Polylactic acid composition and preparation method thereof

A technology of polylactic acid and its composition, which is applied in the field of polymer material processing and preparation, can solve the problems of easy agglomeration, difficulty in uniform dispersion, low interfacial bonding strength, difficulties in research and application, etc., and achieve good hydrophilicity, excellent mechanical properties, broaden the The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

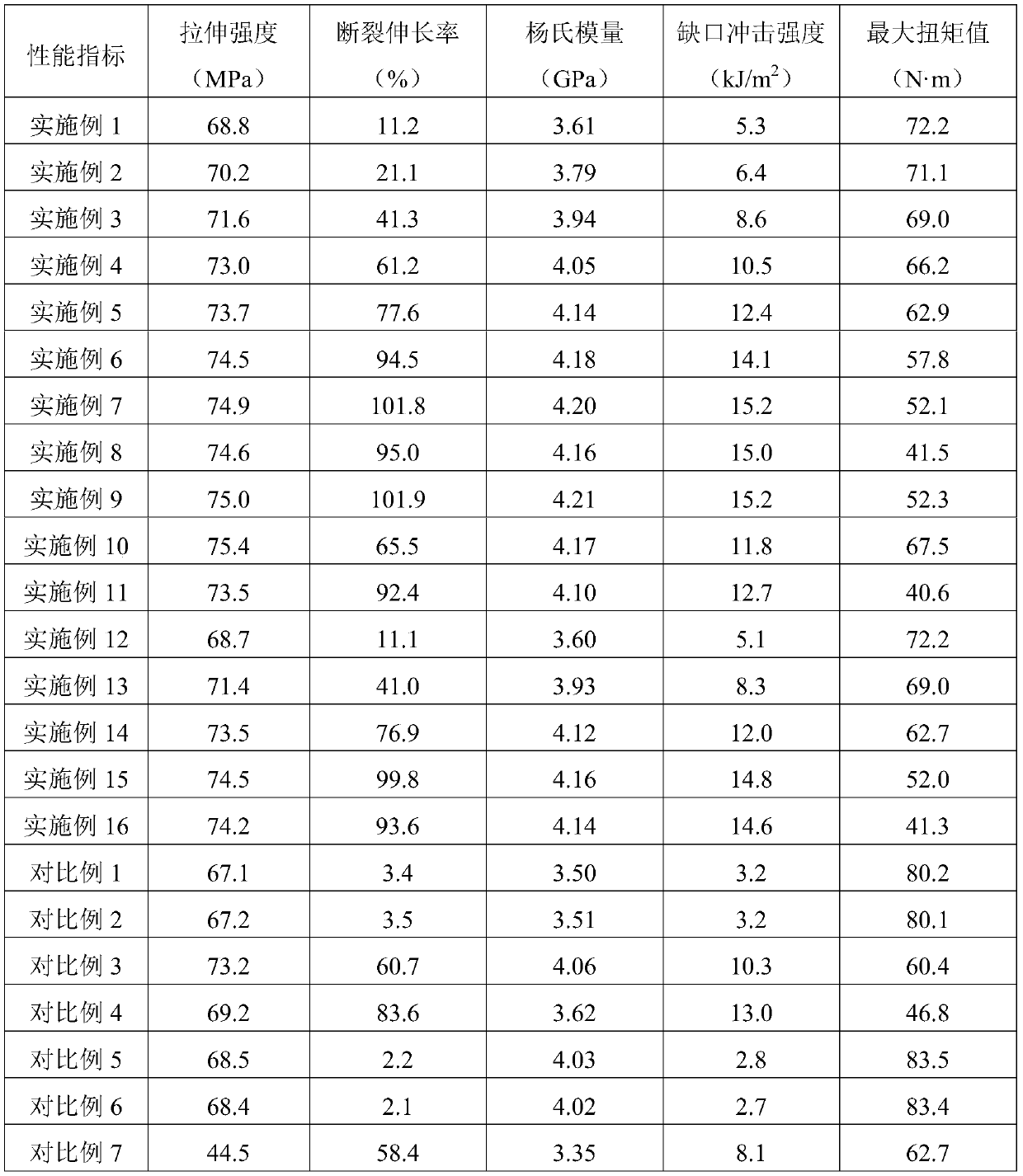

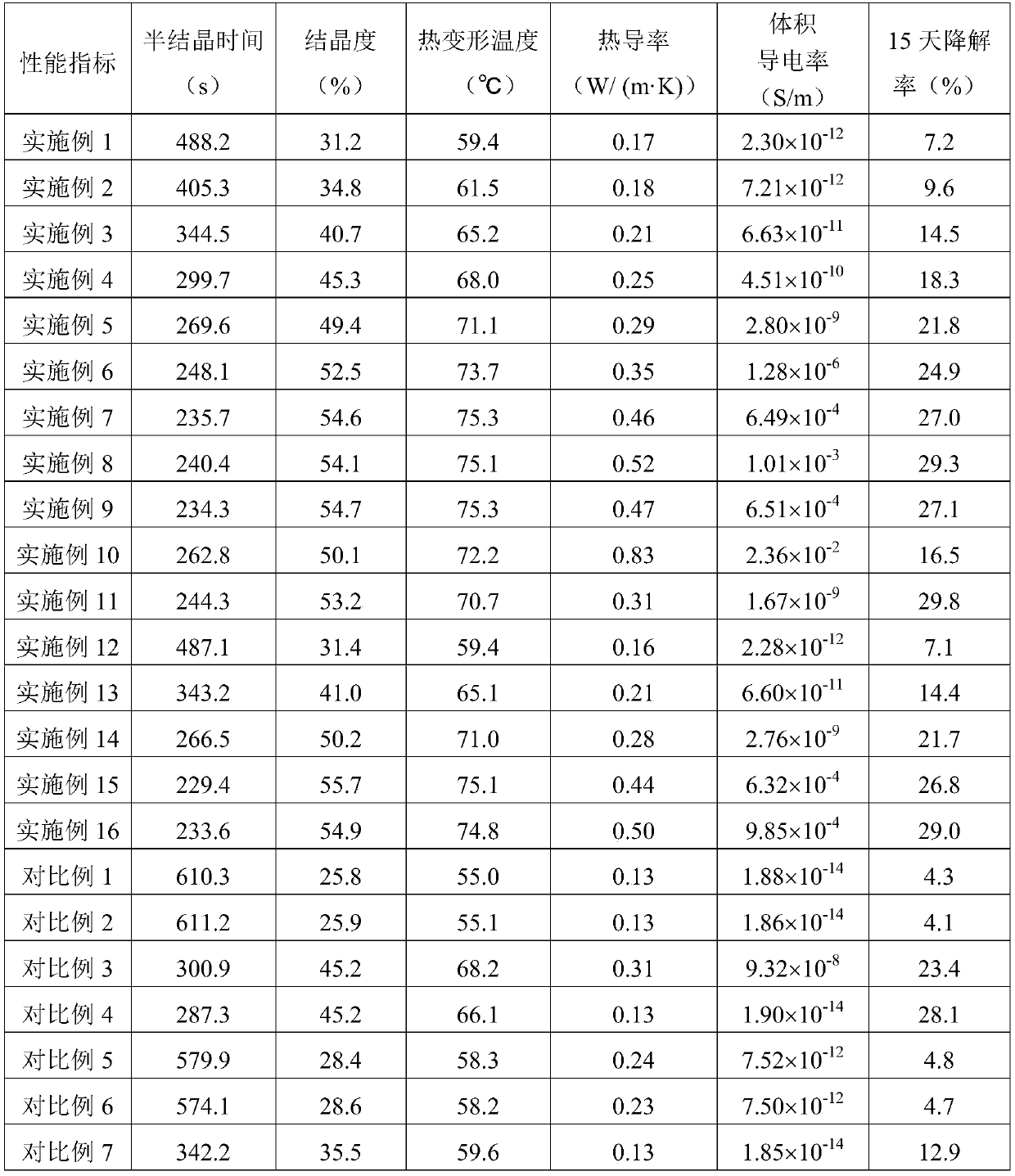

Examples

Embodiment 1

[0049] Dry 100 parts (mass parts, the same below) of poly-L-lactic acid, 1 part of reduced graphene oxide / organic salt microsphere composite powder, and 0.02 part of carbodiimide anti-hydrolysis agent UN-150 in a Hack torque The polylactic acid composition was prepared by high temperature melt blending in a rheometer.

[0050] Torque rheometer processing conditions: working temperature 180°C, rotating speed 60rpm, mixing for 10min until the mixing torque is balanced.

[0051] Wherein, the preparation method of the reduced graphene oxide / organic salt microsphere composite powder is as follows:

[0052] 1. Add 16.37g (0.215mol) 1,3-propanediol, 18.93g (0.210mol) 1,4-butanediol, 7.00g ( 0.035mol) PEG-200, 5.37g (0.040mol) dipropylene glycol and 19.49g (0.165mol) succinic acid, 33.38g (0.165mol) sebacic acid, 17.57g (0.135mol) itaconic acid, 15.67g (0.135mol) fumaric acid, then add 66.9mg antioxidant 1010, 66.9mg antioxidant 168 and 133.8mg hydroquinone, stir and heat up to 170°...

Embodiment 2

[0060] 100 parts of dry poly-L-lactic acid, 2 parts of reduced graphene oxide / organic salt microsphere composite powder, and 0.04 part of carbodiimide anti-hydrolysis agent UN-150 were melted together in a Haake torque rheometer at high temperature. The polylactic acid composition was prepared in a mixed manner.

[0061] Torque rheometer processing conditions: working temperature 180°C, rotating speed 60rpm, mixing for 10min until the mixing torque is balanced.

Embodiment 3

[0063] 100 parts of dry poly-L-lactic acid, 4 parts of reduced graphene oxide / organic salt microsphere composite powder, and 0.08 part of carbodiimide anti-hydrolysis agent UN-150 were co-melted at high temperature in a Haake torque rheometer. The polylactic acid composition was prepared in a mixed manner.

[0064] Torque rheometer processing conditions: working temperature 180°C, rotating speed 60rpm, mixing for 10min until the mixing torque is balanced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com