High-dyeing rate nylon 6 fishing net

A nylon and speed technology, applied in the field of fishing net preparation, can solve the problems of low dyeing fastness, easy fading, slow dyeing rate, etc., and achieve the effects of reducing hydrophobicity, improving the tensile strength of monofilament, and reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

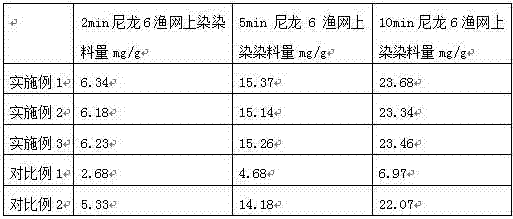

Embodiment 1

[0014] A nylon 6 fishing net with high dyeing rate, which is uniformly mixed with modified nylon 6 98, polyester 6, plasticizer 1.4, and nano-bentonite 0.3 in parts by weight, then melted and extruded by an extruder, cooled and pre-drawn , drafting and setting, winding, thread making, and net weaving to obtain nylon 6 fishing nets;

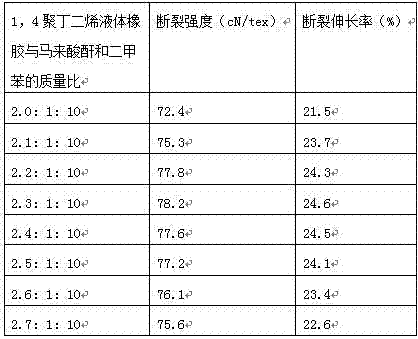

[0015] The preparation method of the modified nylon 6 is as follows: adding 1,4 polybutadiene liquid rubber, maleic anhydride, and xylene to the stirrer, heating in a water bath to 78°C, stirring at a speed of 200r / min for 25min, and then gradually The benzoyl peroxide solution was added dropwise, and the dropwise addition was completed within 20-22 minutes. The total mass of the benzoyl peroxide solution added dropwise was 10% of the mass of the 1,4 polybutadiene liquid rubber, and the temperature was adjusted to 88°C. Stir at a speed of 120r / min for 2 hours to obtain a mixed reaction solution. Add methanol with 80% xylene mass to the mixed react...

Embodiment 2

[0022] A nylon 6 fishing net with high dyeing rate, which is uniformly mixed with modified nylon 6 102, polyester 8, plasticizer 1.6, and nano-bentonite 0.5 in parts by weight, then melted and extruded by an extruder, cooled and pre-drawn , drafting and setting, winding, thread making, and net weaving to obtain nylon 6 fishing nets;

[0023] The preparation method of the modified nylon 6 is as follows: adding 1,4 polybutadiene liquid rubber, maleic anhydride, and xylene to the stirrer, heating in a water bath to 78°C, stirring at a speed of 200r / min for 25min, and then gradually The benzoyl peroxide solution was added dropwise, and the dropwise addition was completed within 20-22 minutes. The total mass of the benzoyl peroxide solution added dropwise was 10% of the mass of the 1,4 polybutadiene liquid rubber, and the temperature was adjusted to 88°C. Stir at a speed of 120r / min for 2 hours to obtain a mixed reaction solution. Add methanol with 80% xylene mass to the mixed reac...

Embodiment 3

[0030] A nylon 6 fishing net with high dyeing rate, which is uniformly mixed with modified nylon 6 100, polyester 7, plasticizer 1.5, and nano-bentonite 0.4 in parts by weight, and then melted and extruded by an extruder, cooled and pre-drawn , drafting and setting, winding, thread making, and net weaving to obtain nylon 6 fishing nets;

[0031] The preparation method of the modified nylon 6 is as follows: adding 1,4 polybutadiene liquid rubber, maleic anhydride, and xylene to the stirrer, heating in a water bath to 78°C, stirring at a speed of 200r / min for 25min, and then gradually The benzoyl peroxide solution was added dropwise, and the dropwise addition was completed within 20-22 minutes. The total mass of the benzoyl peroxide solution added dropwise was 10% of the mass of the 1,4 polybutadiene liquid rubber, and the temperature was adjusted to 88°C. Stir at a speed of 120r / min for 2 hours to obtain a mixed reaction solution. Add methanol with 80% xylene mass to the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com