Method for preparing meso-scale flaky vermiculite and heat-resistant polymer heat insulation composite membrane

A technology of high-temperature-resistant polymer and flaky vermiculite, which is applied in the field of preparation of mesoscopic-scale flaky vermiculite and high-temperature-resistant polymer heat-insulating composite film, can solve the problems of limited application and poor heat insulation performance, and achieve improved Maximum operating temperature, high performance, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

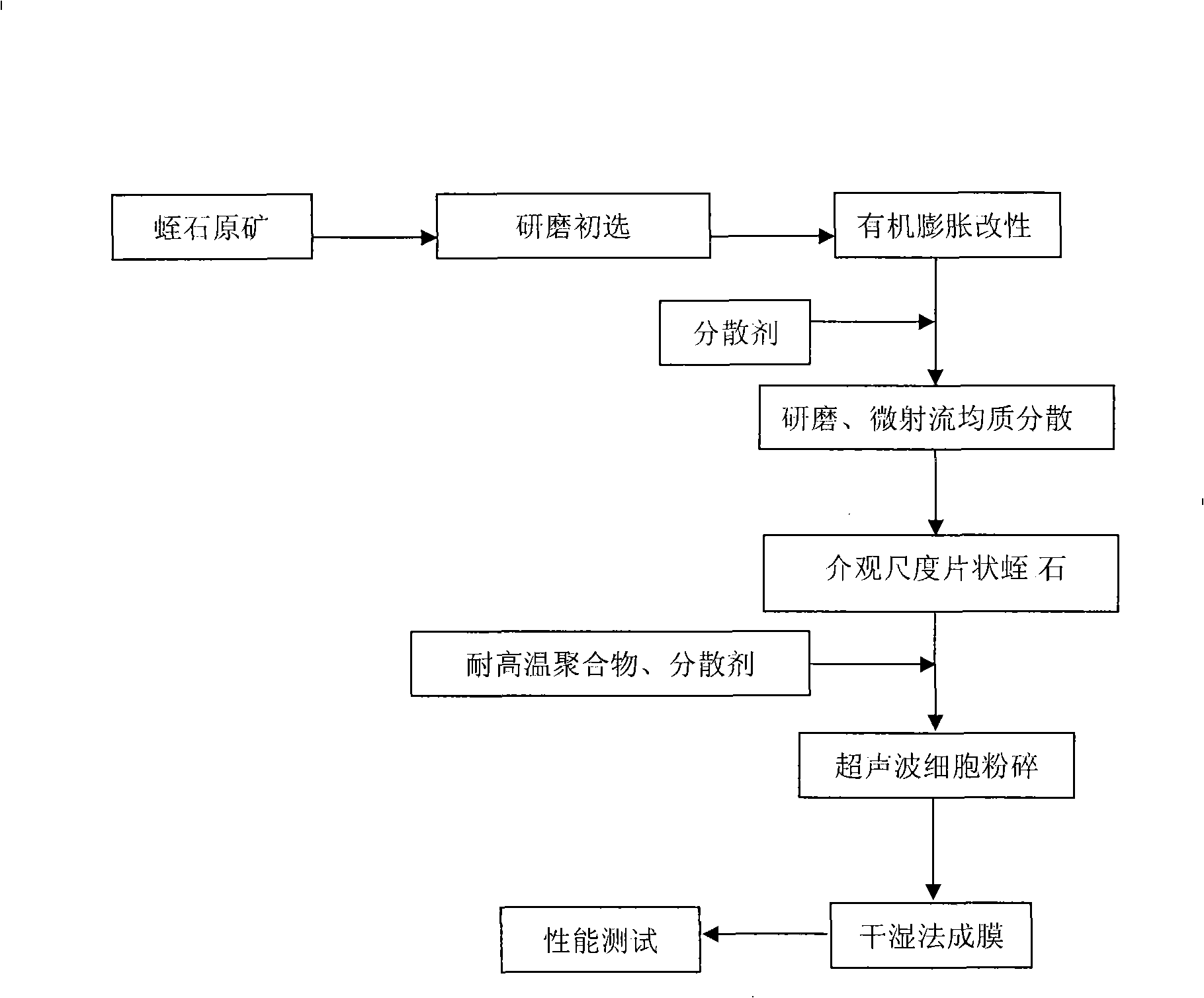

[0025] see figure 1 The present invention can be divided into following steps:

[0026] Step 1. Use zirconia balls with a diameter of 2 to 3 mm to grind the raw vermiculite in a sand mill for 8 hours, then screen out the vermiculite with a particle size of less than 10 μm, and then dry it naturally;

[0027] Step 2. Soak the vermiculite obtained in step 1 in twice-distilled water, add 4 times the amount of dodecyltrimethylammonium chloride for cation exchange, and stir for 6 hours at a temperature of 80°C. Carry out organic expansion modification to the screened vermiculite;

[0028] Step 3, repeatedly washing the vermiculite obtained by step 2 with deionized water until there is no Br - , Cl - Exist, then dry naturally;

[0029] Step 4, taking the weight of the vermiculite obtained in step 3 as 100%, soaking it in 20 times of double distilled water, and then adding 20% of sodium lauryl sulfate;

[0030] Step 5, use zirconia balls with a diameter of 1 mm to grind the ve...

Embodiment 2

[0036] Step 1, grind the raw vermiculite ore with a basket mill for 100 hours, then screen out the vermiculite with a particle size less than 10um, and then dry it naturally;

[0037] Step 2. Soak the vermiculite obtained in step 1 in twice-distilled water, add cetyltrimethylammonium bromide in an amount 8 times the amount of cation exchange, and stir for 100 hours at a temperature of 50°C. Carry out organic expansion modification to the screened vermiculite;

[0038] Step 3, repeatedly washing the vermiculite obtained by step 2 with deionized water until there is no Br - , Cl - Exist, then dry naturally;

[0039] Step 4, taking the weight of the vermiculite obtained in step 3 as 100%, soaking it in 10 times double distilled water, and then adding dispersant FZ100%;

[0040] Step 5, grind the vermiculite aqueous dispersion system obtained by step 4 with a basket mill for 2 hours, then process it 50 times with high-pressure micro-jet homogenization equipment, centrifuge, and...

Embodiment 3

[0046] Step 1. Grind the raw vermiculite with a pulverizer for 2 hours, then screen out the vermiculite with a particle size of less than 10um, and then dry it naturally;

[0047] Step 2. Soak the vermiculite obtained in step 1 in double distilled water, add docosyltrimethylammonium chloride in an amount of 1 times the amount of cation exchange, and stir and react for 12 hours at a temperature of 80°C , carrying out organic expansion modification to the screened vermiculite;

[0048] Step 3, repeatedly washing the vermiculite obtained by step 2 with deionized water until there is no Br - , Cl - Exist, then dry naturally;

[0049] Step 4, taking the vermiculite weight obtained by step 3 as 100%, dipping in 30 times of twice distilled water, then adding 30% of sodium hexametaphosphate;

[0050] Step 5. Grind the vermiculite obtained in step 4 with a pulverizer for 100 hours, then process it once with high-pressure micro-jet homogenization equipment, centrifuge, and vacuum-dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com