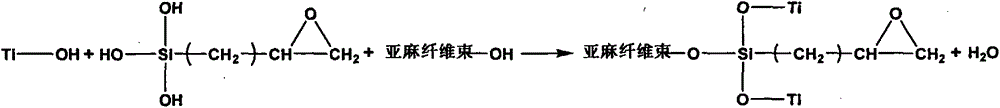

[0024] First prepare nano-titanium dioxide suspension: prepare dehydrated alcohol (Tianjin Fuchen Chemical Reagent Factory, analytically pure grade), silane coupling agent (Nanjing Chengong Organic Silicon Material Co., Ltd., KH-560) by weight ratio 50:10:40 Type γ-(2,3-epoxypropoxy)propyltrimethoxysilane, relative molecular mass 236.34) and distilled water mixed solution, then under stirring at 200 rev / min, gradually add nano titanium dioxide particles with a diameter of 5nm (Zhejiang Hongsheng Material Technology Co., Ltd., HR 3 Type hydrophilic anatase phase nano-TiO 2 , purity > 99%), the mass content of titanium dioxide in the suspension is 0.5%, after complete addition, increase the stirring speed to 1500 rpm, and stir for 60 minutes.

[0025] 24 continuous flax fiber bundles (Harbin Linen Textile Co., Ltd., 15 mid-count twisted wet-spun yarns, 15 twists / 10cm) passed through a distilled water ultrasonic cleaning tank (Shanghai Bilang Instrument Co., Ltd.), and the ultra...

Embodiment 2

[0035] First prepare nano-titanium dioxide suspension: prepare dehydrated alcohol (Tianjin Fuchen Chemical Reagent Factory, analytically pure grade), silane coupling agent (Nanjing Chengong Organic Silicon Material Co., Ltd., KH-560) by weight ratio 90:2:8 Type γ-(2,3-glycidyloxy)propyltrimethoxysilane, relative molecular weight 236.34) and distilled water mixed solution, then under stirring at 1500 rev / min, gradually add nano-titanium dioxide particles with a diameter of 100nm (Zhejiang Hongsheng Material Technology Co., Ltd., HR 3 Type hydrophilic anatase phase nano-TiO 2 , purity > 99%), the mass content of titanium dioxide in the suspension is 15%, after complete addition, increase the stirring speed to 3000 rpm, and stir for 60 minutes.

[0036] 8 continuous flax fiber bundles (Harbin Linen Textile Co., Ltd., 15 mid-count twisted wet-spun yarns, 15 twists / 10cm) passed through a distilled water ultrasonic cleaning tank (Shanghai Bilang Instrument Co., Ltd.), and the ultra...

Embodiment 3

[0046] First prepare nano-titanium dioxide suspension: prepare dehydrated alcohol (Tianjin Fuchen Chemical Reagent Factory, analytically pure grade), silane coupling agent (Nanjing Chengong Organic Silicon Material Co., Ltd., KH-560) by weight ratio 80:10:10 Type γ-(2,3-epoxypropoxy)propyltrimethoxysilane, relative molecular weight 236.34) and distilled water mixed solution, and then under stirring at 1000 rev / min, gradually add nano-titanium dioxide particles with a diameter of 10nm (Zhejiang Hongsheng Material Technology Co., Ltd., HR 3 Type hydrophilic anatase phase nano-TiO 2 , purity > 99%), the mass content of titanium dioxide in the suspension is 5%, after complete addition, increase the stirring speed to 2000 rpm, and stir for 60 minutes.

[0047] 18 continuous flax fiber bundles (Harbin Linen Textile Co., Ltd., 15 mid-count twisted wet-spun yarns, 15 twists / 10cm) passed through a distilled water ultrasonic cleaning tank (Shanghai Bilang Instrument Co., Ltd.), and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com