Perovskite photonic crystal, preparation method thereof, perovskite solar cell and preparation method of perovskite solar cell

A technology of solar cells and photonic crystals, applied in photovoltaic power generation, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of low photoelectric conversion efficiency, achieve improved photoelectric conversion efficiency, good repeatability and stability, and simple preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

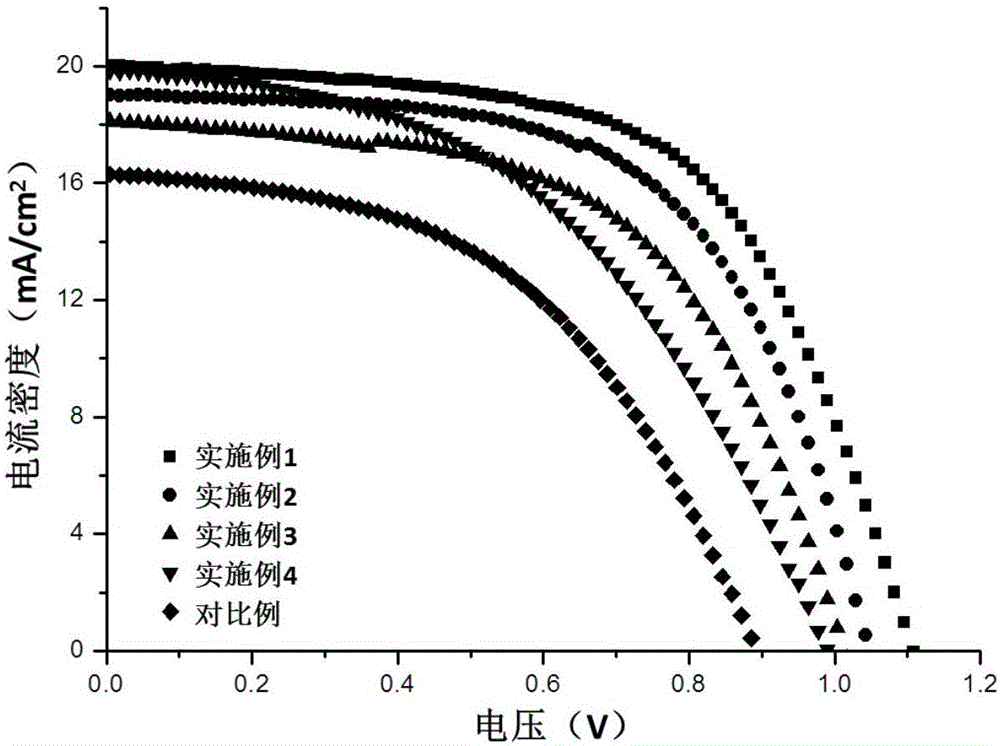

Embodiment 1

[0074] Mix 33% by weight of methylamine ethanol solution and 57% by weight of hydriodic acid aqueous solution according to the volume ratio of 12:5, stir and react for 4 hours at 0°C; then rotate and evaporate at 50°C to collect the product; The above-mentioned rotary steamed product was recrystallized and purified twice, and the recrystallization conditions included: dissolving the above-mentioned rotary steamed product in 60mL of ethanol, and then adding 250mL of diethyl ether; then filtered under reduced pressure to obtain powdered methyl ammonium iodide, at 60°C, vacuum Dry for 24 hours; prepare a mixed solution of 40% by weight in dimethylformamide with lead iodide and the methyl ammonium iodide prepared above according to a molar ratio of 1:1, stir at room temperature for 10 hours, and obtain a compound with a perovskite structure CH 3 NH 3 PB 3 precursor solution.

[0075] The transparent conductive substrate was ultrasonically cleaned in acetone, ethanol, and ultrap...

Embodiment 2

[0081] Mix 33% by weight of methylamine solution and 57% by weight of hydroiodic acid solution according to the volume ratio of 12:5, stir and react for 2 hours at 0°C; The rotary steamed product was recrystallized and purified twice. The recrystallization conditions included: dissolving the above rotary steamed product in 40mL of ethanol, and adding 200mL of ether; then filtered under reduced pressure to obtain powdery crystalline methyl ammonium iodide, at 60°C, vacuum Dry for 24 hours; prepare a mixed solution of 30% by weight in dimethylformamide with lead chloride and the above-mentioned methyl ammonium iodide according to a molar ratio of 1:3, stir at room temperature for 10 hours, and obtain a compound with a perovskite structure CH 3 NH 3 PB 2 Cl precursor solution.

[0082] The transparent conductive substrate was ultrasonically cleaned in acetone, ethanol, and ultrapure water for 10 min, and dried with nitrogen; treated with ultraviolet and ozone for 1 h before us...

Embodiment 3

[0088] Mix 33% by weight of methylamine ethanol solution and 57% by weight of hydrogen iodide solution according to the volume ratio of 12:5, stir and react for 6 hours at 0°C; The above-mentioned rotary steamed product was recrystallized and purified twice. The recrystallization conditions include: dissolving the above-mentioned rotary steamed product in 80mL of ethanol, and then adding 300mL of ether; then filtered under reduced pressure to obtain a white powder of methyl ammonium iodide, at 60°C, vacuum Dry for 24 hours; prepare a mixed solution of 40% by weight in dimethylformamide with lead bromide and the methylammonium iodide prepared above according to the molar ratio of 1:3, stir at room temperature for 10 hours, and obtain a compound with a perovskite structure CH 3 NH 3 I 2 Br precursor solution.

[0089]The transparent conductive substrate was ultrasonically cleaned in acetone, ethanol, and ultrapure water for 10 min, and dried with nitrogen; treated with ultrav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com