Continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material and preparation thereof

A heat-conducting composite material, polypropylene technology, applied in heat-conducting composite materials and its preparation, continuous carbon fiber reinforced polypropylene high-performance conductive field, can solve problems such as limited applications, achieve excellent mechanical properties, broad market prospects, and improve flow performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

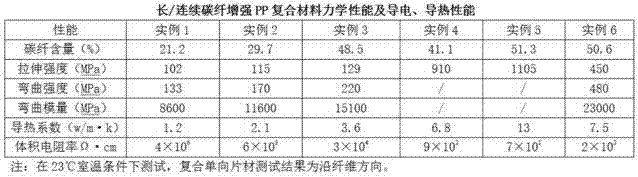

Examples

specific Embodiment 1

[0030] A continuous carbon fiber reinforced polypropylene high-performance conductive and thermally conductive composite material. According to the weight of the material, the formula includes: homopolypropylene resin 100 kg, melt index 40g / 10min; antioxidant 1010 0.1kg; hyperbranched polymer Hyper C100T 0.2kg, ethylene-octene copolymer POE 2kg, PP grafted glycidyl methacrylate PP-g-GMA 1kg.

[0031] A method for preparing a continuous carbon fiber reinforced polypropylene high-performance conductive and thermally conductive composite material, comprising the following steps: after premixing the above components according to a certain proportion, melt mixing and extruding them into a "hanger" type die through a single screw unit Divide the flow, and finally enter the "S" type die to fully impregnate the carbon fiber, and the strands are cooled and granulated by cooling water to produce long carbon fiber reinforced thermoplastic particles LCFRT, with a carbon fiber content of 20...

specific Embodiment 2

[0034] A continuous carbon fiber reinforced polypropylene high-performance conductive and thermally conductive composite material. According to the weight of the material, the formula includes: homopolypropylene resin 100 kg, melt index 60g / 10min; antioxidant 1010 0.2kg, antioxidant 168 0.2kg , antioxidant DSTP0.6kg; hyperbranched polymer Hyper C100T 2 kg, ethylene vinyl acetate EVA 5kg, PP grafted maleic anhydride PP-g-MAH 3kg.

[0035] A method for preparing a continuous carbon fiber reinforced polypropylene high-performance conductive and thermally conductive composite material, comprising the following steps: after premixing the above components according to a certain proportion, melt mixing and extruding them into a "hanger" type die through a single screw unit Divide the flow, and finally enter the "S" type die to fully impregnate the carbon fiber, and the strands are cooled and granulated by cooling water to produce long carbon fiber reinforced thermoplastic particles LC...

specific Embodiment 3

[0038]A continuous carbon fiber reinforced polypropylene high-performance conductive and thermally conductive composite material. The formula includes: 70 kg of homopolymerized PP resin, 100 g / 10 min of melt index, 30 kg of copolymerized PP resin, 60 g / 10 min of melt index; Agent 1010 0.4kg, antioxidant 168 0.1kg, antioxidant PAT218 0.2kg; hyperbranched polymer CYD-2136PE 1.2 kg, ethylene-octene copolymer POE 6kg, PP grafted maleic anhydride PP-g-MAH 5kg .

[0039] A method for preparing a continuous carbon fiber reinforced polypropylene high-performance conductive and thermally conductive composite material, comprising the following steps: after premixing the above components according to a certain ratio, melt and mix them through a twin-screw unit and extrude them into a "hanger" type die Divide the flow, and finally enter the "S" type die to fully impregnate the carbon fiber, and the strands are cooled and granulated by cooling water to produce long carbon fiber reinforced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com