Preparation method of coded aperture for neutron penumbra imaging

A coding aperture and imaging technology, applied in photography, photographic technology, optics, etc., can solve the problems of poor hole precision and surface quality, difficult electrode preparation, and inability to be widely used, and achieve good hole precision and surface quality, surface roughness Small, good effect on neutral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

[0034] The first step is to draw the micro glass tube. Turn on the laser tube pulling instrument, put in the glass tube, conduct a power test, and obtain the critical power to break the glass tube. Replace the new glass tube, enter the tube drawing program, set the working parameters for drawing, and remove the drawn glass tube after the program runs.

[0035] The glass tube is a hollow quartz glass tube with a diameter of 1 mm.

[0036] The RAMP TEST result was 692.

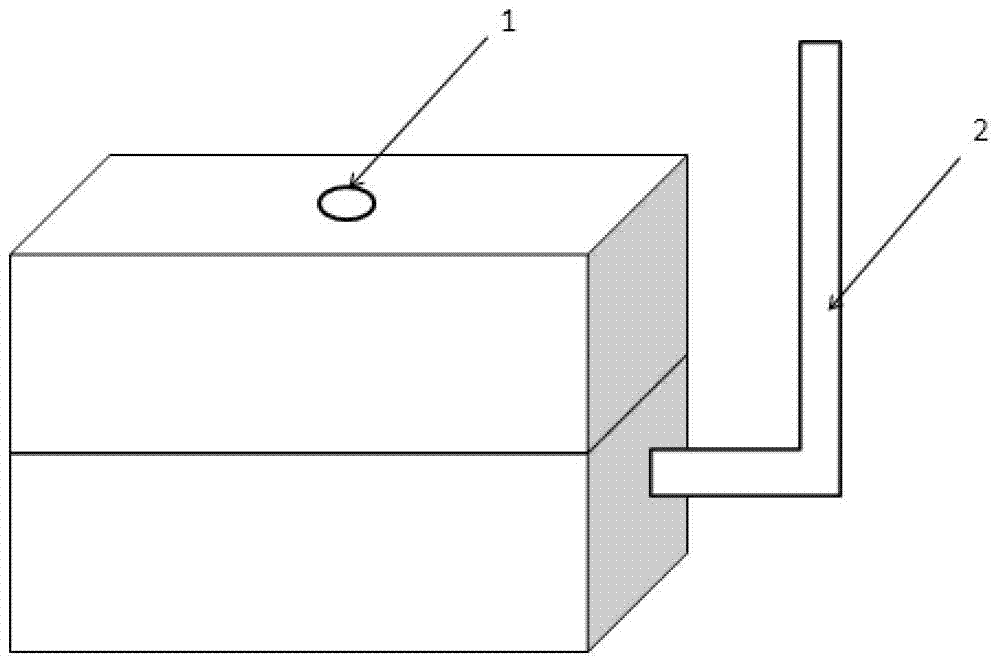

[0037] The shape of the drawn glass tube is as figure 1 As shown, two identical glass tubes with biconical front ends can be obtained after cutting from the middle.

[0038] The working parameters are as follows:

[0039] Heat (output power)

Velocity (pull rate)

Pull

650

45

140

250

[0040] The laser tube pulling instrument used in this example is the P-2000 Laser Based Micropipe...

Embodiment 2

[0053] This embodiment includes the following steps:

[0054]The first step is to draw the micro glass tube. Turn on the laser tube pulling instrument, put in the glass tube, conduct a power test, and obtain the critical power to break the glass tube. Replace the new glass tube, enter the tube drawing program, set the working parameters for drawing, and remove the drawn glass tube after the program runs.

[0055] The glass tube is a hollow quartz glass tube with a diameter of 1 mm.

[0056] The RAMP TEST result was 689.

[0057] The shape of the drawn glass tube is as figure 1 As shown, two identical glass tubes with biconical front ends can be obtained after cutting from the middle.

[0058] The working parameters are as follows:

[0059] Heat (output power)

Velocity (pull rate)

Pull

550

45

140

150

[0060] The laser tube pulling instrument used in this example is the P-2000 Laser Based Micropipet...

Embodiment 3

[0073] This embodiment includes the following steps:

[0074] The first step is to draw the micro glass tube. Turn on the laser tube pulling instrument, put in the glass tube, conduct a power test, and obtain the critical power to break the glass tube. Replace the new glass tube, enter the tube drawing program, set the working parameters for drawing, and remove the drawn glass tube after the program runs.

[0075] The glass tube is a solid quartz glass tube with a diameter of 1 mm.

[0076] The RAMP TEST result is 724.

[0077] The shape of the drawn glass tube is as figure 1 As shown, two identical glass tubes with biconical front ends can be obtained after cutting from the middle.

[0078] The working parameters are as follows:

[0079] Heat (output power)

Velocity (pull rate)

Pull

600

45

140

200

[0080] The laser tube pulling instrument used in this example is the P-2000 Laser Based Micropipett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com