Starlike high impact polystyrene and preparation method thereof

A polystyrene, high-impact technology, applied in the field of polymer material synthesis and preparation, can solve the problems of large residual monomers, easy decomposition and isomerization of the growing active center, and difficulty in realizing all transformations, and achieves a simplified synthesis route. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a 0.5-liter stainless steel reactor with stirring, add 100 g of cyclohexane, 7.6 g of butadiene (Bd), 3.8 g of styrene (St 1 ), the temperature was raised to 60°C, and the polyao type alkyllithium (m-Li 1 ) initiator 0.076mmol, so that the single-arm number average molecular weight of the butadiene block is 10×10 4 , when the polymerization reaction is carried out to 3 hours, the polymerization reaction of butadiene and styrene is completely completed, and a certain amount of anionic polymerization retarder triisobutylaluminum i-Bu is added 3 Al(TIBA) 0.352mmol, then add 150 grams of cyclohexane and 36.4 grams of styrene (St 2 ), after stirring and mixing evenly, add polyao type alkyllithium (m-Li 2 ) Initiator 0.364mmol, continue to react for 4 hours, after the styrene polymerization reaction is all completed, add terminator to end the reaction, add anti-aging agent (Irganox 1010 and 2.6.4 are mixed with 1: 1 by weight) 1 gram, adopt traditional method The glue s...

Embodiment 2-7

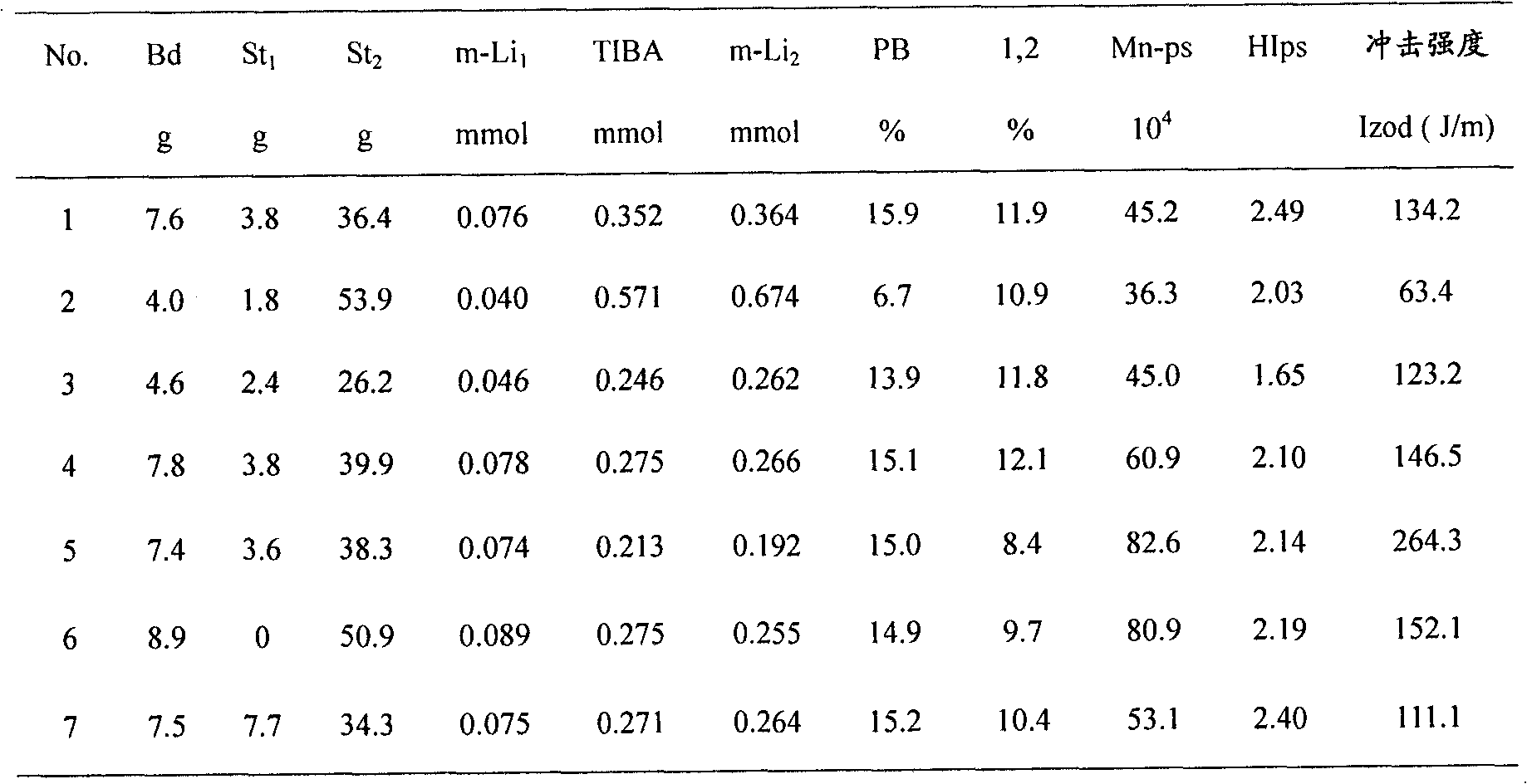

[0022] Polymerization method and process condition are the same as embodiment 1, just butadiene, styrene monomer ratio are different, the consumption of the first and second time polyao type alkyllithium initiators is different, retarder triisobutylaluminum Star-shaped high-impact polystyrene was prepared with different dosages. The polymerization process conditions, product structure and physical property test results are shown in No.2-7 in Table 1, respectively.

[0023] Table 1. Structure and properties of star-shaped high-impact polystyrene

[0024]

[0025] Note: Mn-ps and HIps are star polystyrene molecular weight and molecular weight distribution index measured by gel permeation chromatography (GPC), PB% is polybutadiene content, 1, 2% is polybutadiene Vinyl content in alkenes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com