Safety syringe

A technology of safety syringes and injections, applied in the field of syringes, can solve problems such as infection, unstable movement of injection needles, and increased manufacturing costs of safety syringes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

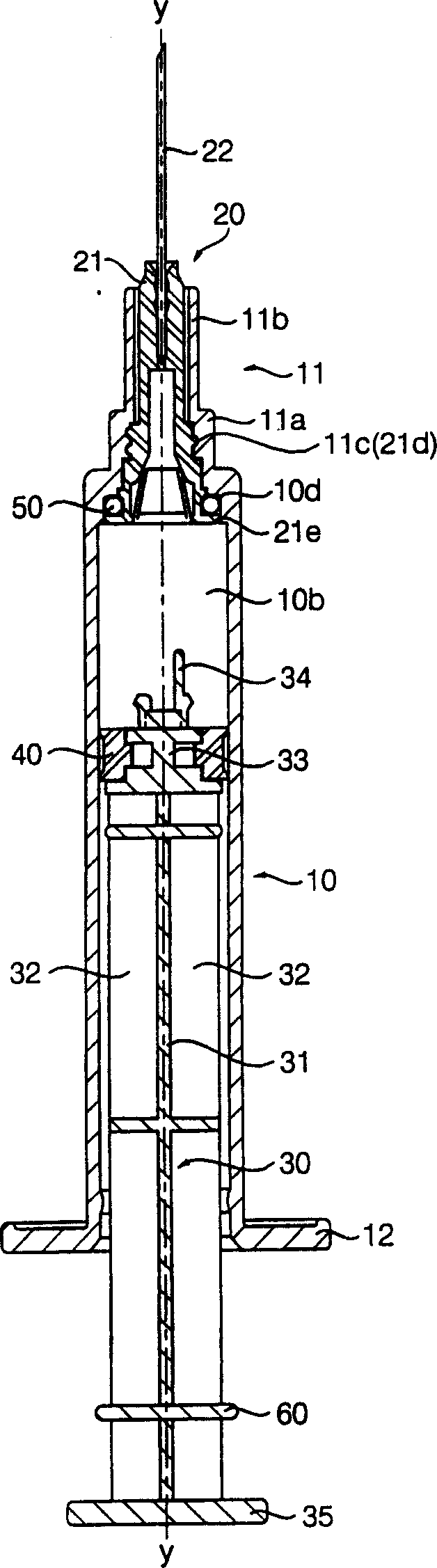

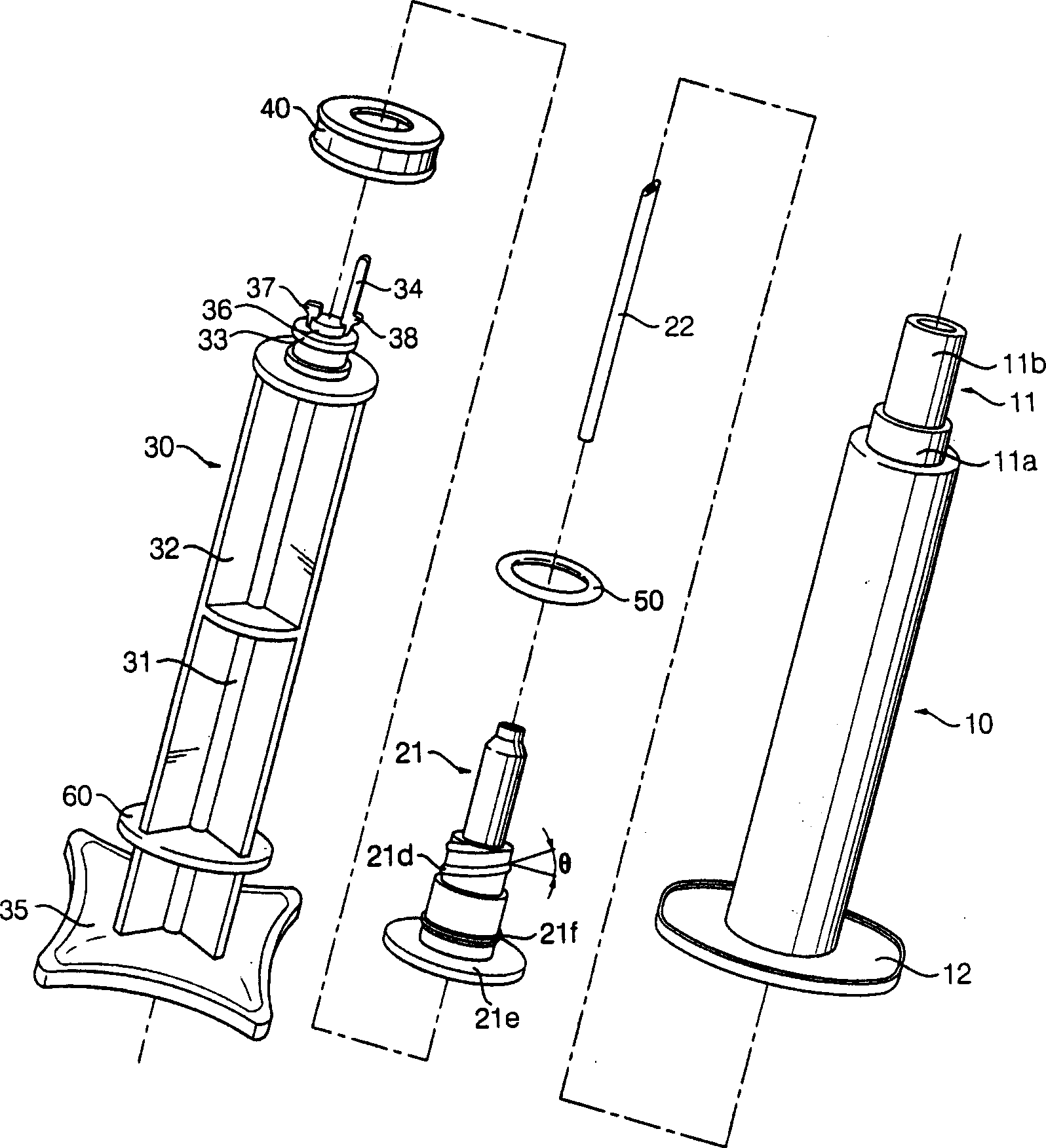

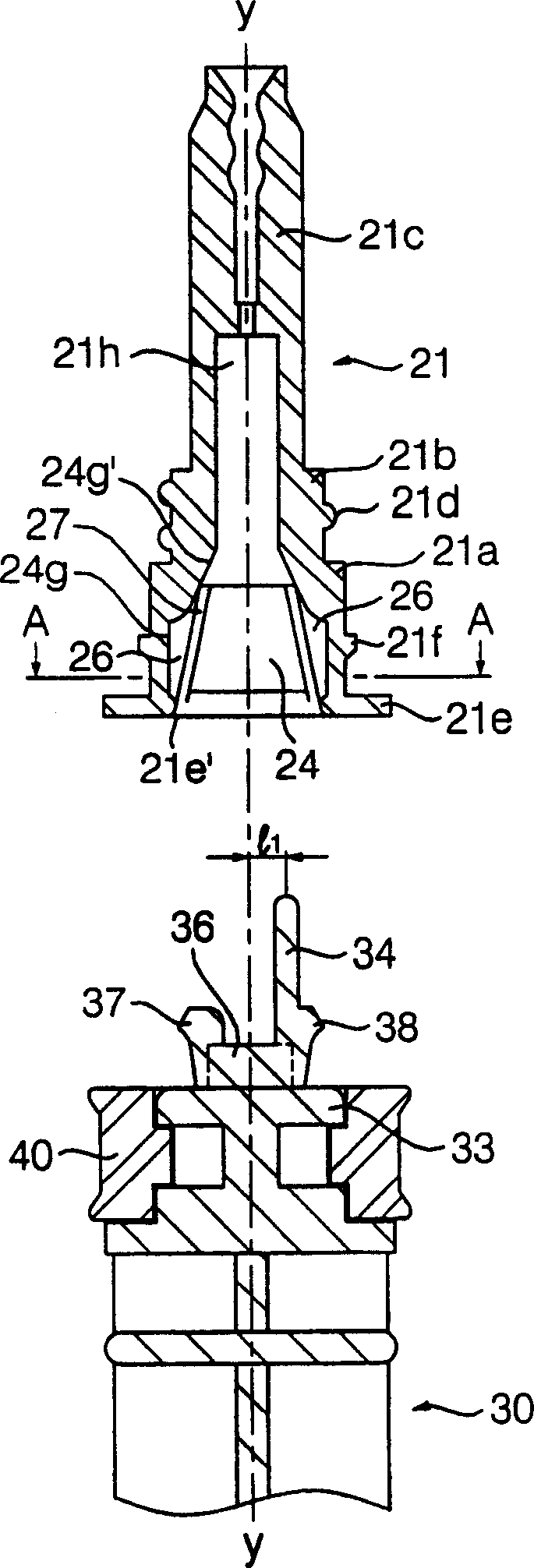

[0035] figure 1 is a sectional view of the safety syringe according to the first embodiment of the present invention; figure 2 is an exploded perspective view of the safety syringe according to the first embodiment of the present invention; image 3 yes figure 1 An enlarged cross-sectional view of the nipple and upper end of the plunger of the safety syringe shown.

[0036] Such as Figure 1-3 As shown, the safety syringe according to the first embodiment of the present invention includes: an elongated syringe 10, which defines a space 10b for containing injection liquid; an injection needle assembly 20, which is connected to the upper end of the syringe 10; and The plunger 30 is partially inserted into the barrel 10 and is movable vertically. The plunger 30 is used to suck the injection liquid into the syringe 10 and discharge the injection liquid contained in the syringe 10 to the outside.

[0037] The upper end of the barrel 10 forms a neck 11 extending upwardly from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com