XF - E18L limit valve

A technology of XF-E18L, limit valve, applied in the field of XF-E18L limit valve, can solve the problems of poor versatility, insufficient return reliability, and unsatisfactory performance of using poppet valve spool, and achieve reliable return , good effect on neutral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

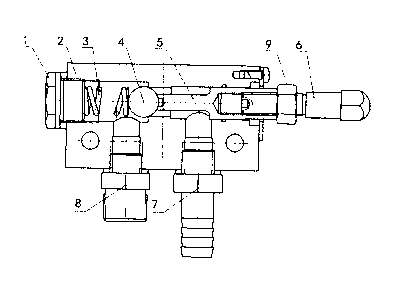

[0006] Example 1, such as figure 1 As shown, the present invention includes a main body 2, a rear end 1, a valve core 5, a screw rod 6, an oil return pipe joint 7, and an oil inlet pipe joint 8. It is characterized in that the limit valve is a steel ball 4, and the two sides of the steel ball are connected with the return spring respectively. 3 is in contact with the spool, the screw rod is provided with an adjusting nut 9, and the valve body is provided with two mounting holes on the same vertical line. The rear end is processed into a threaded structure with round steel, the main body is milled with Q345 material, and then the oil holes are processed on the main body, the valve core is processed with 40Cr material, and the surface roughness is Ra0.4. The adjustment screw is equipped with a corresponding adjustment nut, which can realize the height adjustment function and is suitable for vehicles of different heights. The oil return pipe joint 7 is connected to the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com