A pneumatic metal can clamp

A technology of metal cans and clamps, applied in the direction of metal processing equipment, metal processing machinery parts, clamping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

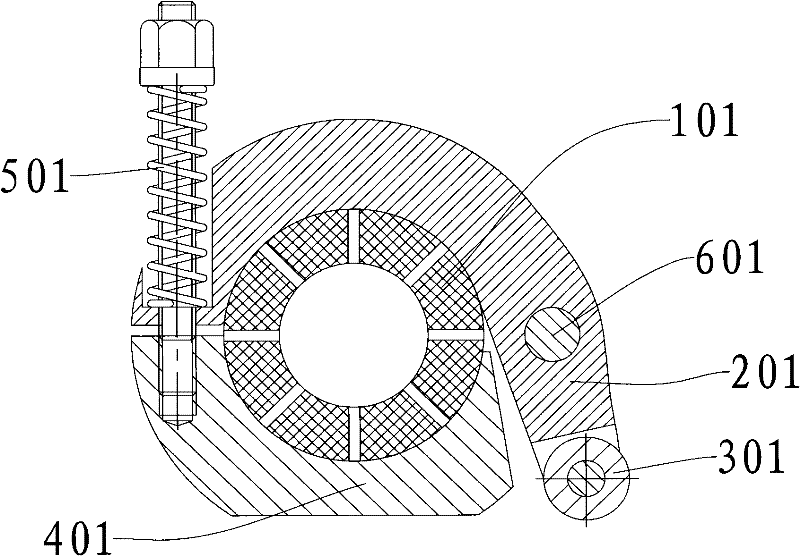

Image

Examples

Embodiment Construction

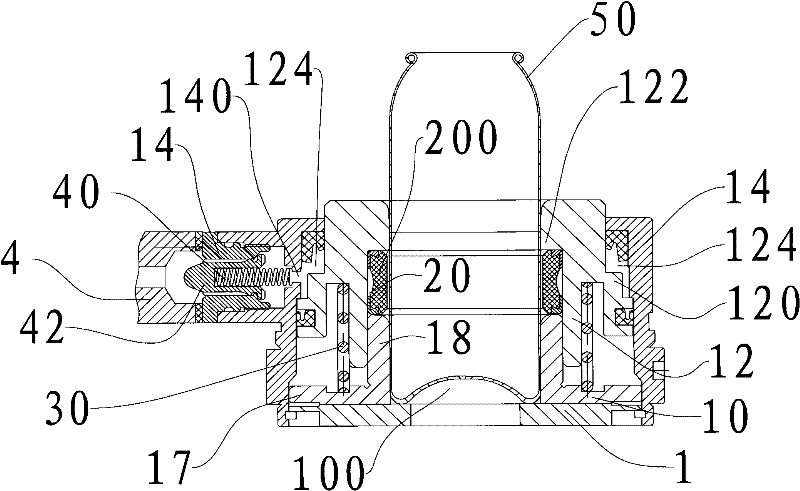

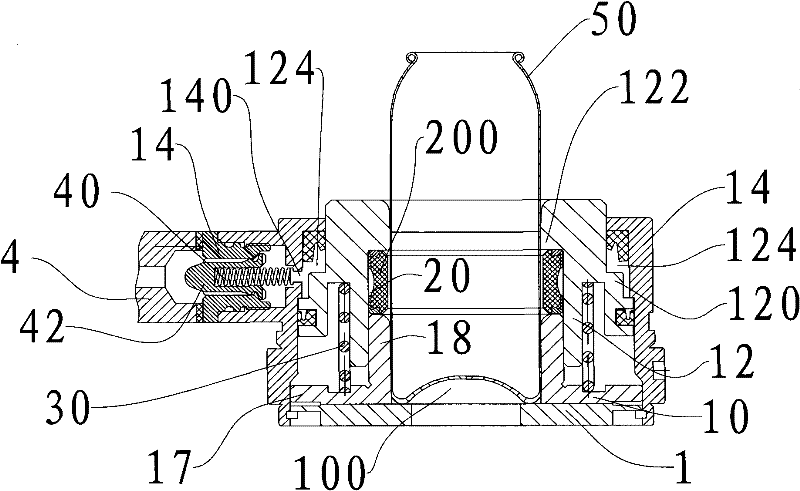

[0014] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Please refer to figure 2 One embodiment shown is a pneumatic metal can clamp, including a high-pressure gas supply system. The metal can clamp includes a base 1 and an annular positioning plate 10 fixed on the base 1, which can The cylinder body 12 slidably sleeved on the outside of the annular positioning plate 10, and the housing 14 fixed to the base 1, the housing 14 is provided with an air inlet 140 connected to the air supply system; the center of the annular positioning plate 10 For the channel 100 for accommodating and clamping the metal can, the top of the cylinder body 12 is provided with an annular protrusion 122 inwardly, and an annular boss 120 is arranged outside the cylinder body 12, the annular boss 120, the shell 14 and the The cylinder block 12 forms a closed air chamber 124; there is an end distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com