Refrigeration cycle device and refrigerant circulation method

A technology of refrigerant cycle and refrigeration cycle, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as parts damage, oil exhaustion, and reduction in the return of refrigeration oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0028] (Structure of Refrigeration Cycle Device 1010)

[0029] refer to Figure 1 to Figure 8 Embodiment 1 will be described.

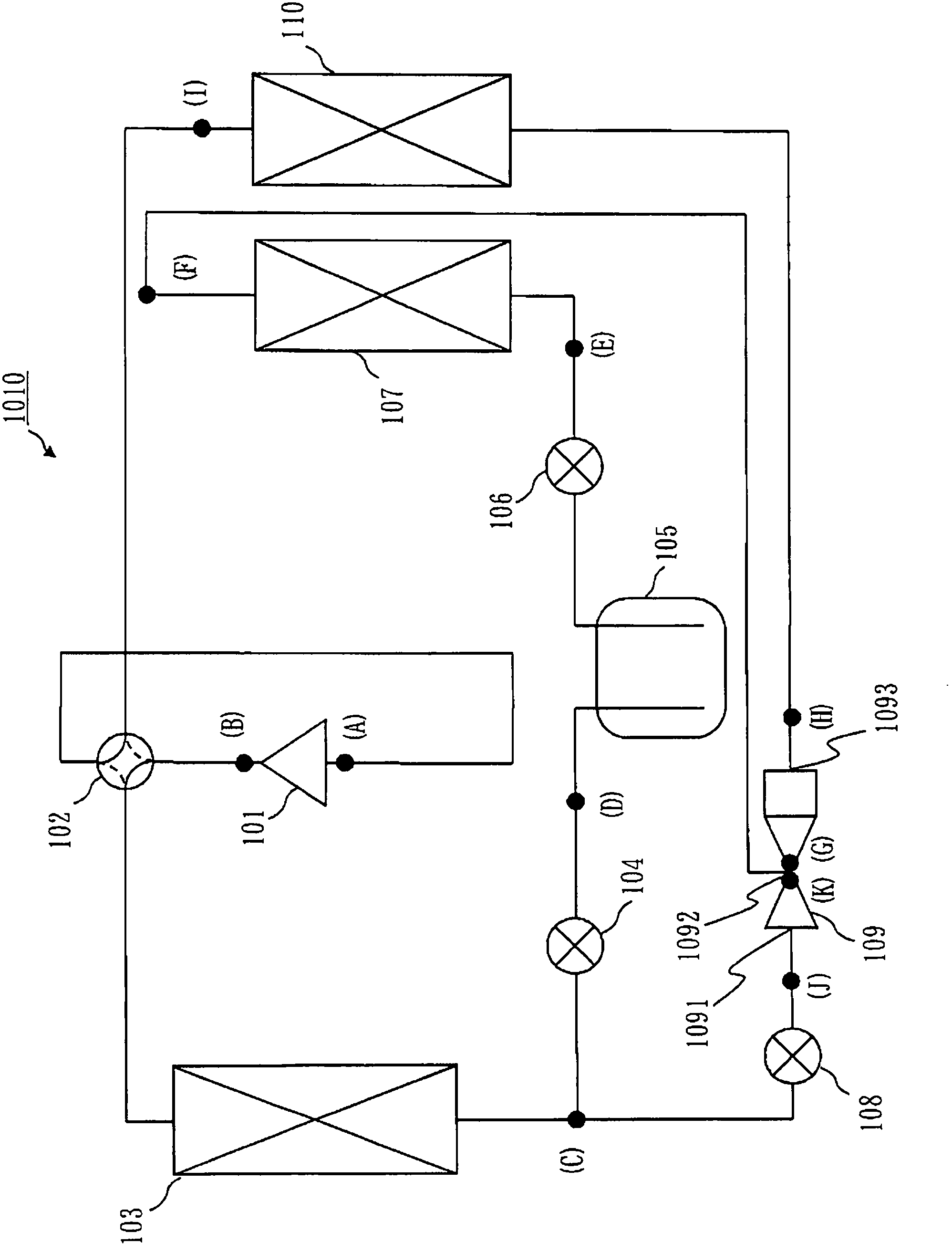

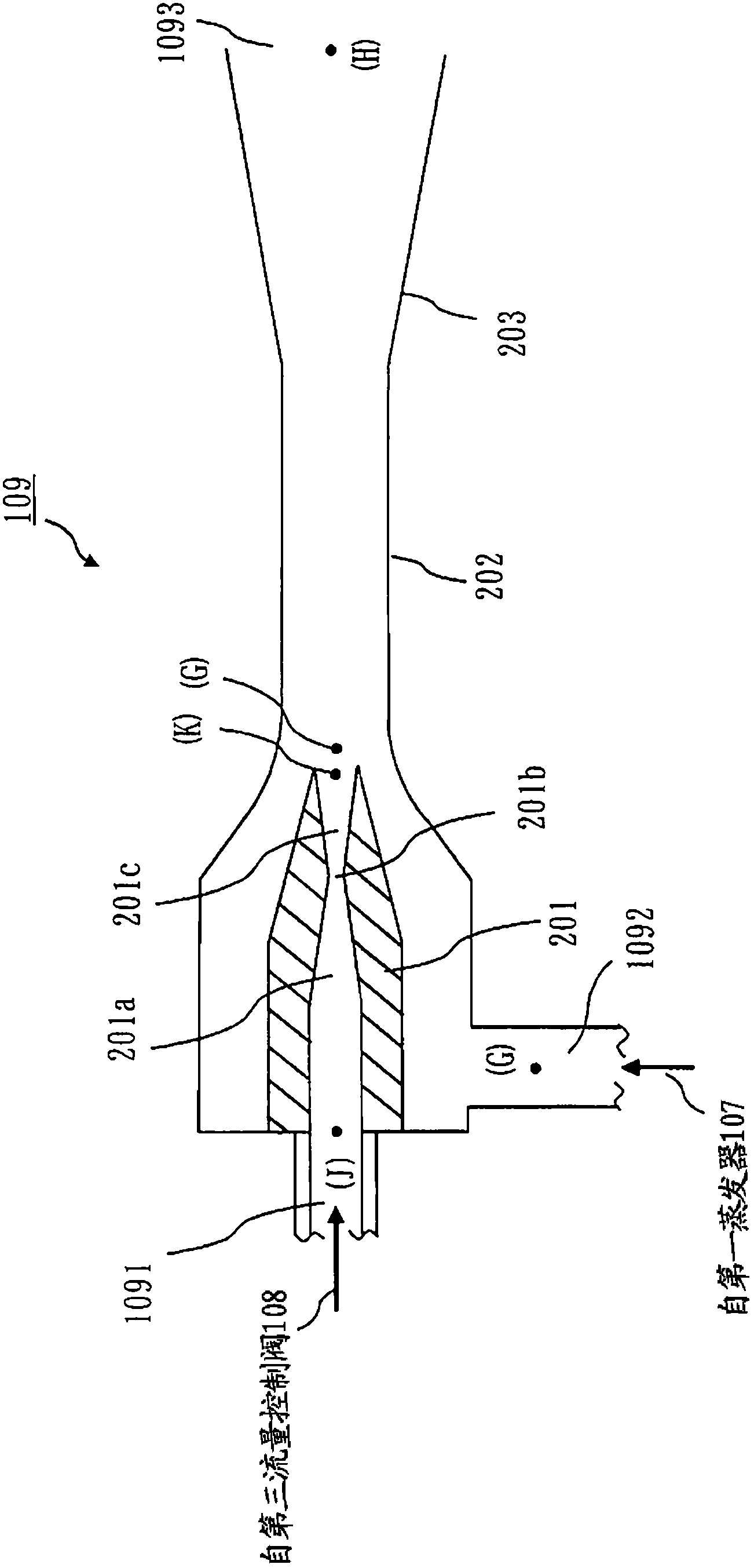

[0030] figure 1 It is a schematic diagram showing the structure of the refrigeration cycle apparatus 1010 of Embodiment 1. The refrigeration cycle device 1010 has an ejector 109 having: a driving refrigerant inflow port 1091 through which a driving refrigerant flows in; a suction refrigerant inflow port 1092 through which a refrigerant is sucked in; The mixed refrigerant outlet 1093 from which refrigerant flows out.

[0031] Refrigeration cycle device 1010 has a first refrigerant passage, which is sequentially connected to compressor 101, condenser 103 as a radiator, first flow control valve 104, refrigerant storage container 105, second The flow rate control valve 106 and the first evaporator 107 are connected to the refrigerant outlet of the first evaporator 107 and the suction refrigerant inlet 1092 of the ejector 109 by piping. In addition, t...

Embodiment approach 2

[0060] refer to Figure 9 ~ Figure 11 Embodiment 2 will be described.

[0061] Figure 9 The refrigeration cycle apparatus 1020 of Embodiment 2 is shown.

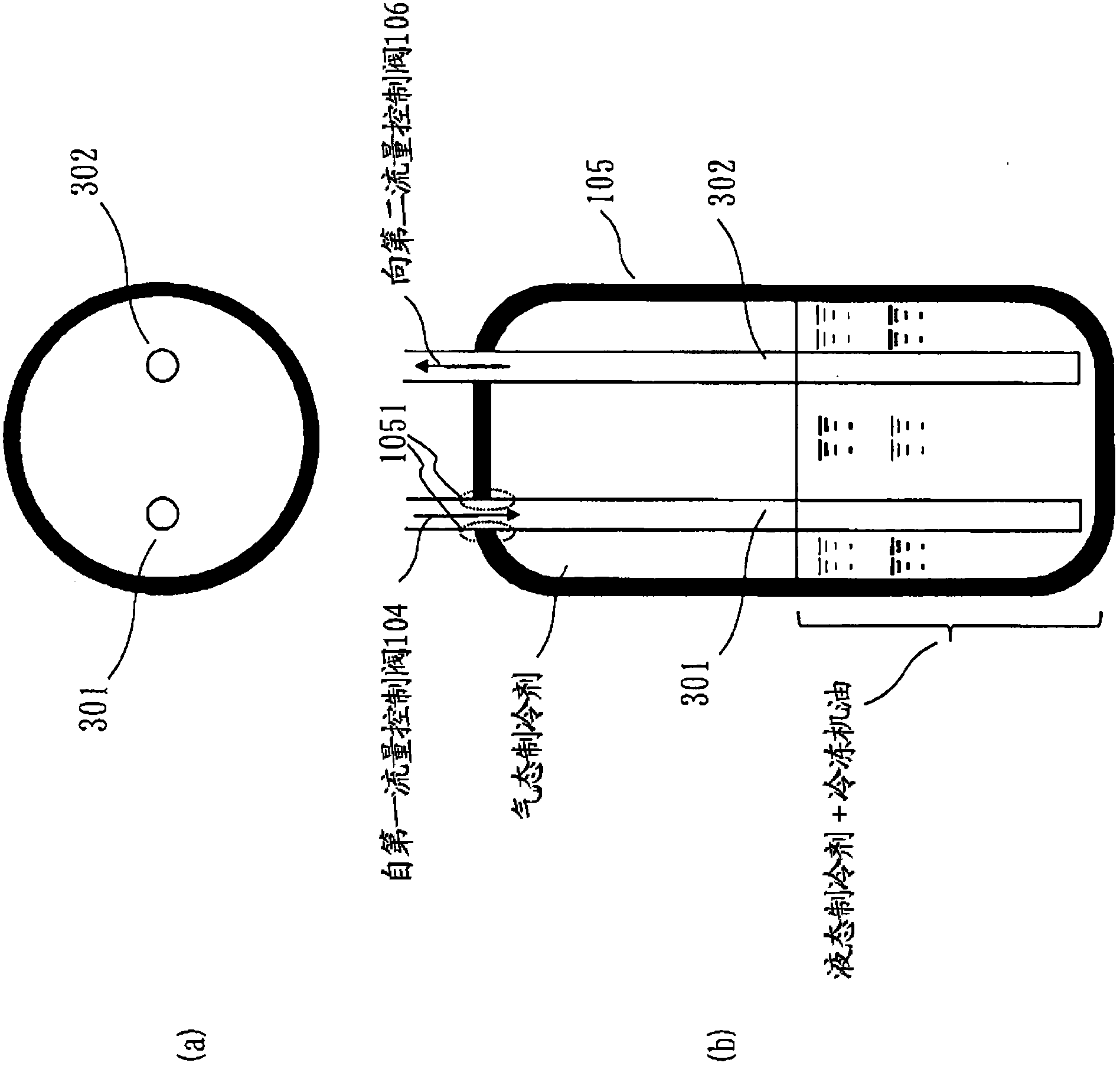

[0062] Figure 10 The structure of the refrigerant storage container 105 of Embodiment 2 is shown. Figure 10 (a) is a plan view of the refrigerant storage container 105 . Figure 10 (b) is a longitudinal sectional view of the refrigerant storage container 105 . In Embodiment 2, the refrigerant piping 310 connecting the second evaporator 110 , the four-way valve 102 , and the suction port 402 of the compressor 101 passes through the inside of the refrigerant storage container 105 . In addition, in showing Embodiment 1 figure 1 , can also be used with Figure 9 Similarly, the refrigerant piping 310 is configured to pass through the refrigerant storage container 105 .

[0063] In addition, an internal heat exchanger 112 is connected between the refrigerant storage container 105 and the second flow rate control valve 1...

Embodiment approach 3

[0069] refer to Figure 12 , Figure 13 The refrigeration cycle device 1030 according to Embodiment 3 will be described. In Embodiment 3, while avoiding depletion of refrigerating machine oil, in an environment where the outside air temperature is low, the suction density of the compressor 101 is low, and the heating capacity is reduced, a compressor with an injection port is used to Increase heating capacity.

[0070] Figure 12 It is a refrigerant circuit diagram of the refrigeration cycle apparatus 1030 of Embodiment 3. The bypass circuit 121 of the refrigeration cycle device 1020 in the second embodiment is connected to the suction pipe of the compressor 101, but the bypass circuit 122 of the refrigeration cycle device 1030 in the third embodiment is connected to the injection port 101-1 of the compressor 101. differ on this point.

[0071] In Embodiment 3, the internal heat exchanger 112 is connected between the refrigerant storage container 105 and the second flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com