Closed three-element impeller slot welding machining and robot automatic welding control method

A technology of automatic welding and control methods, applied in the direction of computer control, program control, general control system, etc., to achieve accurate processing, improved economic benefits, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The best implementation of the present invention will be further described below in conjunction with the accompanying drawings.

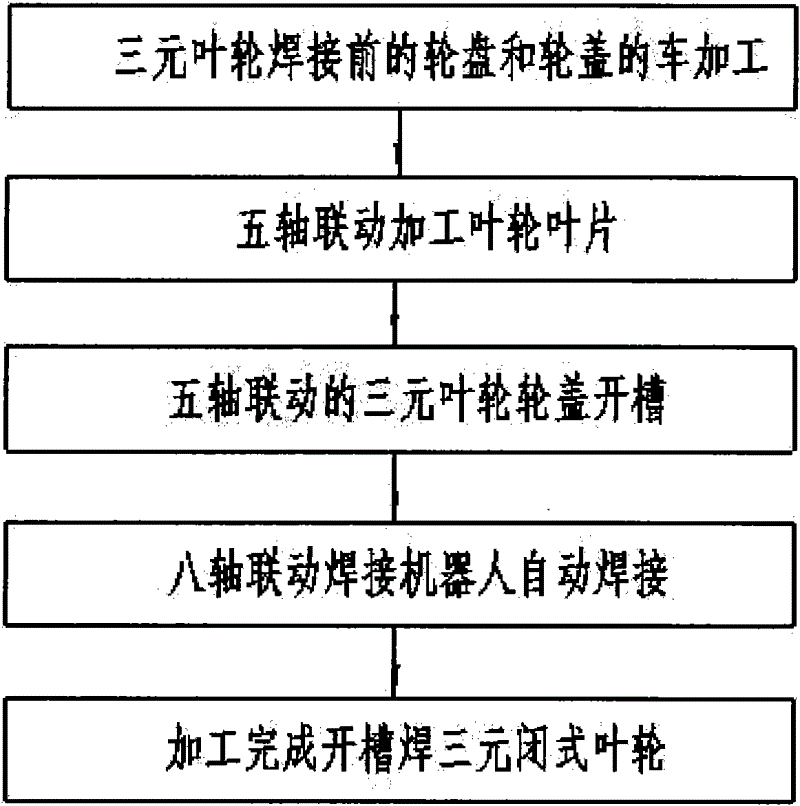

[0053] Such as figure 1 As shown, the closed ternary slotted welding impeller processing and robot automatic welding control method of the present invention comprises the following steps:

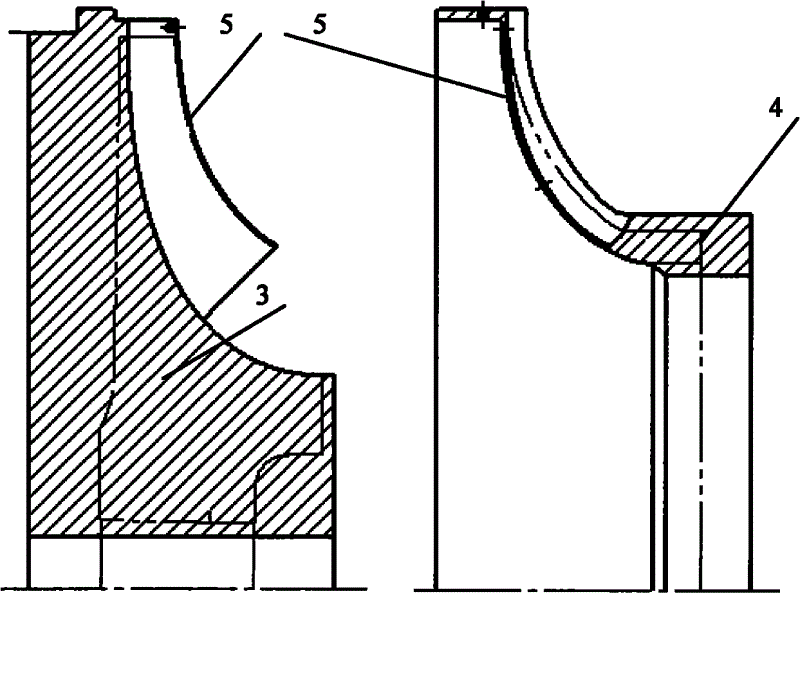

[0054] Turning the blank to form the wheel disc 3 and the wheel cover 4;

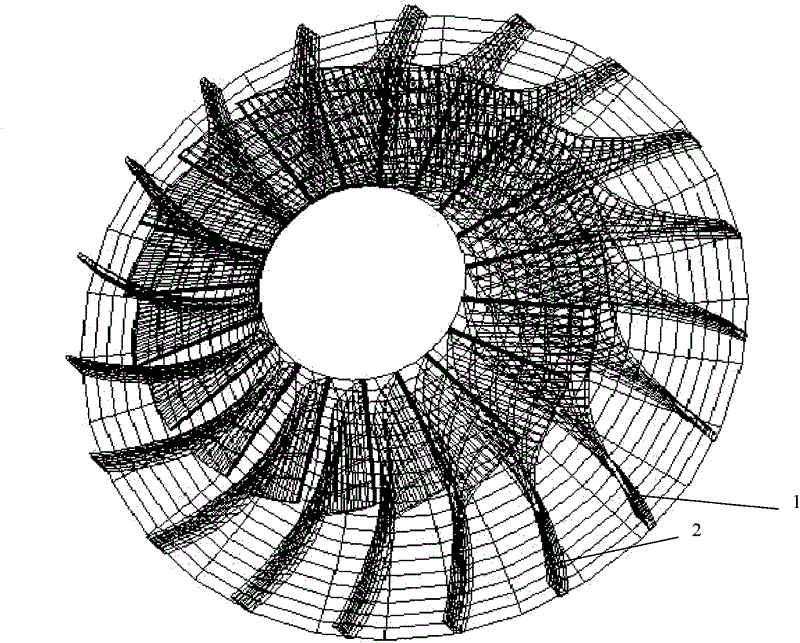

[0055] Mill out the blade 1 on the disc 3;

[0056] Mill out the groove body on the wheel cover 4;

[0057] The wheel disc 3 and the wheel cover 4 are welded together by a welding robot to complete the automatic welding of the closed three-dimensional slotted impeller.

[0058] For the closed ternary impeller, the two-piece welding process is adopted. Before the blade 1 is milled, the problem of good contact between the processed wheel cover 4 and the milled blade 1 must be solved first. Such as figure 2 As shown, it is a schematic diagram of the model of the processed blade 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com