Lithium ion rechargeable battery and process for poducing the rechargeable battery

A technology for secondary batteries and manufacturing methods, applied in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of peeling of the bonding interface, inability to manufacture high-performance batteries, and inability to densify various components, and prevent delamination. layer, the effect of realizing high performance and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

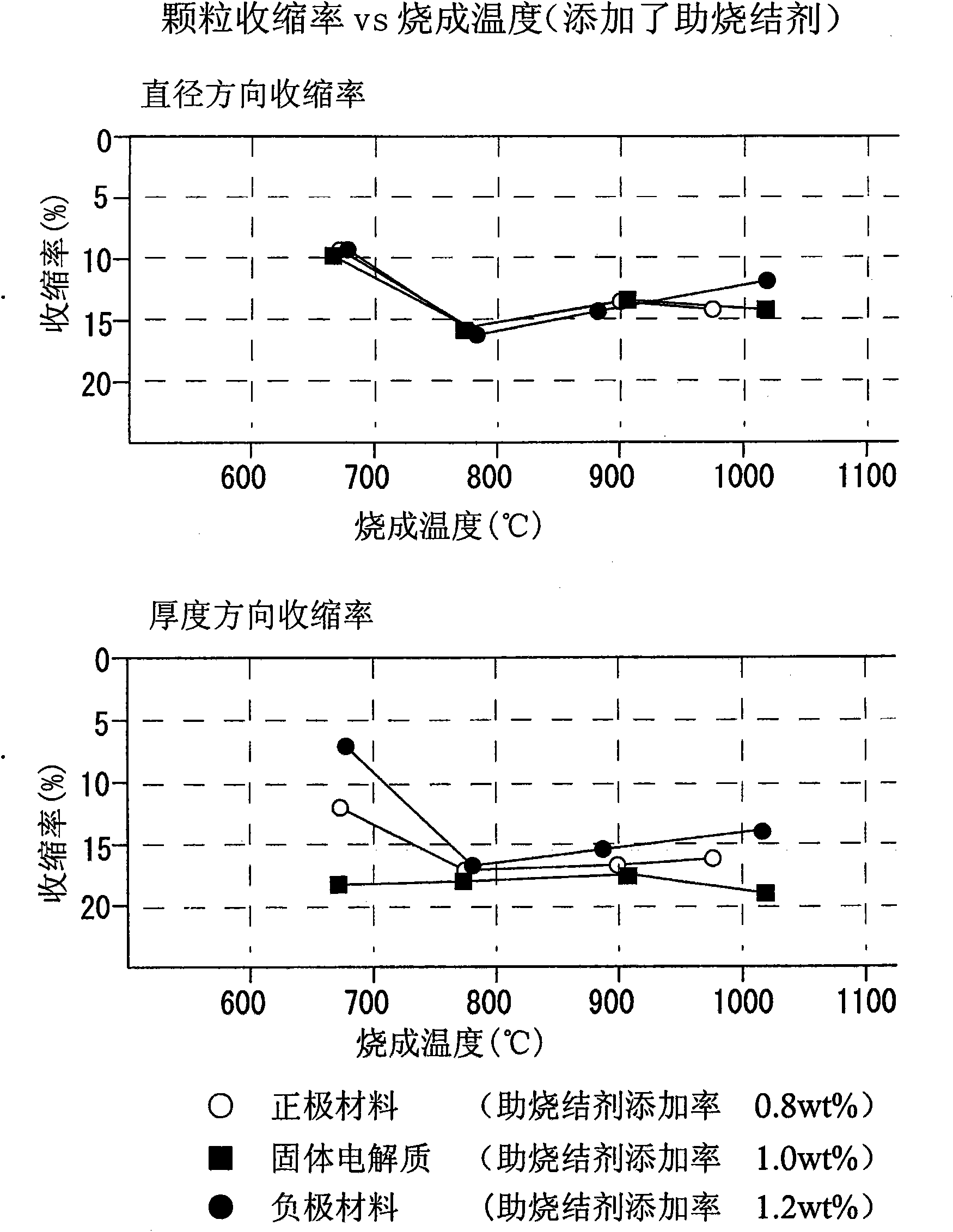

[0108] [Adjust shrinkage by adding sintering aid]

[0109] A sintering aid is added to the positive electrode material, solid electrolyte material, and negative electrode material constituting the lithium-ion secondary battery to produce pellets, and the shrinkage of the pellets caused by firing is measured, and the cross-section is observed by SEM.

[0110] (production of samples)

[0111] The samples used this time are figure 1 The shrinkage shown was evaluated for the same specimens tested. The method of preparing the sample will be described in more detail below.

[0112] The positive electrode material is represented by the chemical formula as LiMnO 2 The substance, MnCO manufactured by Chuo Denki Kogyo 3 ・(C2-SP) and Li manufactured by Nippon Chemical Industries 2 CO 3 It was synthesized as a raw material and pre-baked at 800° C. for 2 hours. The solid electrolyte material is represented by the chemical formula Li 7 PSiO 8 The substance, Li manufactured by Wako ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com