Patents

Literature

46results about How to "Good neutral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

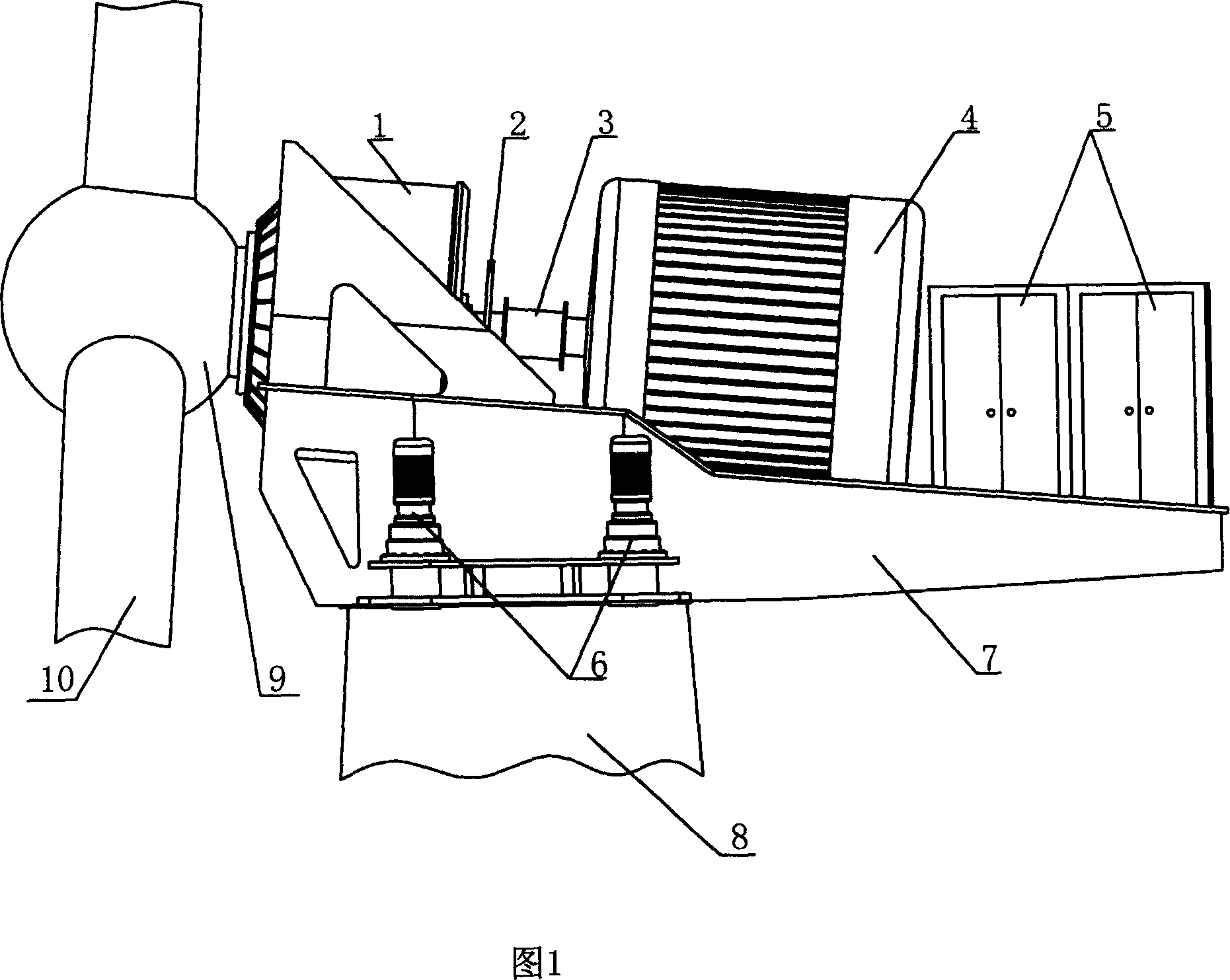

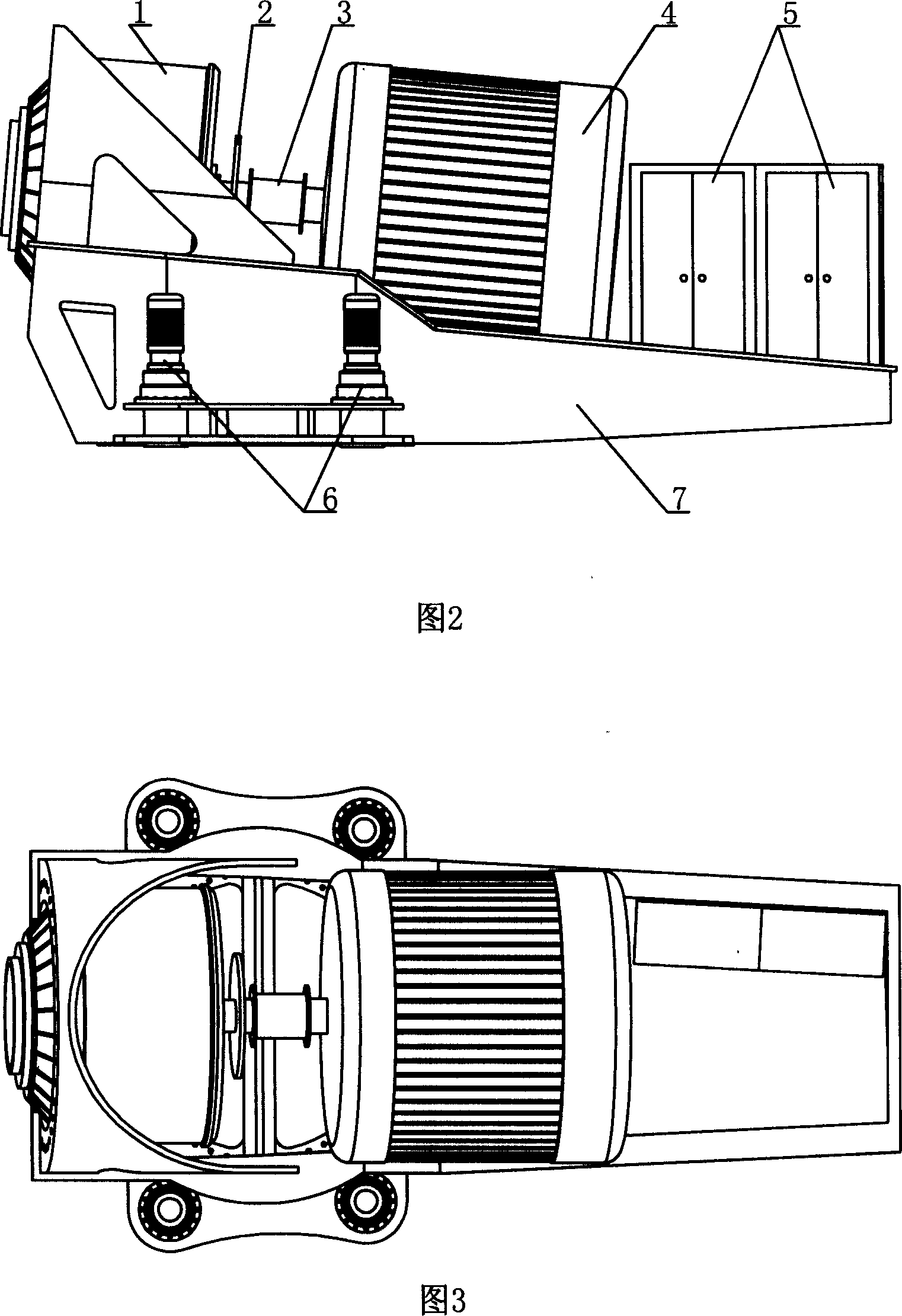

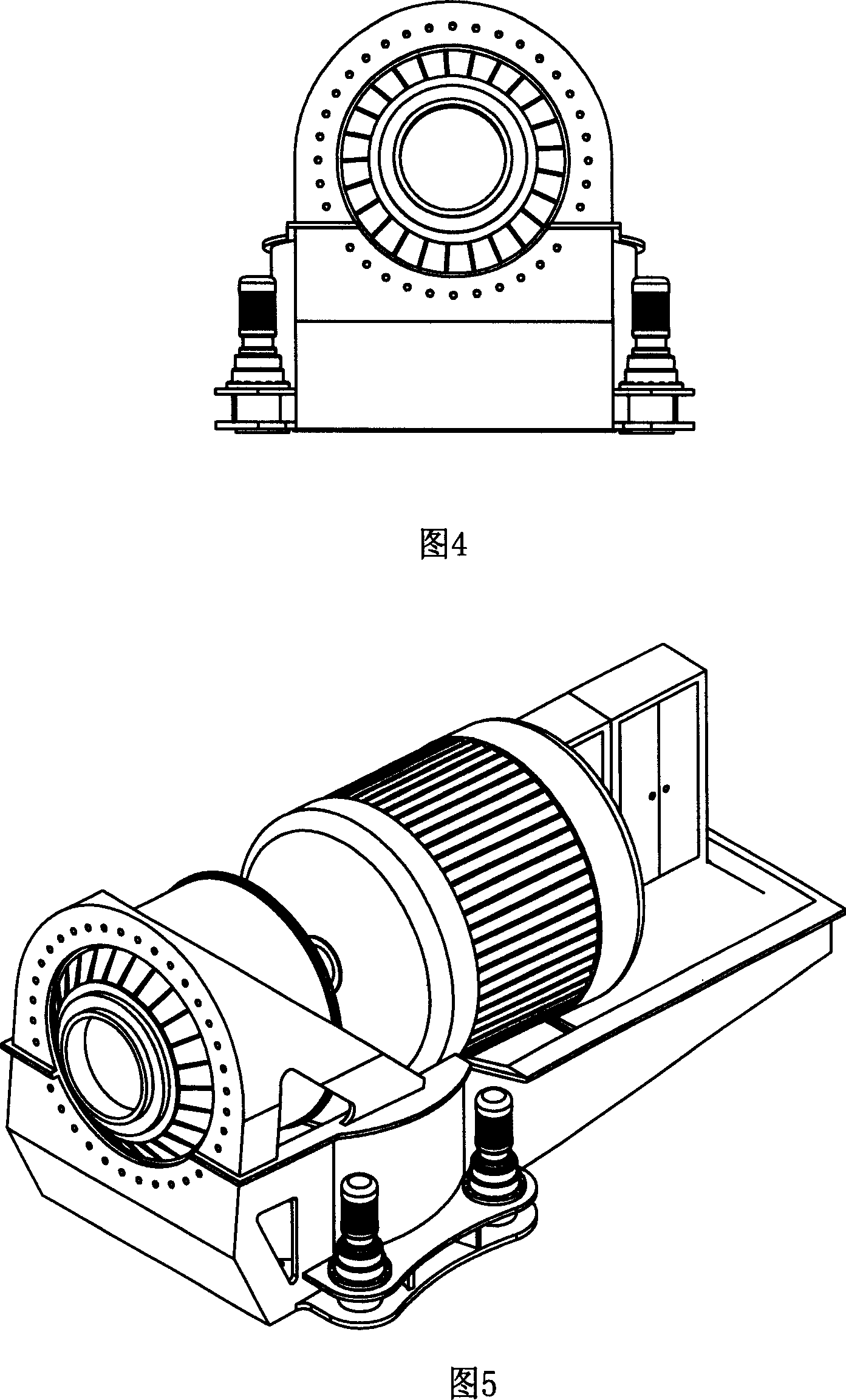

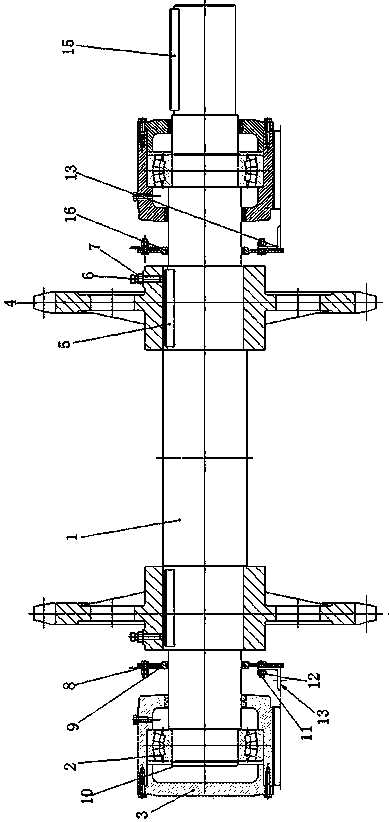

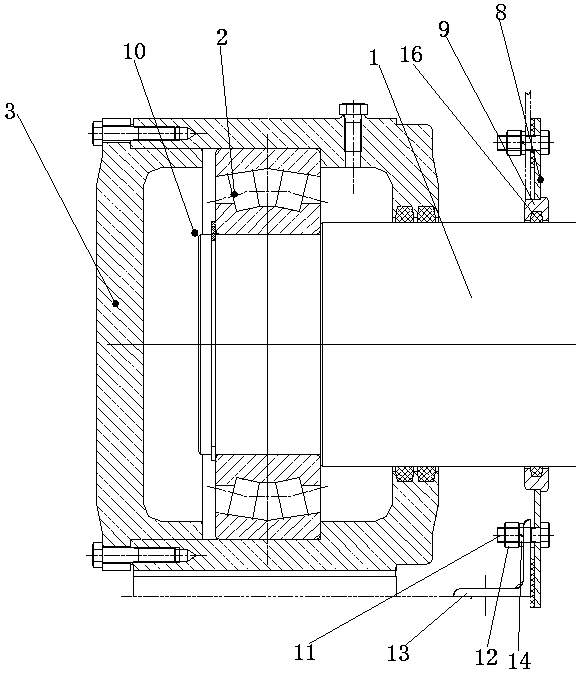

Megawatt semi-direct driving wind-power generator group

InactiveCN101016881AReduce axial playStable structureWind motor controlMachines/enginesNacelleLow speed

A megawatt-level semi-direct driving wind generator comprises a wind wheel, a distance changer, a main axle, a speed accelerating box, a coupler, a generator, a cabin chassis, a bias motor and a control system. The chassis is fixed with the bias motor and the generator, the accelerating box is fixed with the side wall of the chassis, the accelerating box is first-stage planet accelerating gear box, and the motor is low-speed permanent magnetic three-phase synchronous generator. The invention can stabilize the transmission of transmitter, reduce impact, and reduce sealing demand or the like, with adjustable installed height, simple structure, high strength and accurate angle control on distance change as 0.1 degree, to output constant power.

Owner:SHENYANG POLYTECHNIC UNIV

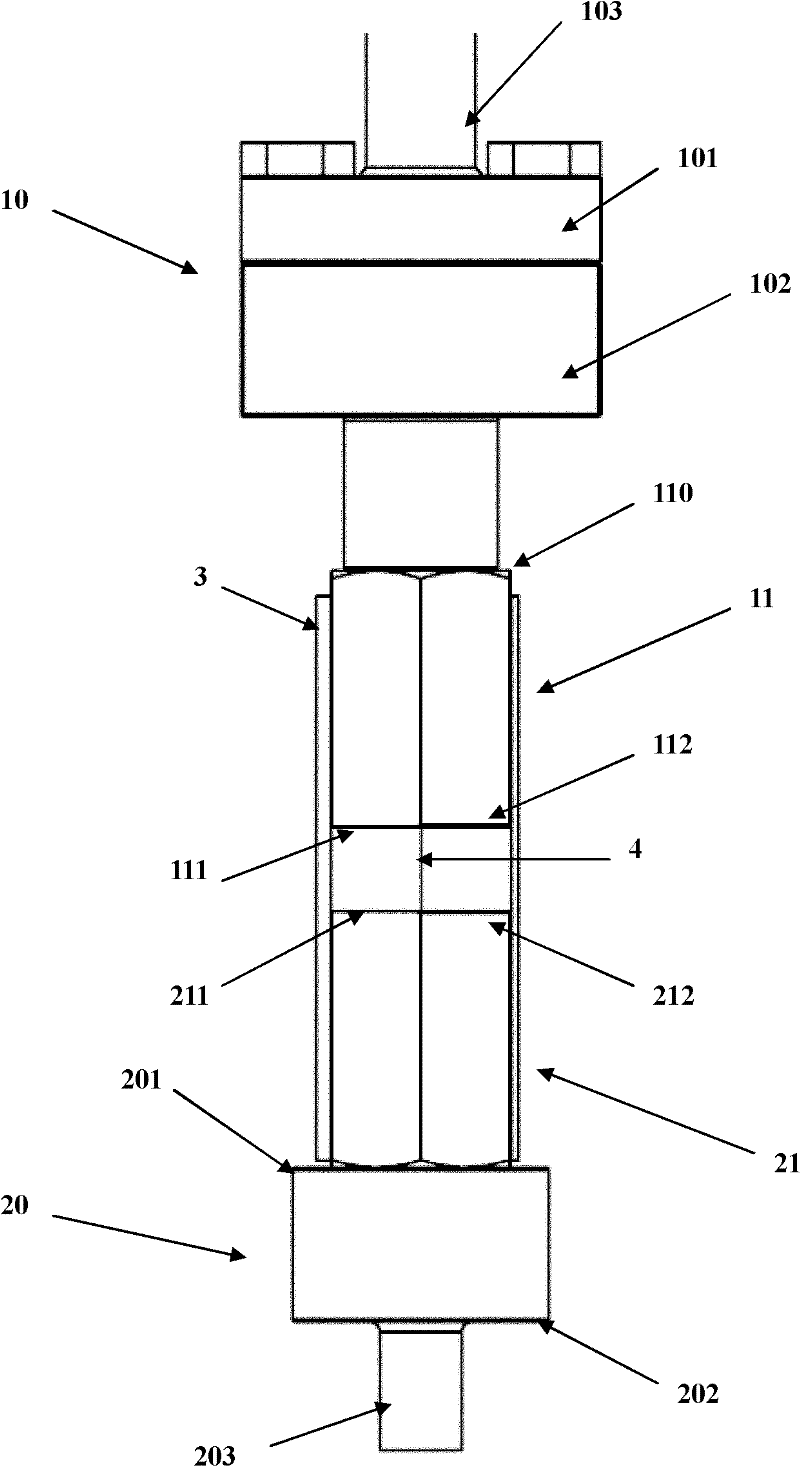

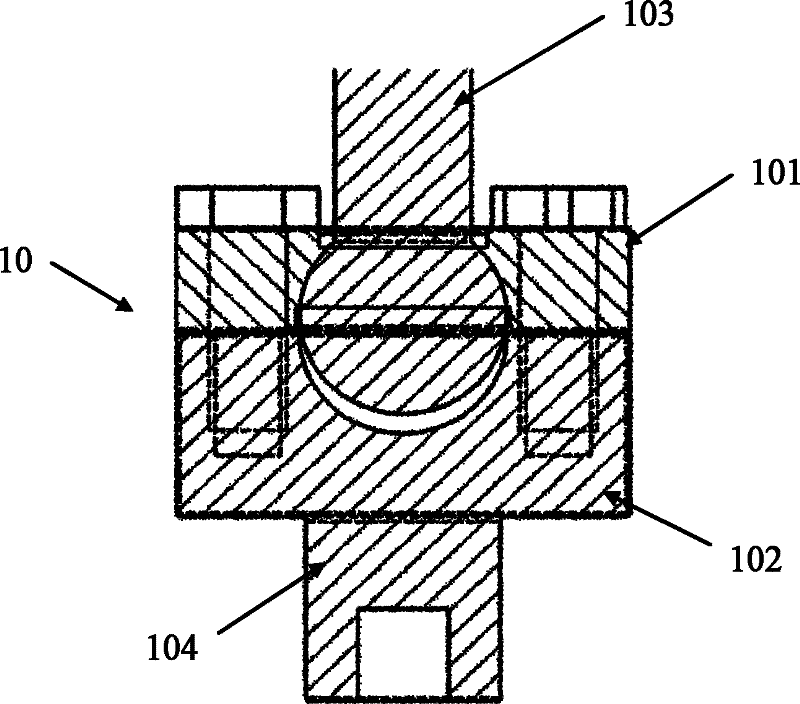

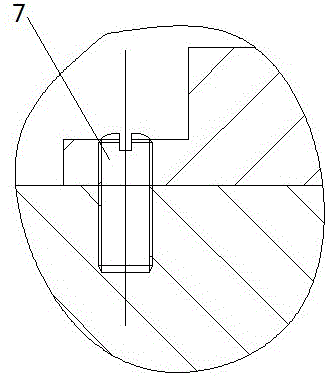

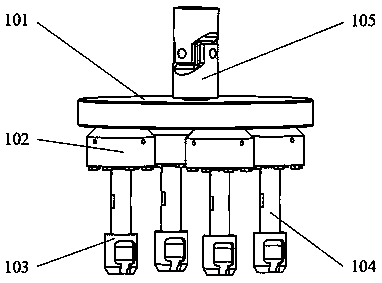

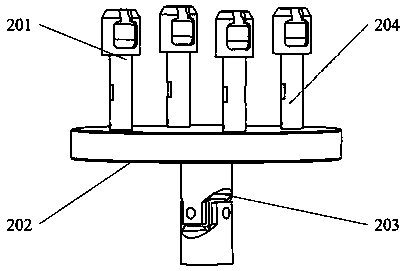

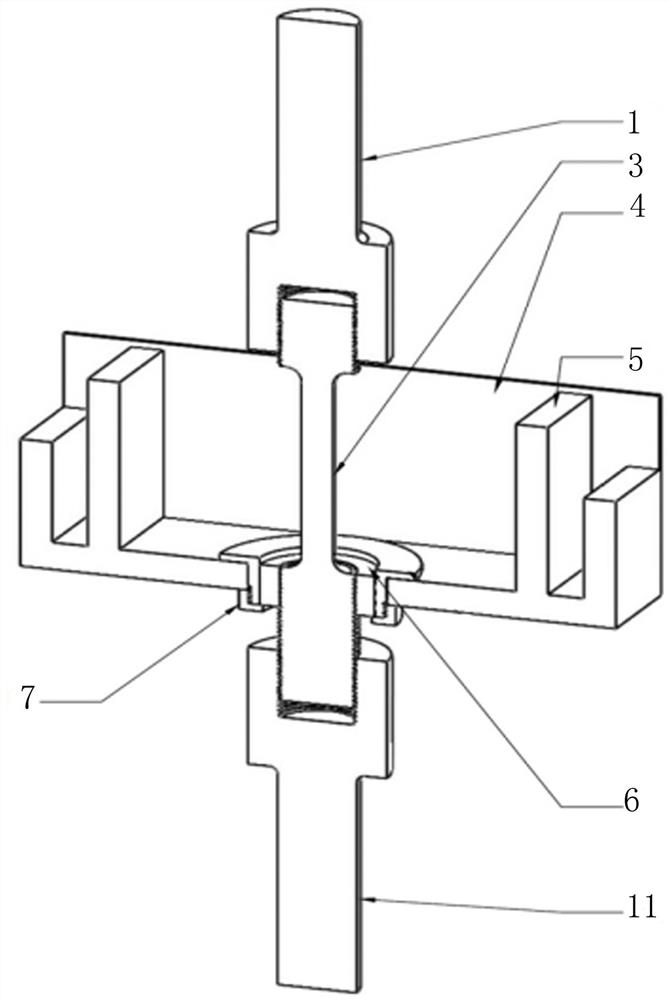

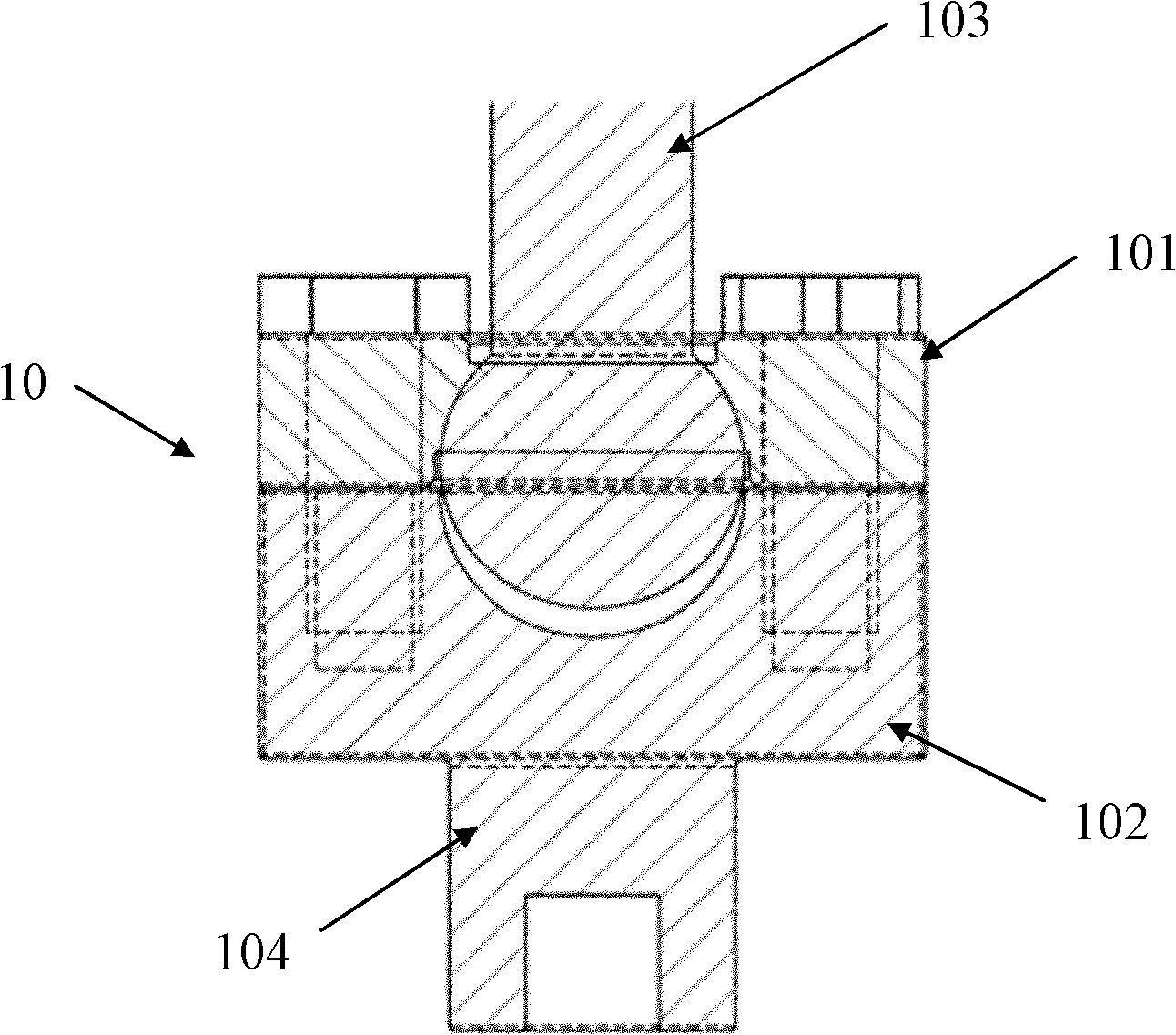

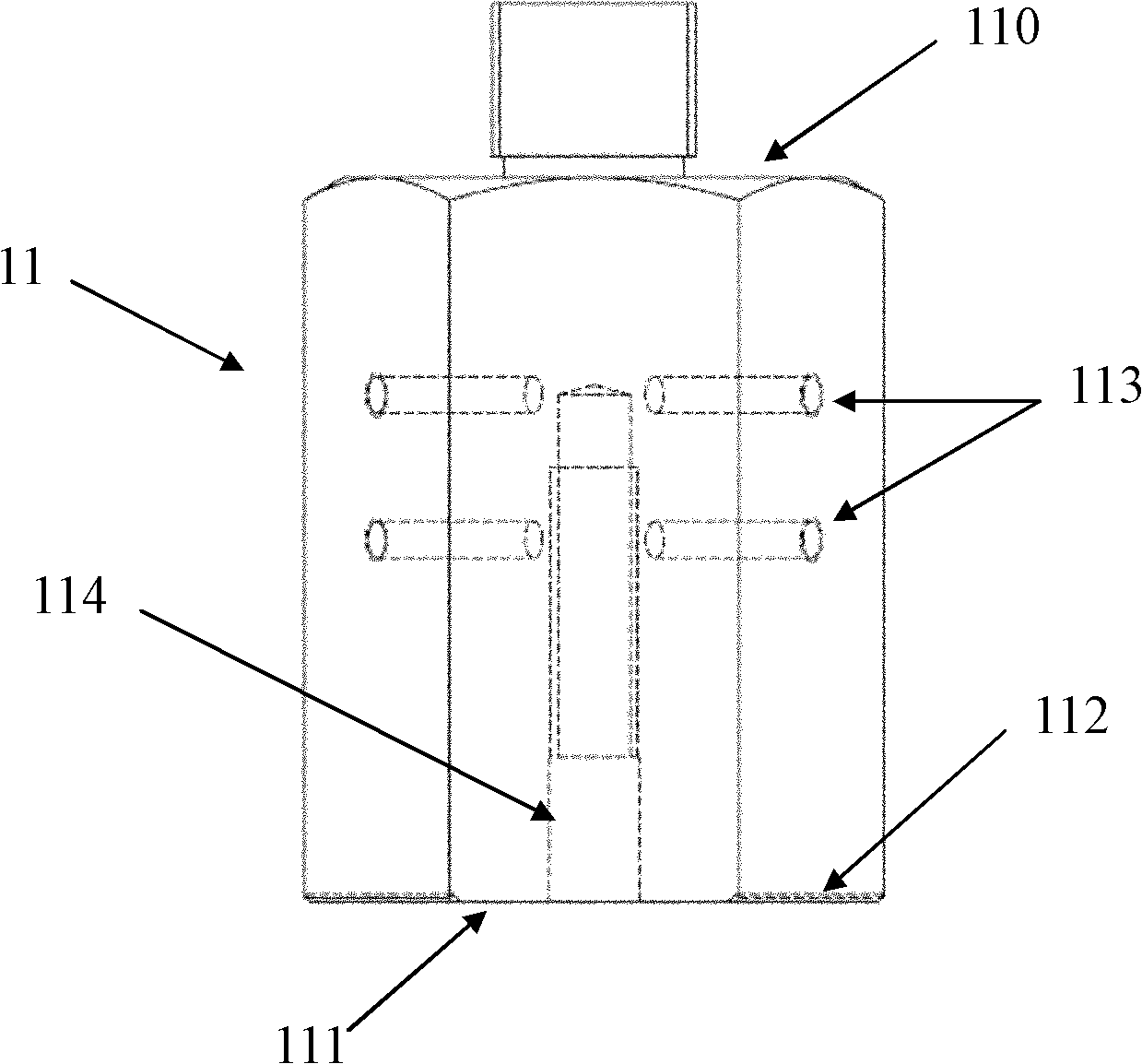

Testing clamp for testing tensile stress-tensile strain of metal bar samples

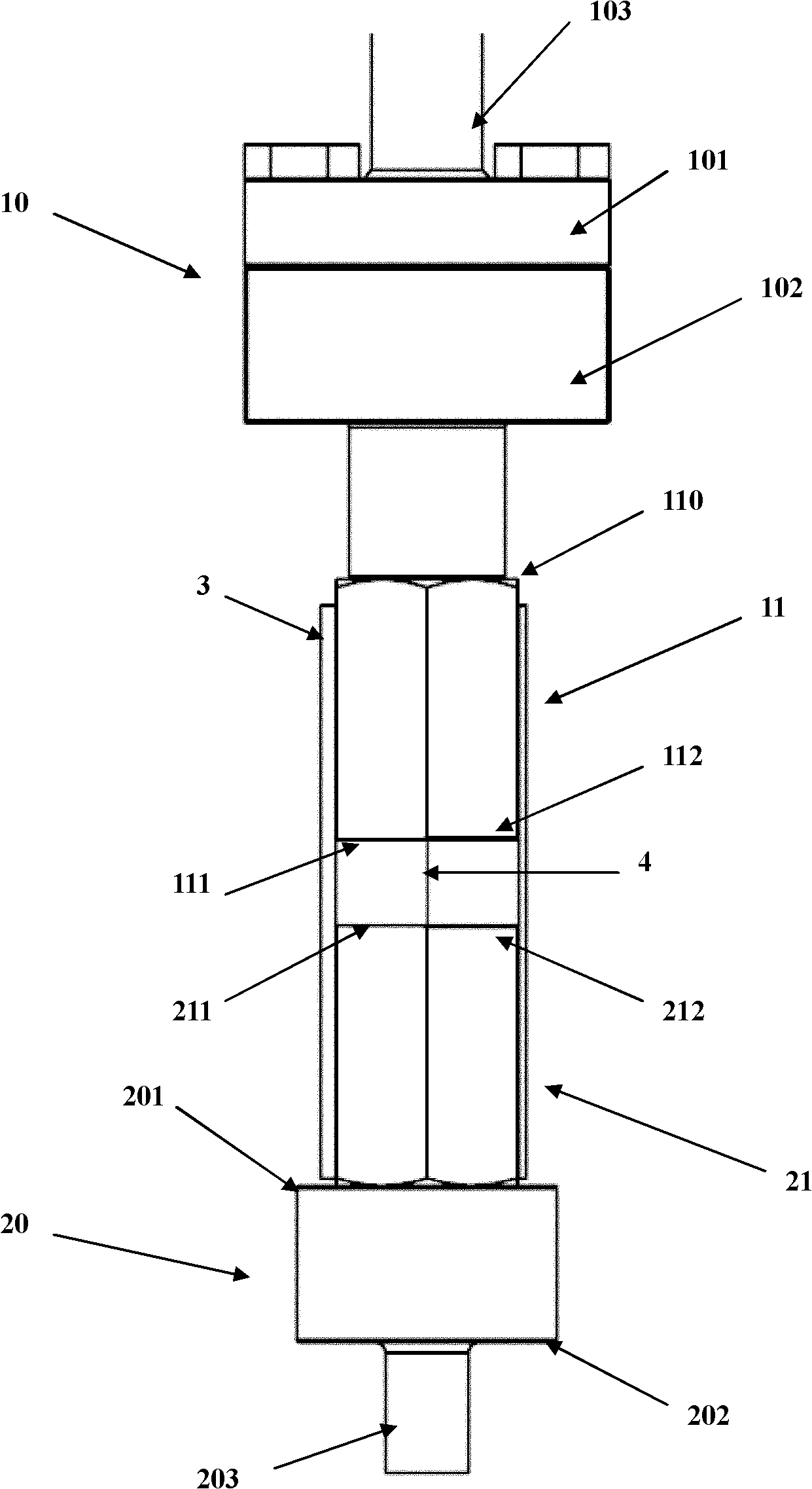

The invention relates to a testing clamp for testing tensile stress-tensile strain of a metal bar samples. The clamp comprises an upper connecting part, a lower connecting part, an upper clamping head, a lower clamping head and a guiding baffle plate fixing member, wherein a drag link ball of the upper connecting part is disposed in a shrinkage pool which is formed by a pressure flange and an upper connecting workpiece; the upper clamping head and the lower clamping head are equilateral polyhedra which are in the same shape and in a vertical arrangement, are separated by a distance of 1-3 cm, and are respectively provided with horizontal knife-edge grooves on opposite surfaces; the upper clamping head is threadedly connected with the upper connecting part, and the lower clamping head is threadedly connected with the lower connecting part; the guiding baffle plate fixing member coats three adjacent side surfaces of the upper clamping head and the lower clamping head which are opposite placed, has three vertical baffle plates, is fixed with the upper clamping head, and positions and guides the upper clamping head and the lower clamping head; and a middle vertical baffle plate is fixed with a side surface of the upper clamping head, wherein the side surface is provided with a first horizontal screw hole. The testing clamp has characteristics of easy installation and accurate position, and can achieve tensile stress-tensile strain mechanical performance tests for standard or non-standard metal bar samples under a low temperature environment with a temperature ranging form the room temperature to 4.2 K.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

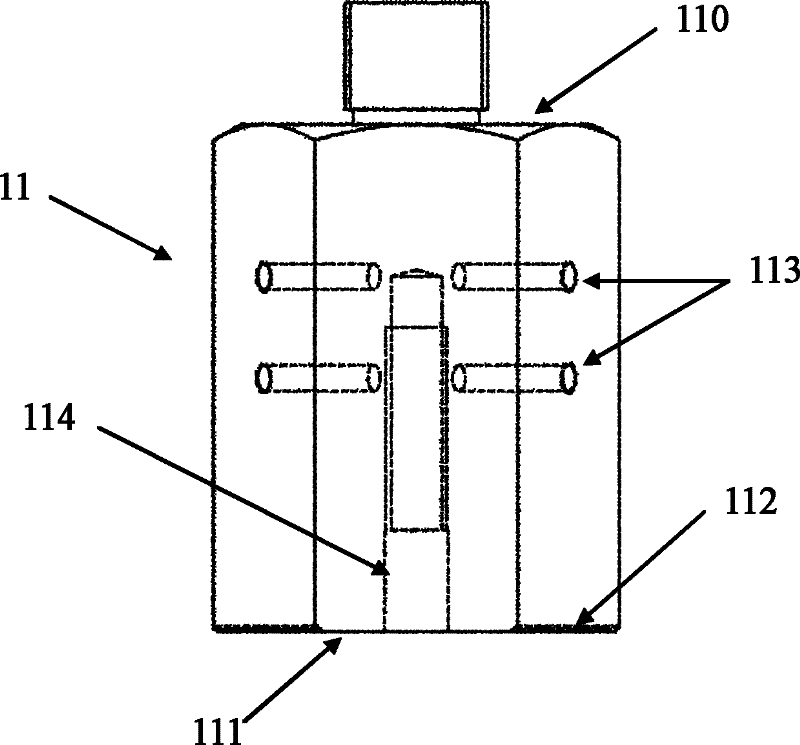

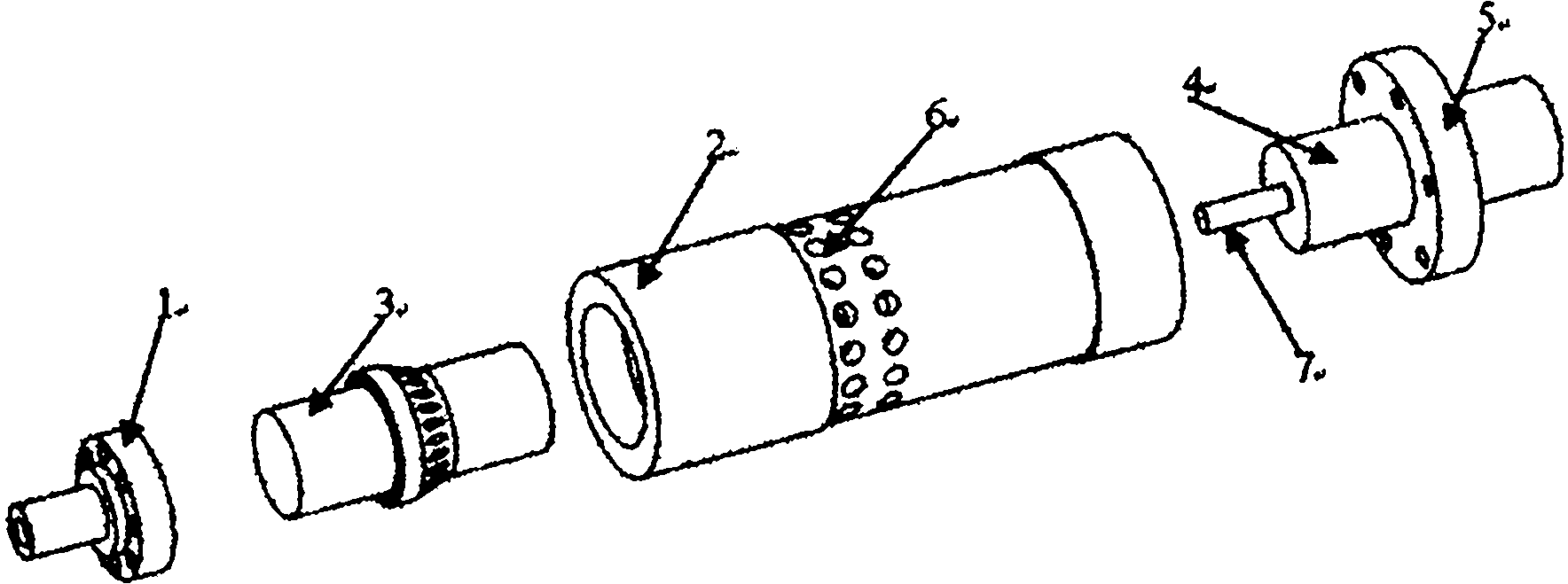

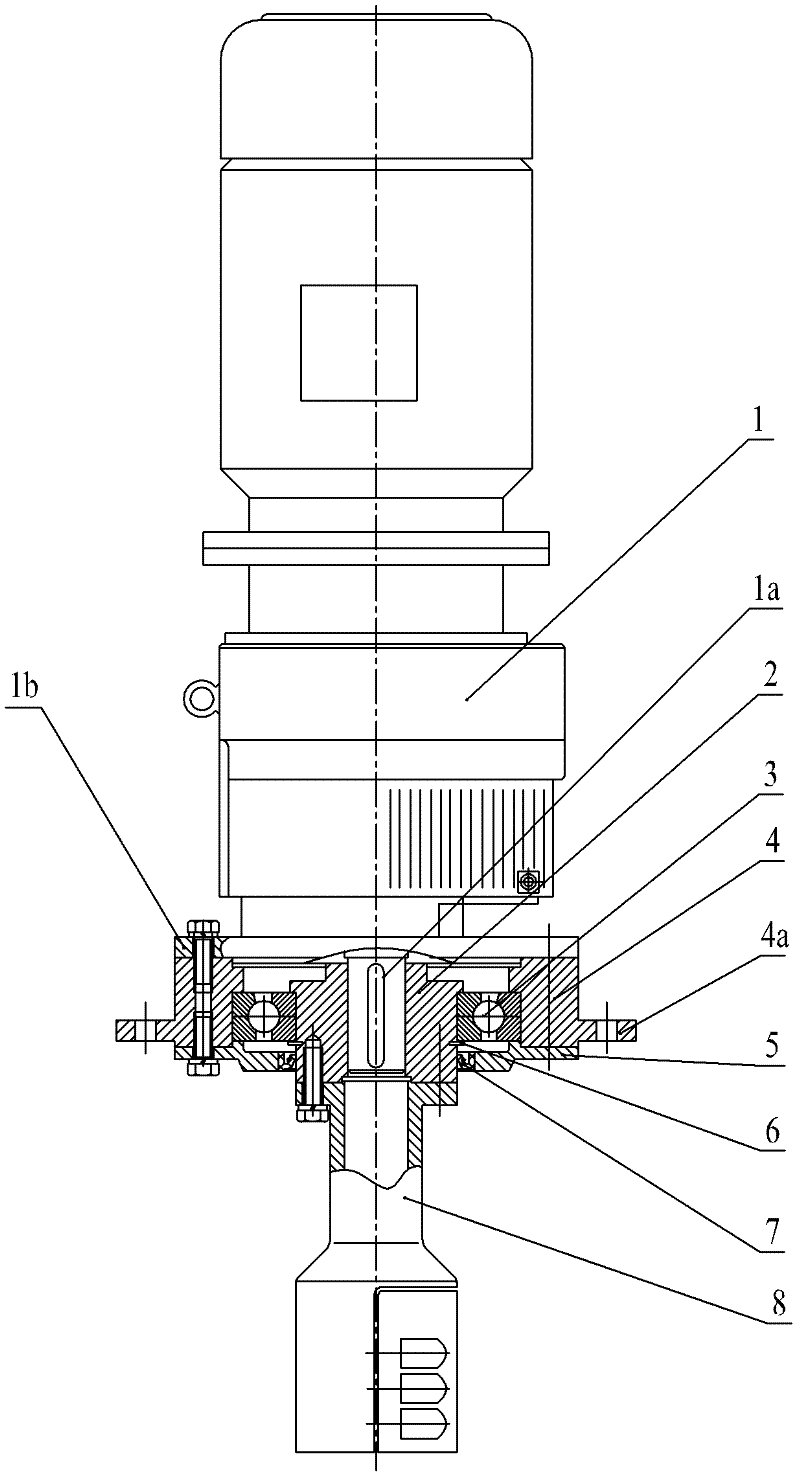

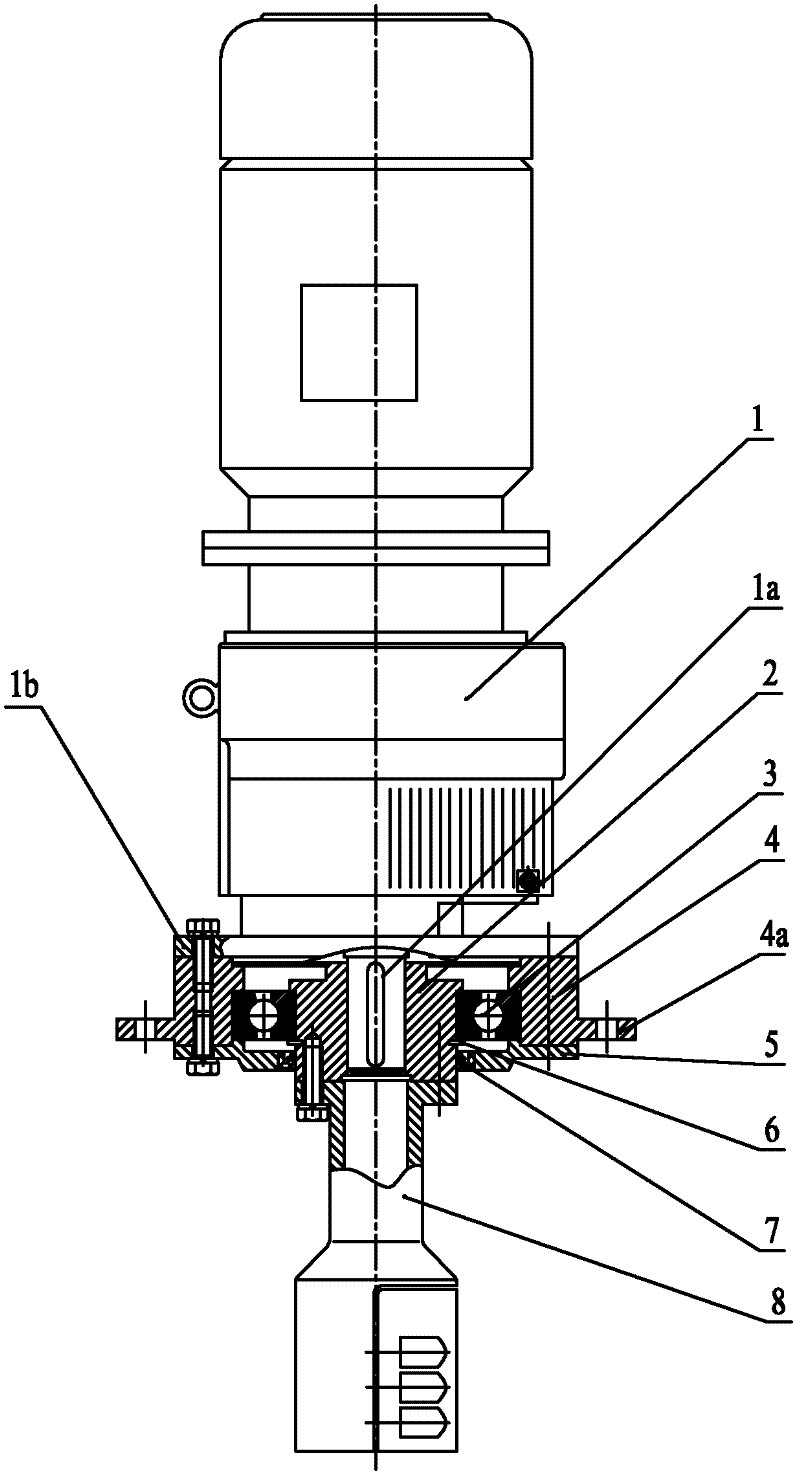

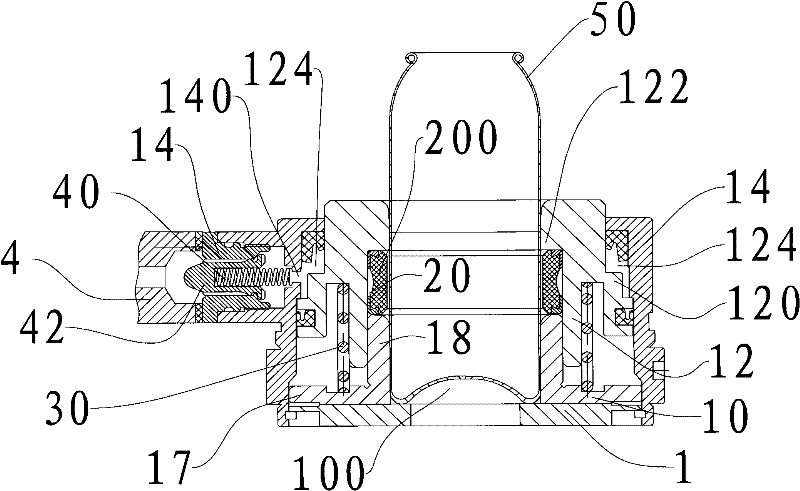

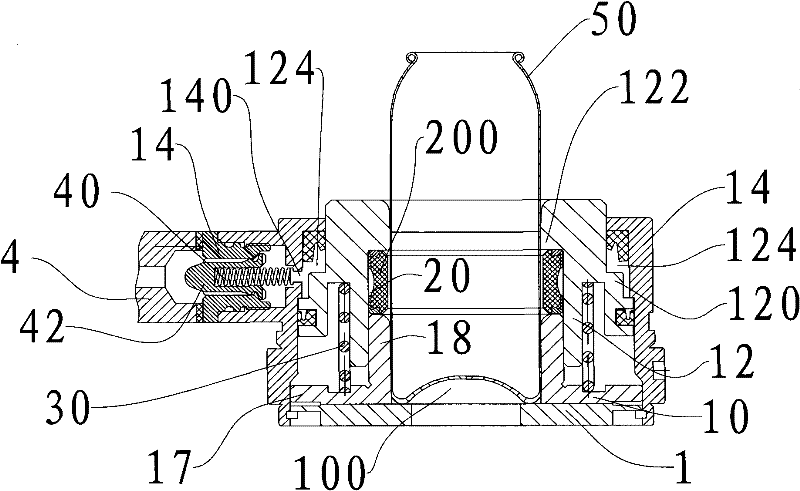

Ultrasonic transducer and amplitude modulator combined piece

InactiveCN102172574AThe transmission direction of ultrasonic vibration is stableImprove reliabilityMechanical vibrations separationNon-electric welding apparatusEnergy consumptionUltrasonic vibration

The invention discloses an ultrasonic transducer and amplitude modulator combined piece, which comprises a top cover, a shell, an ultrasonic transducer, an amplitude modulator and a positioning ring, wherein the ultrasonic transducer, the amplitude modulator and the positioning ring are fixed in the shell; the amplitude modulator is connected with one end of the shell; the other end of the shell is connected with the top cover through clearance fit; the positioning ring and the amplitude modulator are fastened and connected together; and the ultrasonic transducer and the amplitude modulator are fixed, sealed and connected into one piece. The ultrasonic transducer and amplitude modulator combined piece can improve the accuracy and reliability of ultrasonic vibration processing and solve the problems of the clamping rigidity difference between the conventional ultrasonic transducer and amplitude modulator, difficulty in node finding and large energy consumption in a transmission process and is greatly improved in dust prevention, clamping, precision and energy transmission efficiency.

Owner:SHANGHAI JIAO TONG UNIV +1

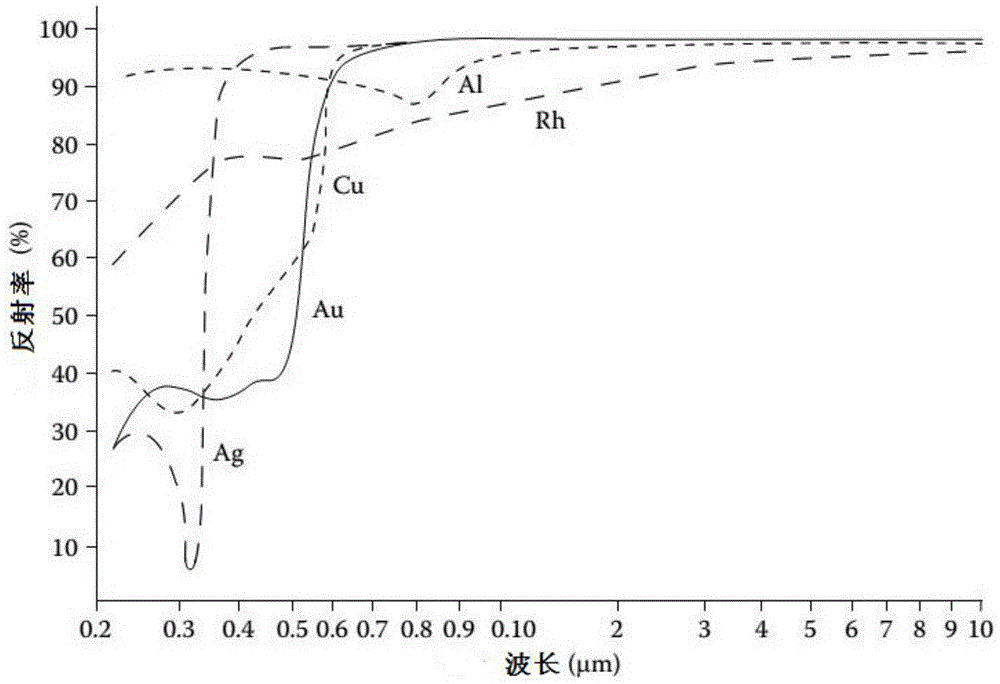

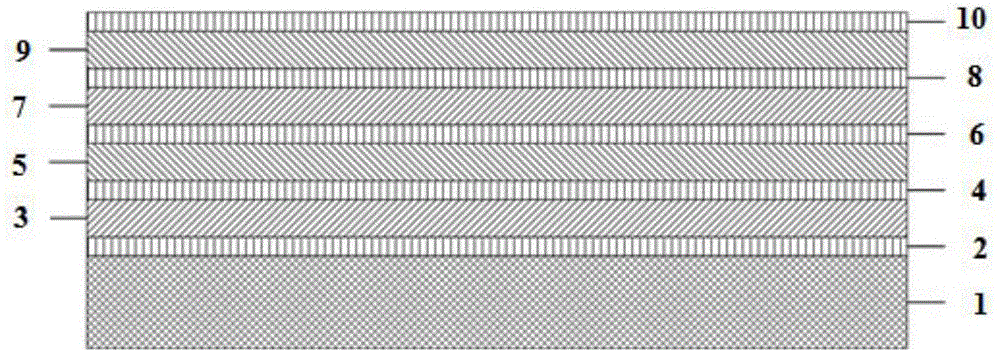

Aluminum-silver multilayer broadband reflection film based on aluminum oxide interlayer

The invention discloses an aluminum-silver multilayer broadband reflection film based on an aluminum oxide interlayer and belongs to the technical field of thin film deposition. The aluminum-silver multilayer broadband reflection film solves the problems that in the prior art, an aluminum film is low in reflectivity at the visible band, a silver film is low in reflectivity at the ultraviolet band, and the environmental adaptability is poor. The aluminum-silver multilayer broadband reflection film comprises a substrate, a first aluminum oxide film, a first aluminum film, a second aluminum oxide film, a first silver film, a third aluminum oxide film, a second aluminum film, a fourth aluminum oxide film, a second silver film and a fifth aluminum oxide film, wherein the substrate, the first aluminum oxide film, the first aluminum film, the second aluminum oxide film, the first silver film, the third aluminum oxide film, the second aluminum film, the fourth aluminum oxide film, the second silver film and the fifth aluminum oxide film are arranged compactly in sequence from bottom to top, cover the ultraviolet band, the visible band and the infrared band and all have high reflectivity; besides, the aluminum-silver multilayer broadband reflection film has good neutral performance even used at a large angle and also has good environmental adaptability.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

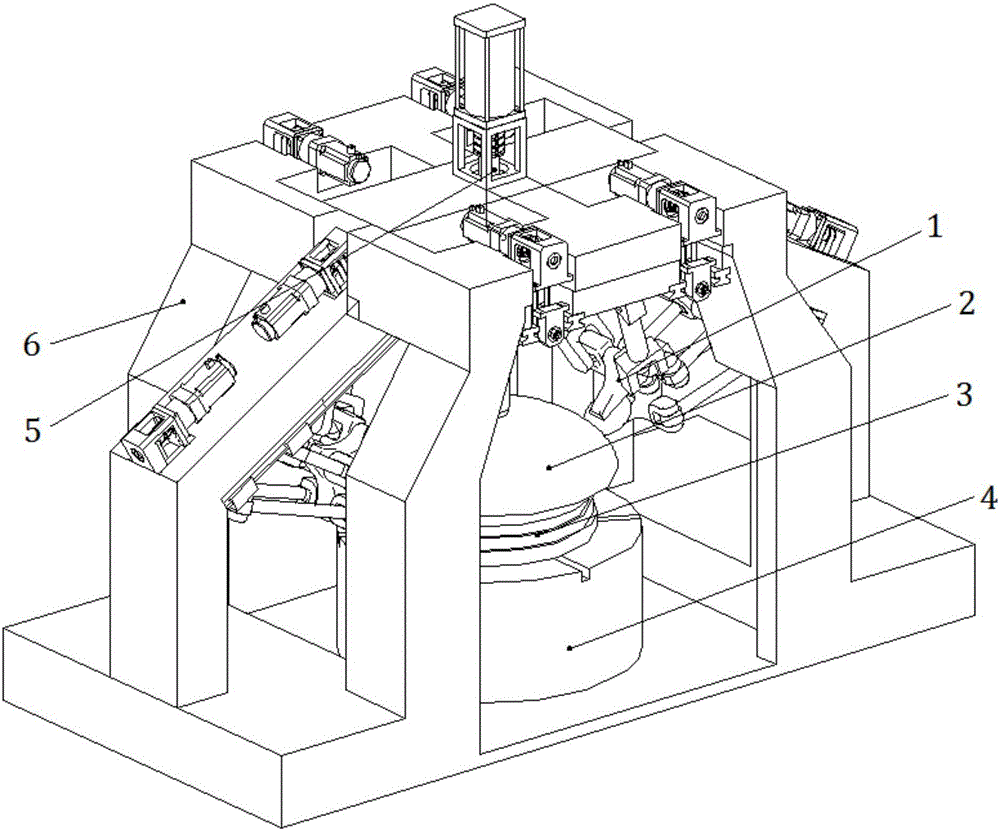

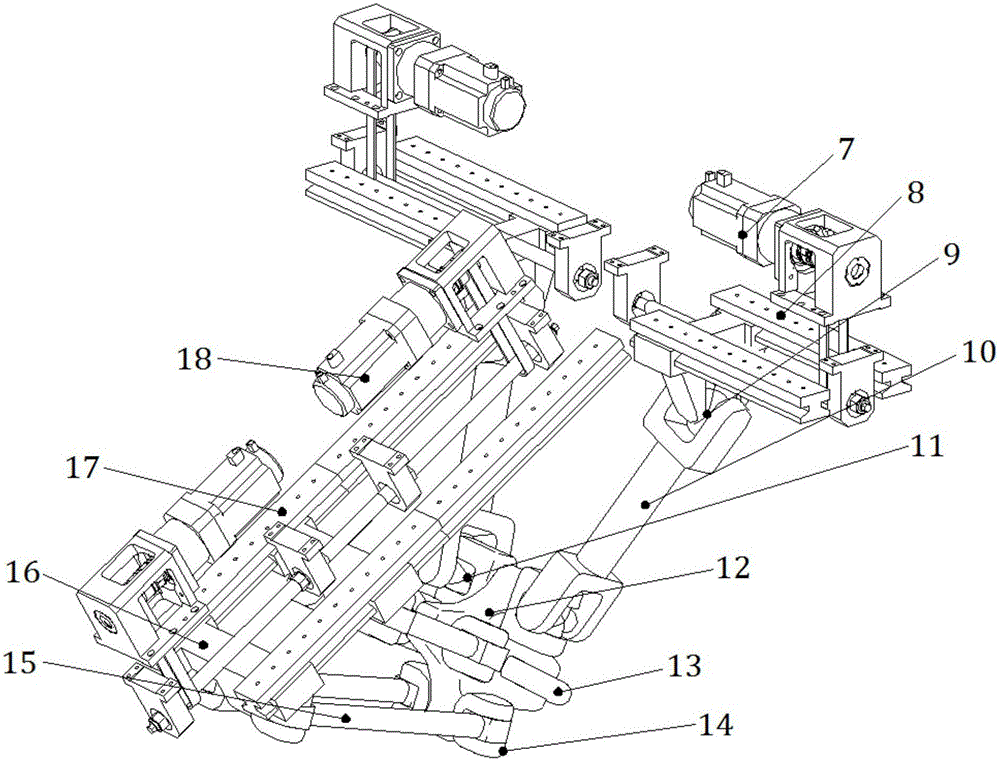

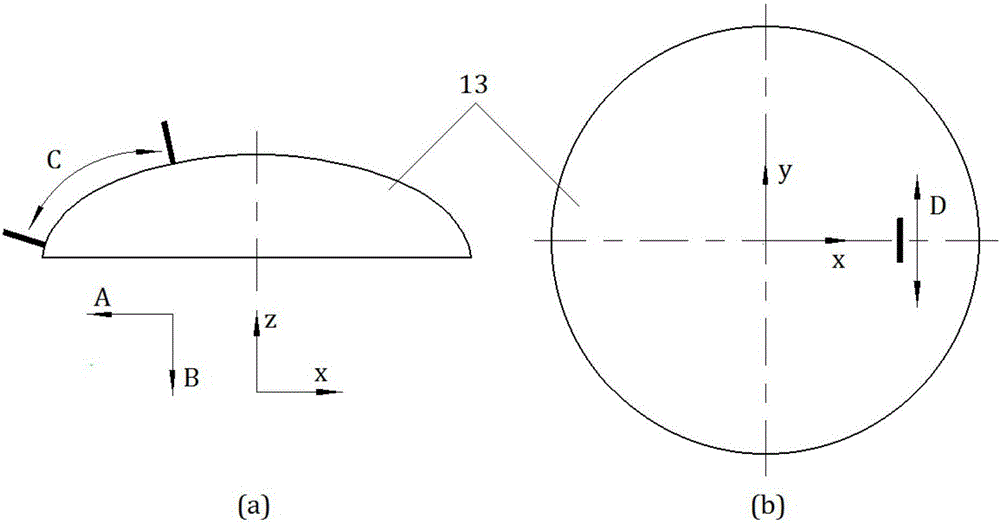

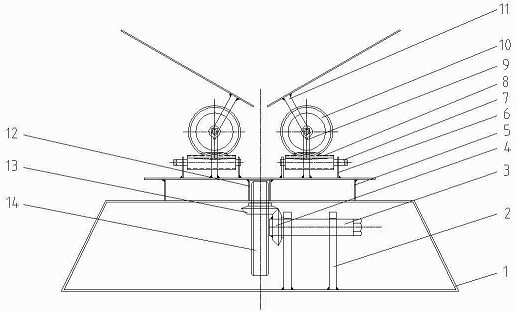

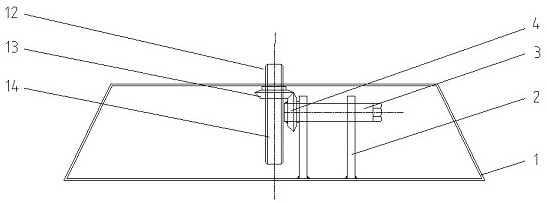

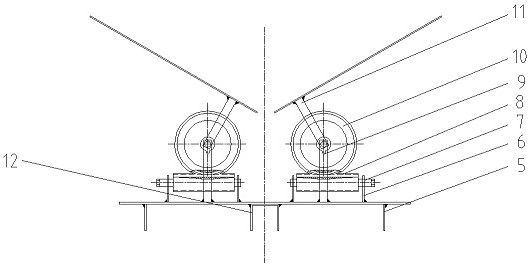

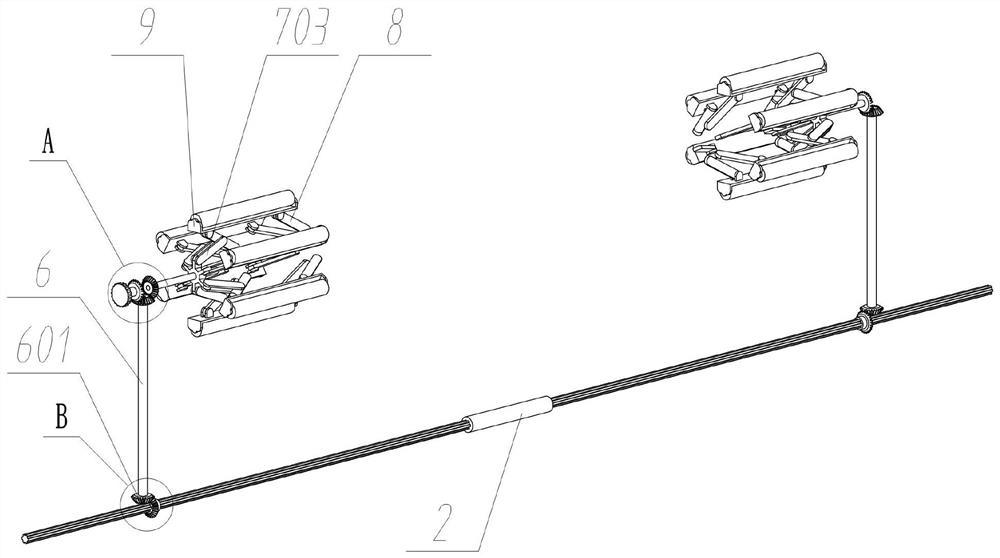

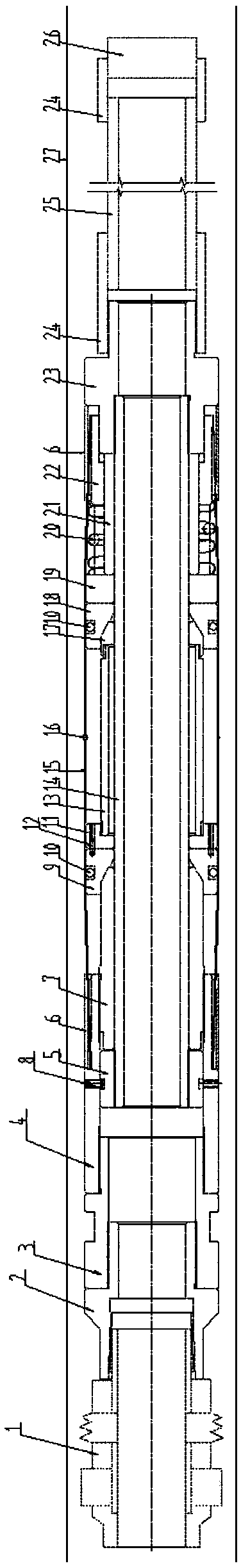

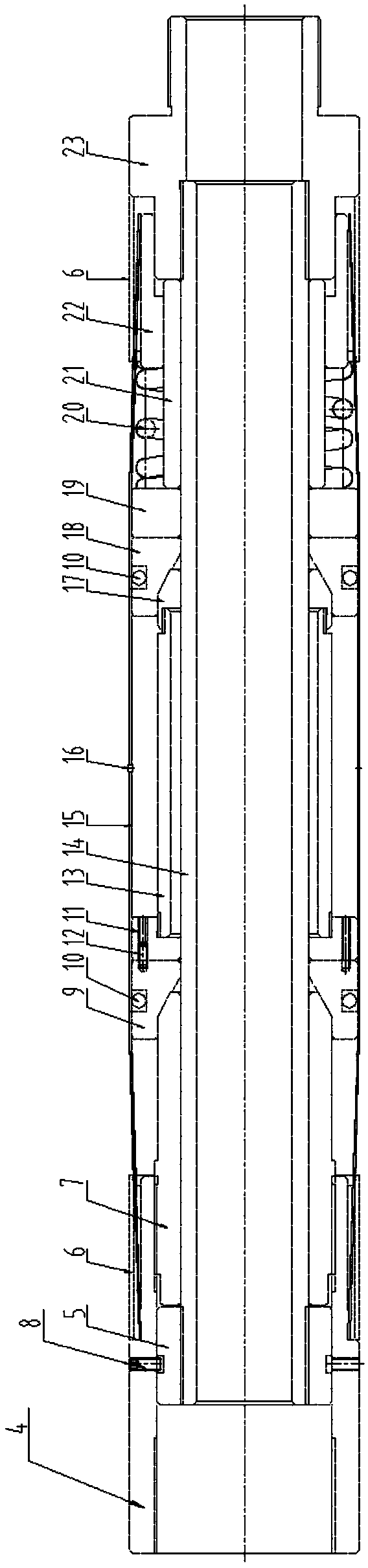

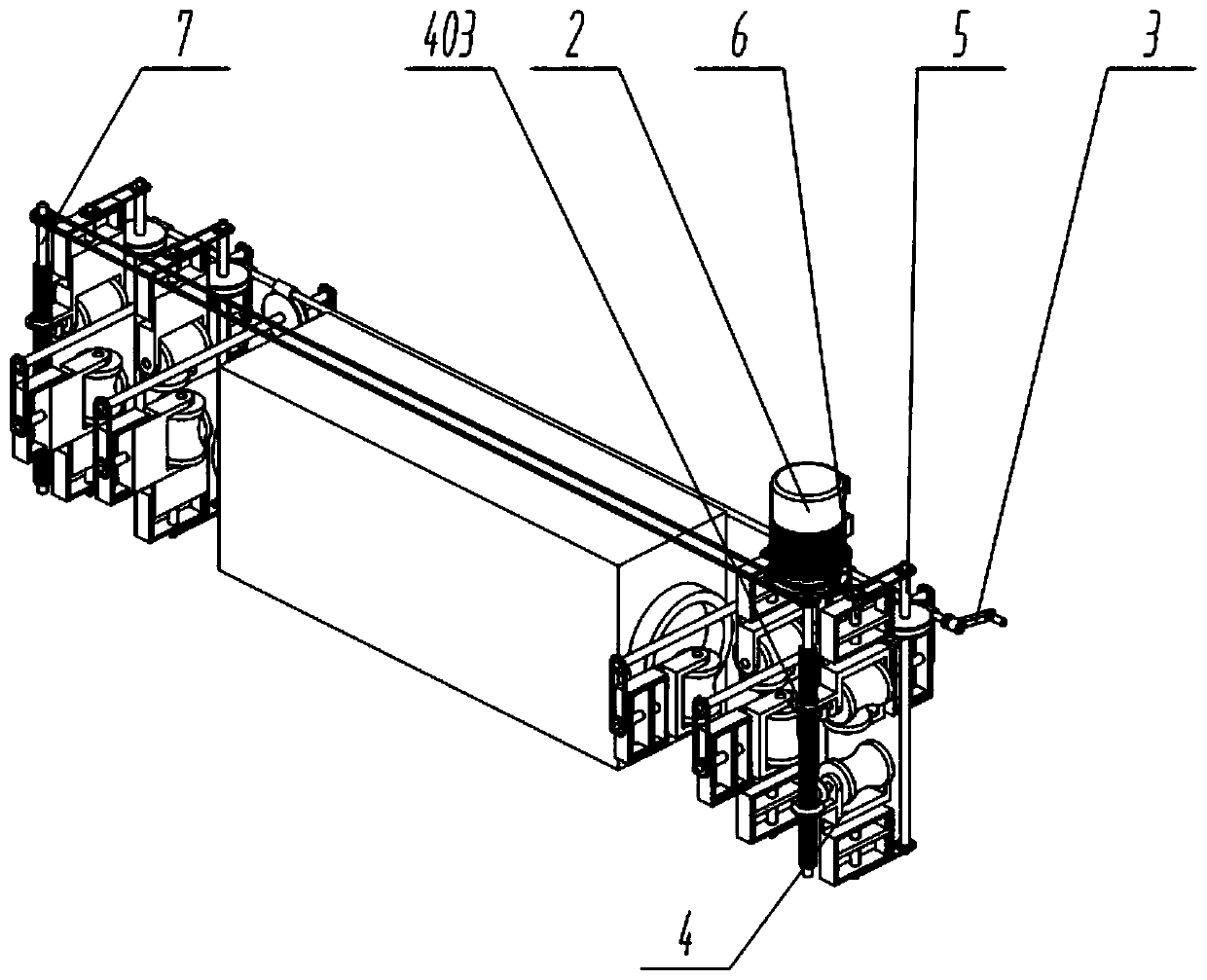

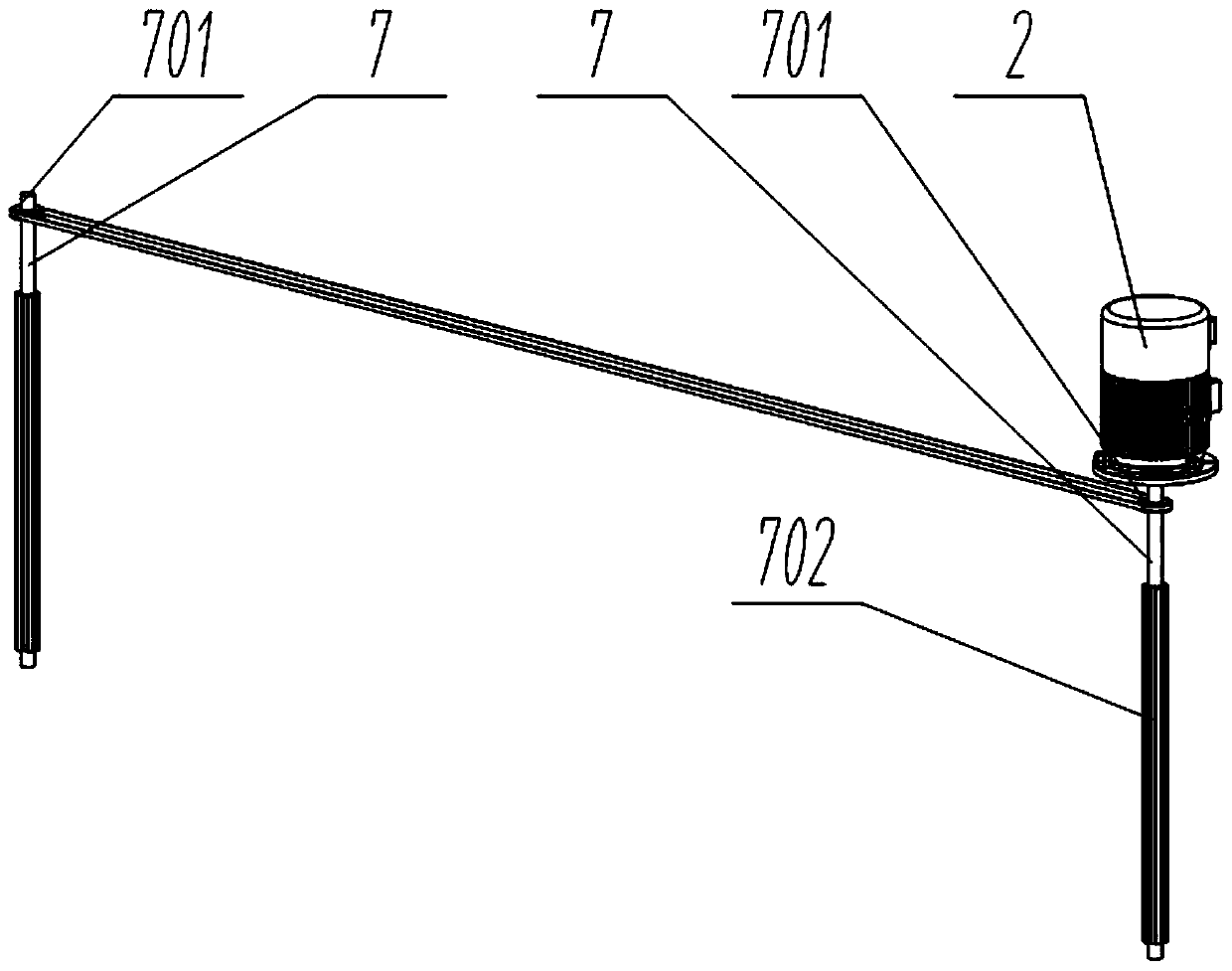

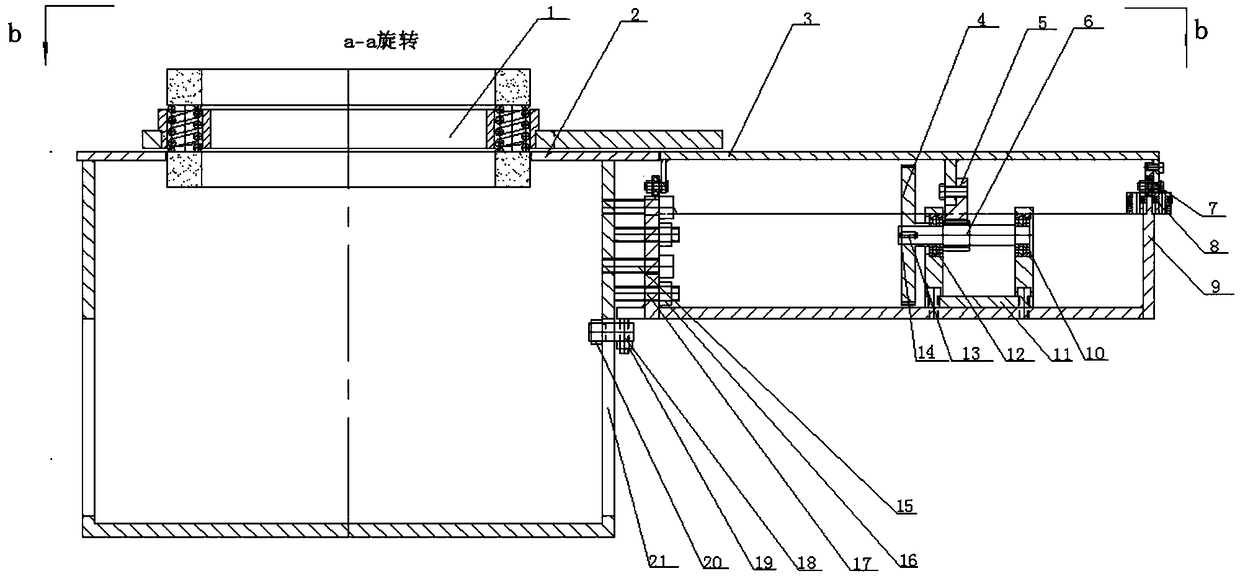

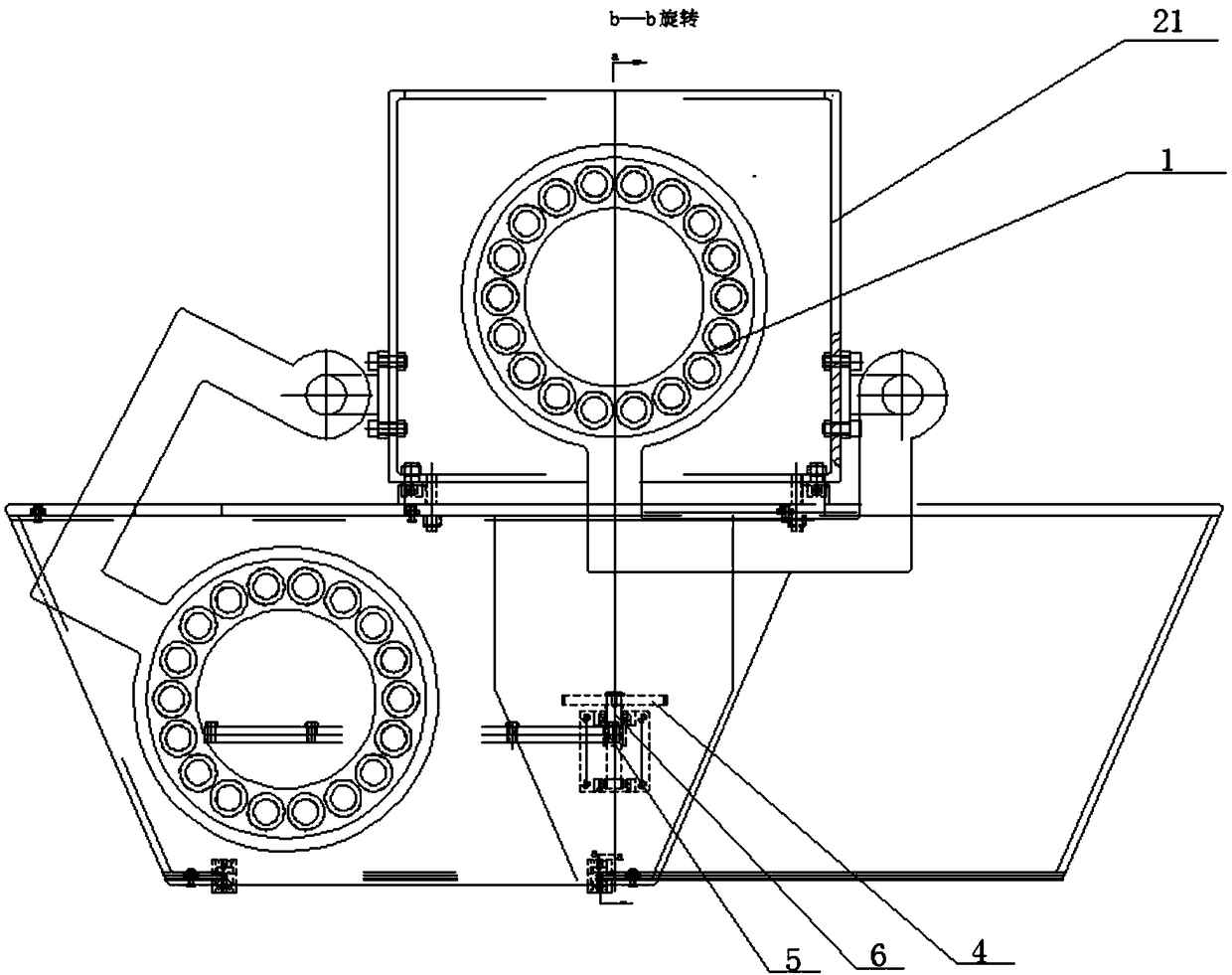

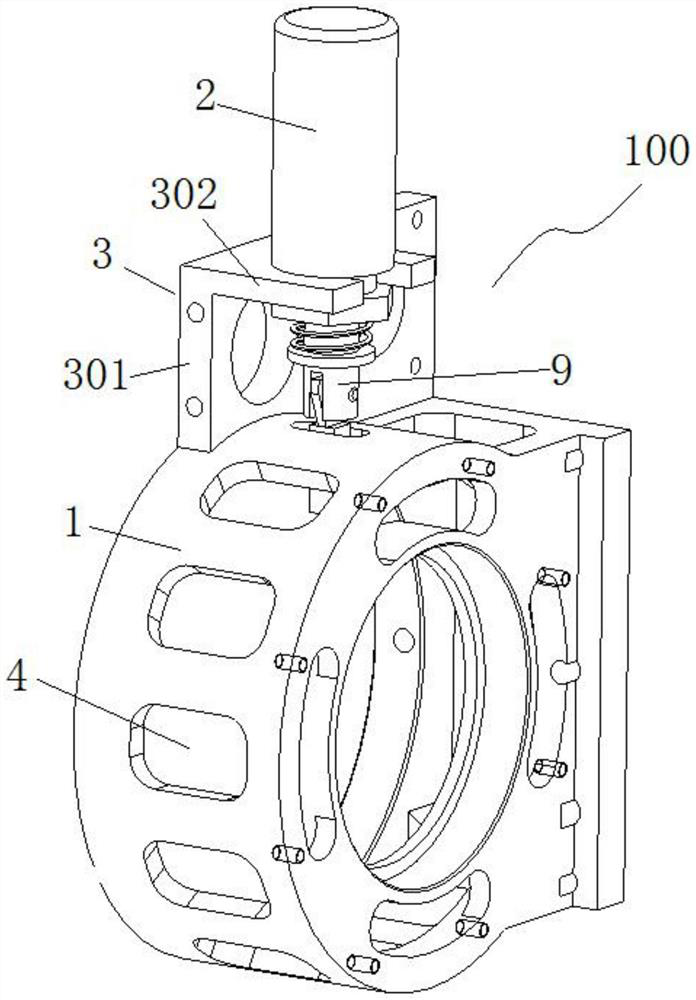

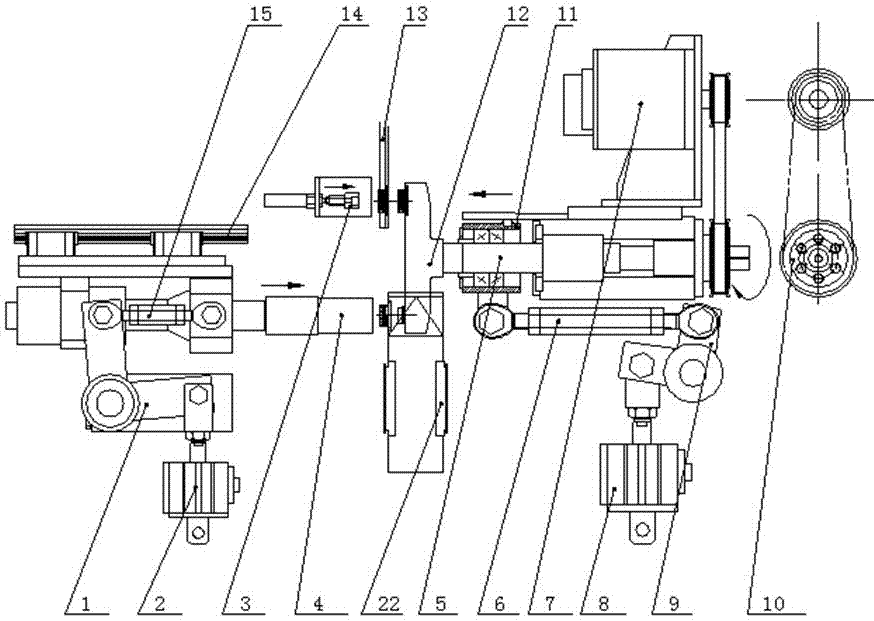

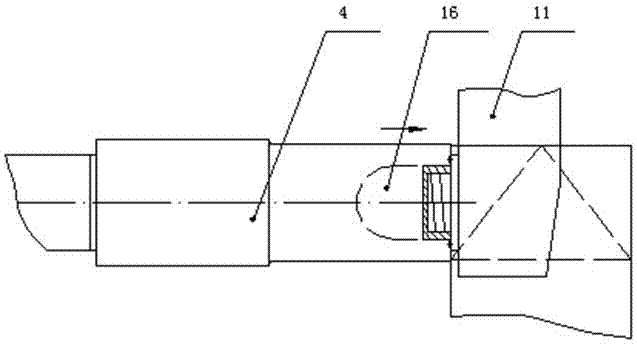

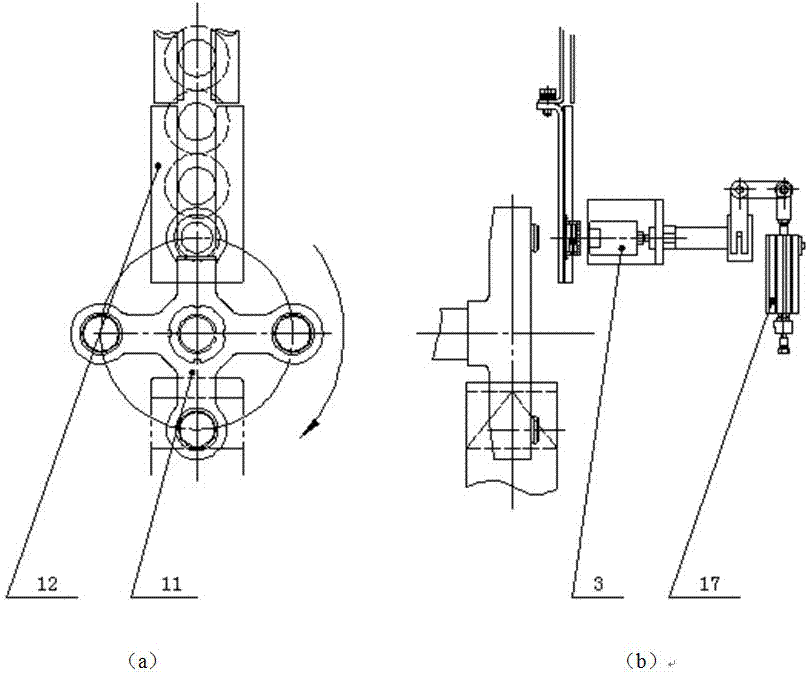

Upright spinning machine tool device with spinning roller pose adjustable

An upright spinning machine tool device with the spinning roller pose adjustable comprises oblique spinning mechanisms, a spindle, an ejector rod and a device body shell, wherein the spindle is arranged in the device body shell and right faces the ejector rod arranged on the upper portion of the device body shell, and the oblique spinning mechanisms are symmetrically arranged on the two sides of the ejector rod and embedded into the device body shell. Each oblique spinning mechanism comprises a four-freedom-degree parallel robot, two transverse motors, two oblique motors, two parallel transverse screw guide rails and two oblique screw guide rails, wherein the two oblique screw guide rails are coaxially arranged, the two transverse screw guide rails are coaxially arranged, and a T-shaped structure is formed by the oblique screw guide rails and the transverse screw guide rails; and the four-freedom-degree parallel robot is connected with the two transverse screw guide rails and the two oblique screw guide rails, and the transverse motors and the oblique motors are arranged on the transverse screw guide rails and the oblique screw guide rails correspondingly and drive the four-freedom-degree parallel robot to move. The upright spinning machine tool device is reasonable in design, high in machining precision and wide in application range.

Owner:SHANGHAI JIAO TONG UNIV

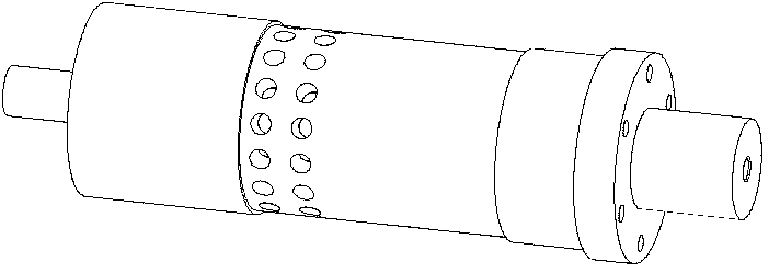

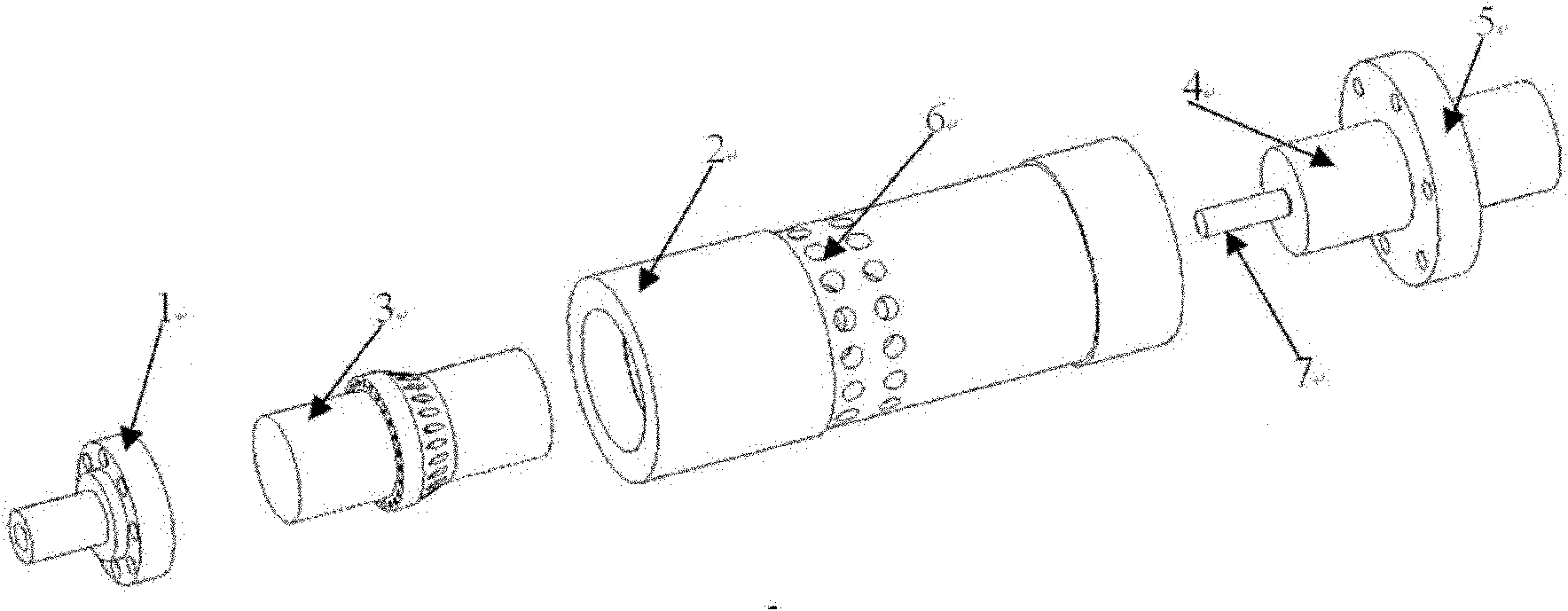

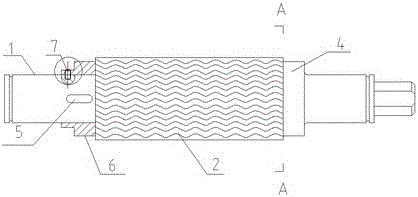

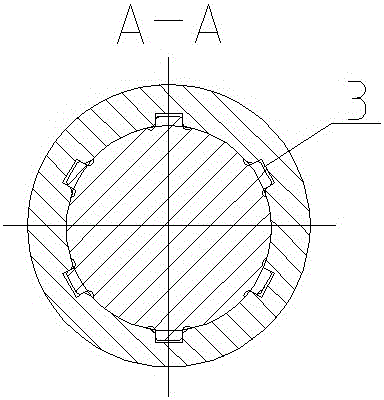

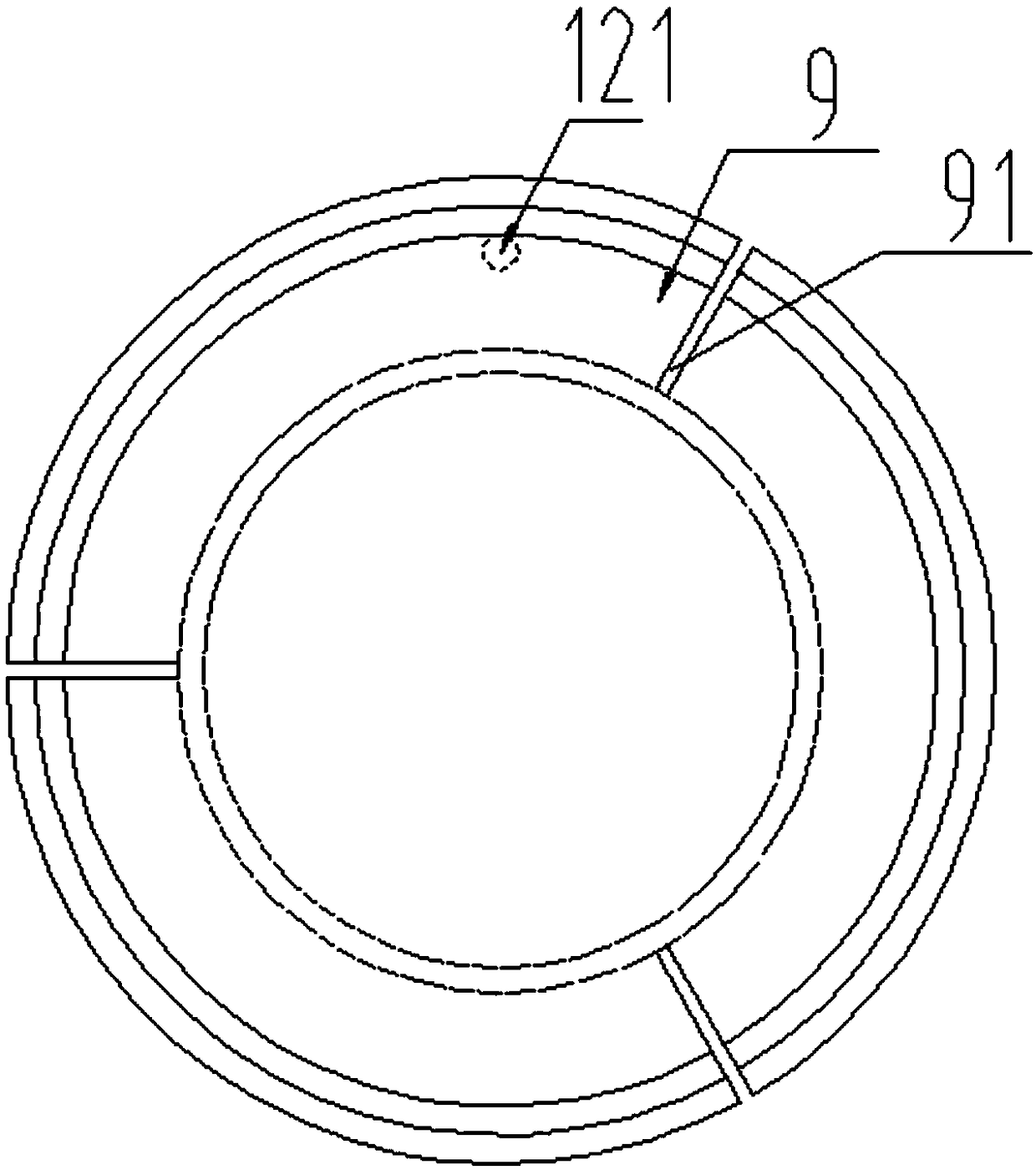

Combined type roller for rolling wave form corrugated composite boards

InactiveCN106734214ASolve deviationIncrease contact areaRollsMetal rolling arrangementsWave formComposite slab

The invention discloses a combined type roller for rolling wave form corrugated composite boards and belongs to the technical field of rollers. The combined type roller for rolling wave form corrugated composite board belts comprises a roller shaft, a roller shell, a spline, a flat key, a locking check ring and a screw. The combined type roller is structurally characterized in that an external spline is arranged on the roller shaft, an internal spline groove is formed in the roller shell, the roller shell is arranged on the roller shaft, the spline plays a role in positioning and is a rectangular spline, the outer surface of the roller shell is in a wave form corrugation shape, the metal composite board belts with wave form corrugation can be rapidly rolled, the contact area of a metallic matrix can be increased by using the wave form corrugation roller for making blanks, the combination strength of composite board interfaces can be enhanced, and the recombination rate of composite board interfaces can be increased; a step-shaped shaft shoulder is arranged at one end of the roller shaft and axially fixes the roller shell; and locking positioning, in the axial and radial directions of the roller shaft, of the other end of the roller shell is achieved through the cooperation of the flat key, the locking check ring and the screw. According to the combined type roller, the centring precision of the roller is high, the stability of centring is extremely high, axial roller shifting is prevented, the roller shell can be rapidly dismounted, and the assembling period of the combined type roller is shortened.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

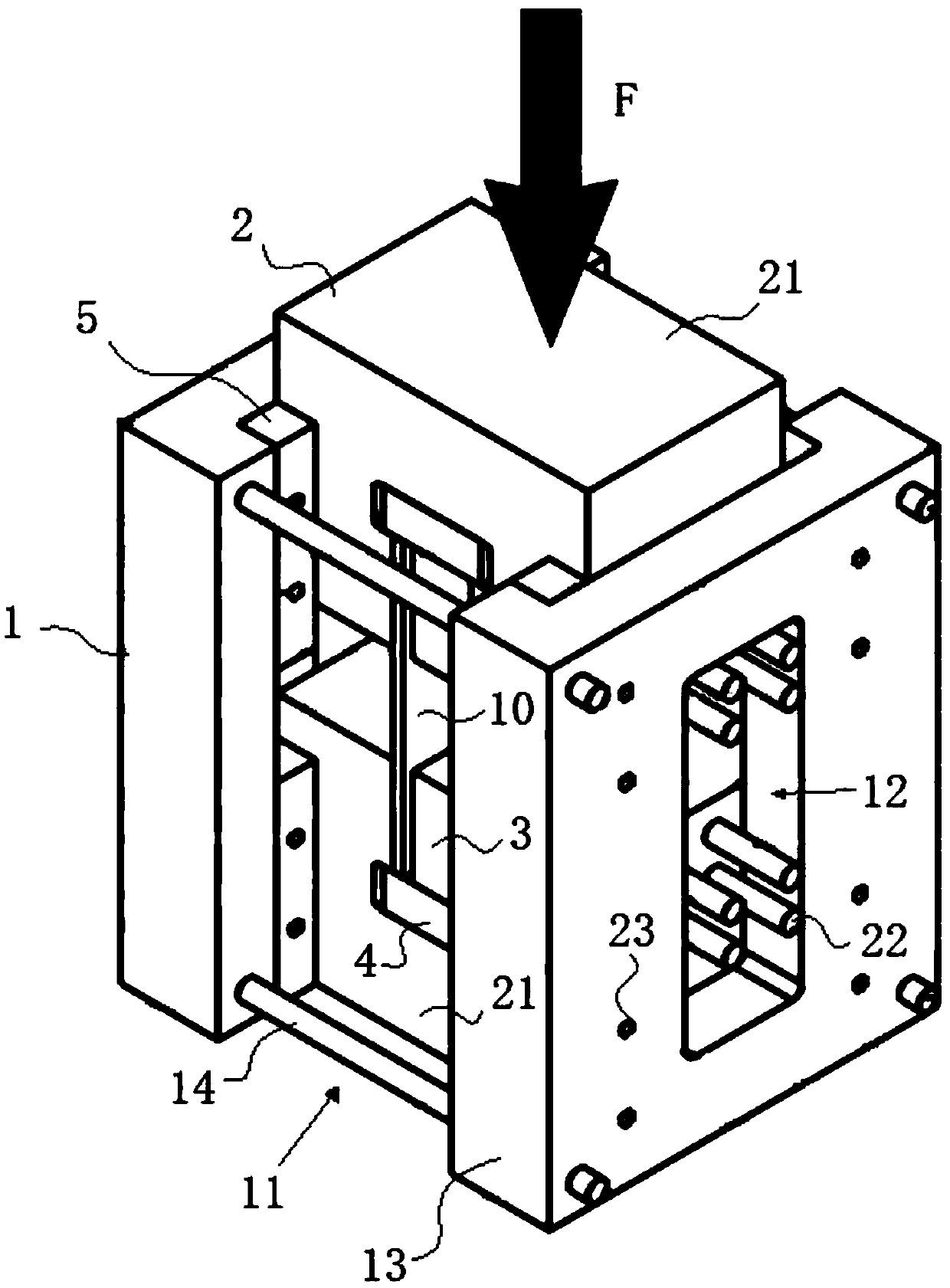

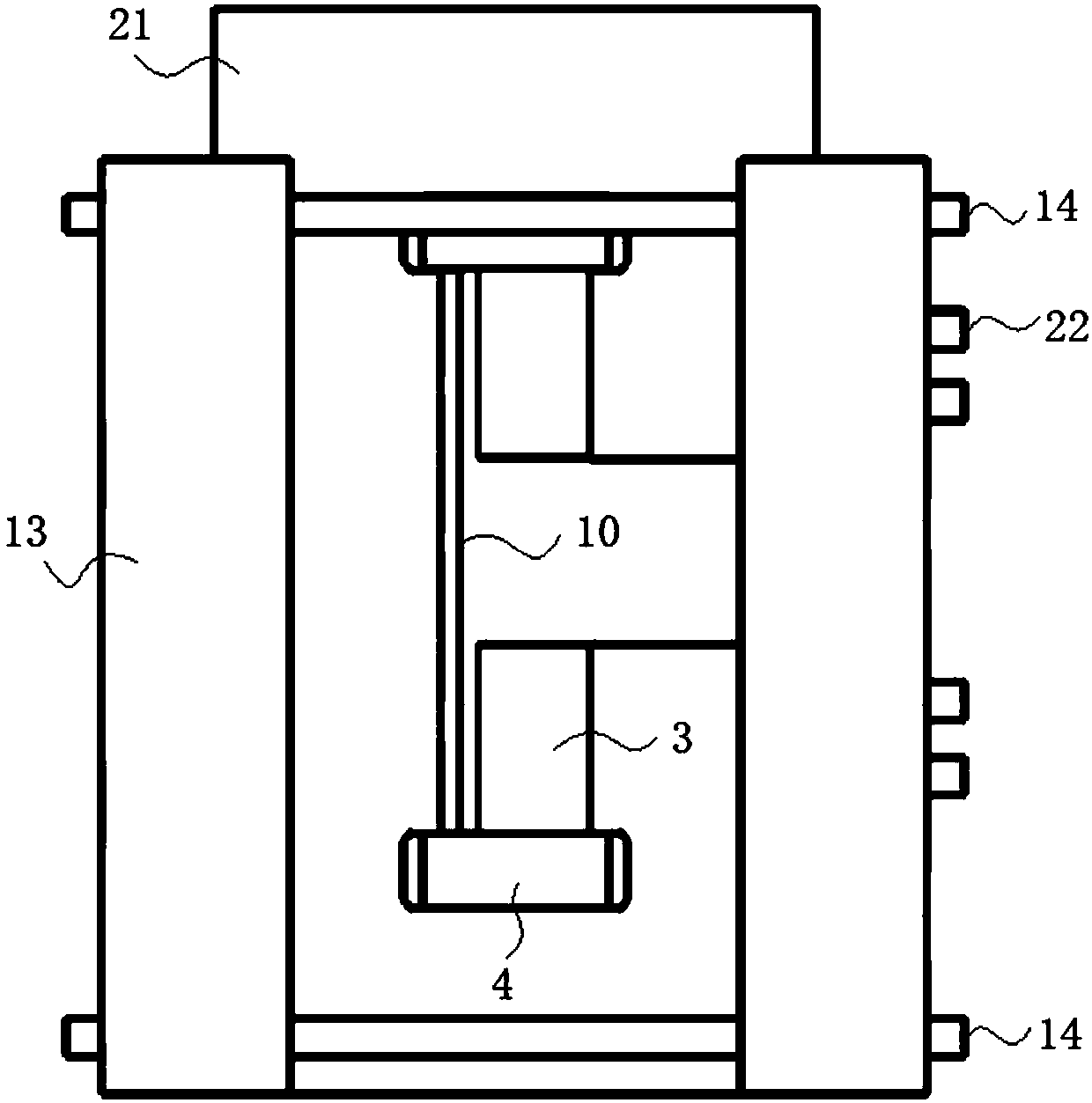

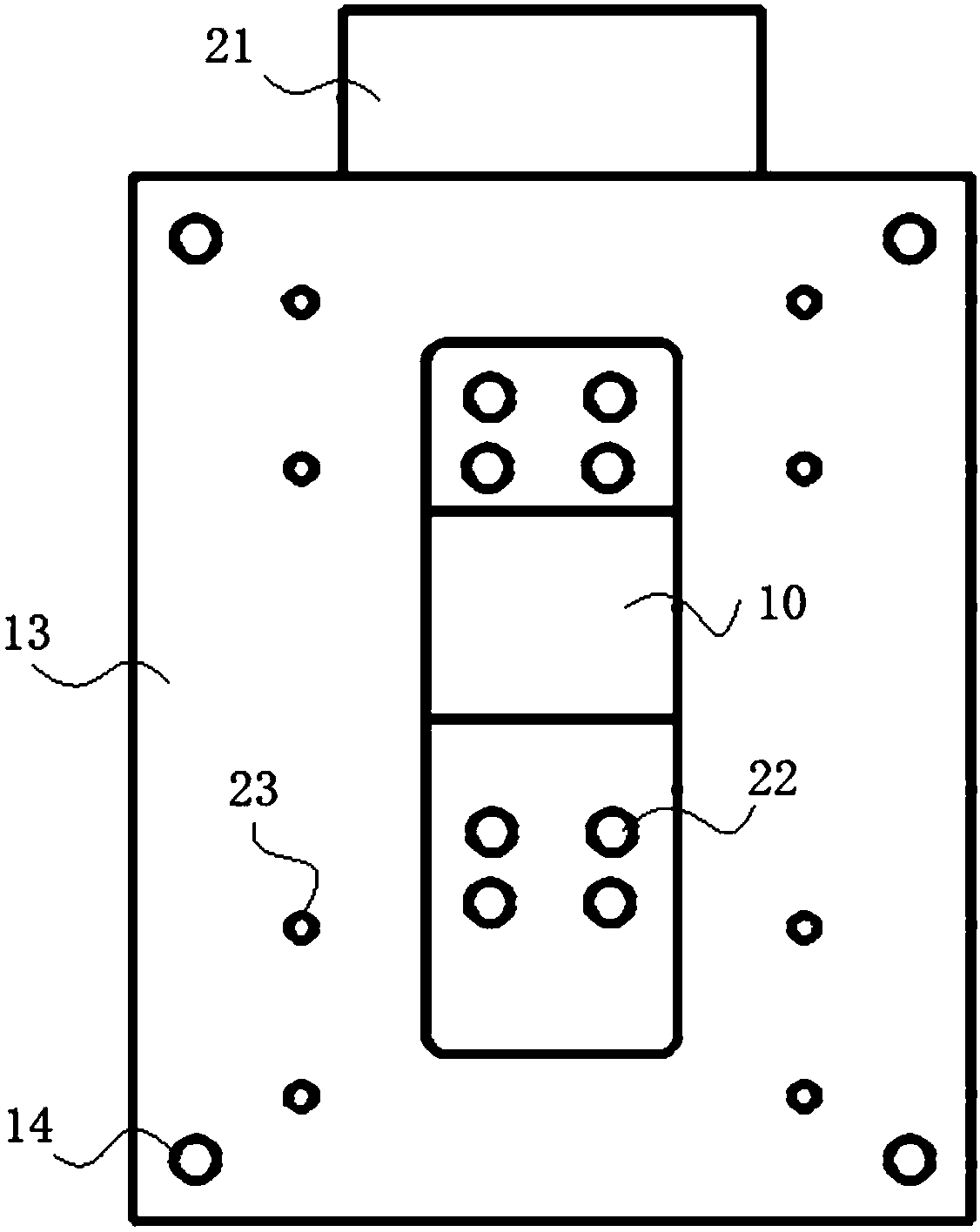

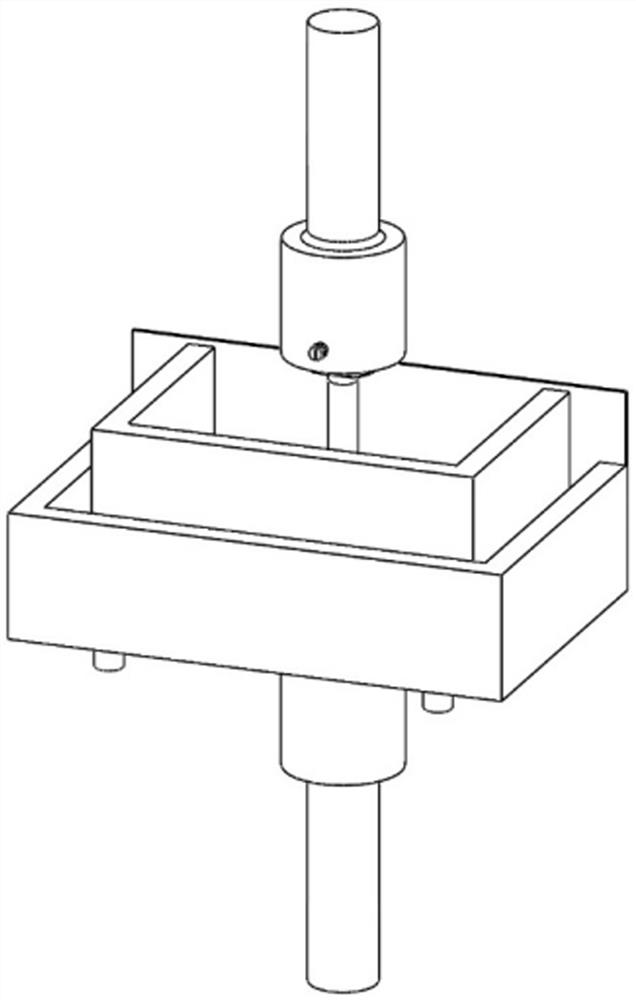

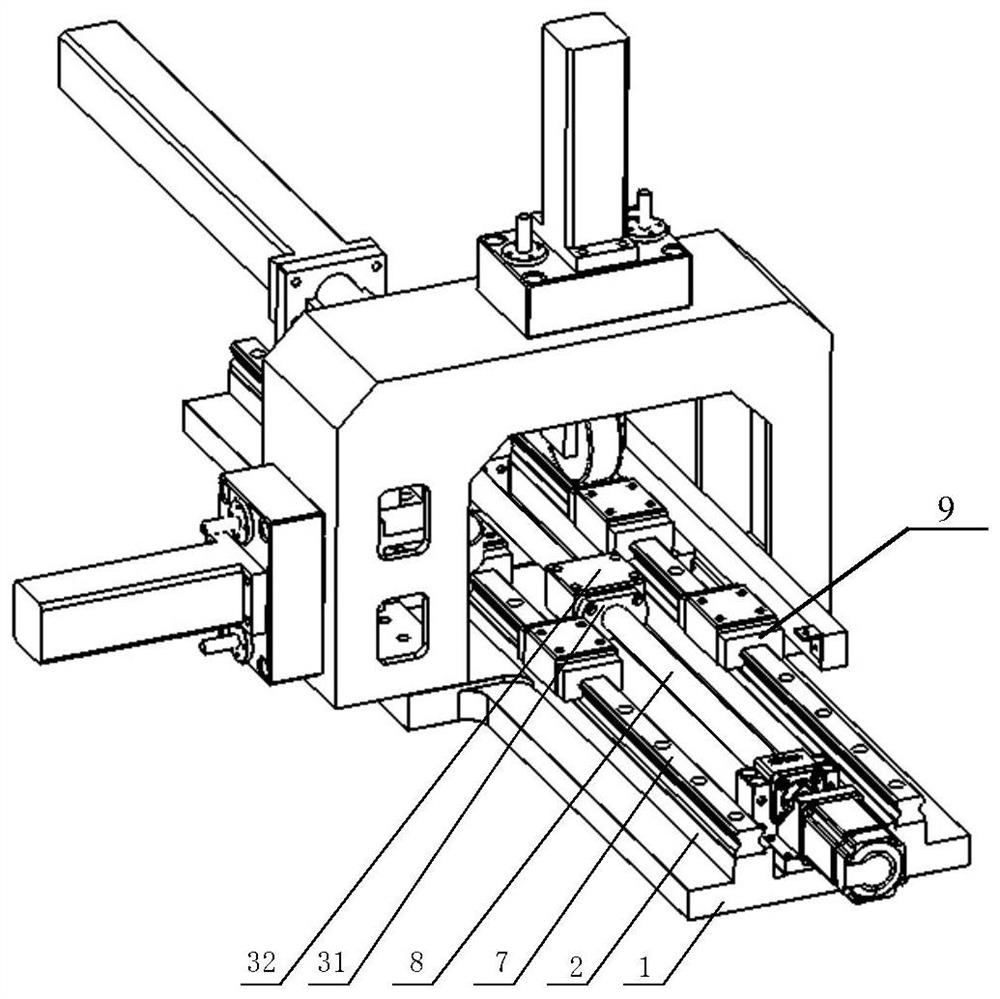

Device for compression fatigue test after impact of composite laminate

Belonging to the technical field of composite material testing, the invention relates to a device for compression fatigue test after impact of a composite laminate, and the device is used for compression test on a laminate test piece after impact. The device includes: a guide component, which is internally equipped with a guide channel having a guide direction consistent with the loading directionof a loading mechanism; a loading component, which is arranged in the guide channel, and is connected to the loading mechanism for transferring a loading force to the laminate test piece; fixation components, which are fixed to the plane of the laminate test piece to make the panel of the laminate test piece parallel to the loading direction of the loading mechanism. The test device provided by the invention has the advantages that: the composite laminate test piece can be directly used for fatigue test without cutting, and during use of the test device, the laminate test piece has good centering performance, and in the test process, the laminate test piece can undergo compression displacement only under one degree of freedom, thus ensuring no instable failure to the laminate test piece.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

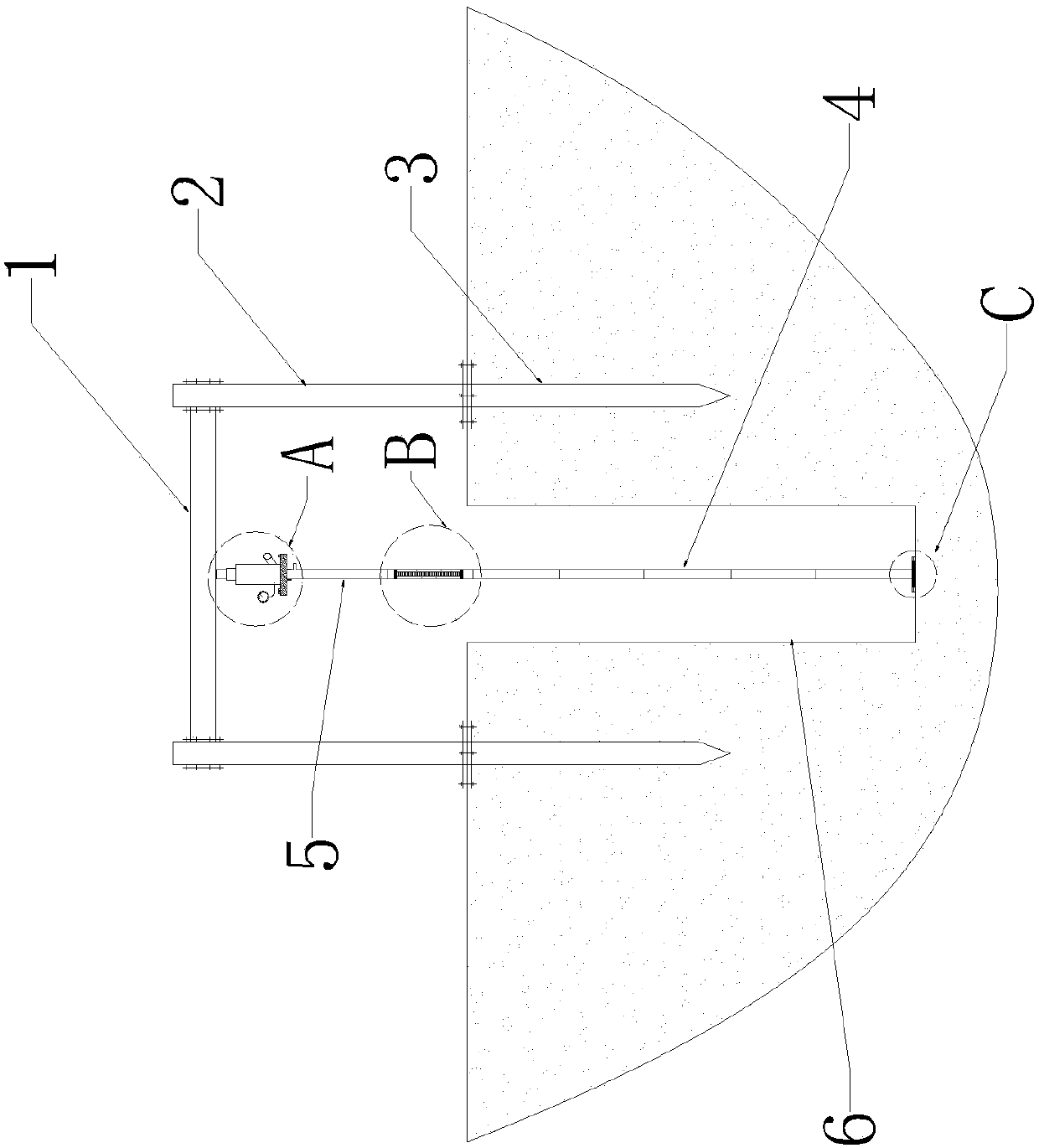

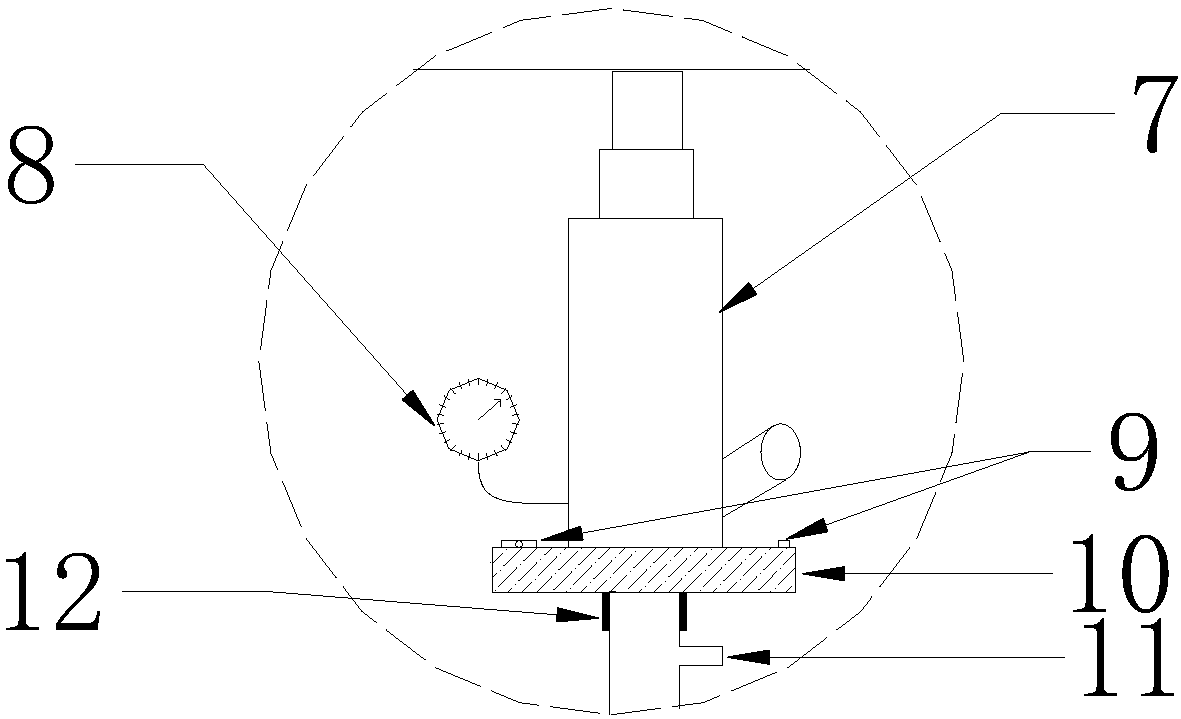

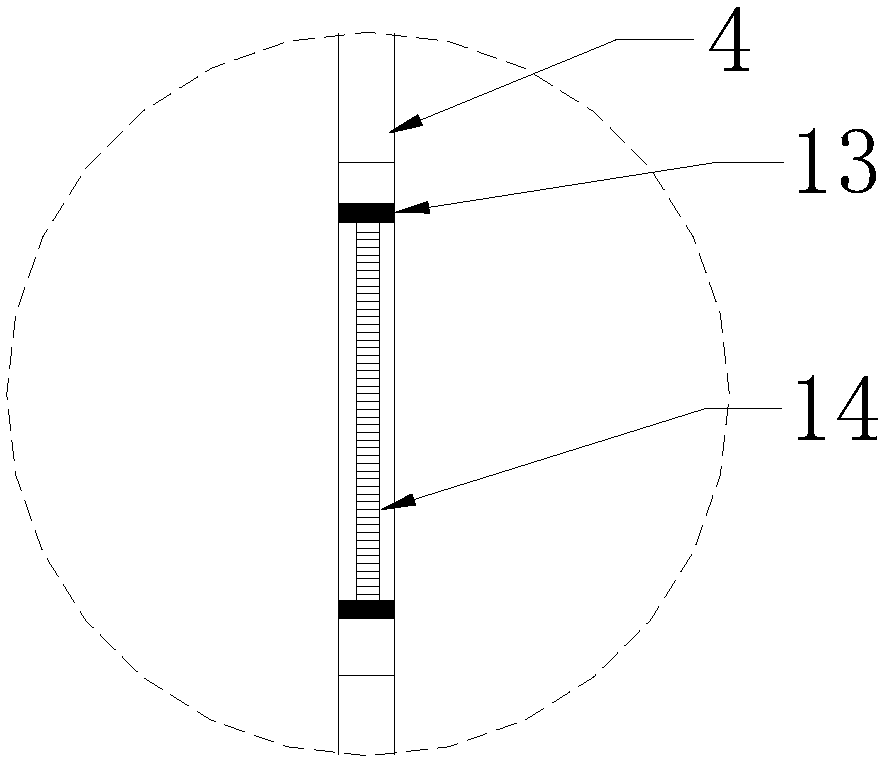

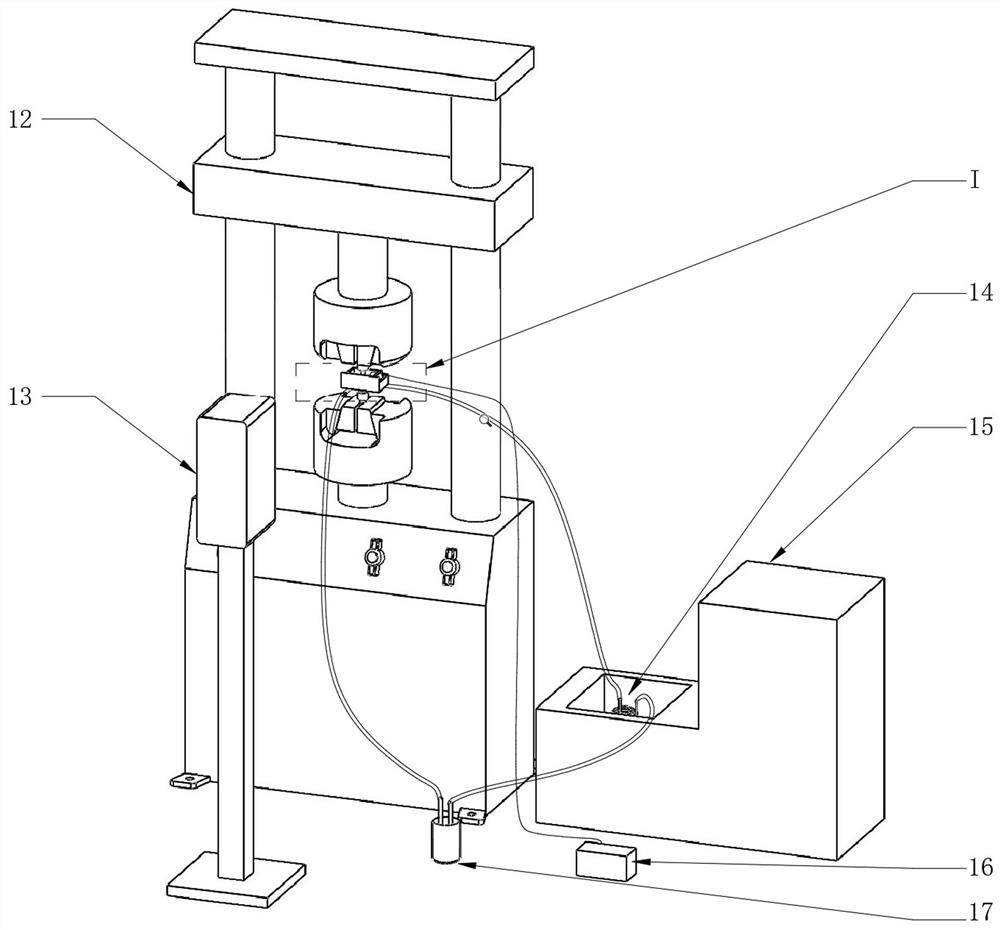

Equipment and method for measuring coefficient of collapsibility of loess

PendingCN108020460AReduce the probability of trial failureLow cost of measurementMaterial strength using tensile/compressive forcesSteel columnsLoess

The invention discloses equipment and method for measuring the coefficient of collapsibility of loess, and relates to the field of civil engineering measurement equipment. The equipment comprises a reaction frame, a vertical oil jack, a centering bearing plate, a dowel steel, a bottom bearing plate and observation equipment, wherein the reaction frame comprises a reaction cross beam, a stand column and a spiral steel column; the vertical oil jack is provided with a hydraulic pressure indicator, bubble levels are arranged at four corners of the centering bearing plate; the observation equipmentcomprises a digital level and an indium steel ruler matched with the digital level; and the indium steel ruler is fixed on the dowel steel through a ruler hoop. According to the equipment, the problem that loading is easily eccentric due to existence of a force-measuring loop in the prior art can be effectively controlled by using the hydraulic gauge, and the dowel steel is directly used as waterdelivery pipe for delivering water to an exploratory well, each part of the reaction frame is connected by adopting screws with simple assembly and disassembly, and the counter force provided by utilizing the spiral steel column and the pulling resistance of a soil mass is better than that provided by utilizing dead weight of overloading.

Owner:ANHUI UNIV OF SCI & TECH

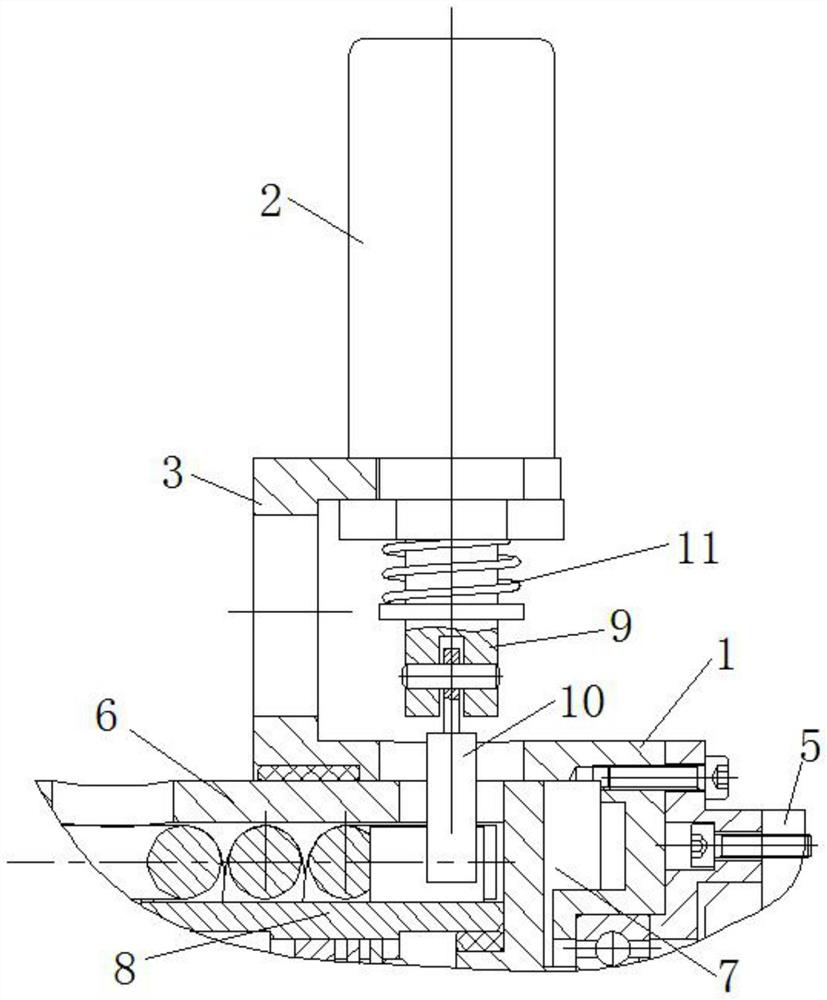

Efficient high-temperature tensile clamping device and testing method

PendingCN111060390AEasy clampingGuaranteed Parallel TestingMaterial strength using tensile/compressive forcesUniversal jointEngineering

The invention relates to an efficient high-temperature tensile clamping device and an efficient high-temperature tensile testing method, which belong to the technical field of testing machines and precise instruments. The efficient high-temperature tensile clamping device comprises upper clamps, lower clamps and clamping assemblies, wherein the upper clamps are connected with a high-temperature tensile testing device (external equipment) by means of universal joints I, the lower clamps are connected with the high-temperature tensile testing device (external equipment) by means of universal joints II, the clamping assemblies are connected with upper open groove clamping heads by means of upper spherical hinges I, the clamping assemblies are connected with lower open groove clamping heads bymeans of lower spherical hinges II, the clamping assemblies comprise rod-shaped sample clamping assemblies and plate-shaped sample clamping assemblies, and the clamping assemblies can realize clamping of plate-shaped and rod-shaped samples of different materials and sizes. The efficient high-temperature tensile clamping device has the advantages that the structure is simple, samples are convenient to clamp, the centering performance is good, parallel testing of the plurality of samples can be guaranteed, the testing efficiency is greatly improved, and technical guarantee is provided for high-temperature mechanical property testing of key structural materials in the fields of aerospace, automobile manufacturing, national defense and military industry and the like.

Owner:JILIN UNIV

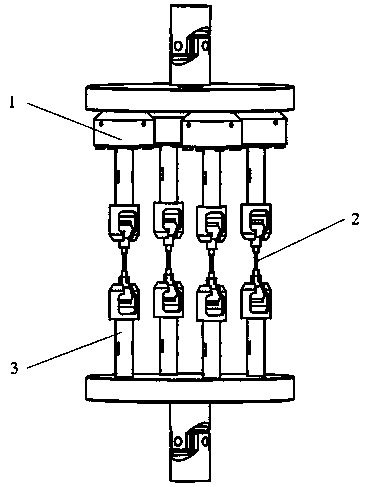

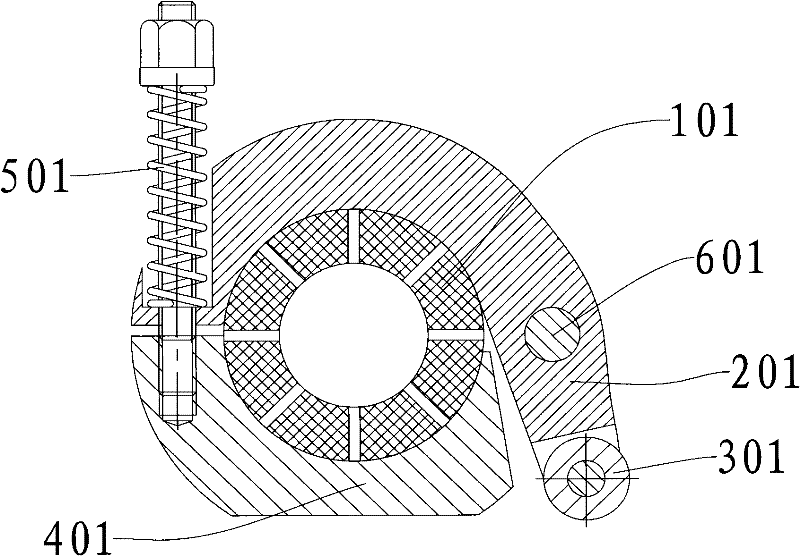

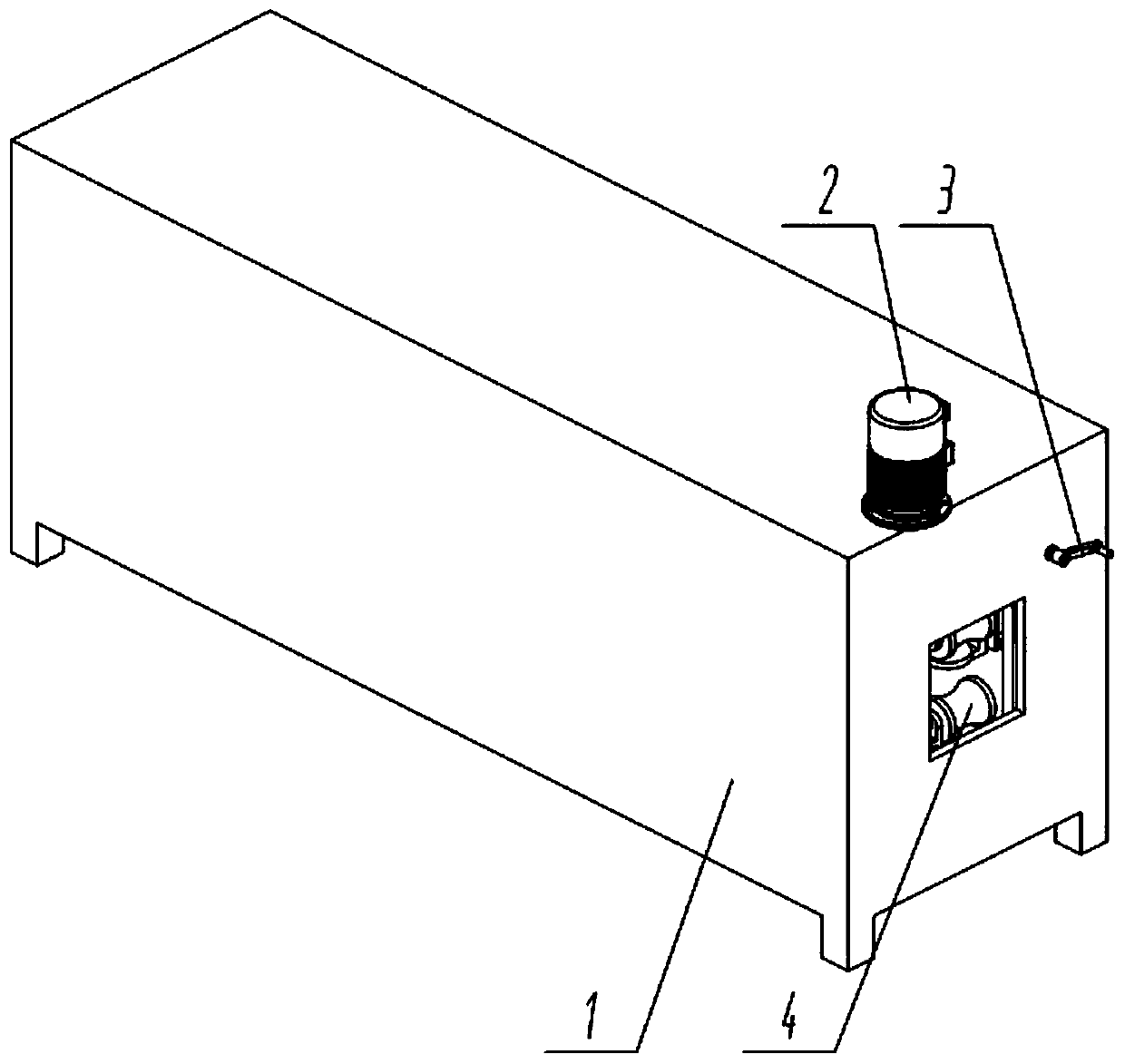

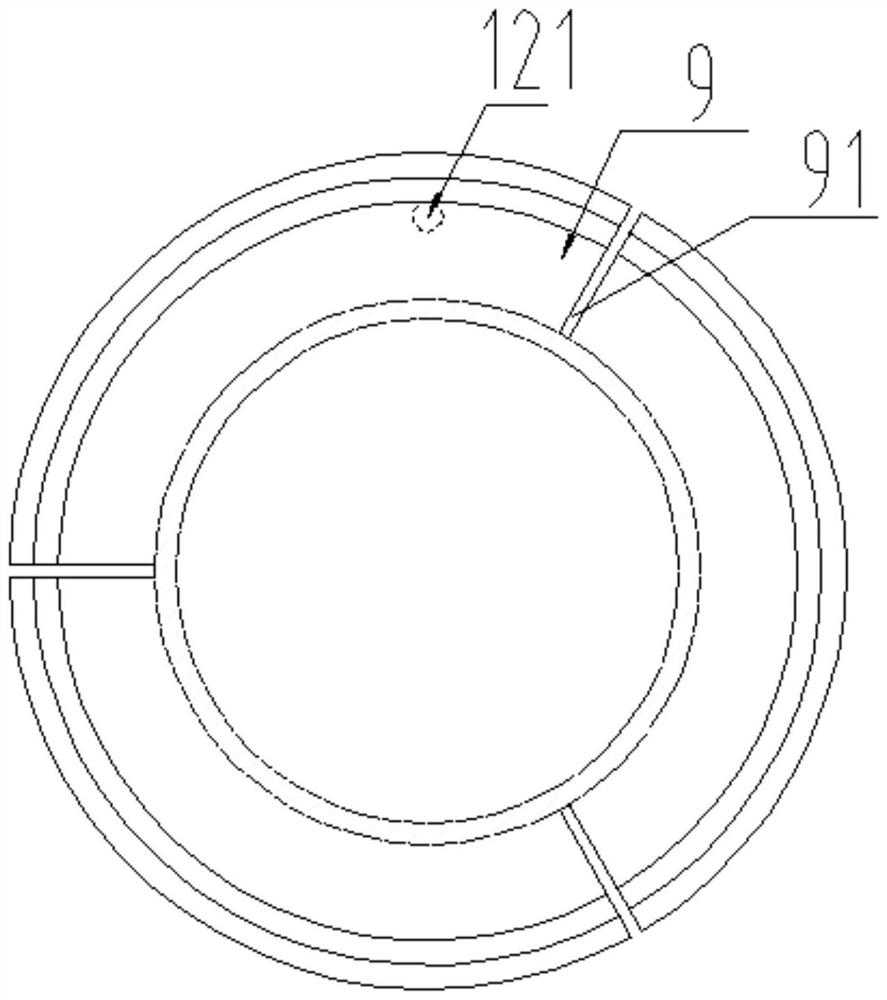

Fixing device for loop laying tube of loop laying head

InactiveCN105964726AGuaranteed weightGuaranteed to maintain the same weightEngineeringStructural engineering

The invention relates to a fixing device for a loop laying tube of a loop laying machine. The fixing device is characterized by comprising a loop laying head body, the loop laying tube, tube clamps and a fixing assembly, wherein the loop laying tube is arranged at the loop laying head body according to Archimedes spiral; the tube clamps are arranged on the loop laying tube and the loop laying head body; the fixing assembly is used for fixing the tube clamps and the loop laying head body and comprises fixing pins and bolts, the fixing pins are arranged in pin holes of the tube clamps and the loop laying head body, and the bolts are arranged in the fixing pins. The fixing device can prevent bump between the tube clamps of the loop laying head and a protection cover, protects the tube clamps of the loop laying head from wearing, guarantees stable dynamic balance of the loop laying head and reduces vibration of the loop laying head greatly.

Owner:JIANGSU YONGGANG GROUP CO LTD

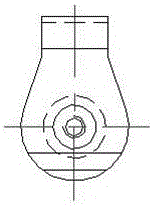

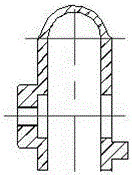

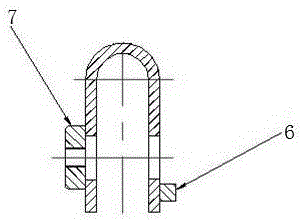

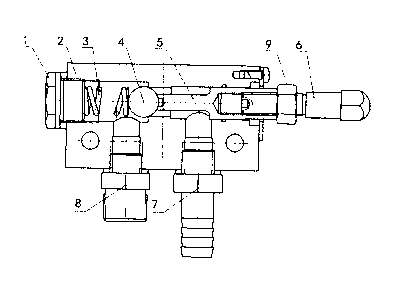

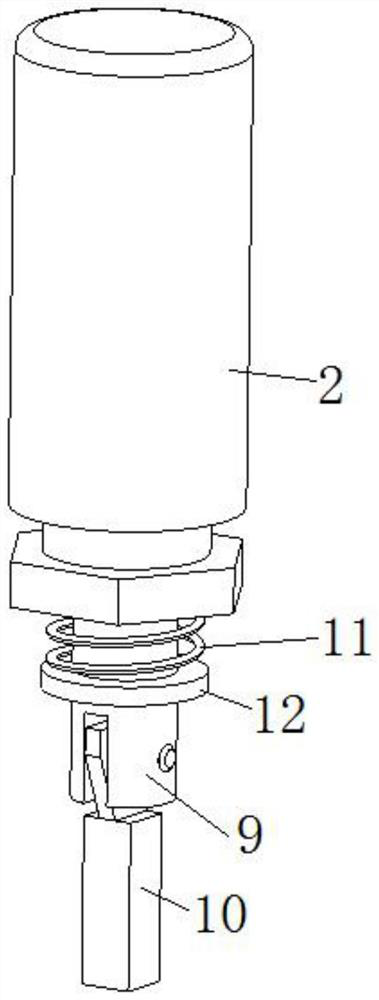

XF - E18L limit valve

The invention discloses an XF - E18L limit valve which comprises a main body (2), a rear end (1), a valve core (5), a screw (6), an oil return pipe connector (7) and an oil inlet pipe connector (8). The XF - E18L limit valve is characterized in that the limit valve is a steel ball (4), two sides of the steel ball (4) are respectively in contact with a return spring (3) and the valve core (5), an adjusting nut (9) is arranged on the screw (6), and two installation holes on the same perpendicular line are formed in the valve body. The XF - E18L limit valve adopts the steel ball as the valve core and adopts the spring for return centering. Compared with a prior cone valve type valve core, the valve core has the advantages of being good in centering performance, reliable in returning, and the like. Due to the fact that the adjustable adjusting screw is arranged on the limit valve, a user is enabled to set the cargo tank lifting angle as needed according to the vehicle type, a large quantity of usage cost is saved for the user, and replacement of components is enabled to be convenient and fast. The limit valve is installed vertically, adopts two parallel bolt holes, and has the advantages of being convenient to install, reliable in installation, and the like.

Owner:SICHUAN SINOTRUK WANGPAI XINGCHENG HYDRAULIC PARTS

High-strain creep-fatigue coupling test method for material in low-temperature corrosion environment

PendingCN113281156ASimple stepsEasy to operateMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesStructural engineeringCorrosion fatigue

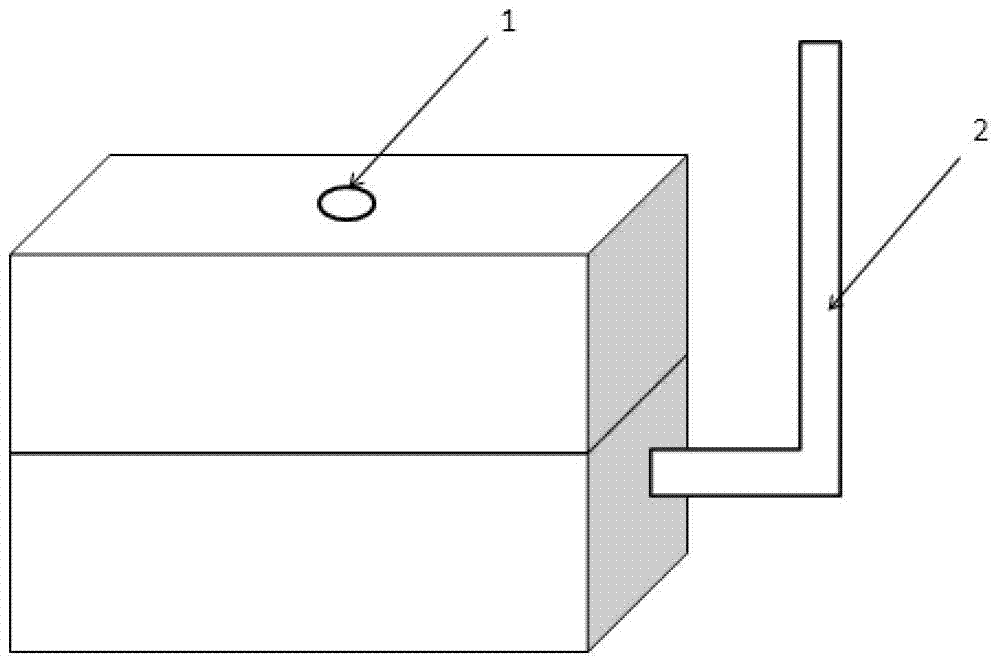

The invention discloses a high-strain creep-fatigue coupling test method for a material in a low temperature corrosion environment. The test is carried out by means of a test device, and the test device comprises a fatigue tester, a low temperature instrument, a video extensometer, a corrosion solution container, a submersible pump arranged in the corrosion solution container, a multilayer spiral pipe, a box-shaped corrosion tank, an upper clamping rod and a lower clamping rod; the space in the box-shaped corrosion tank is divided into a cuboid chamber and a U-shaped chamber through a U-shaped overflow plate, the bottom wall of the cuboid chamber is provided with a through hole and a liquid inlet hole through which a metal sample passes, the bottom wall of the U-shaped chamber is provided with a liquid outlet hole which can be connected with a corrosion solution container through a conduit, and a multi-layer spiral pipe in the low-temperature instrument is respectively connected with the liquid inlet hole and the submersible pump; and after the test device is assembled, a metal sample is tightly connected into the box-shaped corrosion tank, and then the test can be carried out. The test method provided by the invention meets the test requirements of a high-strain fatigue creep test in a low-temperature corrosion environment, and corrosion fatigue creep tests at different temperatures can be realized.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Adjusting and supporting device for pipeline installation

The invention relates to an adjusting and supporting device for pipeline installation, and belongs to the technical field of medium conveying pipeline installation. According to the technical scheme, a driving bevel gear (4) is fixed to a height adjusting force application rod (3); a driven bevel gear (13) meshed with the driving bevel gear (4) is arranged on a height adjusting lead screw (14); the upper end of the height adjusting lead screw (14) is inserted into a positioning sleeve (12); the positioning sleeve (12) is fixed to an upper supporting frame (5); a pipe diameter adjusting mechanism support (6) is fixed on the upper supporting frame (5); a pipe diameter adjusting force application rod (7) is horizontally and rotatably connected to the pipe diameter adjusting mechanism support (6); a worm gear (10) is meshed with a worm (8); and a pipe diameter adjusting supporting plate (11) is connected with the worm gear (10) through a connecting rod (15). The adjusting and supporting device for the pipeline installation provided by the invention has the beneficial effects that installation of pipelines with different pipe diameters can be met, and the installation precision and effect of the pipelines are effectively guaranteed.

Owner:HANDAN IRON & STEEL GROUP +1

Lifting machine upper chain wheel set device

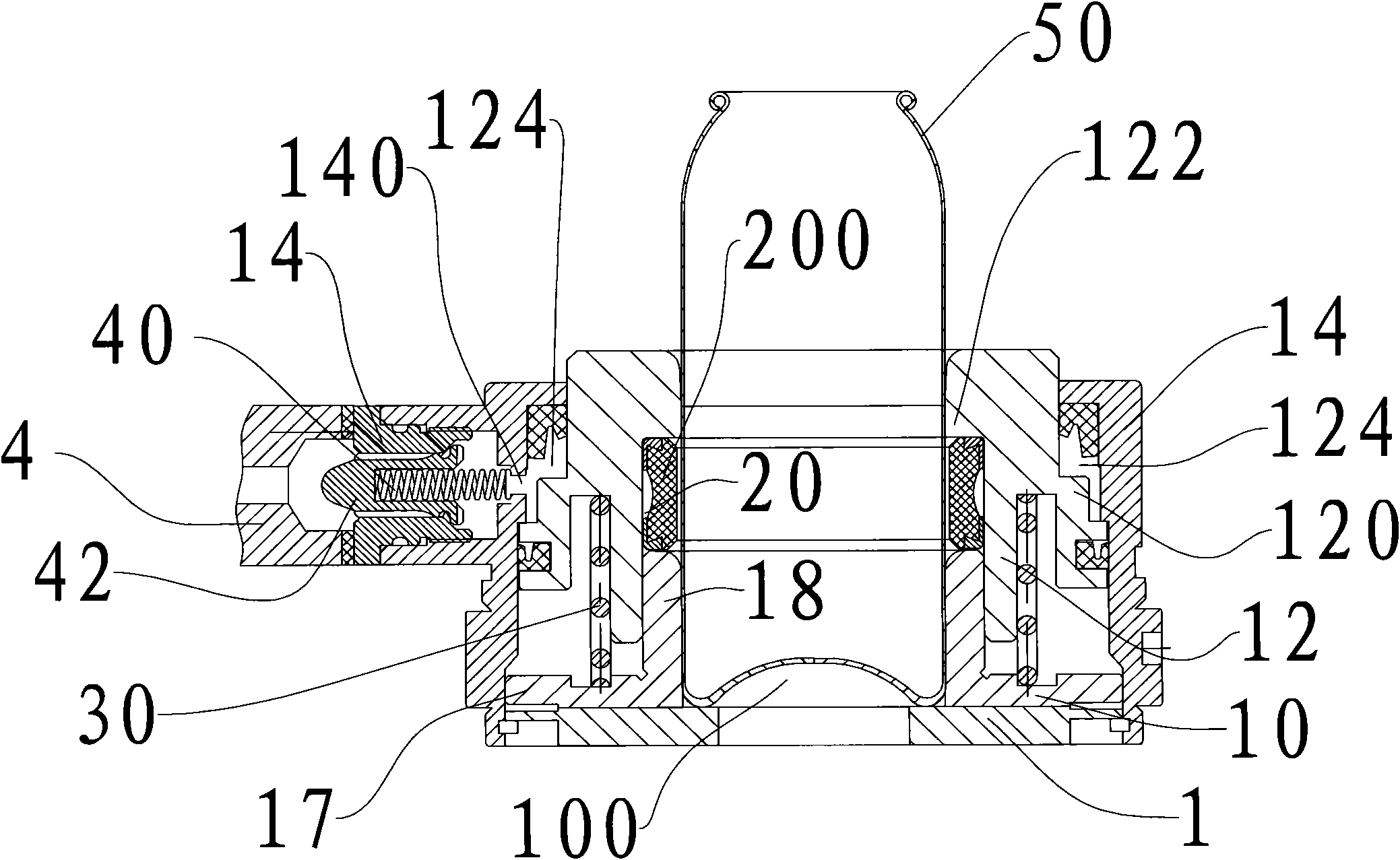

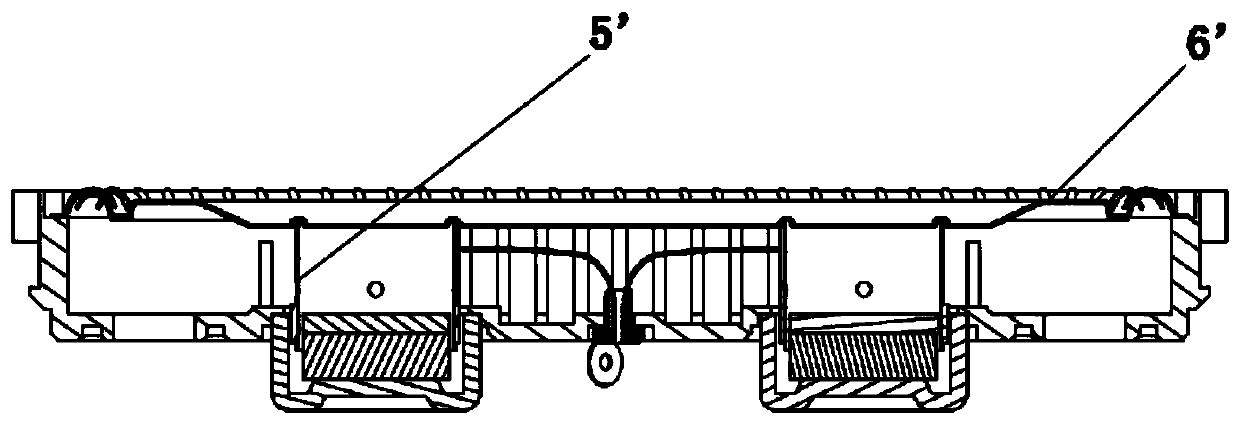

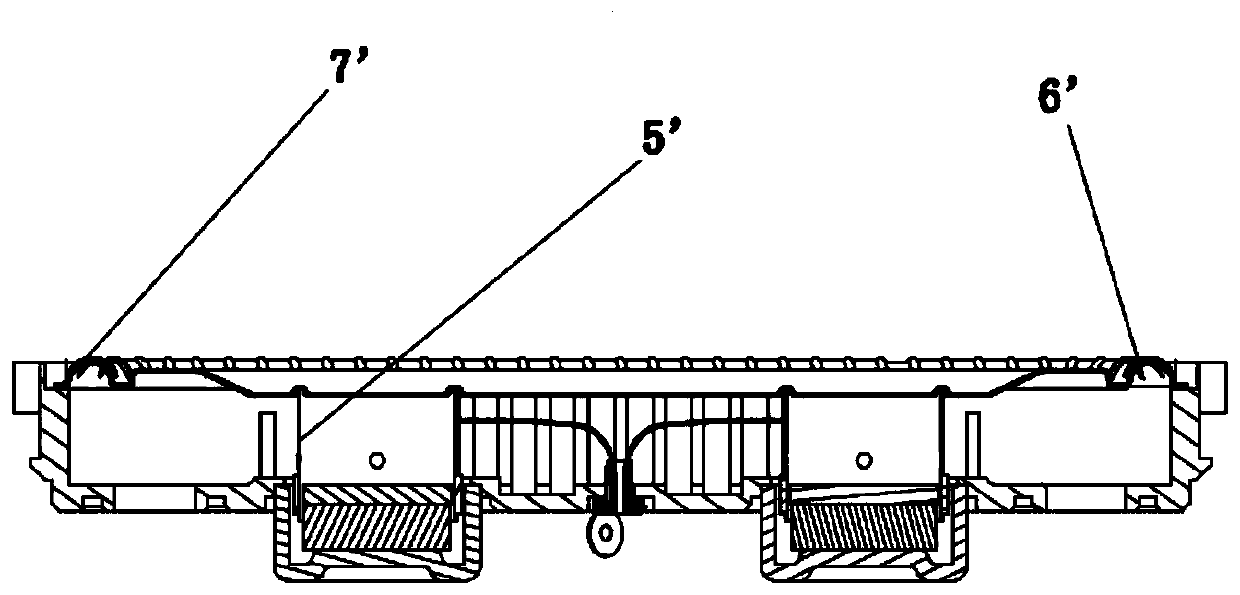

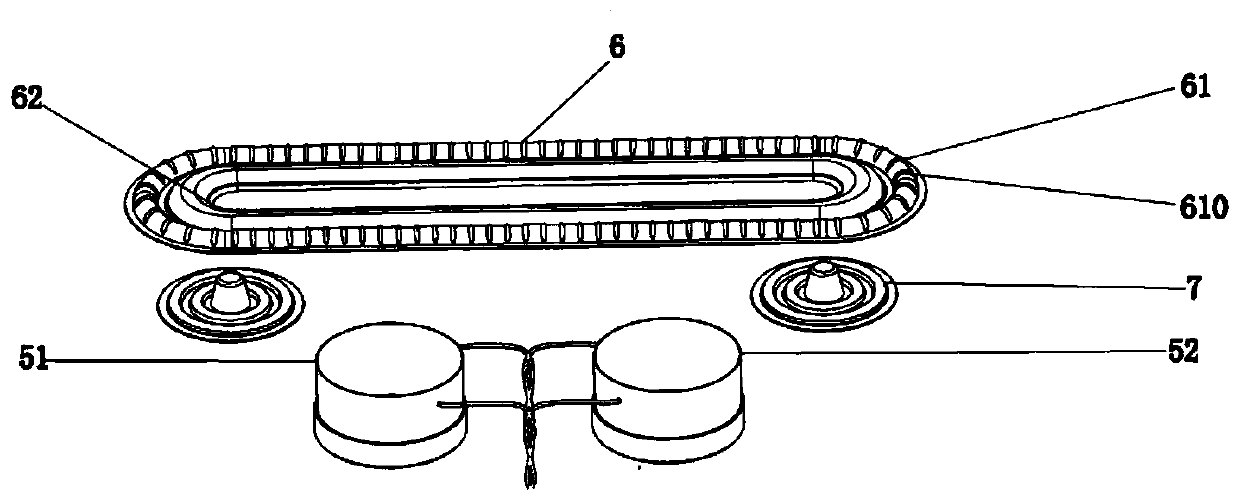

PendingCN110792757AGood neutralReduce wearEngine sealsGearing detailsCouplingRolling-element bearing

The invention aims to provide a lifting machine upper chain wheel set device. Transmission is achieved by both a chain wheel set with a split block chain wheel and a shaft by means of friction througha bearing on a rolling bearing house. Due to the split mode, the problems of chain wheel bearing falling, shaft end abrasion, breaking and the like are well solved, abrasion between an upper shaft and the bearing and abrasion between the upper shaft and the split block chain wheel are reduced, the service life is obviously improved, and the operation rate of equipment is greatly improved; meanwhile, common flat key coupling is adopted, so that a high-speed, impact-bearing or variable-load shaft is better adapted; a common flat key is good in alignment performance, high in positioning precision and convenient to disassemble and assemble, and abrasion is reduced; and a sealing assembly is mounted between the split block chain wheel and the bearing so as to prevent leakage of lubricating oil, dust invasion or leakage of dust to the outside, and the sealing effect is good.

Owner:WUHU CRANE & CONVEYOR

Loading plate of reduction gear used for mixing

The invention relates to a loading plate of a reduction gear used for mixing, which comprises a sleeve, a rolling bearing, a loading base, a bearing gland and a shaft coupling, wherein the output shaft of the reduction gear is inserted into the sleeve, the sleeve is mounted inside the loading base through the rolling bearing, the loading base is fixed on the flange of the reduction gear, a flange plate is arranged on the loading base and used for connecting and fixing a tank opening support, the bearing gland is fixed on the loading base, a seal ring is arranged between the bearing gland and the sleeve, one end of the shaft coupling is fixedly connected with the sleeve, and a mixing shaft is mounted and fixed inside the shaft coupling. The loading plate is connected and assembled with the reduction gear by means of sleeve insertion, and is convenient for installation. The loading plate occupies less space in the height direction. In a case that a frame is unavailable, the loading plate can replace the frame to improve internal stress conditions of the reduction gear, increase the service life of the reduction gear and prevent oil leakage of the reduction gear. The loading plate is connected with the mixing shaft through the split jacket-type shaft coupling, so as to facilitate rapid installation and uninstallation and ensure good alignment.

Owner:JIANGSU HAOTELONG MIX EQUIP

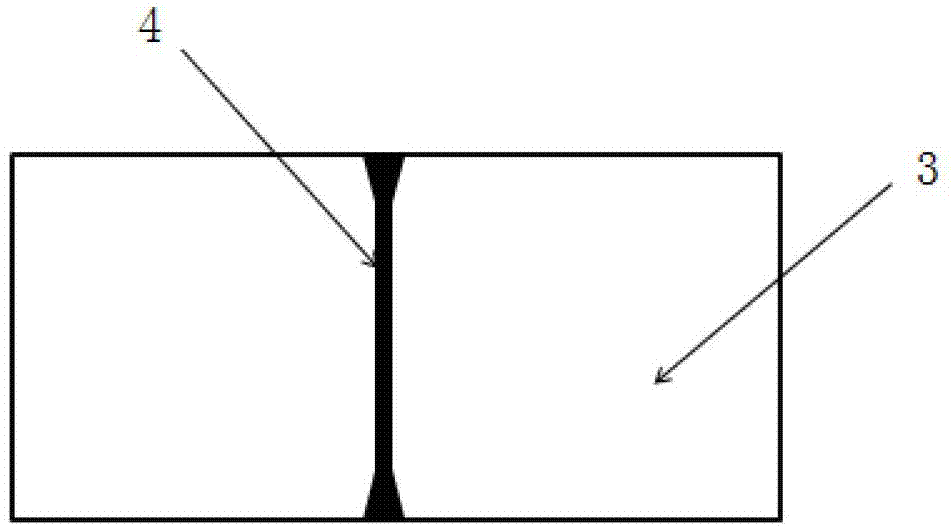

Preparation method of coded aperture for neutron penumbra imaging

ActiveCN102956280AHigh softening pointHigh hardnessX-ray/infra-red processesConversion screensHydrogen chlorideNeutron

The invention discloses a preparation method of a coded aperture for neutron penumbra imaging. The method includes the steps of: firstly drawing a quartz glass tube through a laser tube drawer to obtain a quartz glass tube which satisfies the aperture shape requirement of a penumbra hole; fixing the glass tube in a die and adding smelted liquid heavy metal to the die; after the heavy metal is cooled and solidified, dissolving the quartz glass tube in the metal block through hydrogen chloride solution; and incising the metal block along the middle part to obtain two penumbra holes which contain double-pyramid type thick apertures. The double-pyramid type thick apertures, the diameter change of which can be controlled, are suitable for penumbra hole design of different neutron penumbra imaging technologies. The preparation method is simple in preparation process, and the coded aperture prepared through the method in which a glass tube drawing technology and a metal die cavity forming technology are combined is low in cost and convenient for popularization.

Owner:SHANGHAI JIAO TONG UNIV

A pneumatic metal can clamp

ActiveCN102259311AEasy to operateGood neutralWork holdersPositioning apparatusClosed chamberEngineering

The invention discloses a pneumatic metal can clamping unit which comprises a high pressure air supply system, a base, an annular positioning plate arranged on the base, a cylinder capable of being sleeved outside of the annular positioning plate, a shell fixedly connected with the base and an air inlet which is arranged on the shell and connected with the air supply system, wherein the center of the annular positioning plate is provided with a channel for accommodating and clamping a metal can; the top of the cylinder is inwards provided with an annular bump; an annular boss is arranged outside the cylinder; the annular boss, the shell and the cylinder form a closed air chamber; a certain distance is reserved between the lower end of the cylinder and the annular positioning plate; and the lower end of the bump and the annular positioning plate form an annular groove in-built with an elastic rubber block. By adopting the pneumatic metal can clamping unit in the technical scheme, the clamping is reliable, the clamping force is uniform and adjustable, the operation is simple, the centering property is excellent, a centering error generated by relaxation can be avoided, and appearance defects such as pollution, scratches and the like on an aluminium pot product can be avoided.

Owner:汕头市东方科技有限公司

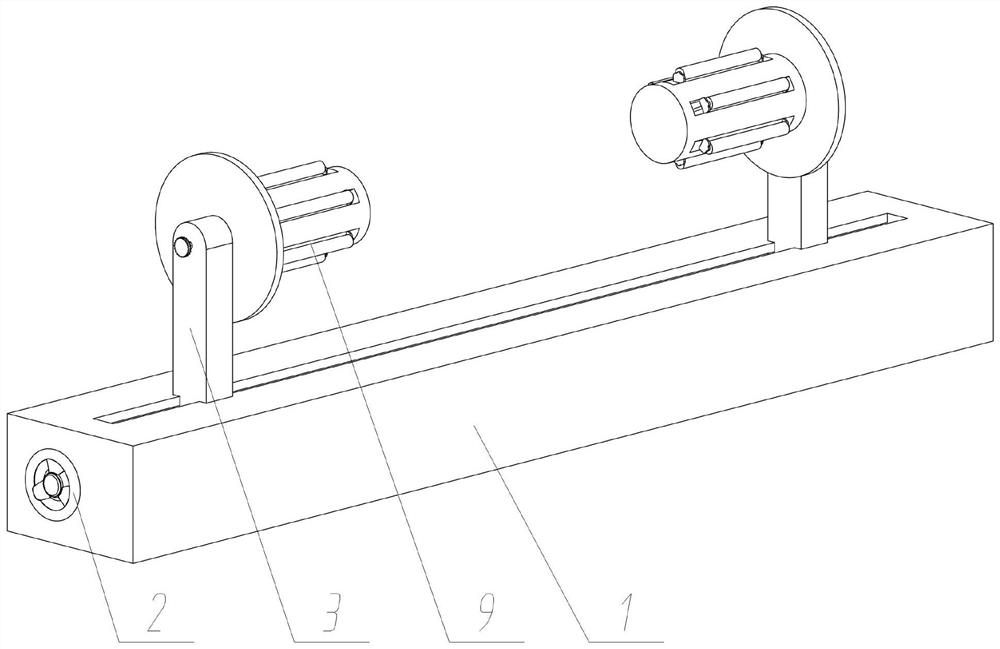

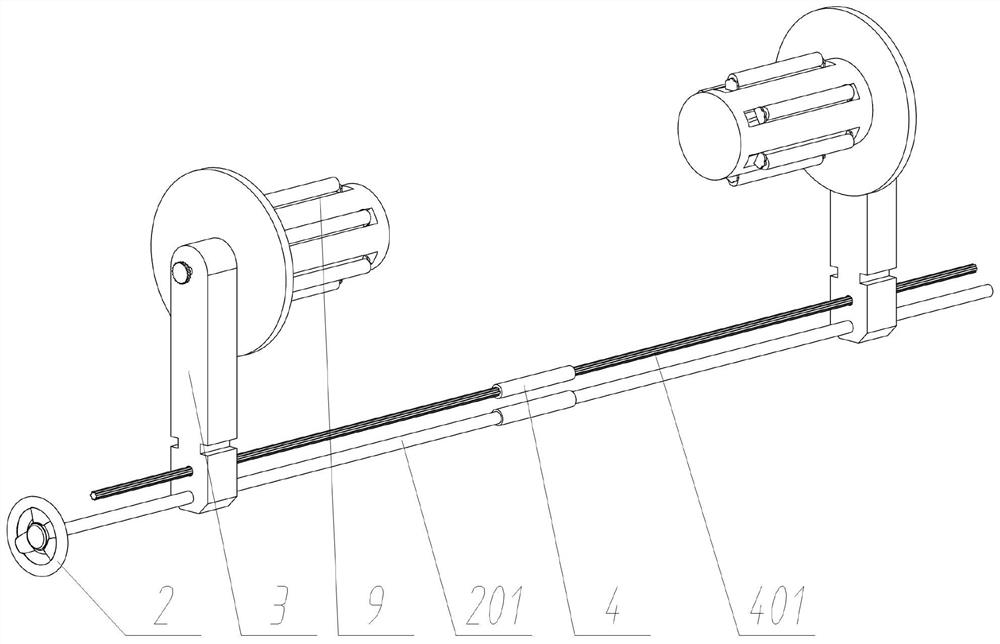

Adjustable structure for fixing winding drums for textile machinery

The invention discloses an adjustable structure for fixing winding drums for textile machinery, and relates to the technical field of the textile machinery. The adjustable structure solves the problems that existing textile winding drums are troublesome to adjust and operate in use, the winding drums with different diameters need to be replaced according to needs in use, supporting frames of the winding drums are poor in universality, and the winding drums with different diameters and different lengths are hardly supported. The adjustable structure comprises a mounting base; the left end faceof the mounting base is rotationally connected with a set of width adjusting operation parts; the top of the mounting base is slidably connected with two sets of adjusting sliding seats; six pairs oftight supporting connecting parts are connected to the outer circle faces of the adjusting sliding seats in a circumferential array arrangement and hinge joint mode; and the outer sides of each pair of tight supporting connecting parts are each connected with a tight supporting assembly in a hinged mode. The structure can support and position the winding drums with different lengths and differentdiameters, has good centering performance, can effectively avoid cloth deflection caused by poor centering performance, and is high in applicability, easy to use and convenient to operate.

Owner:温州邑品鞋业有限公司

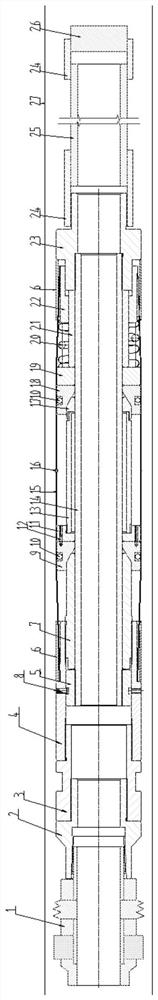

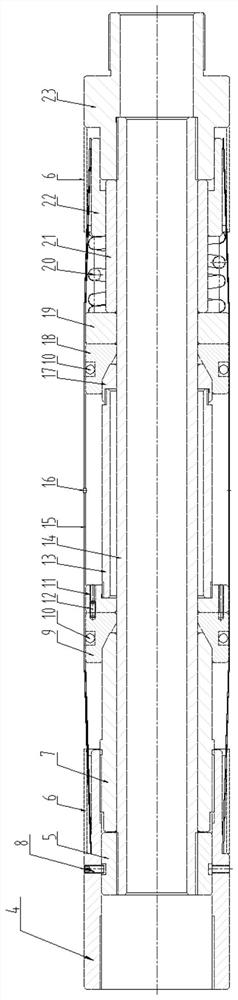

Elastic sieve pipe and sand prevention pipe column

The invention discloses an elastic sieve pipe and a sand prevention pipe column. The elastic sieve pipe comprises a central slotted sieve pipe, a pressure transmitting piece, a supporting cylinder sleeve, a reset mechanism, and an outer-layer slotted sieve pipe; the outer side of the upper end of the central slotted sieve pipe is fixed to the lower end of an upper joint through a central sieve pipe coupling, a control pin and an upper cylinder body, and the lower end of the central slotted sieve pipe is fixedly connected with the upper end of a lower joint; the pressure transmitting piece is arranged outside the central slotted sieve pipe in a sleeving mode, and an upper expansion mechanism and a lower expansion mechanism are arranged at the two ends of the pressure transmitting piece correspondingly; the supporting cylinder sleeve and the reset mechanism are arranged between the lower expansion mechanism and the lower joint; the two ends of the outer-layer slotted sieve pipe are positioned through sieve pipe protecting sleeves, and the middle of the outer-layer slotted sieve pipe is matched with the upper expansion mechanism and the lower expansion mechanism; and when the pipe column is tripped, the control pin is sheared off, the gravity of the pipe column is transmitted to the upper expansion mechanism and the lower expansion mechanism, and thus the elastic sieve pipe is set. According to the elastic sieve pipe and the sand prevention pipe column, it can be ensured that set sand is basically avoided in a wellbore, the good sand prevention effect is achieved, the pump inspection cycle is effectively prolonged, meanwhile, during using, tripping and salvaging operation is easy and convenient, safety and reliability are achieved, and the cost is low.

Owner:PETROCHINA CO LTD

Batch straightening device for steel pipes for buildings

The invention discloses a batch straightening device for steel pipes for buildings, relates to the technical field of steel pipe processing, and solves the problems that roller wheels of an existing steel pipe straightener can only be adjusted unilaterally and are prone to eccentricity during adjustment, the center needs to be adjusted during adjustment, the operation is troublesome, and the production efficiency is low. The batch straightening device for steel pipes for buildings comprises a steel piece straightener main body, the top of the steel pipe straightener main body is fixedly connected with a group of feeding driving motors; a plurality of groups of adjusting lead screws are in axle connection with the front and back of the inside of the steel pipe straighter main body; and a plurality of groups of adjusting middle driven shafts are in axle connection with the front and back of the inside of the steel pipe straighter main body. According to the batch straightening device forsteel pipes for buildings, the distance between straightening rollers can be adjusted according to needs so as to straighten steel pipes with different diameters, meanwhile, the device can realize good transmission so as to feed steel pipes, the device is good in centering performance, adjustment of concentricity is not needed in use, the adjustment is convenient, the adjustment speed is high, and the working efficiency is greatly improved.

Owner:鲍玲芳

Spring removing mechanism

ActiveCN108818184ASmooth rotationGood neutralGrinding feedersPlane surface grinding machinesEngineeringElectrical equipment

The invention discloses a spring removing mechanism which comprises a box body. A portal is connected to the box body, a spring removing door is in sliding connection with the portal, a bearing pedestal is fixedly connected with the interior of the portal, a gear shaft is arranged in the bearing pedestal, a rack engaged with the gear shaft is connected to the bottom of the spring removing door, one end of the gear shaft is provided with a power gear, and the power gear is connected with a power device. The spring removing door is controlled by an electric device to move, the automatic removingprocess of a spring in a grinding disc can be achieved, the production efficiency of a spring grinding machine is greatly improved, the labor intensity of operators is lowered, and the problem that the spring falls down to the gap between an inner table plate and the spring removing door in a clamped mode in the grinding disc moving process to affect work is avoided by adjusting the up-down left-right gap between the spring removing door and the inner table plate.

Owner:SHAOXING JIADU SPRING MACHINE

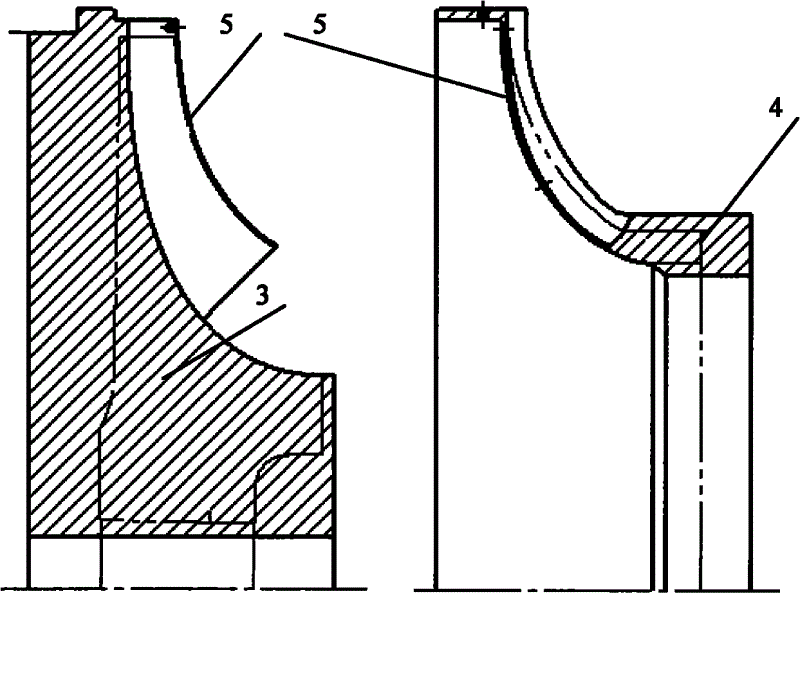

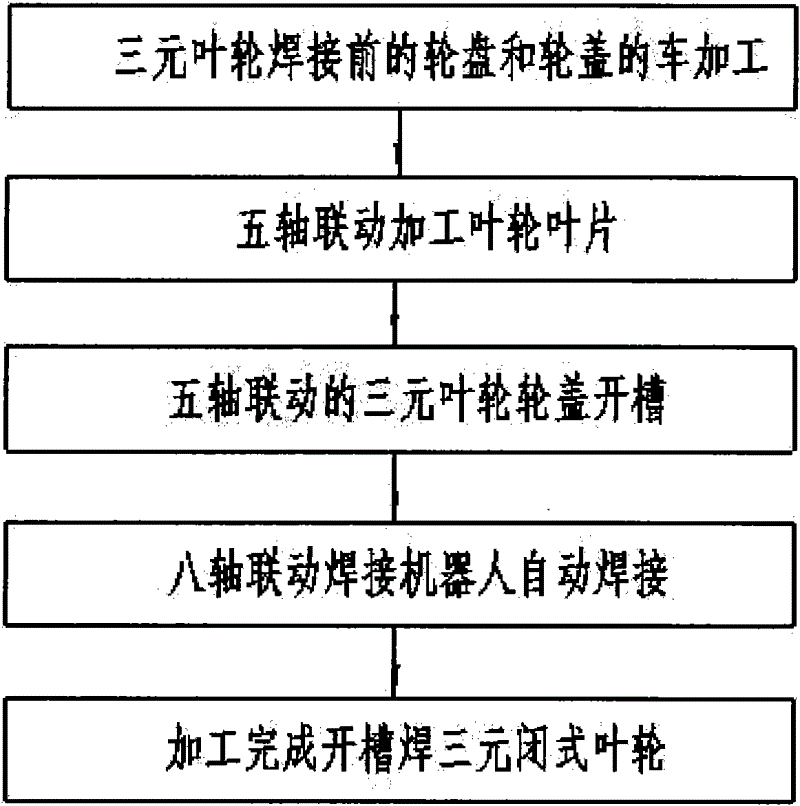

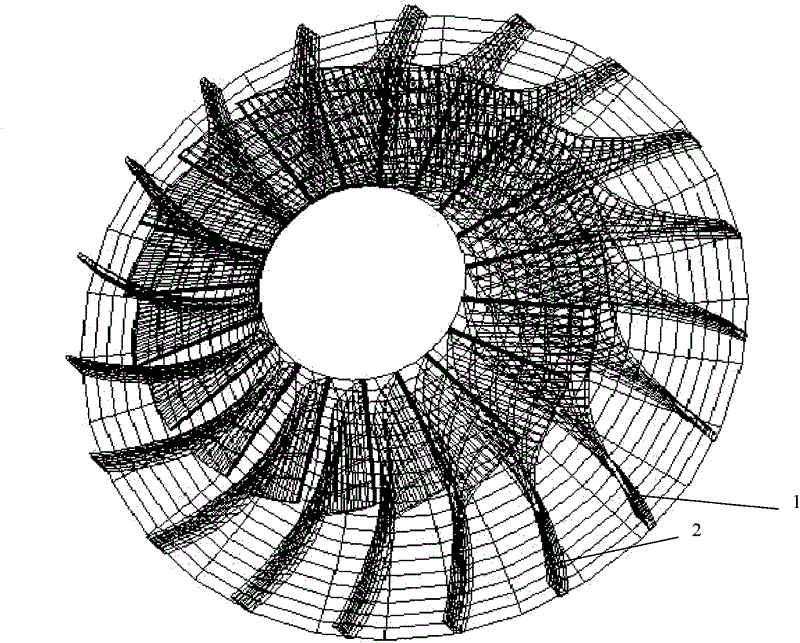

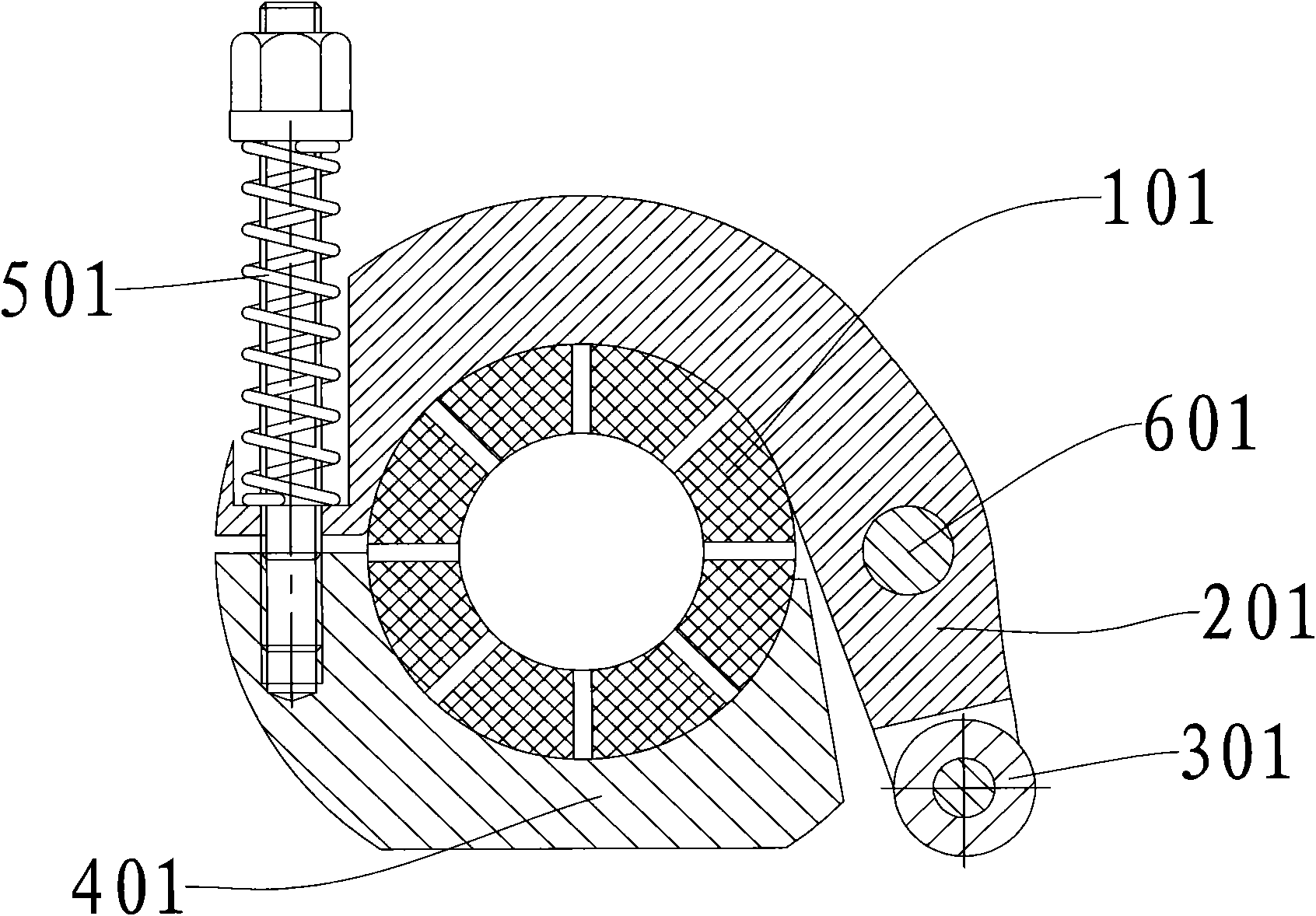

Closed three-element impeller slot welding machining and robot automatic welding control method

ActiveCN102107361BReduce welding distortionPrecise processingProgramme controlComputer controlImpellerEngineering

The invention relates to a closed three-element impeller slot welding machining and robot automatic welding control method, which comprises the following steps of: turning a blank to obtain a wheel disc and a wheel cover; milling blades on the wheel disc; milling a slot body on the wheel cover; welding the wheel disc and the wheel cover into a whole through a welding robot to finish automatic slot welding of a closed three-element impeller, wherein the step of welding the wheel disc and the wheel cover into a whole comprises the following substeps of: calling a test point access subprogram and storing M test points from a welding slot in a welding robot controller; controlling a welding gun to weld corresponding blades in the impeller; calculating and correcting an angle of a rotary worktable if the count value is smaller than the preset value, and calibrating the position of the next welding slot of the impeller further; and continuously welding the next welding slot. The wheel coverand wheel disc molded lines of the three-element impeller are accurately machined, the welding slot and the blades have good centering properties, automatic welding control of the welding robot is stable and accurate, and the machining efficiency of the closed three-element impeller is improved.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

Pneumatic metal can clamping unit

ActiveCN102259311BEasy to operateGood neutralWork holdersPositioning apparatusEngineeringHigh pressure

The invention discloses a pneumatic metal can clamping unit which comprises a high pressure air supply system, a base, an annular positioning plate arranged on the base, a cylinder capable of being sleeved outside of the annular positioning plate, a shell fixedly connected with the base and an air inlet which is arranged on the shell and connected with the air supply system, wherein the center of the annular positioning plate is provided with a channel for accommodating and clamping a metal can; the top of the cylinder is inwards provided with an annular bump; an annular boss is arranged outside the cylinder; the annular boss, the shell and the cylinder form a closed air chamber; a certain distance is reserved between the lower end of the cylinder and the annular positioning plate; and the lower end of the bump and the annular positioning plate form an annular groove in-built with an elastic rubber block. By adopting the pneumatic metal can clamping unit in the technical scheme, the clamping is reliable, the clamping force is uniform and adjustable, the operation is simple, the centering property is excellent, a centering error generated by relaxation can be avoided, and appearance defects such as pollution, scratches and the like on an aluminium pot product can be avoided.

Owner:汕头市东方科技有限公司

A disengagement mechanism capable of being used in a wheel-leg vehicle suspension

The invention discloses a separation and joint mechanism that can be used for wheel-leg type vehicle suspension, comprising electromagnetic pins arranged outside the thigh motor mounting seat, the thigh motor mounting seat is fixedly connected with the vehicle body, and thighs are installed on one side of the thigh motor mounting seat The motor, the thigh motor is connected with the upper end of the thigh which is movable in the mounting seat of the thigh motor, and the upper end of the thigh is provided with a suspension mechanism. Transmission connection; the thigh motor mounting seat and the upper end of the thigh are provided with a plurality of first oblong holes arranged in the axial direction, the lower part of the electromagnetic pin is provided with a telescopic part, and the end of the telescopic part can pass through the thigh motor mounting seat and the upper end of the thigh in turn The first oblong hole, and abuts against the torsion spring support seat of the suspension mechanism. The invention realizes the active control of the separation and combination of the suspension of the wheel-leg vehicle, so as to achieve the purpose of the suspension function and vibration reduction during the wheel-type movement, and the purpose that the suspension does not function during the leg-type movement.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

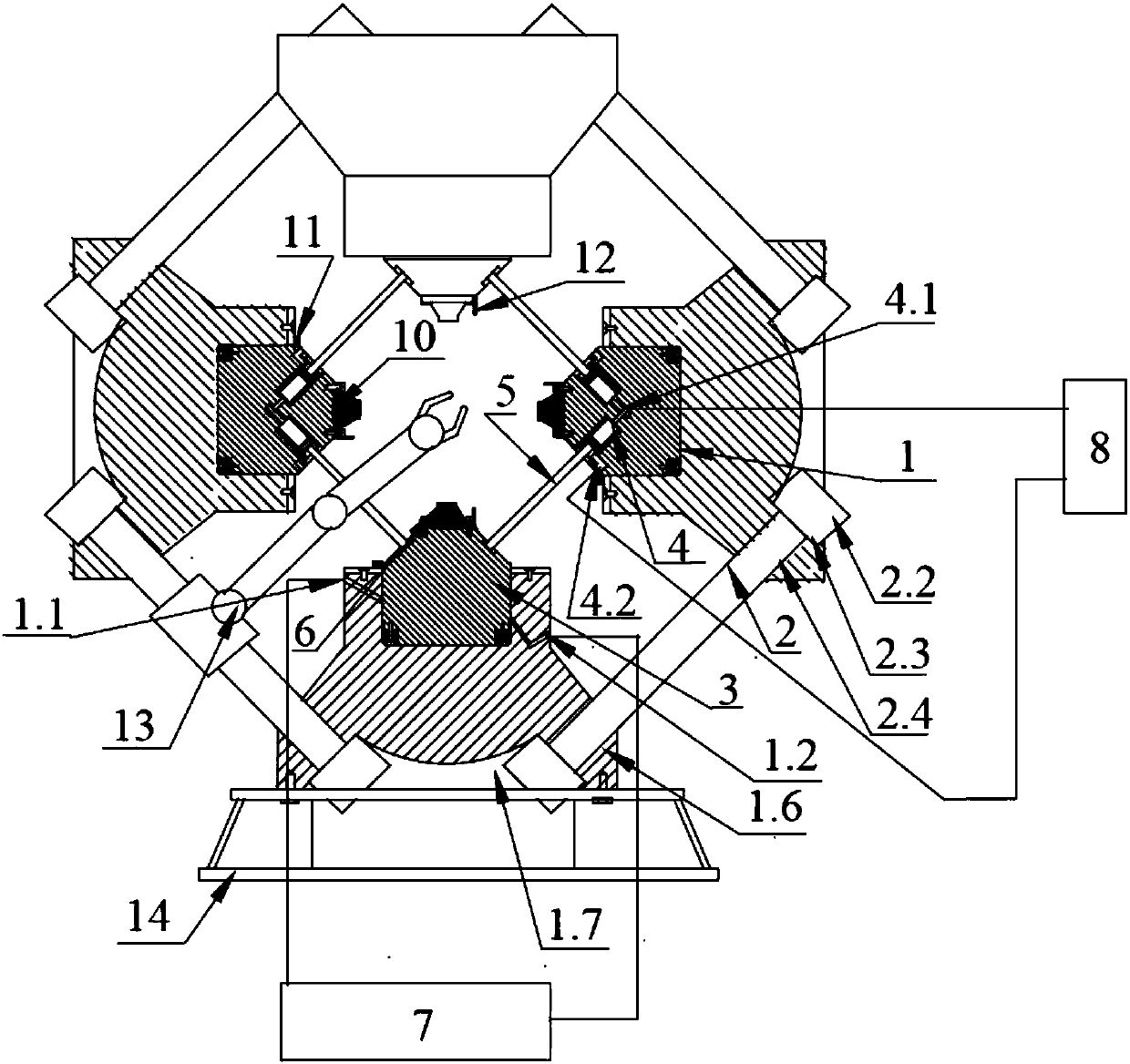

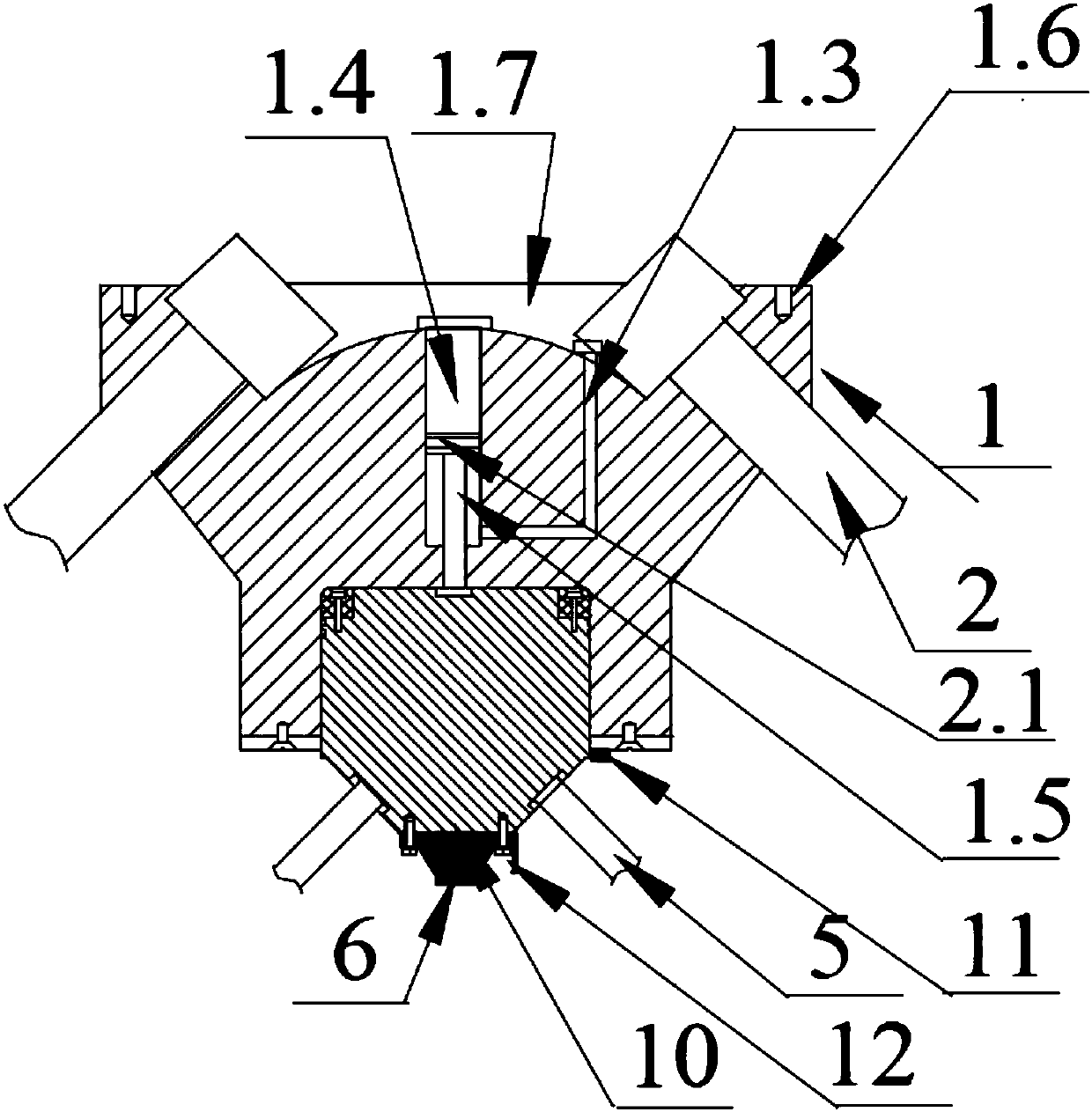

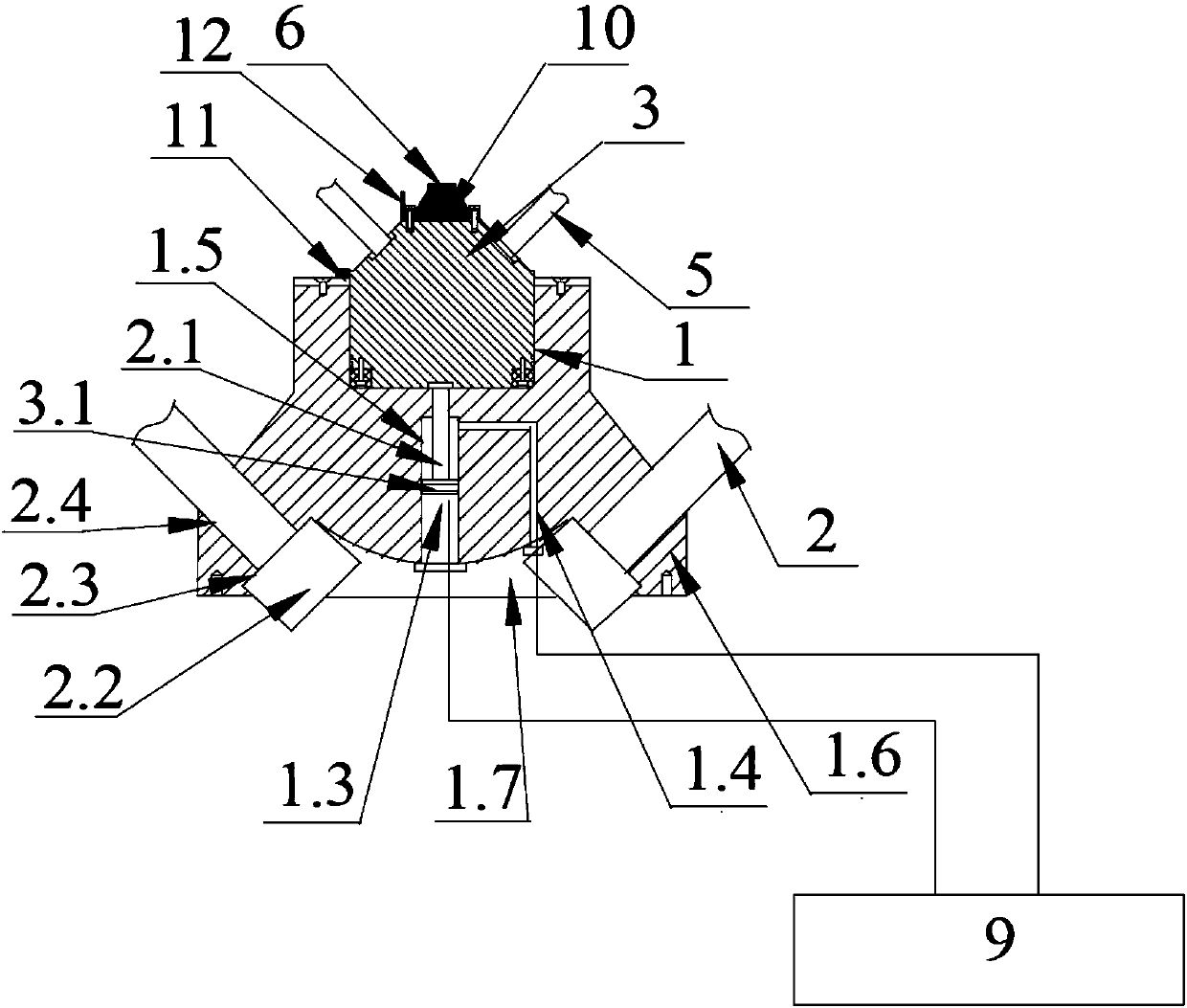

Intelligent polyhedron anvil press machine

InactiveCN109794205ASimple structureSmall form factorUltra-high pressure processesAutomatic controlEngineering

The invention discloses an intelligent polyhedron anvil press machine. The intelligent polyhedron anvil press machine comprises six anvil press oil cylinders which are arranged to be of a regular hexahedron structure through pairing symmetry, one or more connecting rods are arranged between every two anvil press oil cylinders, an anvil press piston is arranged in each anvil press oil cylinder, a guiding oil cylinder and a guiding piston rod which are matched mutually are arranged between every two anvil press pistons, one end of each anvil press piston is connected with an anvil press head, oil inlets and oil return ports of the six anvil press oil cylinders are each connected with a first reversing valve through an oil pipe, and oil inlets and oil return ports of the six guiding oil cylinders are each connected with a second reversing valve through an oil pipe. The intelligent polyhedron anvil press machine has the advantages that the structure is simple, the size of the appearance issmall, the weight is low, durability is realized, operation is flexible, mechanical properties are good, synchronous work of the multiple cylinders can be absolutely guaranteed, aligning performanceis good, and automatic control can be realized completely.

Owner:卞政卫

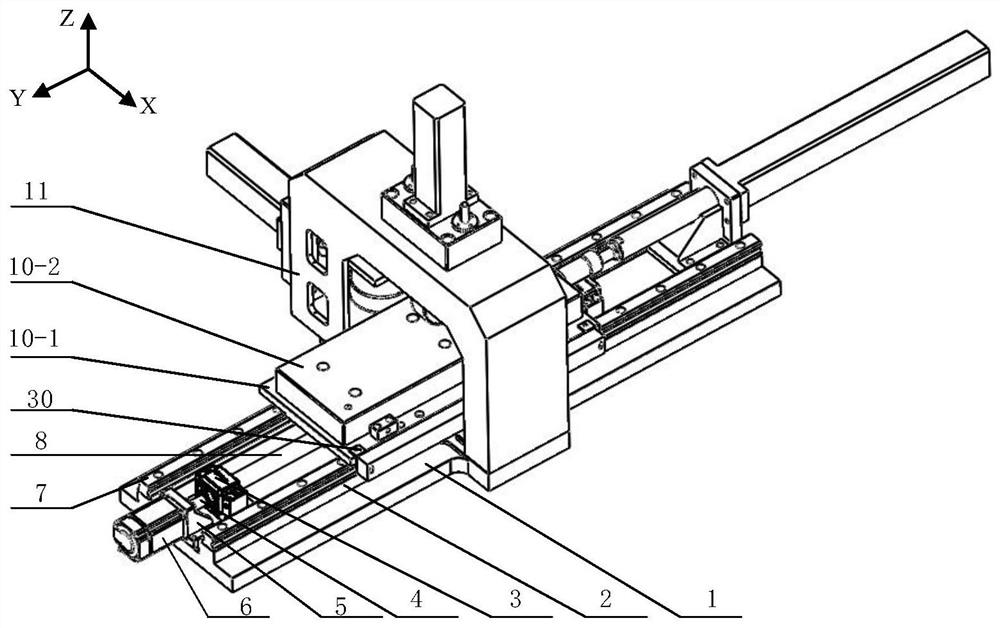

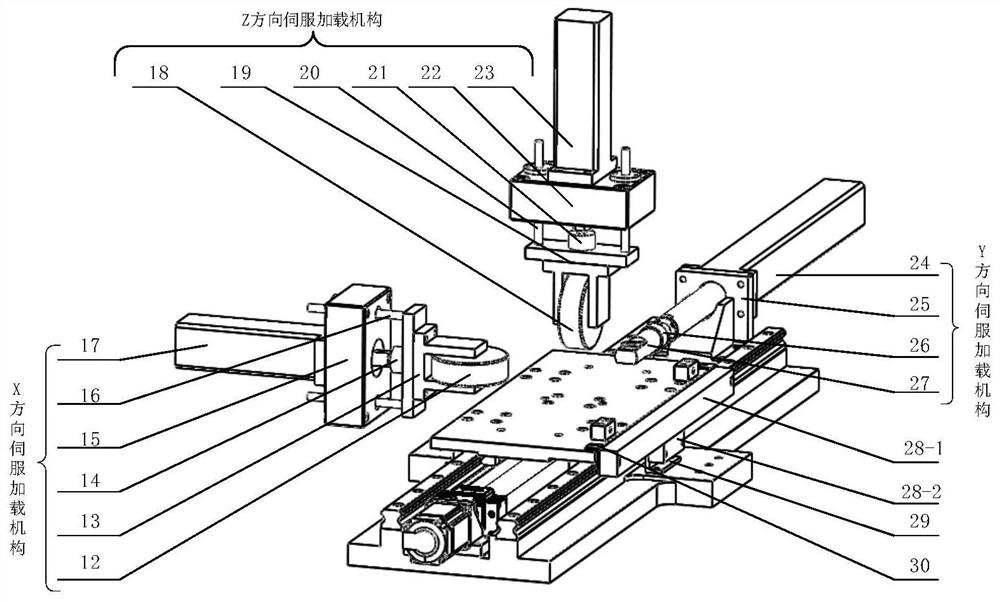

A performance testing method and device for a digital twin model of a machine tool

ActiveCN109773588BEliminate errorsPrecise cutting force loadingMeasurement/indication equipmentsVibration accelerationControl system

The invention relates to a machine tool digital twin model performance test method and device, and belongs to the field of device intellectualization and digitization. The machine tool digital twin model performance test device comprises a machine base, a work table a, a work table b, a portal frame and a control system. A grating ruler displacement sensor is arranged between the machine base andthe work table a. An X-direction servo loading mechanism and a Z-direction servo loading mechanism are arranged on the portal frame. A Y-direction servo loading mechanism is arranged on the machine base. The X-direction servo loading mechanism, the Z-direction servo loading mechanism and the Y-direction servo loading mechanism are internally provided with tension and pressure sensors correspondingly. Three-direction vibration acceleration sensors are arranged on a lead screw bearing pedestal, a nut base and guide rail slide blocks correspondingly. A servo motor and all the sensors are connected with the control system. According to the machine tool digital twin model performance test method and device, the machine tool true machining process is simulated through the loading mechanisms, required reliability data are collected through all the sensors, and platform support is provided for digital twin model performance degradation renewing experimental verification of damageable parts andaccelerated life attenuation and life prediction of precise parts.

Owner:SHANDONG UNIV

Elastic screen and sand control string

Owner:PETROCHINA CO LTD

Ultrasonic filling capping method

InactiveCN106995200AImprove efficiencyImprove sealingFlanged caps applicationDrive shaftElectric machinery

The invention relates to an ultrasonic filling capping method. A heat seal layer of a bottle cap is molten in an ultrasonic local heating mode, so that a capping process for filing carton boxes is realized. A device for realizing the method comprises a cap taking assembly, an ultrasonic capping assembly and a conveying mechanism, wherein the cap taking assembly comprises a cap taking rotor, a transmission shaft and a bottle cover pusher; under driving of an air cylinder, the cap taking assembly and the ultrasonic capping assembly realize axial feeding; and rotation of a rotor of the cap taking assembly is driven by a servo motor belt wheel. A conveying mechanism is clamped by double rows of roller chains to realize transportation. The device is high in capping connecting strength, is good in sealing property and is high in efficiency. The method is co-driven in a pneumatic mode and an electric mode, and bottle cap aligning property is good.

Owner:TONGJI UNIV

Vibration system of sound production device and the sound production device

InactiveCN110662141AMaximum diameterFree up spaceElectrical transducersLoudspeakersSound productionMechanical engineering

The invention discloses a vibration system of a sound production device, and the system comprises a vibrating diaphragm assembly which including a folding ring located at the outer side and a body located at the inner side of the folding ring; a voice coil assembly which comprises a cylindrical framework and a voice coil wound on the outer side of the framework, wherein the voice coil assembly isconnected with the body through the framework; an elastic member; and at least two elastic components which, are fixed with the body and are separated from the voice coil assembly. The vibration system of the sound production device can meet the design requirements of narrow and thin products, the space utilization rate of the products is increased, F0 is reduced, distortion is improved, and therefore the performance of the products is optimized. The invention further discloses the sound production device using the vibration system.

Owner:GOERTEK INC

Testing clamp for testing tensile stress-tensile strain of metal bar samples

The invention relates to a testing clamp for testing tensile stress-tensile strain of a metal bar samples. The clamp comprises an upper connecting part, a lower connecting part, an upper clamping head, a lower clamping head and a guiding baffle plate fixing member, wherein a drag link ball of the upper connecting part is disposed in a shrinkage pool which is formed by a pressure flange and an upper connecting workpiece; the upper clamping head and the lower clamping head are equilateral polyhedra which are in the same shape and in a vertical arrangement, are separated by a distance of 1-3 cm, and are respectively provided with horizontal knife-edge grooves on opposite surfaces; the upper clamping head is threadedly connected with the upper connecting part, and the lower clamping head is threadedly connected with the lower connecting part; the guiding baffle plate fixing member coats three adjacent side surfaces of the upper clamping head and the lower clamping head which are opposite placed, has three vertical baffle plates, is fixed with the upper clamping head, and positions and guides the upper clamping head and the lower clamping head; and a middle vertical baffle plate is fixed with a side surface of the upper clamping head, wherein the side surface is provided with a first horizontal screw hole. The testing clamp has characteristics of easy installation and accurate position, and can achieve tensile stress-tensile strain mechanical performance tests for standard or non-standard metal bar samples under a low temperature environment with a temperature ranging form the room temperature to 4.2 K.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com