Anti-corrosion super-hydrophobic coating and preparing method and application thereof

A super-hydrophobic coating and corrosion-resistant technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, natural rubber coatings, etc. problems, to achieve the effect of improving self-cleaning ability, controllable process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

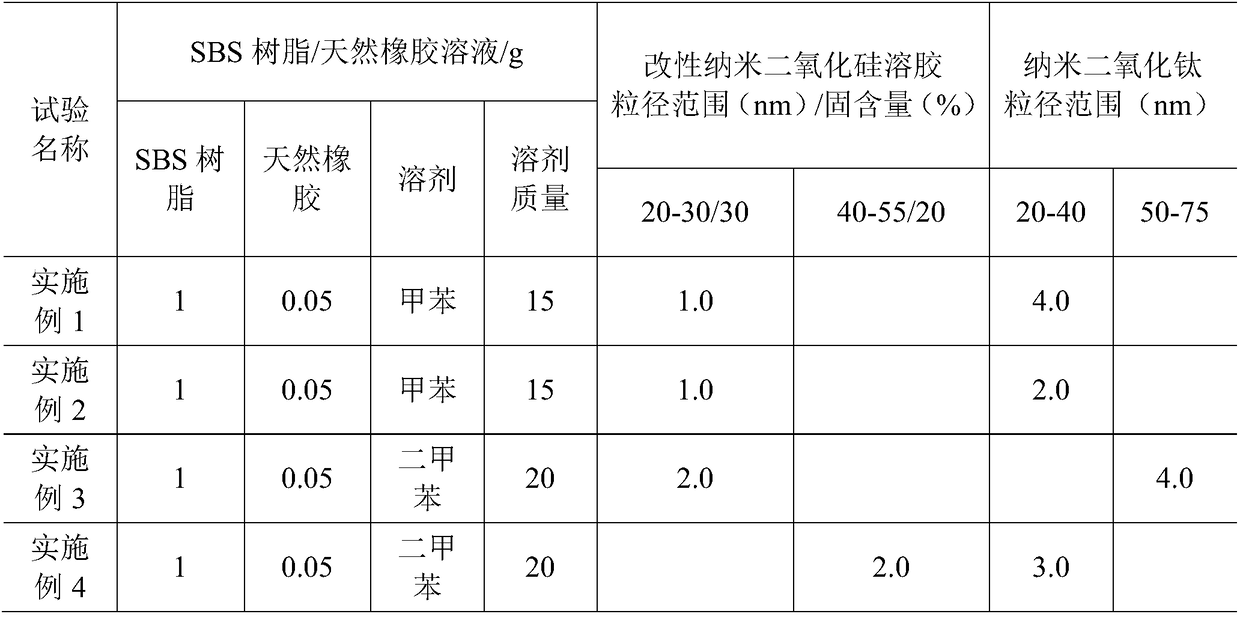

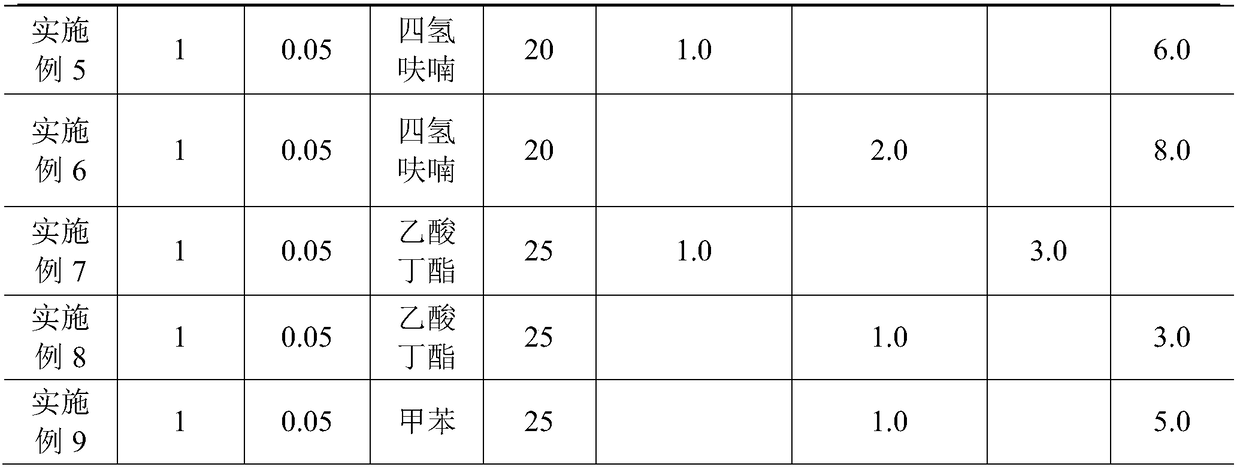

Embodiment 1-9

[0026] A corrosion-resistant super-hydrophobic coating and its preparation method and application, the specific steps comprising:

[0027] S1, the SBS resin, natural rubber and solvent are dissolved in the solvent in a mass ratio of 0.8-1.2 parts: 0.01-0.15 parts, 15-25 parts, and stirred at room temperature to obtain a SBS resin / natural rubber solution;

[0028] Specifically, the solvent is one or more of toluene, xylene, ethyl acetate, butyl acetate, tetrahydrofuran;

[0029] S2, the nano-silica sol (abbreviation: modified nano-silica sol) and nano-titanium dioxide that the silane coupling agent is modified in proportion are added in the SBS resin / natural rubber solution that makes in step S1, at room temperature Stir and serve;

[0030] Specifically, 1.0-2.0 parts of nano-silica sol modified by a silane coupling agent, and 2.0-8.0 parts of nano-titanium dioxide;

[0031] Specifically, the silica sol is a nano-silica sol modified by a silane coupling agent with a solid con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com