Preparation method and use of millimetre-sized mesoporous carbon spheres

A millimeter-scale, mesoporous carbon technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of low adsorption rate, low specific surface area, low adsorption capacity, etc. Simple method conditions and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

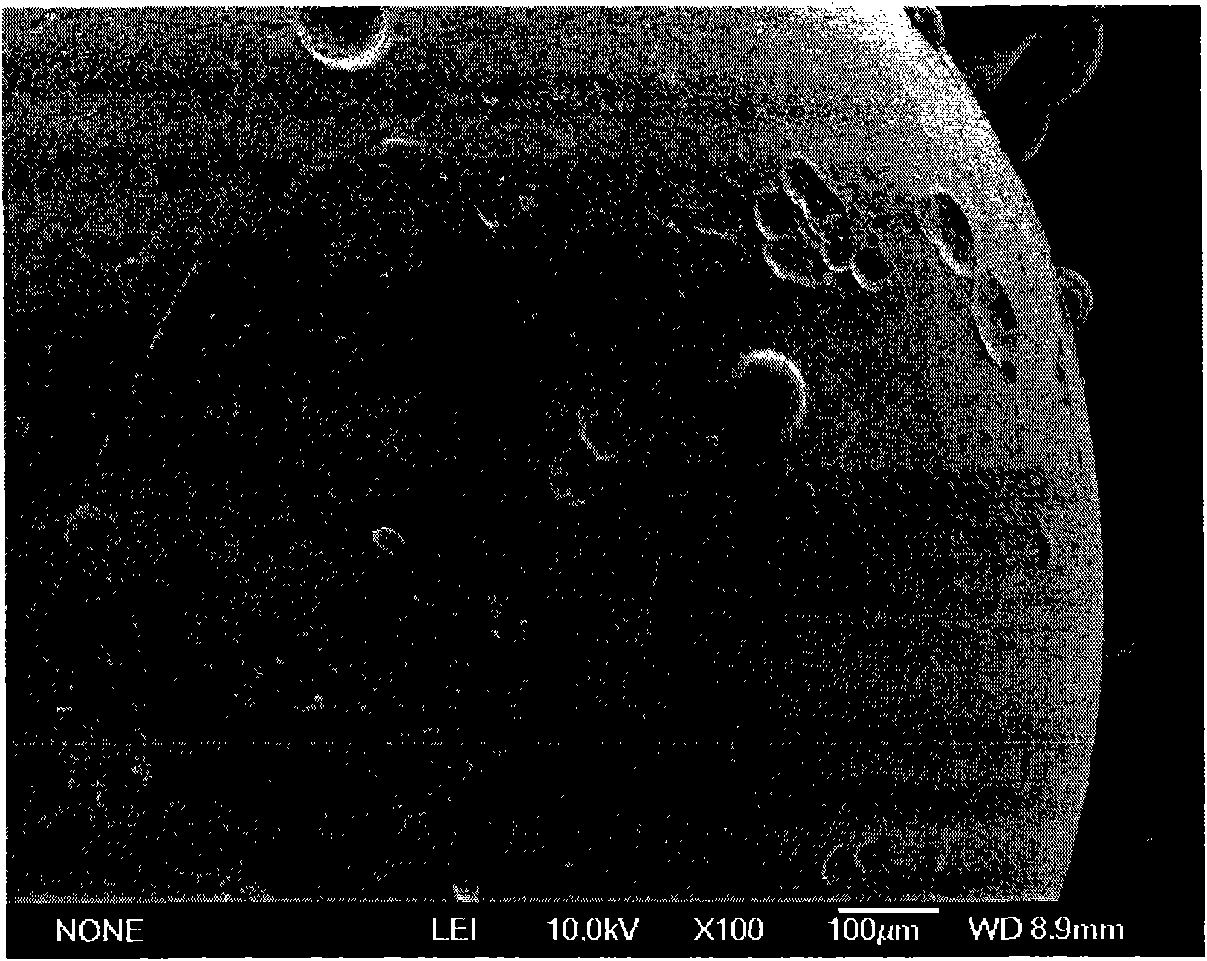

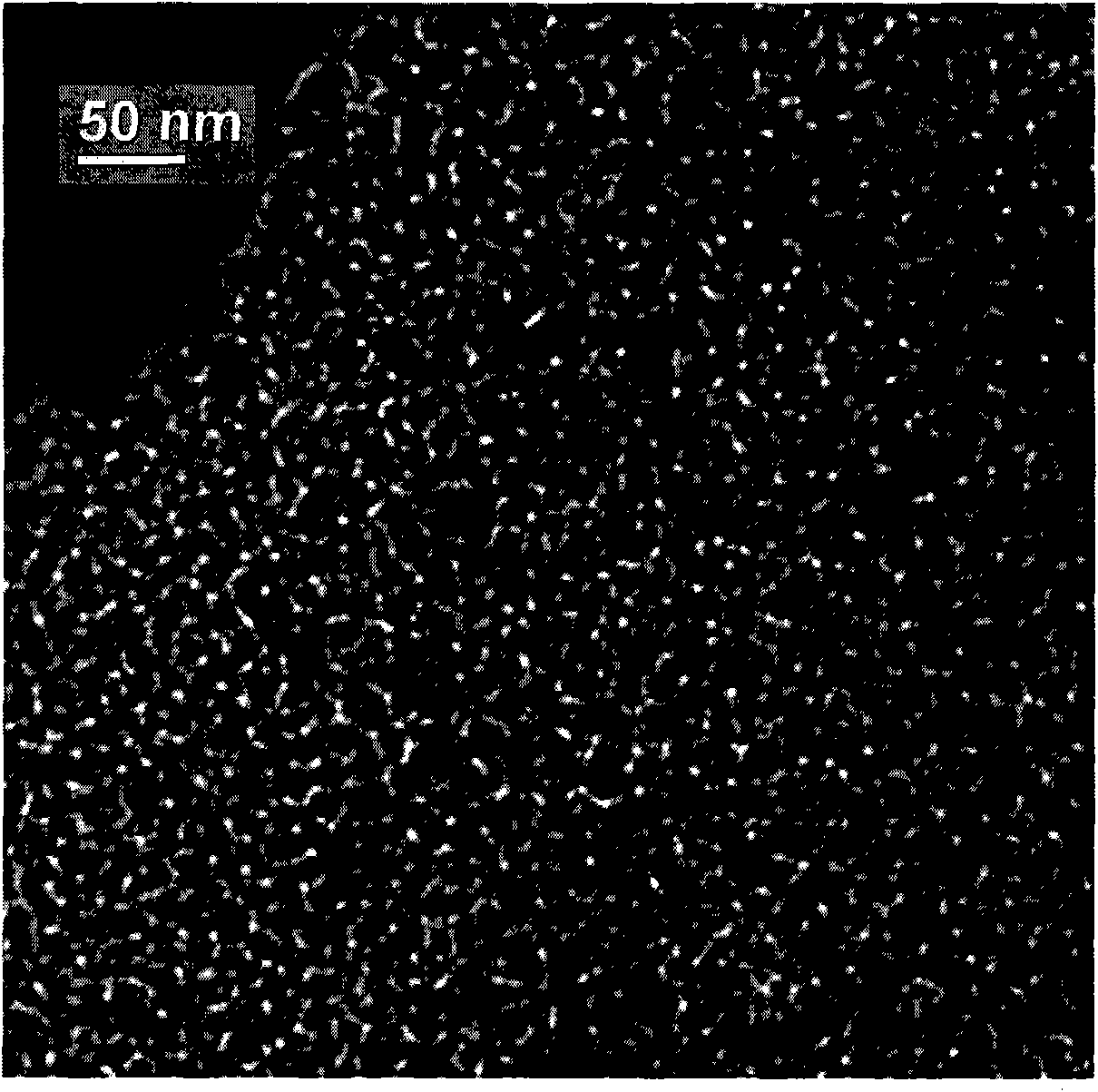

Embodiment 1

[0043] First, 4.6 g of resorcinol was dissolved in 40 g of ethanol; then 6 g of furfural and 0.75 g of 1 wt % hydrogen chloride ethanol solution were added. It was then stirred for 30 min at 10°C. Add molar concentration then and be the aqueous solution 1.8mL of the hexamethylenetetramine of 2.54mol / L and 8g F 127 Stirring for 60min, the molar ratio of its components, F 127 : resorcinol: furfural: HCl: hexamethylenetetramine: ethanol: water = 0.015: 1: 1.5: 0.005: 0.1: 20: 0.75. The above solution was put into 500mL liquid paraffin solution containing 8g Span-80, and then pre-polymerized for 120min under stirring at 60°C. Then, it was heated at 115° C. for 240 min with stirring. Filtrate and wash the recovered product, dry at 100°C for 12 hours, put the obtained pellets into an atmosphere furnace, raise the temperature at 2°C / min to 800°C for 4 hours, and carry out the whole carbonization process under a nitrogen atmosphere to obtain millimeter-sized Mesoporous carbon sphe...

Embodiment 2

[0045] The synthesis process was the same as that described in Example 1, except that the stirring temperature was 0° C. and the stirring time was 120 min during the preparation of the precursor solution. The diameter of the obtained mesoporous carbon sphere is 1.1-1.8mm, and the specific surface area of the sphere is 590.2m 2 / g, the most probable pore size is 6.1nm, and the pore volume is 0.45cm 3 / g.

Embodiment 3

[0047] The synthesis process was the same as that described in Example 1, except that the stirring temperature was 15° C. and the stirring time was 10 min during the preparation of the precursor solution. The diameter of the obtained mesoporous carbon sphere is 0.8-1.3mm, and the specific surface area of the sphere is: 650.0m 2 / g, the most probable pore size is 9.8nm, and the pore volume is 0.50cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com