Patents

Literature

65results about How to "Prevent import" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

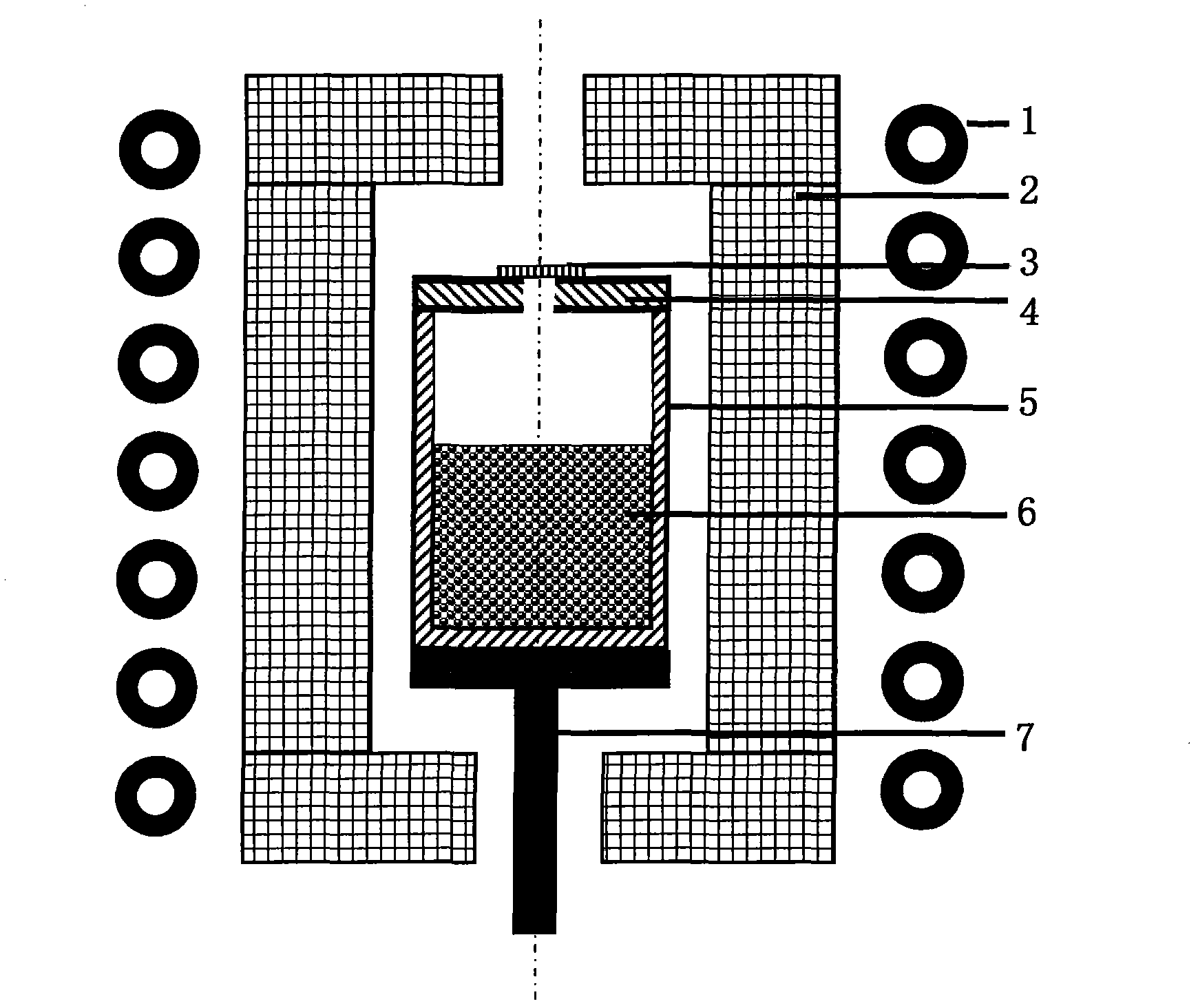

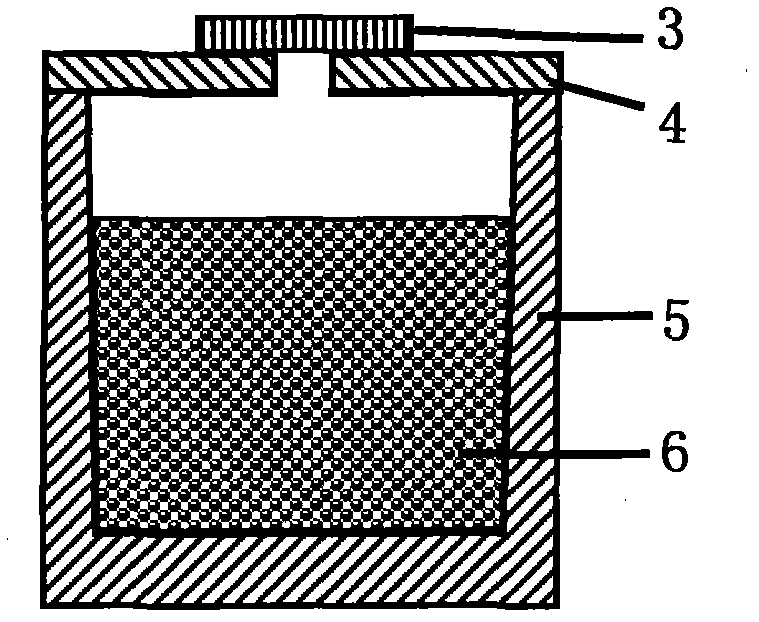

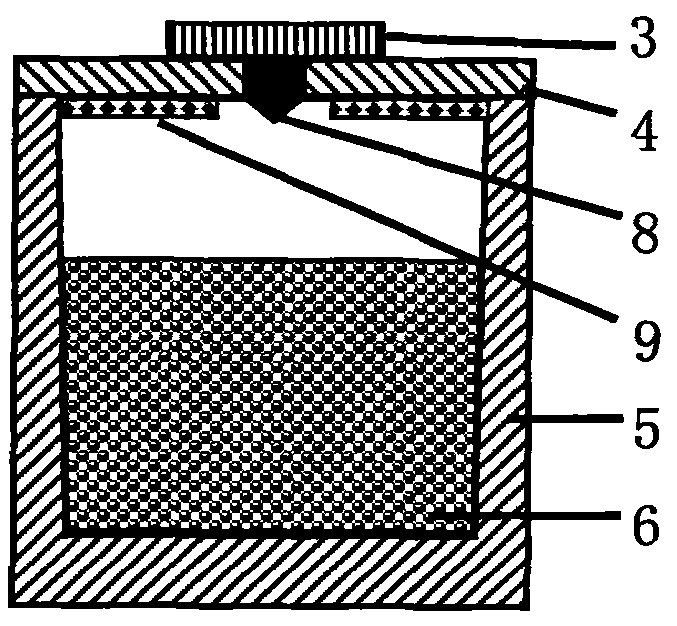

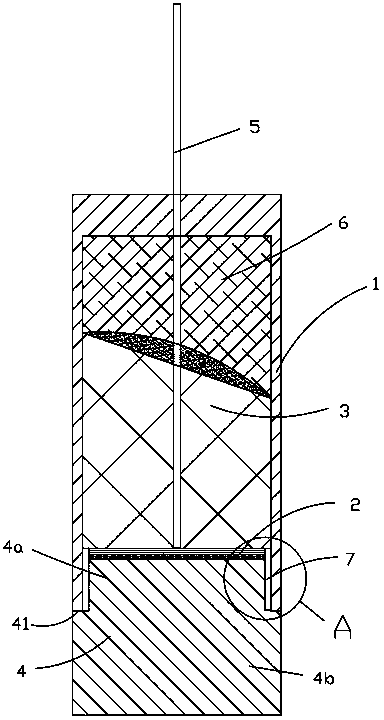

Device and process for preparing aluminum nitride crystals by adopting spontaneous crystal seed method

InactiveCN103103611ASimple growth processStrong operabilityPolycrystalline material growthFrom frozen solutionsCrucibleSingle crystal

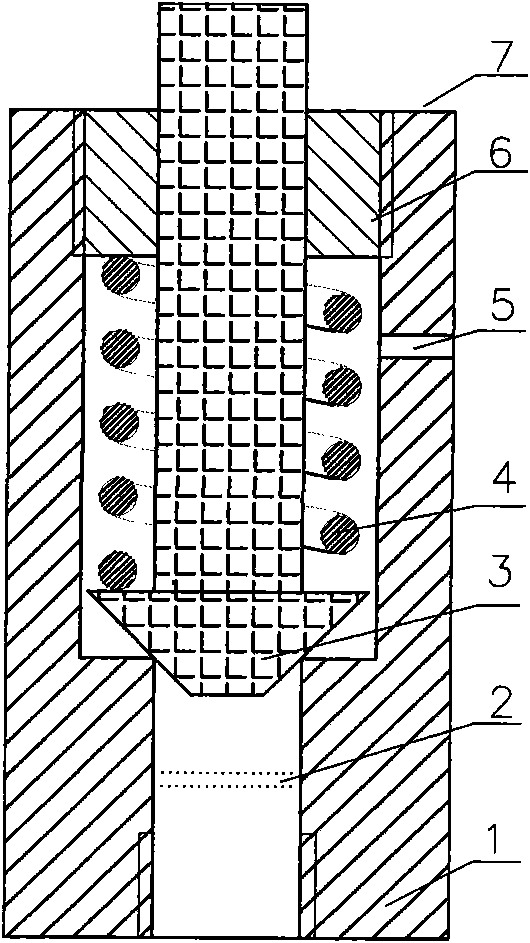

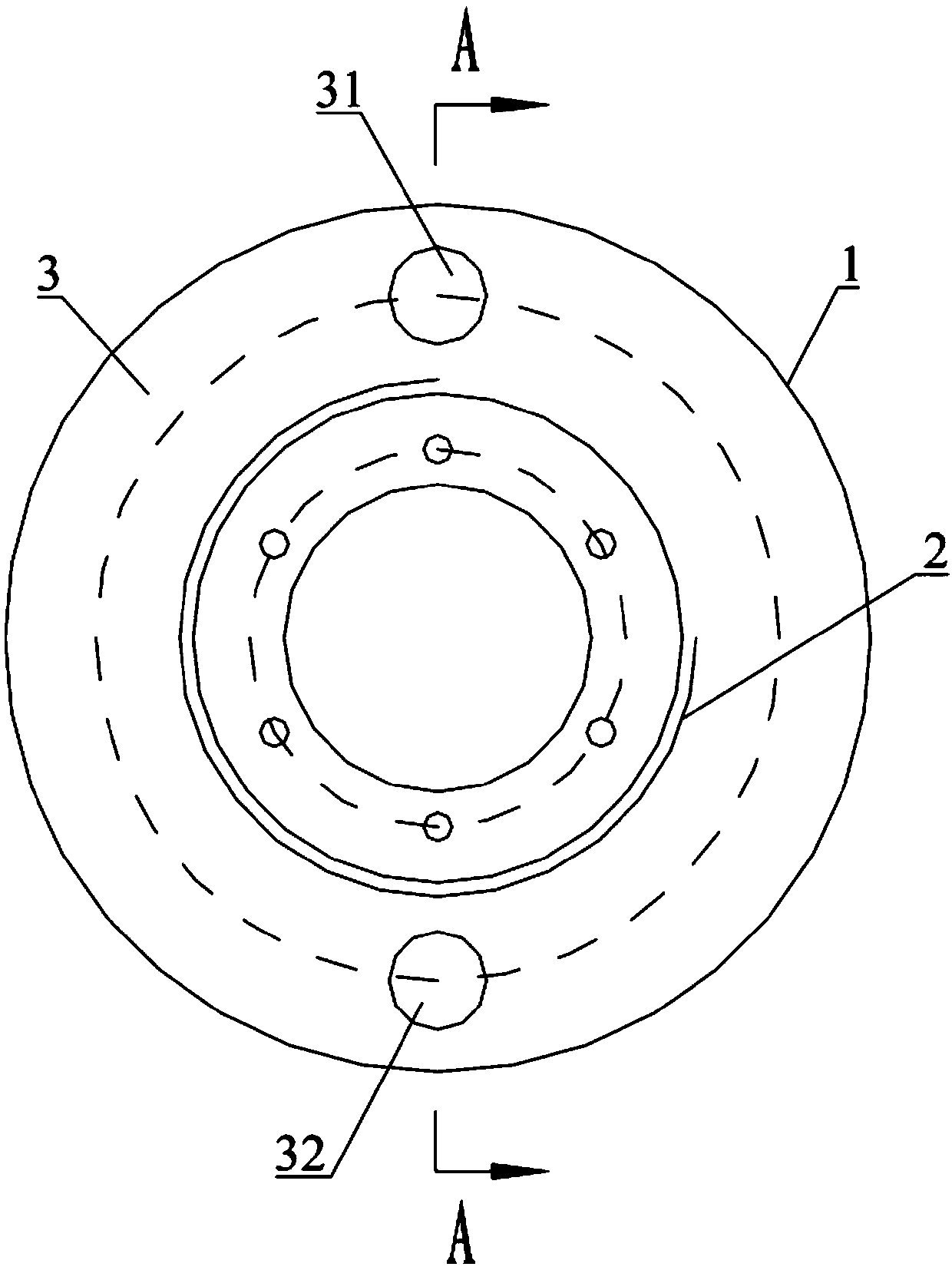

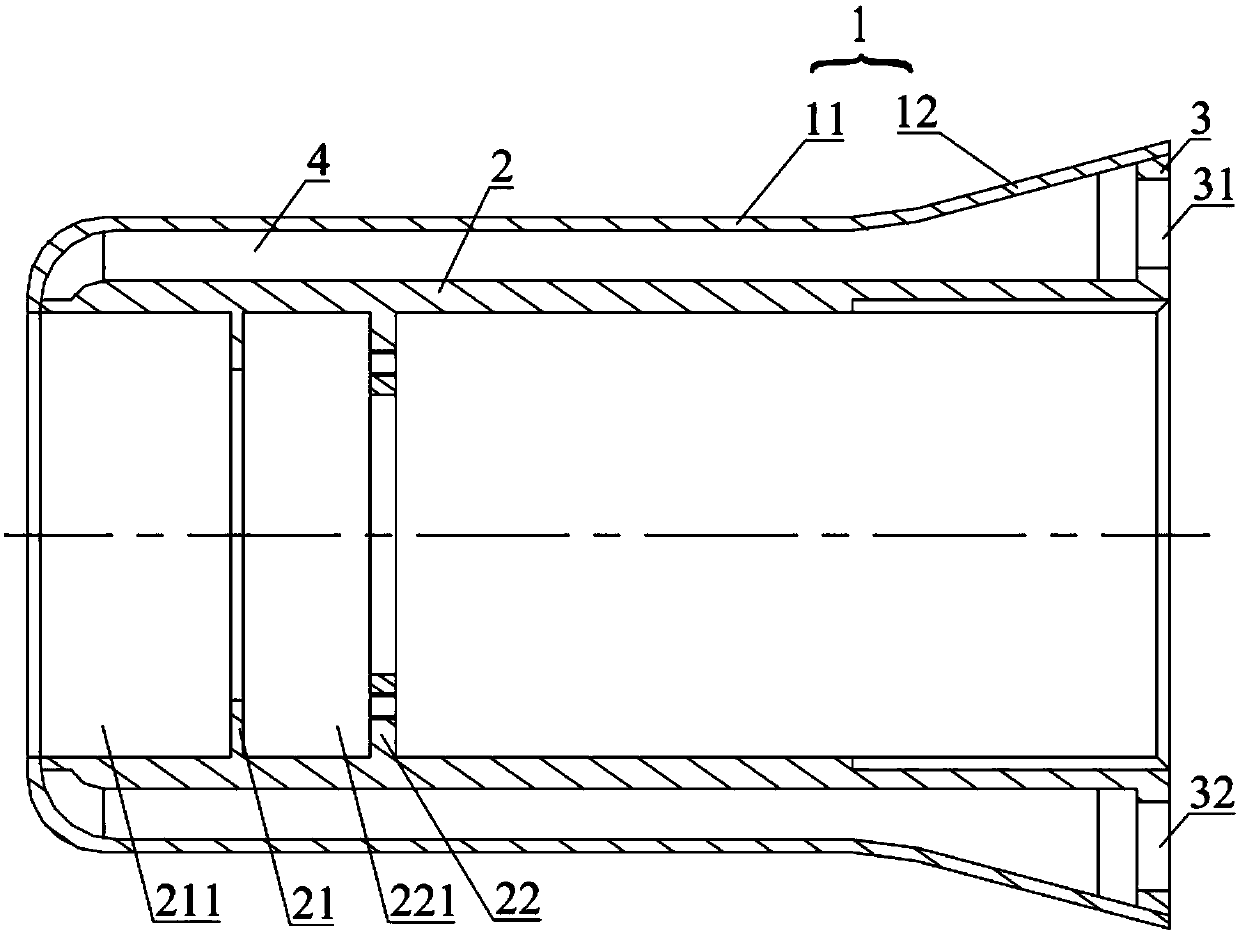

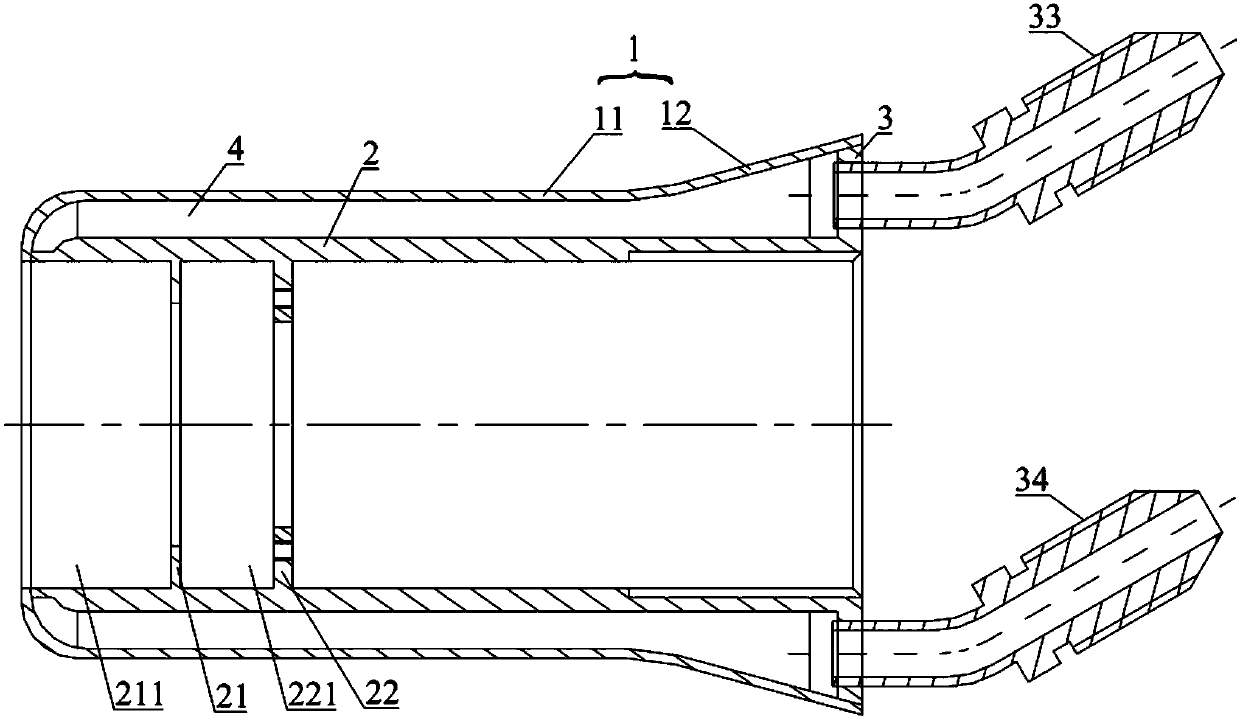

The invention belongs to the field of crystal preparation, and in particular relates to a device for preparing aluminum nitride crystals and a corresponding process. The invention provides the device and the process for preparing aluminum nitride crystals by adopting a spontaneous crystal seed method. The device comprises an inductive heating coil, an insulating layer, a crucible device and a crucible lifting device. The crucible device consists of a crucible body, a crucible cover and a cover sheet. A hole which is 1-2mm in diameter is formed in the crucible cover, the cover sheet is located above the crucible cover and completely shields the hole, and the area of the cover sheet is between those of the hole and the crucible cover. The preparation process comprises the two steps of: (1) obtaining aluminum nitride single crystals through spontaneous crystallization at the hole to be used as the crystal seeds due to limit of anisotropic crystalline characteristic of aluminum nitride and geometric dimension of the hole at lower temperature; and (2) obtaining large-dimensional aluminum nitride crystals by weakening the anisotropic crystalline characteristic of aluminum nitride at high temperature and meanwhile slowly adjusting the position of the crucible by lifting through the lifting device.

Owner:SHENZHEN UNIV

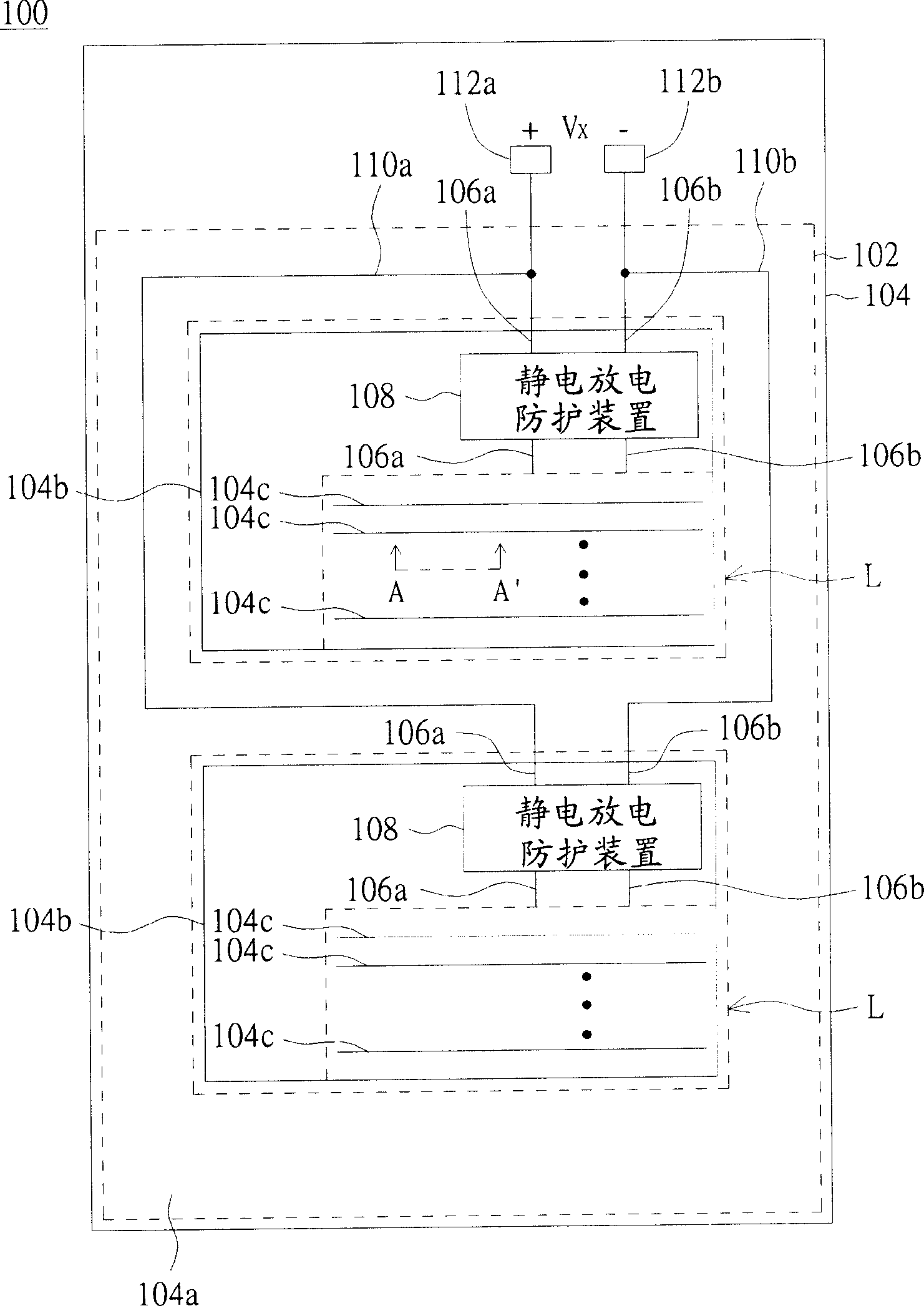

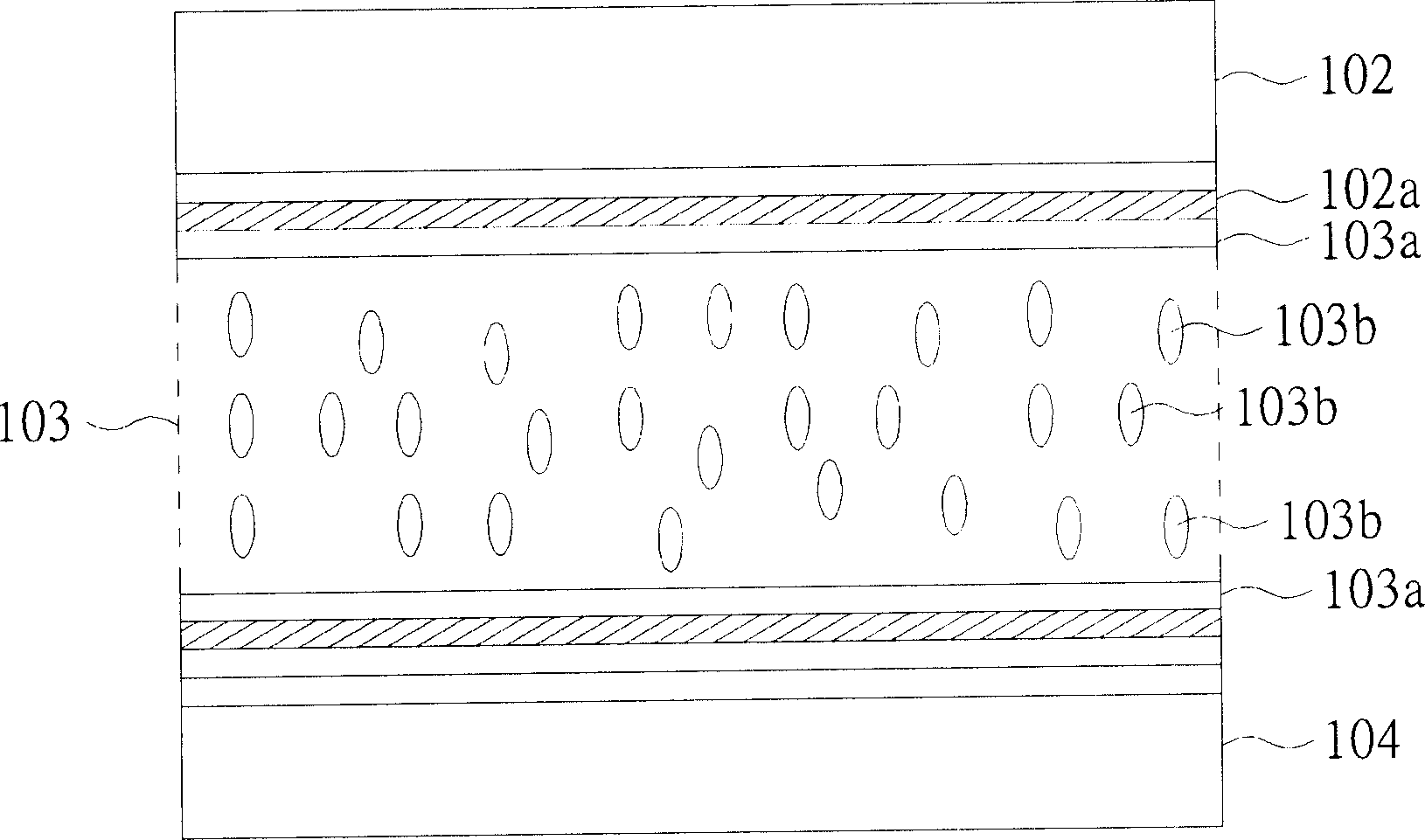

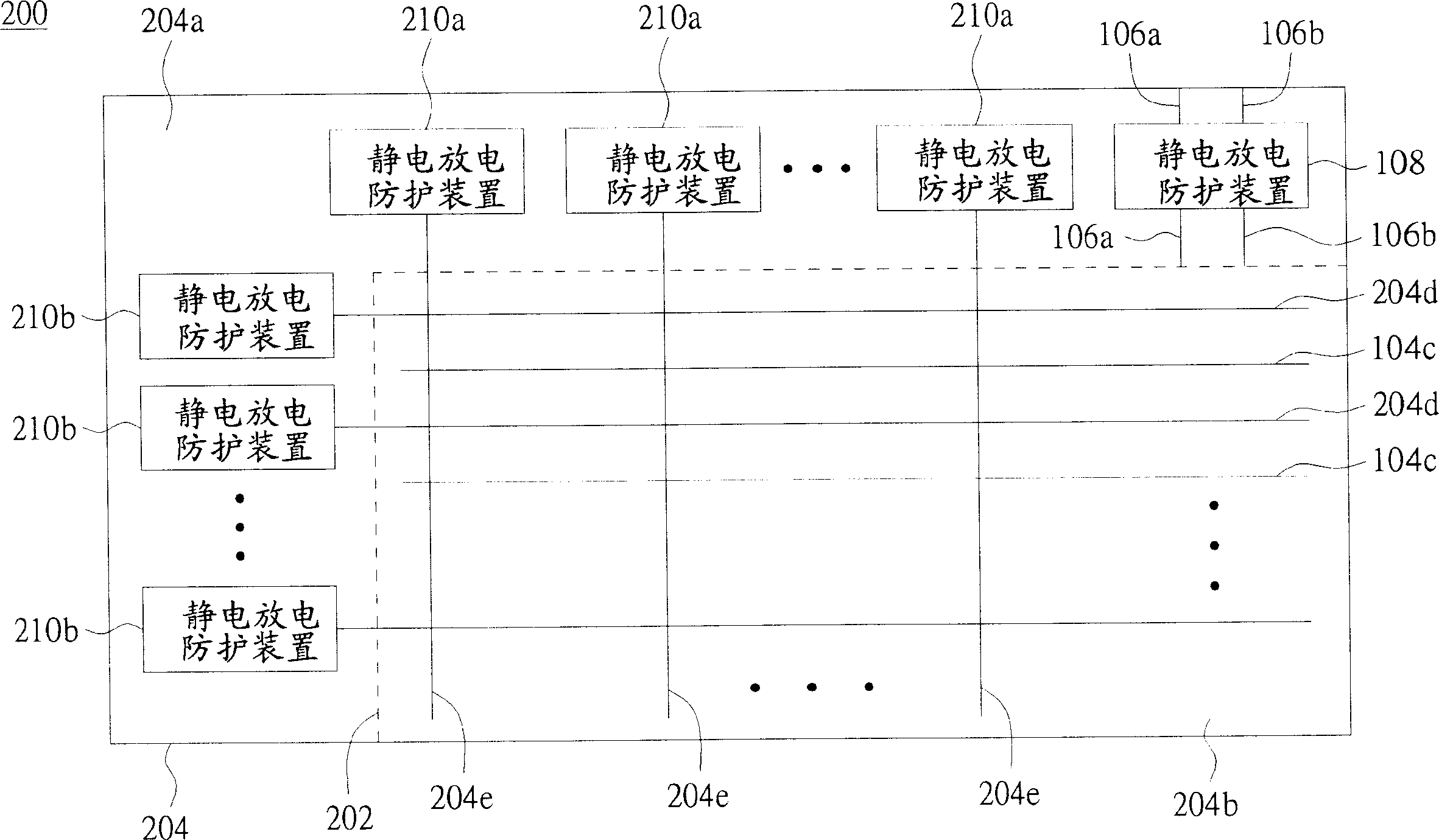

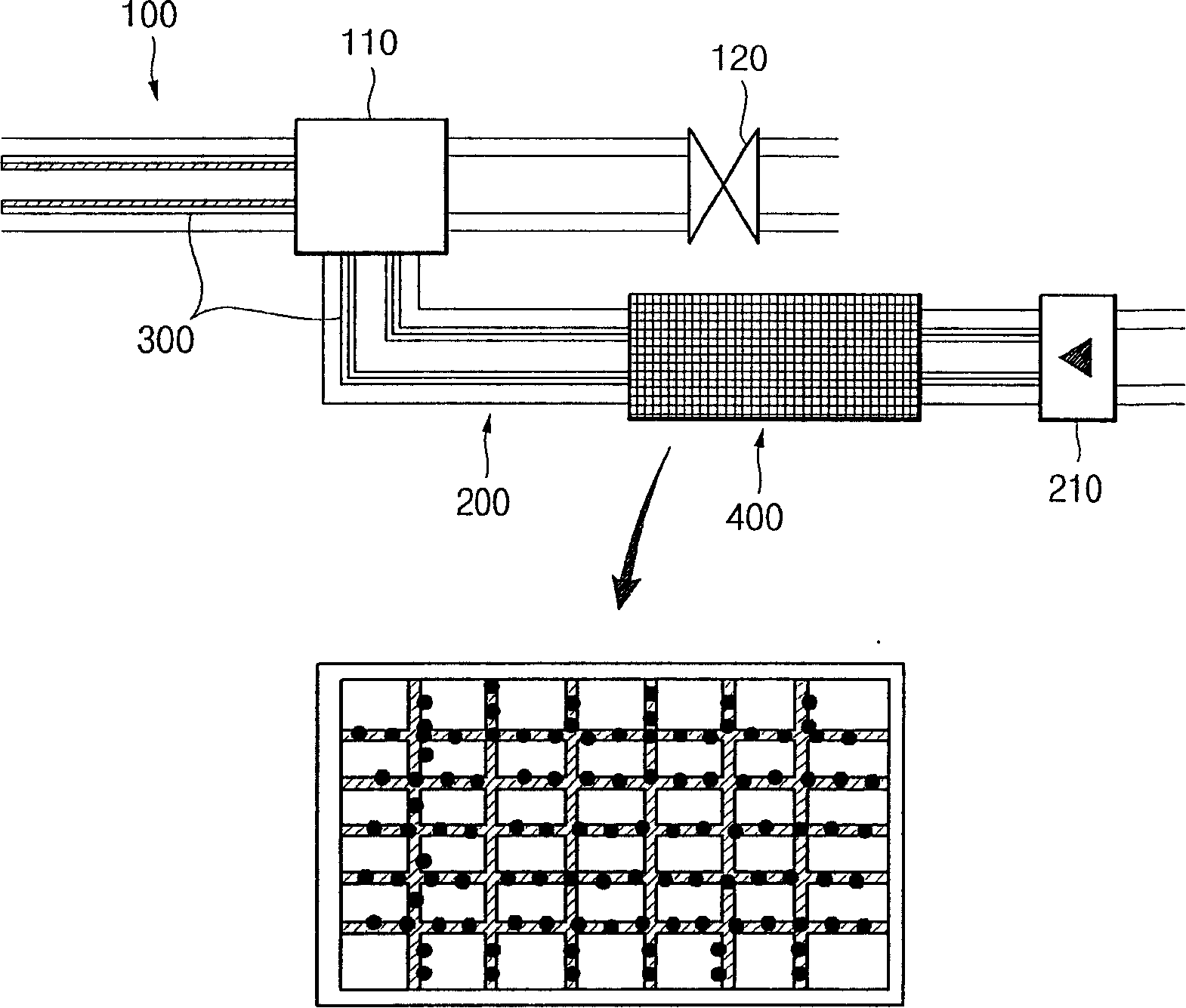

Motherboard of liquid crystal display and liquid crystal display faceplate

ActiveCN1916710AReduce the chance of damageImprove yieldStatic indicating devicesLiquid-crystal displayElectrostatic discharge

A mother board of liquid crystal display is prepared as setting liquid crystal layer between the first base plate and the second base plate, setting the first and the second wirings on face plate region, setting the first static discharge protective unit on face plate region and electric-connecting it to the first and the second wirings, setting the third and the fourth wirings on nonfaceplate region and electric-connecting them separately to the first and the second wirings.

Owner:AU OPTRONICS CORP

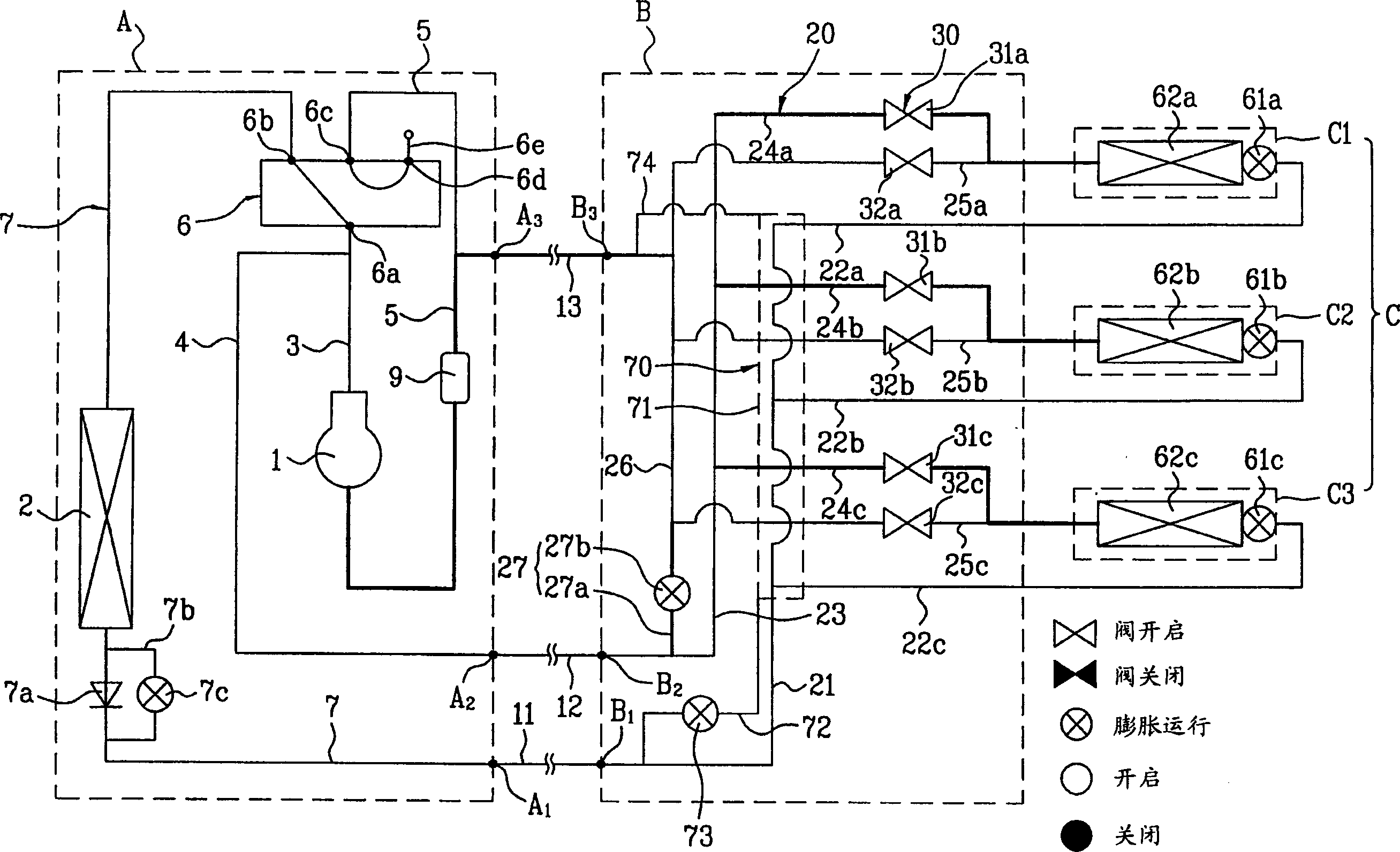

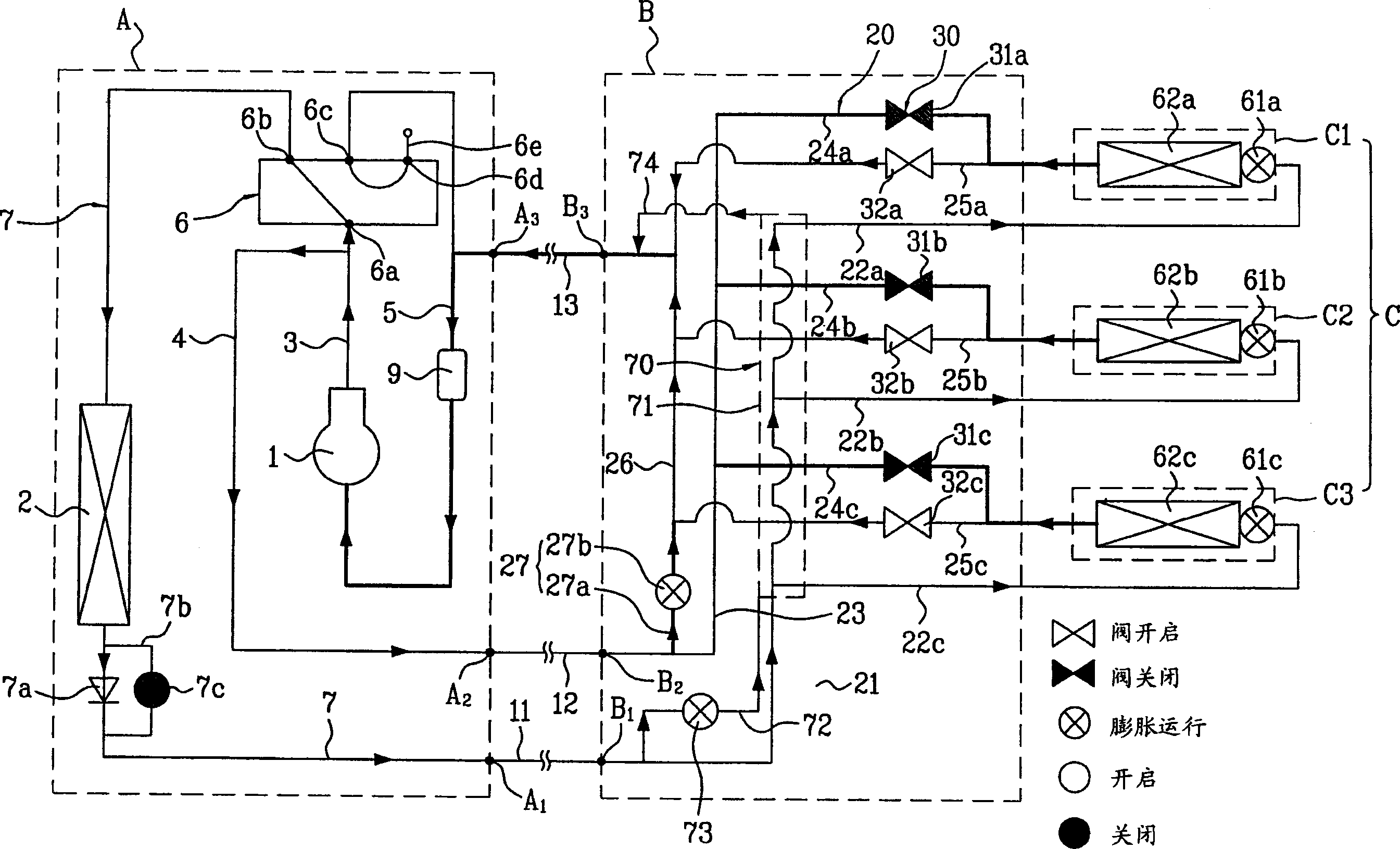

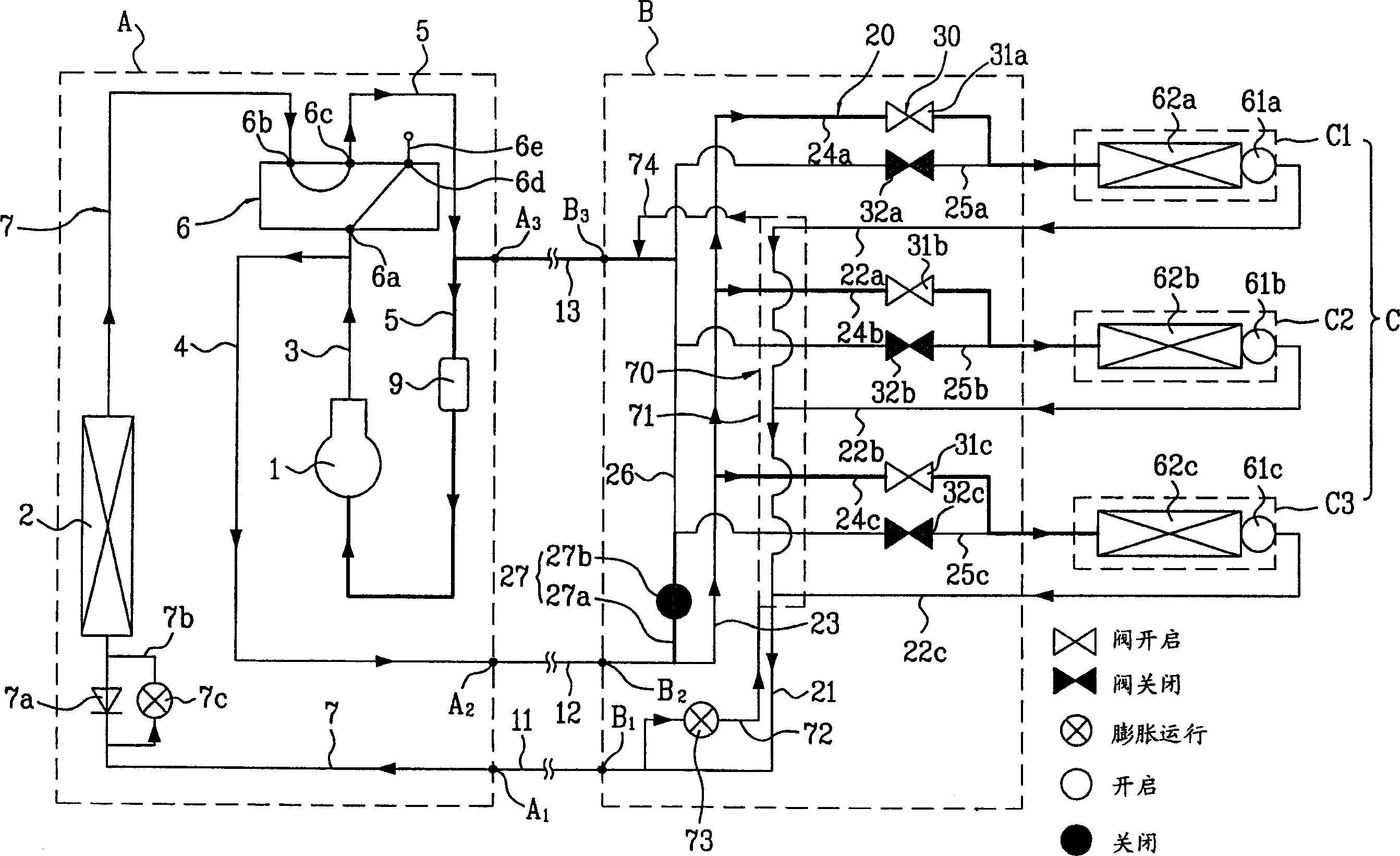

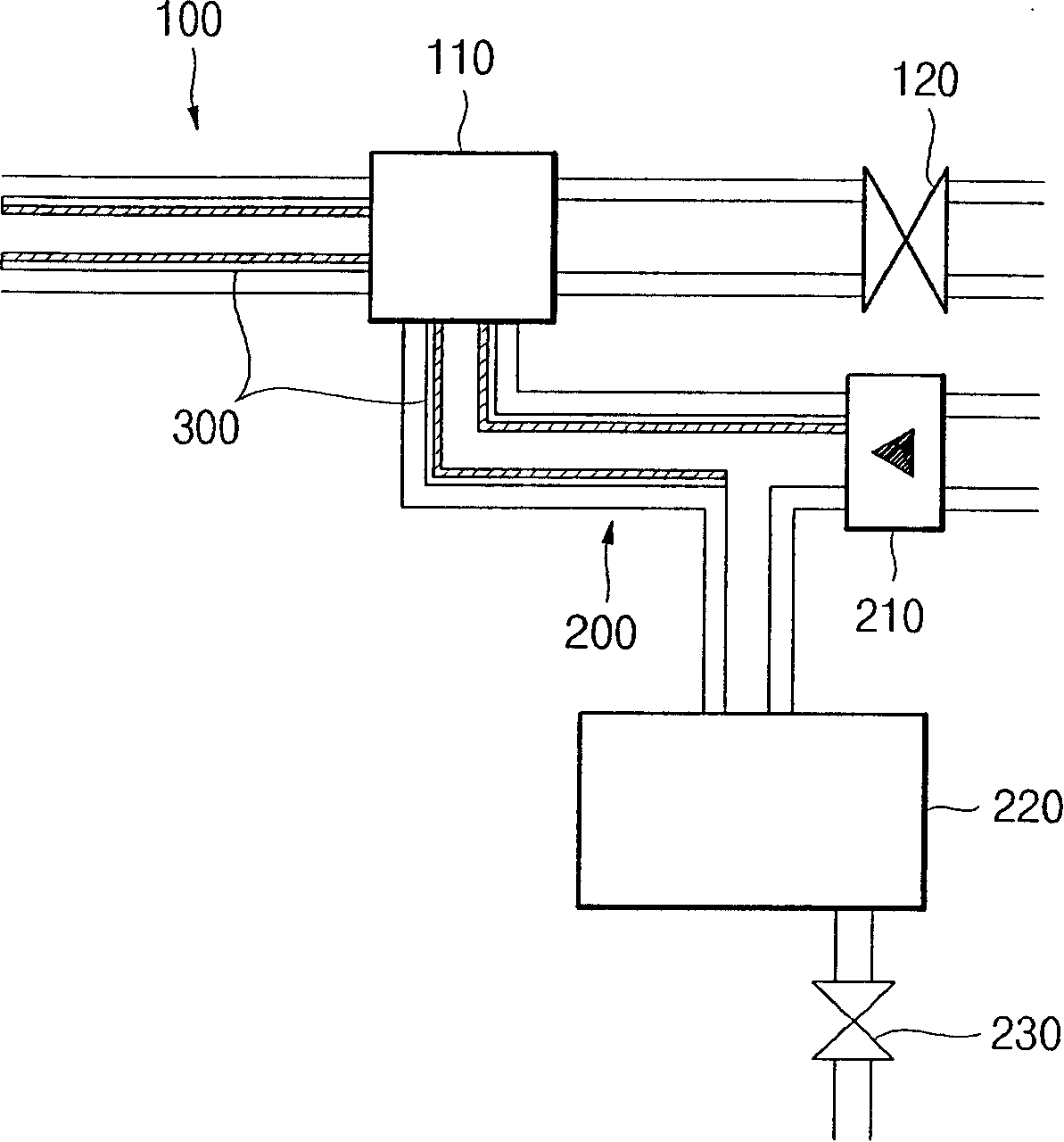

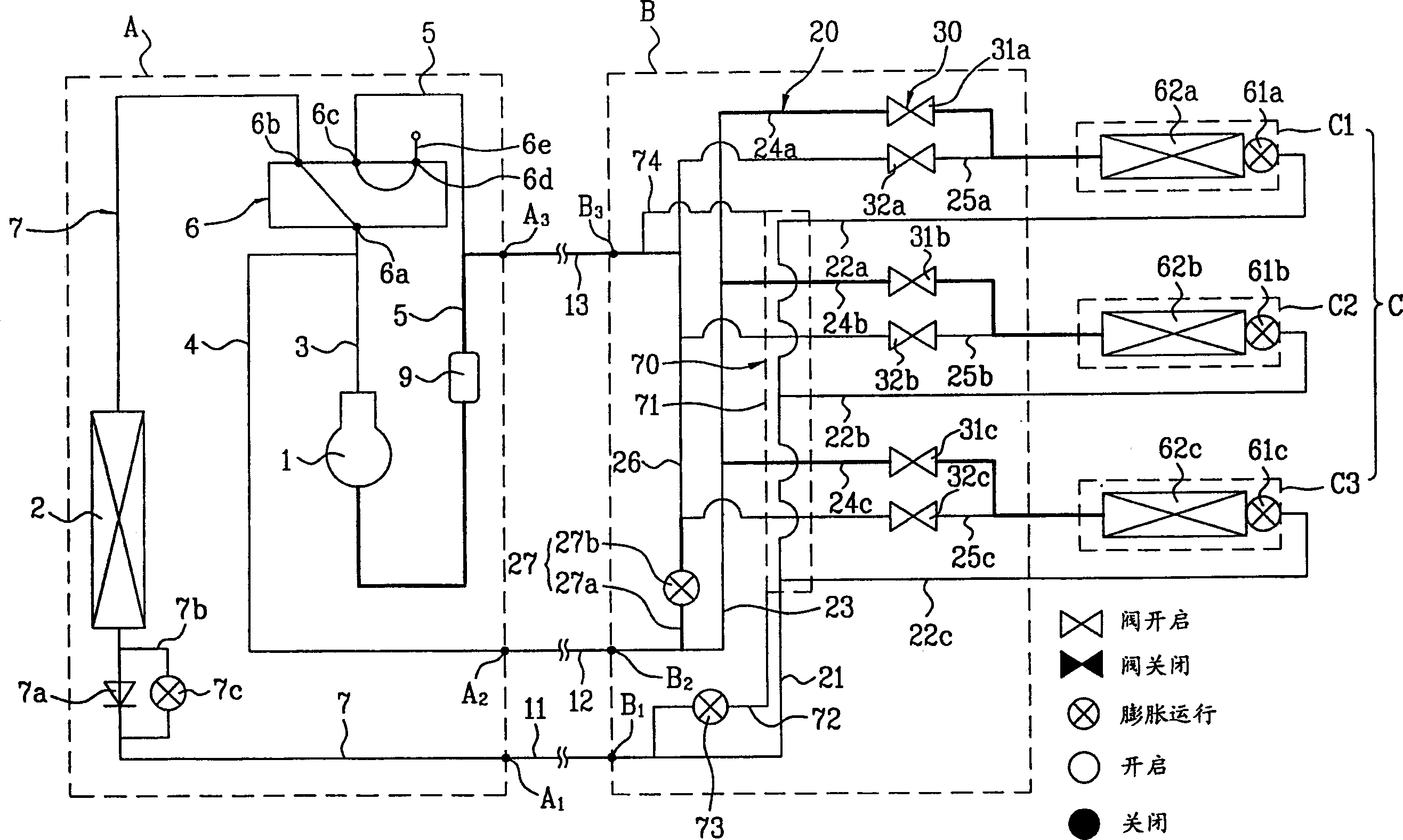

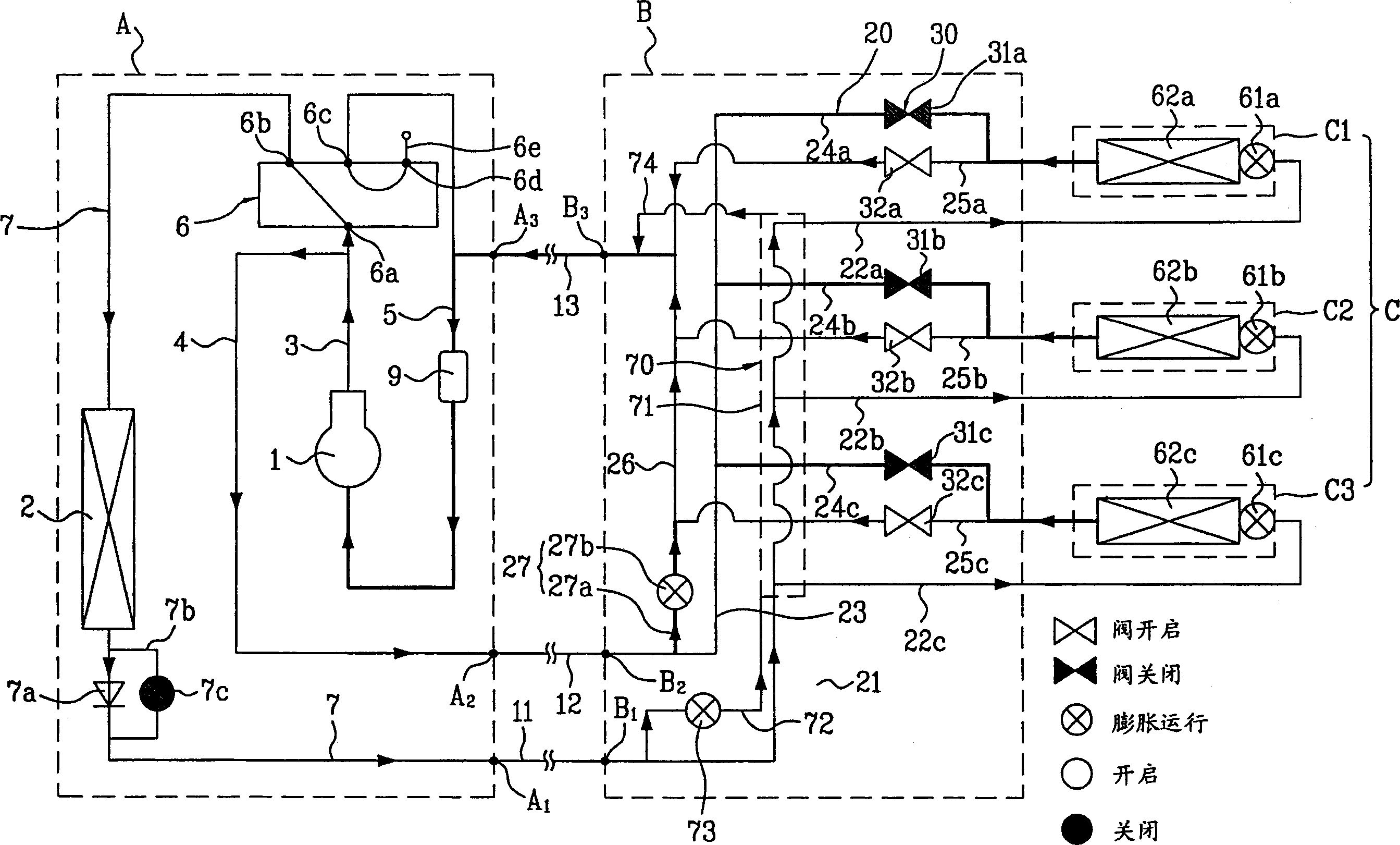

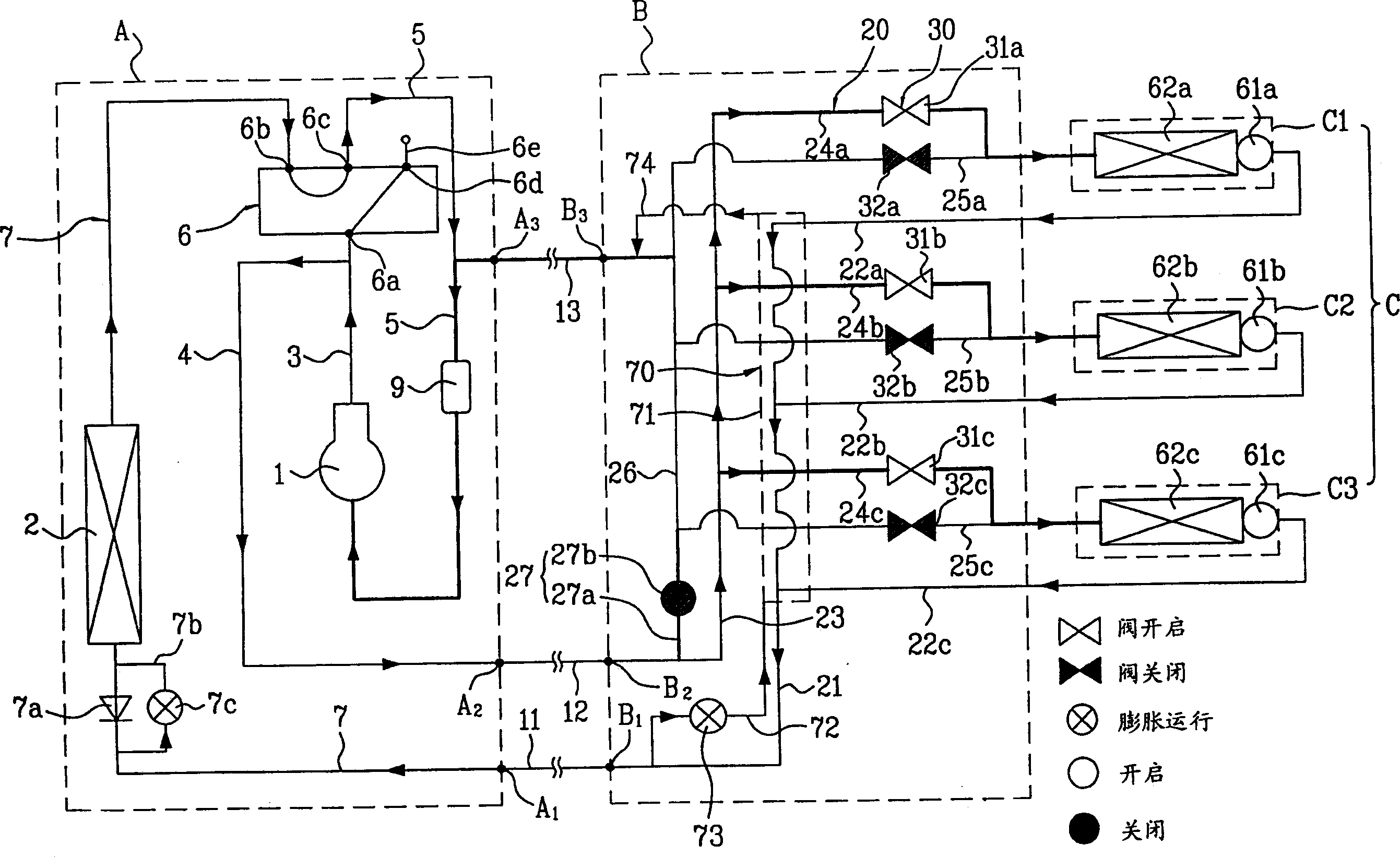

Duplex air governor

InactiveCN1517609APrevent importPrevents cooling performance from deterioratingMechanical apparatusCompression machines with several evaporatorsSuper coolingOperation mode

Multi-type air conditioner including an outdoor unit having a compressor, an outdoor heat exchanger, a flow path control valve for controlling a flow path of the refrigerant from the compressor, an outdoor expansion device for expanding liquid refrigerant introduced thereto in a condensed state via indoor units and providing to the outdoor heat exchanger when the room is heated, and an outdoor unit piping system, a plurality of indoor units each having an indoor expansion device, an indoor heat exchanger, and an indoor piping system, a distributor for selectively distributing the refrigerant from the outdoor unit to the indoor units and returning to the outdoor unit again proper to respective operation modes, and means for super cooling the refrigerant condensed at the outdoor heat exchanger or the indoor heat exchangers and flowed to the indoor expansion devices or to the outdoor expansion device, thereby super cooling the refrigerant supplied to the evaporator.

Owner:LG ELECTRONICS INC

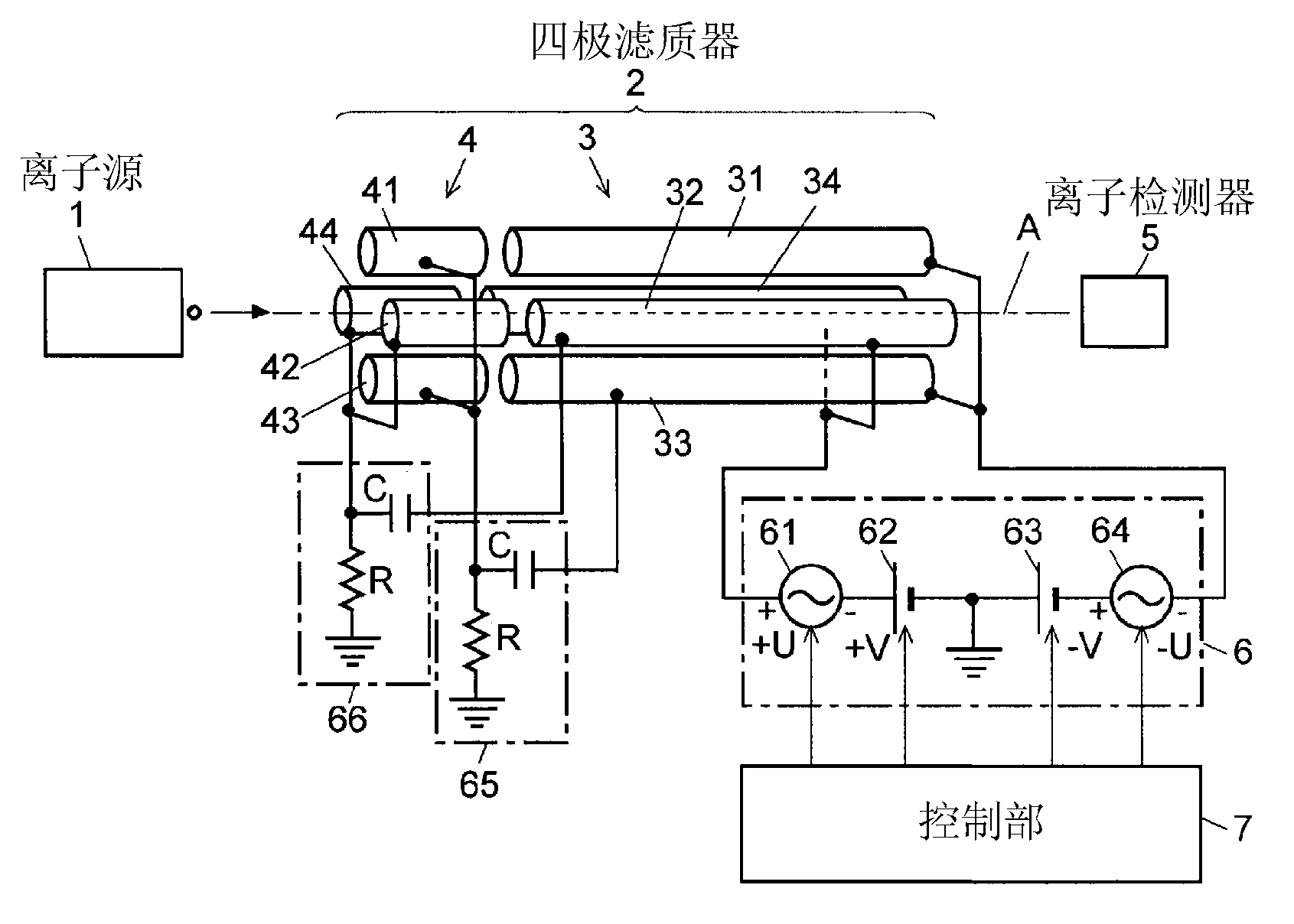

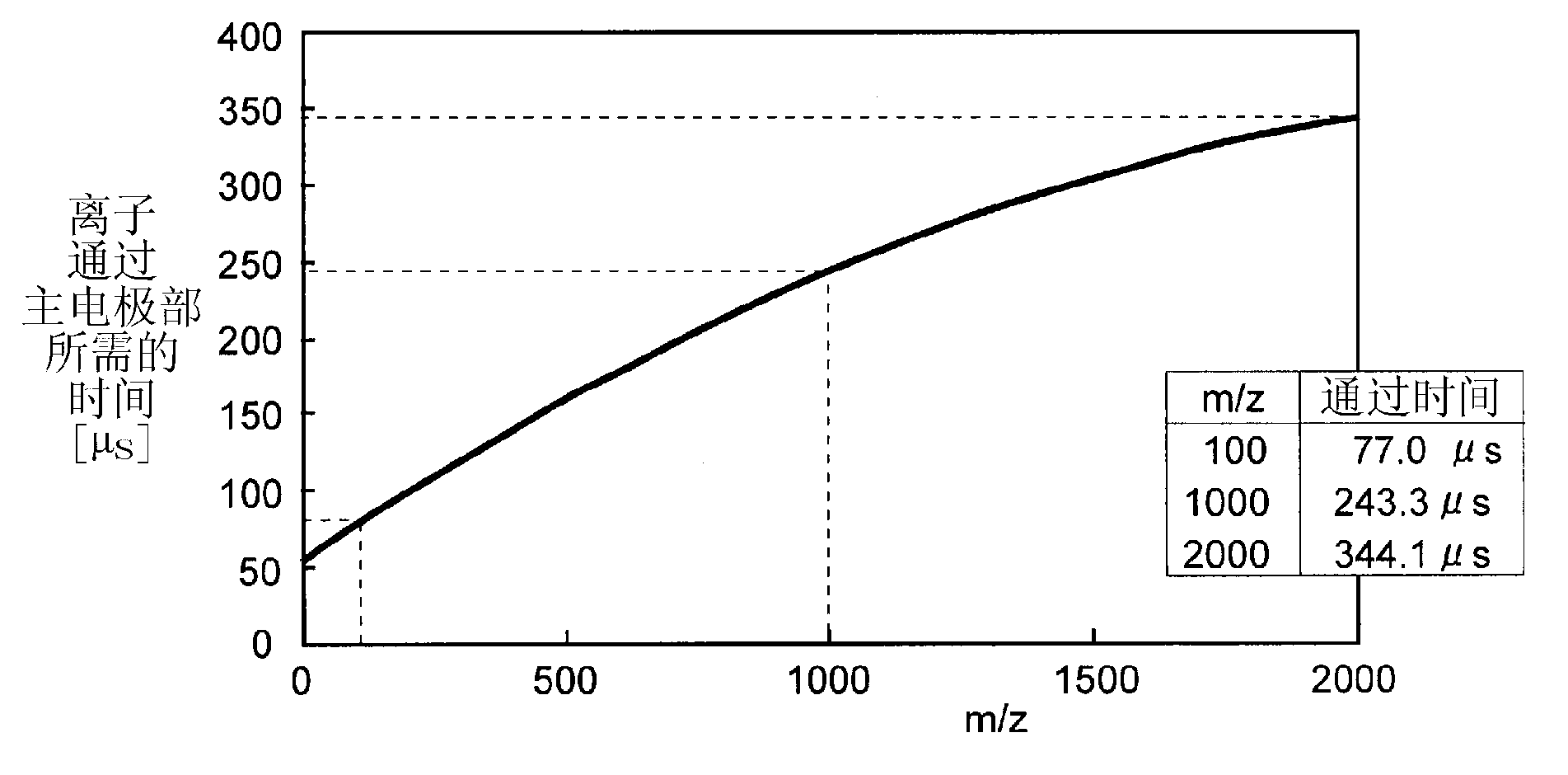

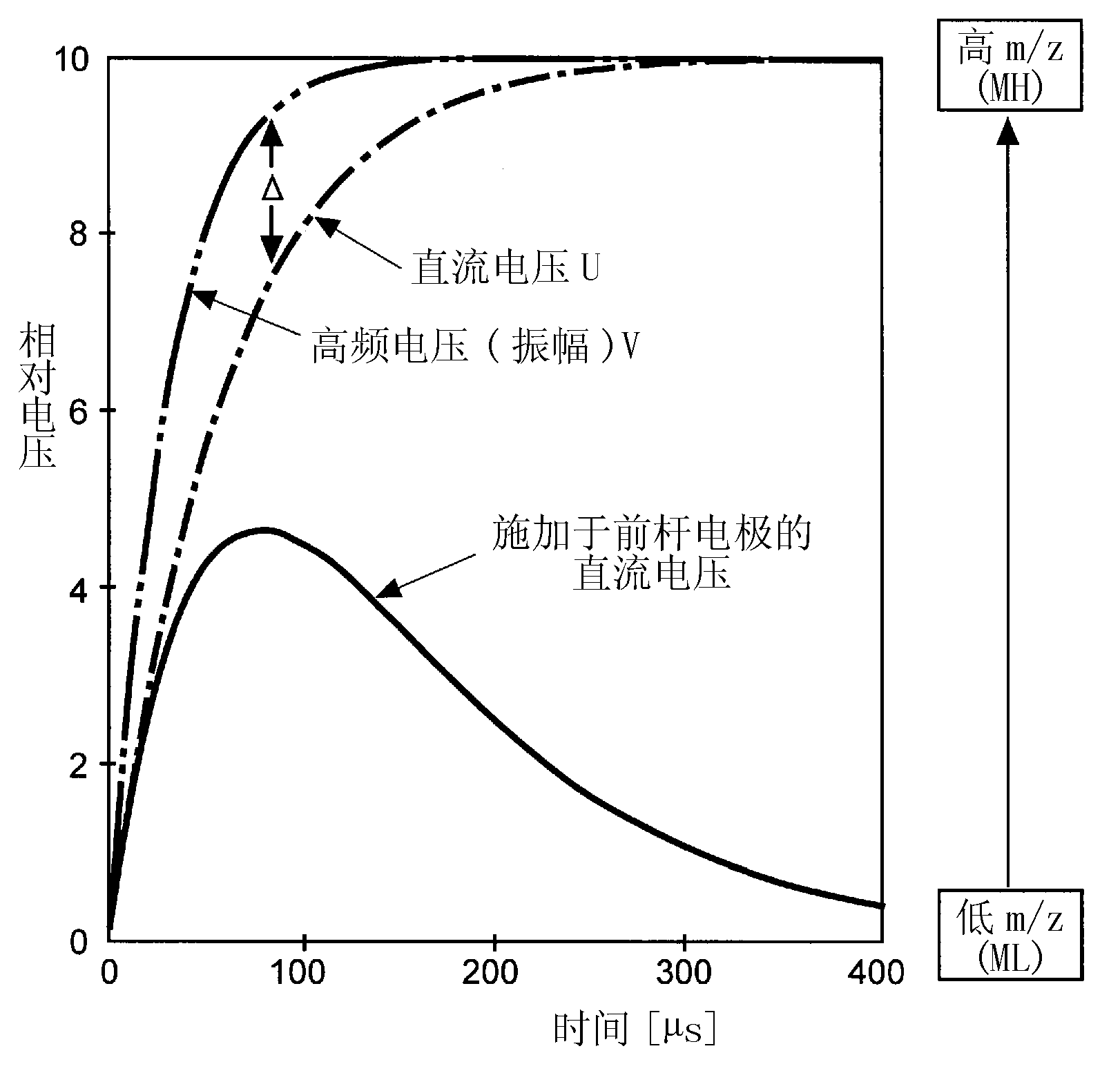

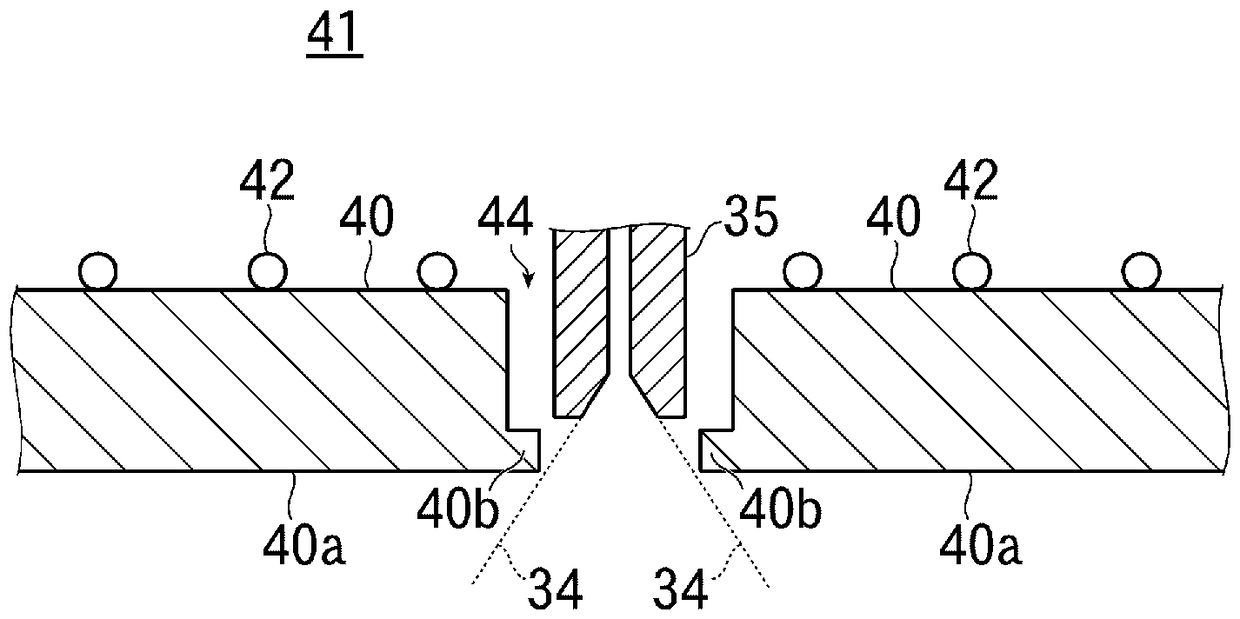

Quadrupolar mass analysis device

ActiveCN102834897AAvoid incidenceAvoid damageStability-of-path spectrometersSpectrometer circuit arrangementsTransient stateVoltage source

Disclosed is a quadrupolar mass analysis device provided with direct-current voltage sources (62, 63) having response characteristics wherein the response time of the direct-current voltage is shorter than the time required when an ion having the maximum mass-to-charge ratio among ions introduced to a quadrupolar mass filter (2) passes through the quadrupolar mass filter (2). Main rod electrodes (31-34) and front rod electrodes (41-44) are connected via primary differentiation circuits (65, 66). Thus, in the transient state of voltage variation in association with the changing of mass-to-charge ratios, among ions entering the quadrupolar mass filter (2), ions having a low m / z can be eliminated in a front electrode portion (4), and ions having a high m / z can be eliminated in a main electrode portion (3). Accordingly, a large amount of ions can be prevented from passing through the quadrupolar mass filter (2) and entering an ion detector (5).

Owner:SHIMADZU SEISAKUSHO CO LTD

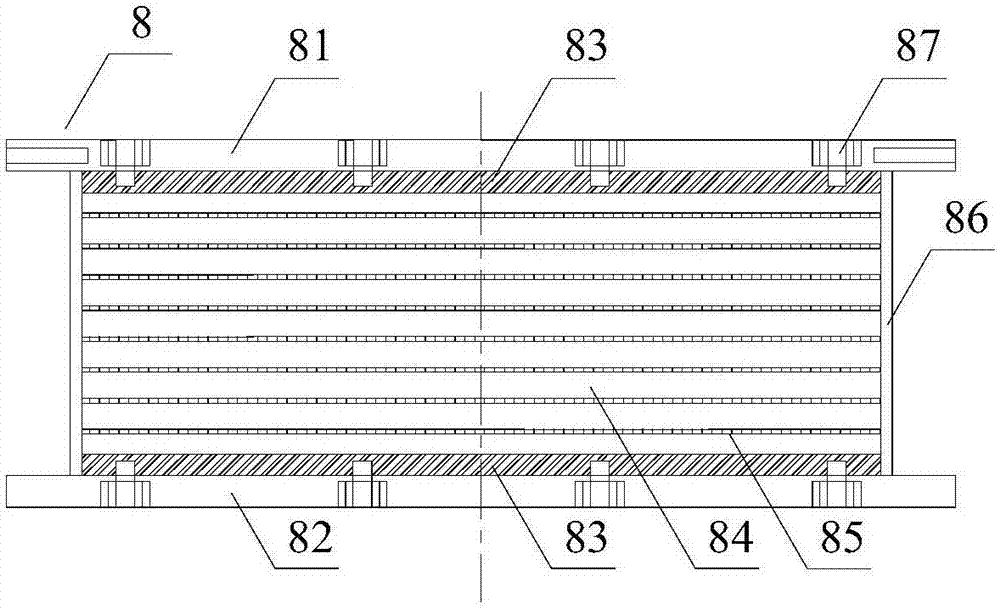

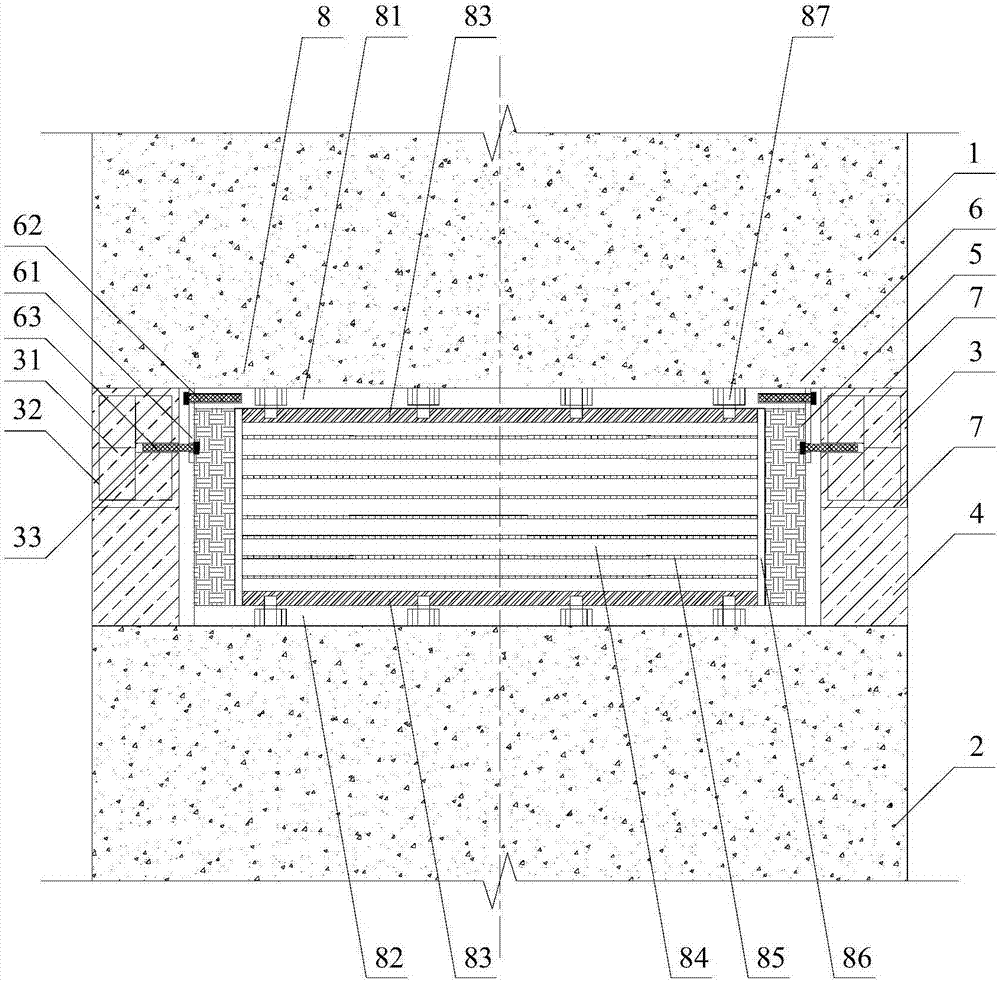

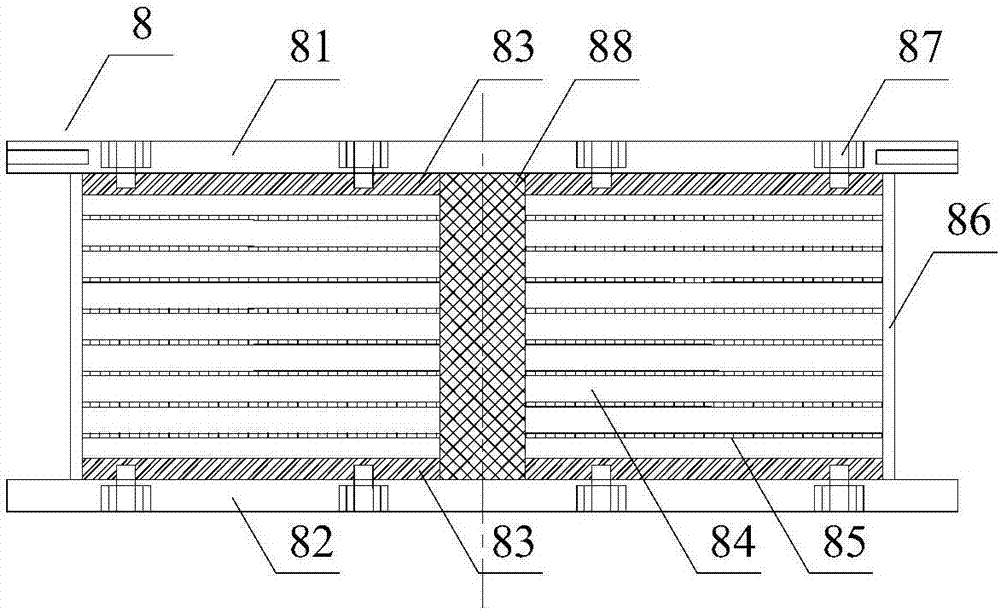

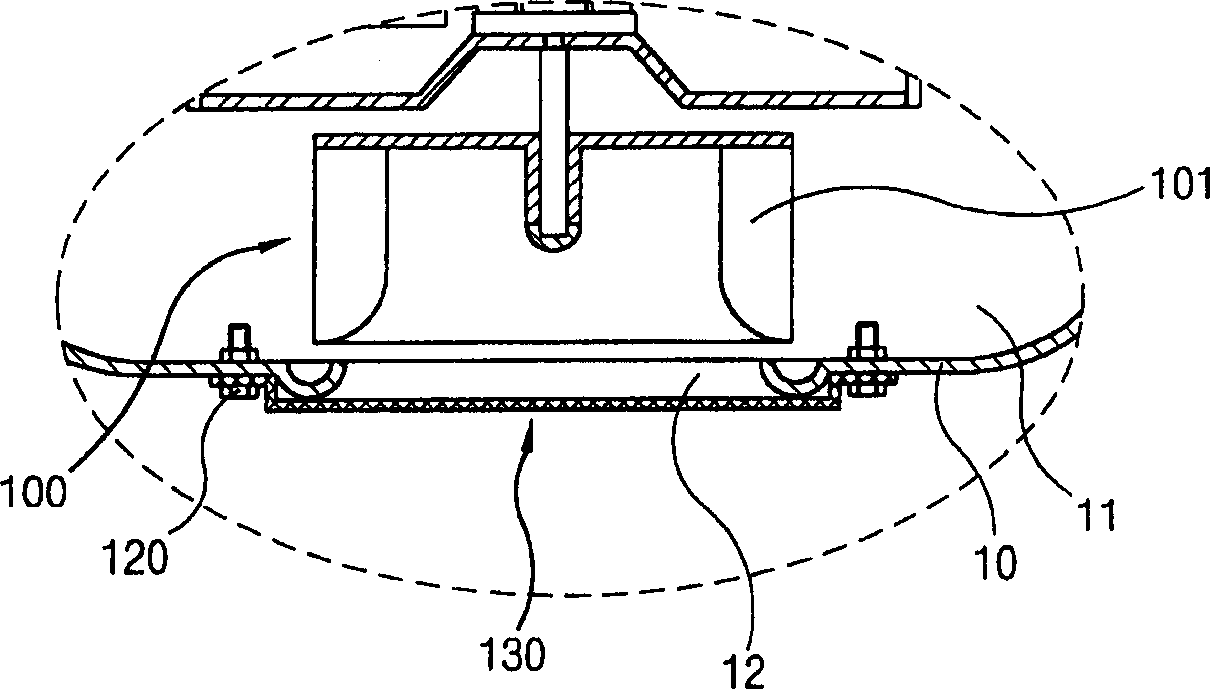

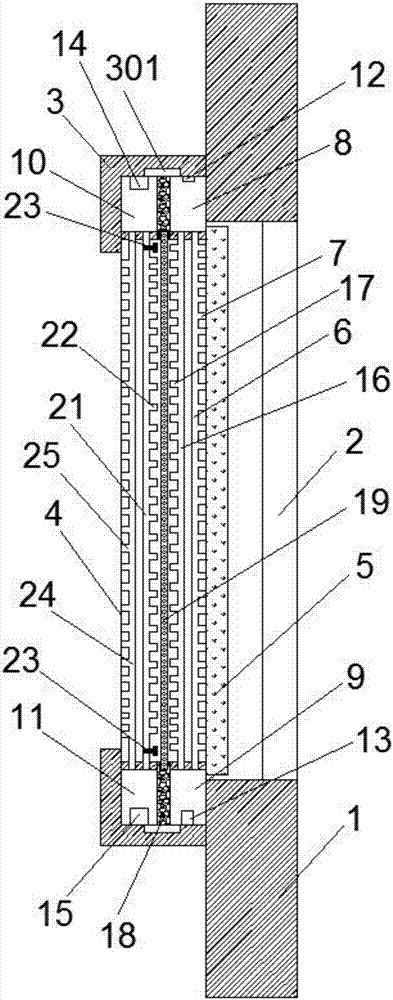

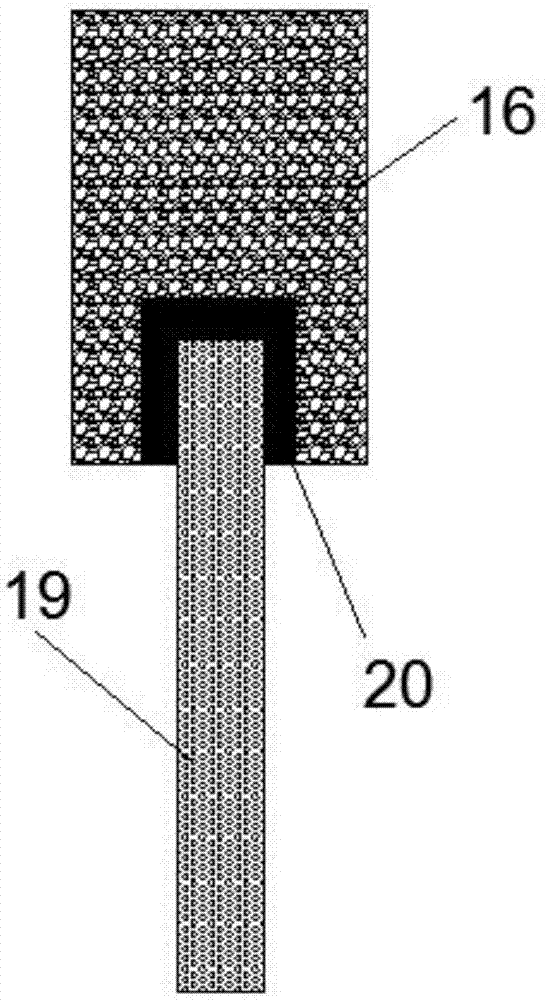

Fire-proof protecting device of building shock-insulation rubber supporting seat and construction method thereof

ActiveCN106968501AEasy connectionSimple construction operationProtective buildings/sheltersFire proofingAdhesiveEngineering

The invention discloses a fire-proof protecting device of a shock-insulation rubber supporting seat. The fire-proof protecting device comprises upper heat-insulation profiles, lower heat-insulation profiles, aluminum silicate fiber blankets connecting pieces and fire-proof blocking materials. The fire-proof blocking materials are adhered between the contact faces of the upper heat-insulation profiles and upper layer columns. The lower heat-insulation profiles are arranged on the top faces of lower layer columns in a masonry mode through fire-proof adhesives. The fire-proof blocking materials are adhered between the upper heat-insulation profiles and the lower heat-insulation profiles. The spaces between the upper heat-insulation profiles and the shock-insulation rubber supporting seat as well as between the lower heat-insulation profiles and the shock-insulation rubber supporting seat are filled with the aluminum silicate fiber blankets. Through a fire-proof protecting construction method, good fire-proof protecting for the shock-insulation rubber supporting seat can be achieved, it can be ensured that fire-proof protecting is not destroyed during shock-insulation supporting seat deformation, and meanwhile the method has the advantages of being convenient to operate and wide in application range.

Owner:应急管理部天津消防研究所

Fan with dustproof device

InactiveCN1403721APrevent importReduce noisePump componentsPoint-like light sourceEngineeringNoise generation

A fan having a dust-proof apparatus includes: a casing having a passage; a rotation driving unit installed inside the casing; a plurality of blades positioned in the passage and coupled to a rotational shaft of the rotation driving unit so as to be rotated; and a dust-proof member installed at an entrance of the passage to cover the entrance of the passage, and integrally coupled to the blades so as to be rotated together with the blades. Since insects or big dusts can be prevented from being introduced according to an air flowing generated as the blades are rotated, and the coupling state between parts is firm. In addition, since the eccentricity is minimized, the parts are not damaged, and as a noise generation is restrained, so that reliability can be heightened.

Owner:LG ELECTRONICS INC

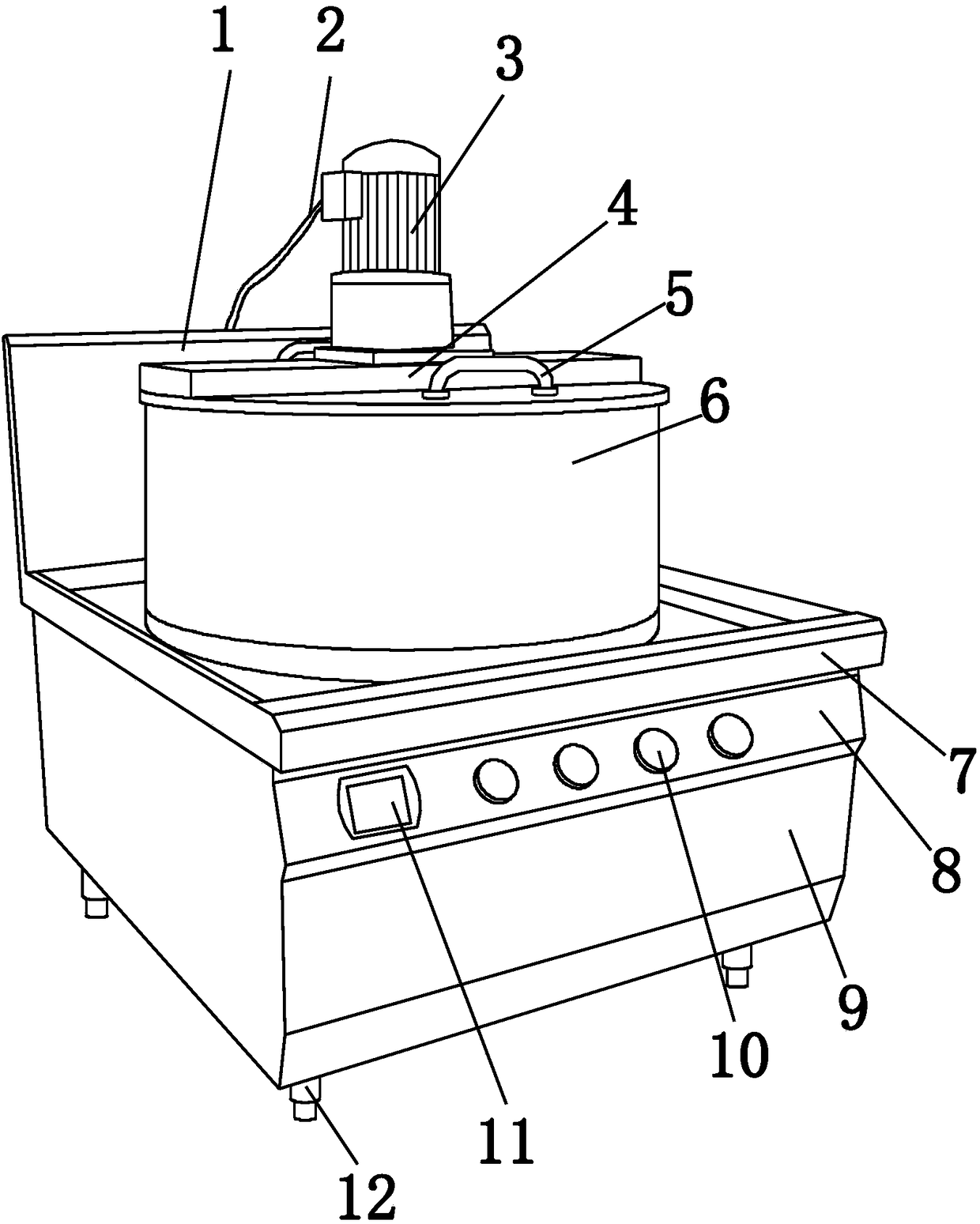

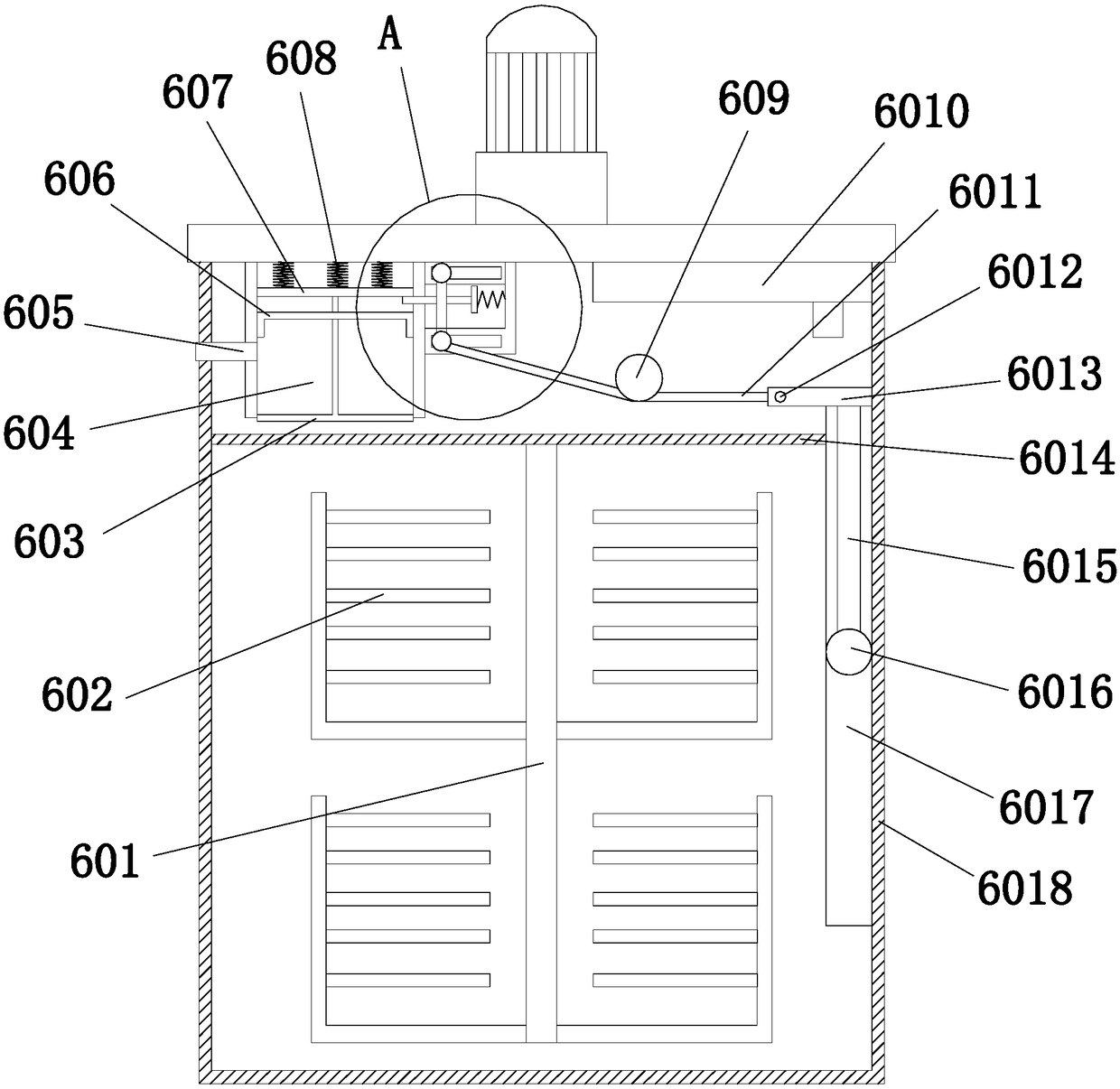

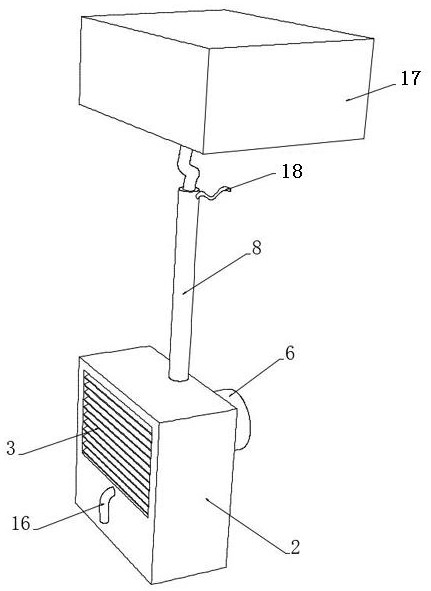

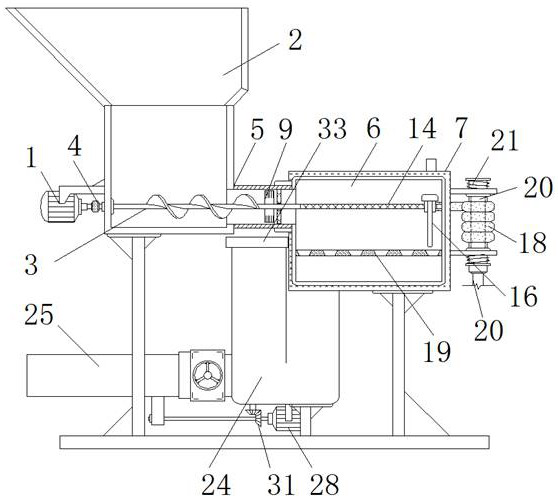

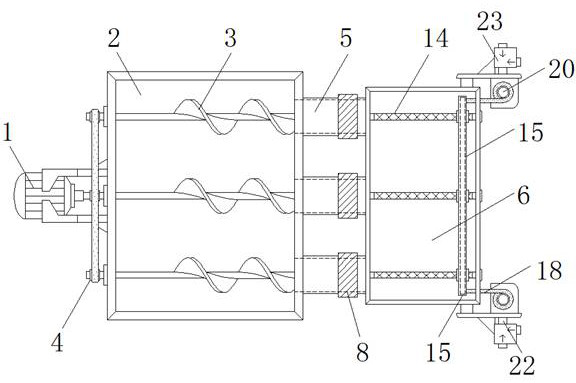

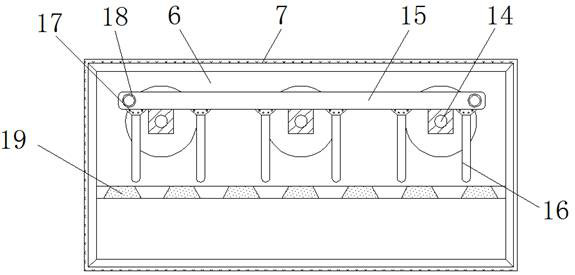

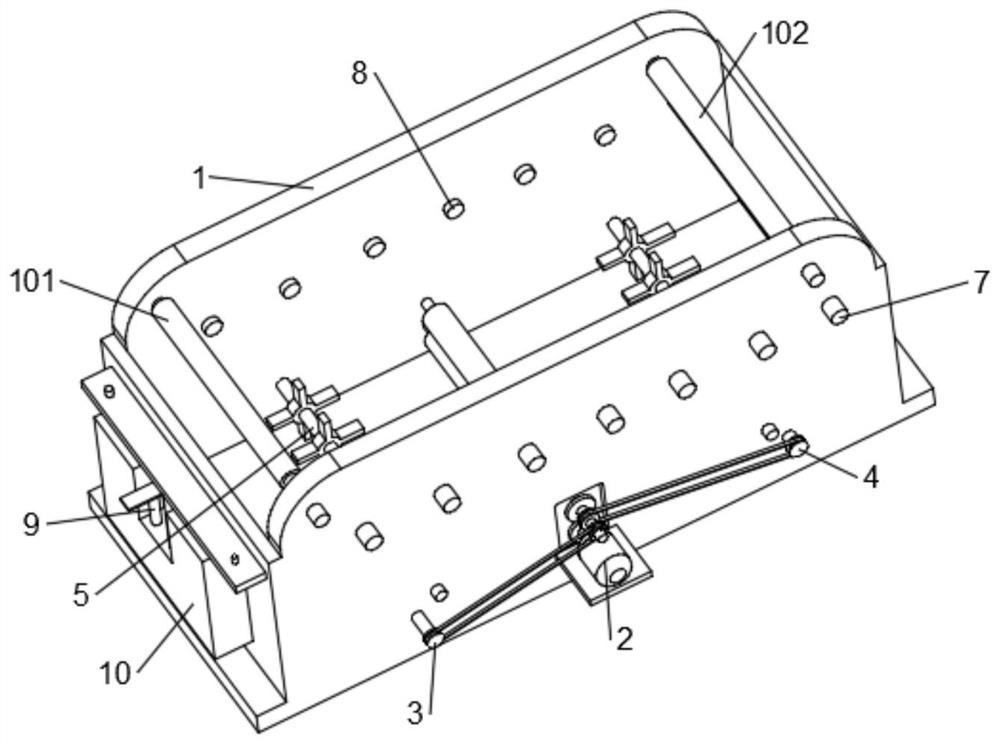

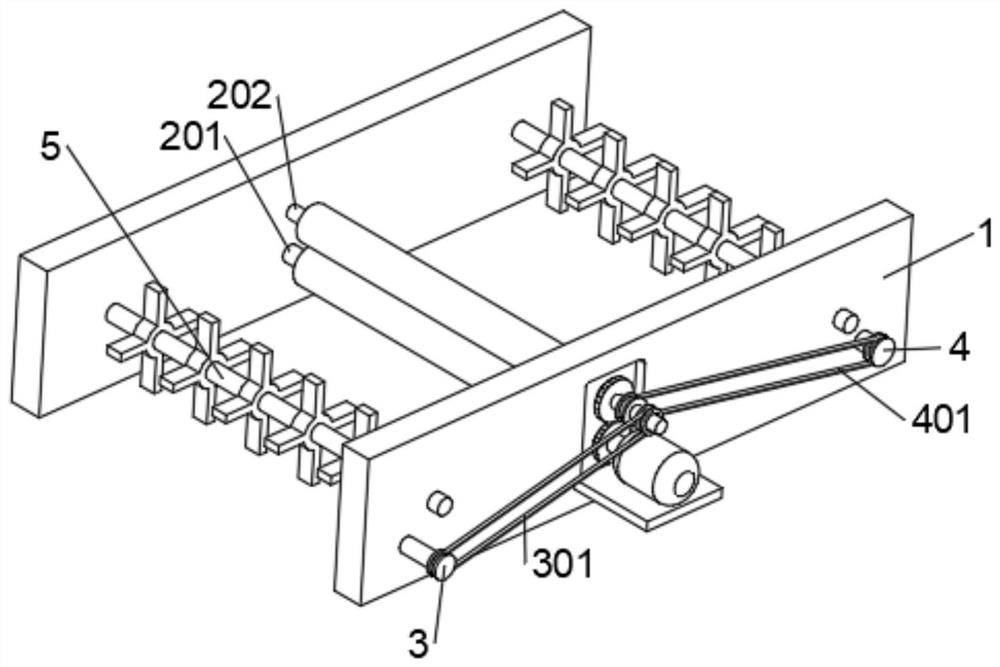

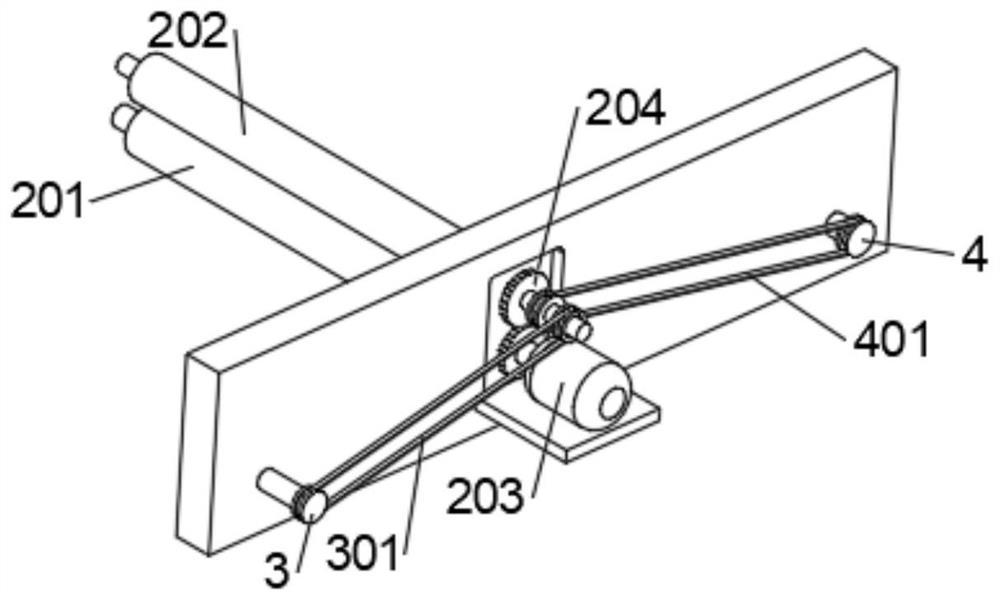

Baking soda water fast preparation device for food production

InactiveCN108144483APrevent importEffective quantificationTransportation and packagingRotary stirring mixersWater levelMechanical engineering

The invention discloses a baking soda water fast preparation device for food production. The device structurally comprises a protection baffle, a power line, a transmission motor, a wiring groove, a handle, a stirring barrel, a working table surface, a control panel, a control cabinet, operation buttons, a display screen and fixing feet. The device has the advantages that a floating ball and a buoyancy push rod are controlled to ascend and descend according to the water level in a barrel body, and then a transmission rope drives a plug-pin transmission block and a plug-pin rod to move and disengage from limiting positions, so that a discharging plate conducts discharging; a material feeding port is sealed through a sealing plate during discharging, so that the situation that the material feeding port continues to discharge materials is prevented; a stirring switch is automatically triggered for stirring through a lifting plate, so that quantitative addition of the materials is achieved, and the preparation efficiency and quality are greatly improved.

Owner:丁继来

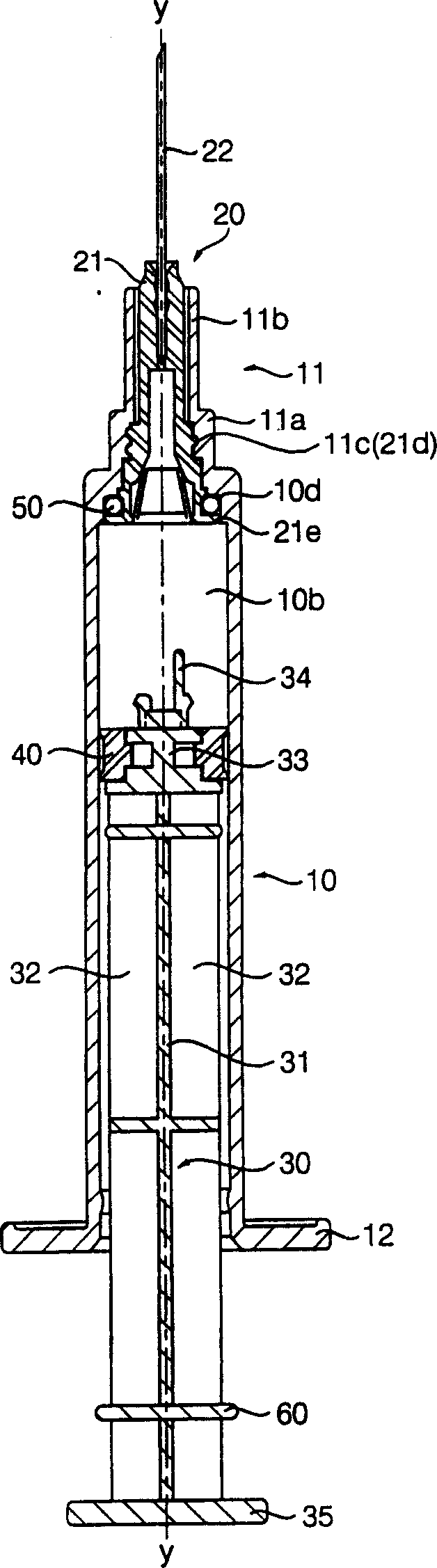

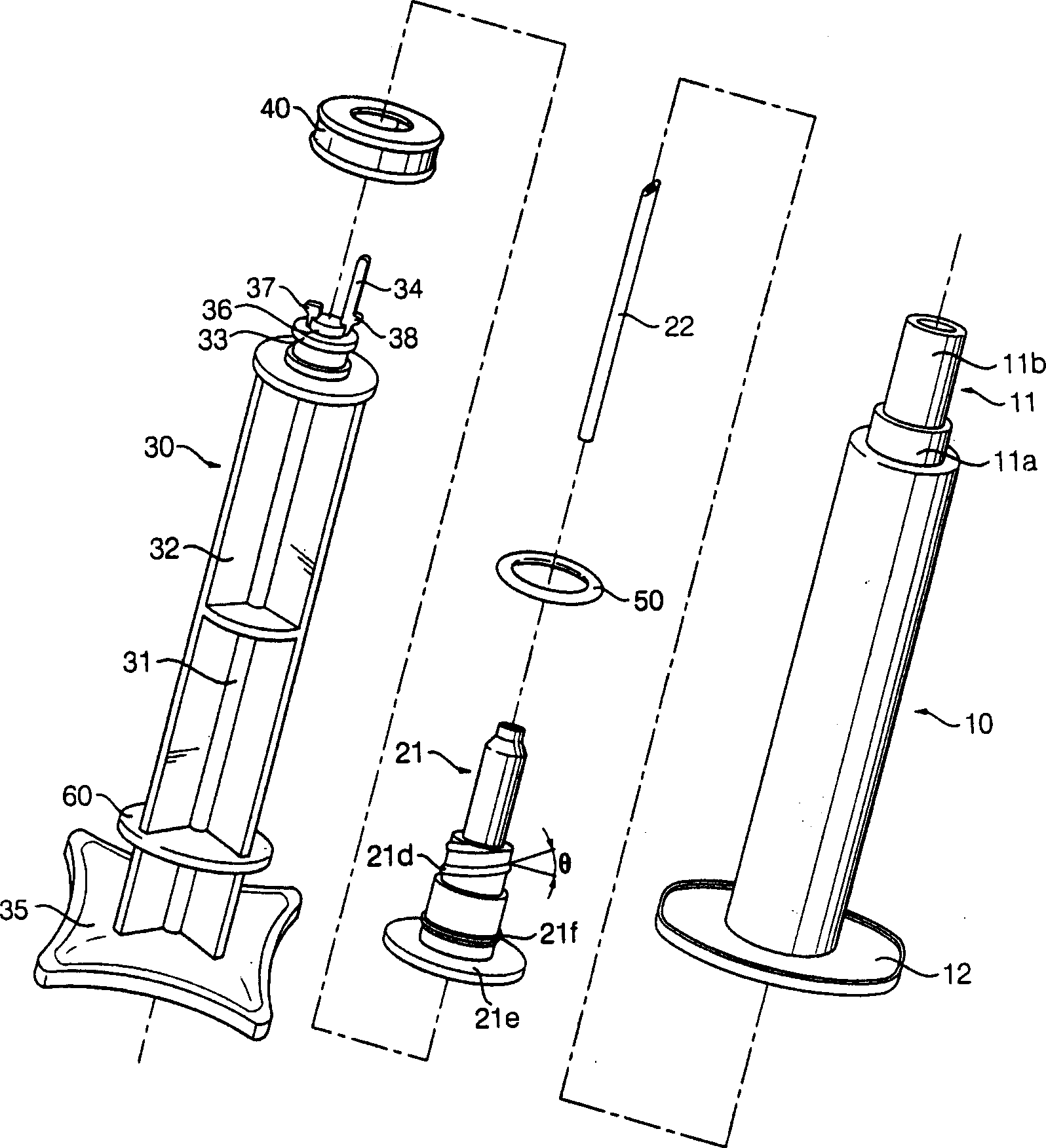

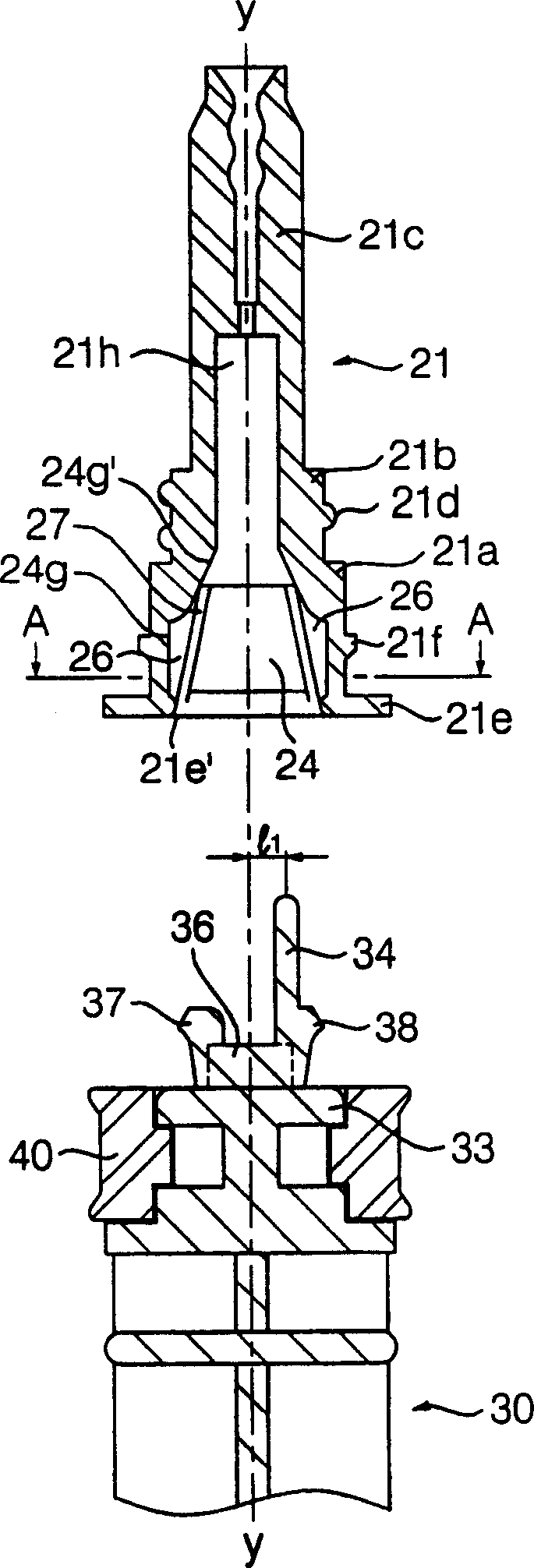

Safety syringe

InactiveCN1512899ASolve mobile instabilityReliable returnAmpoule syringesPharmaceutical containersO-ringEngineering

Disclosed herein is a safety syringe. According to the safety syringe of the present invention, an adapter connected to an injection needle is threadedly coupled with the neck of a cylinder while interposing an O-ring therebetween. Thus, the movement of the injection needle is effectively prevented while in use, and thus the injection needle can be pricked accurately at a desired position of the patient's body. Since the adapter is formed with grooves, whereas a plunger is formed with two protrusions positioned diametrically opposite to each other so as to be inserted into the grooves, the adapter is rotated and then moved downwardly in accordance with the successive rotation and downward movements of the plunger after the adapter is released from the neck of the cylinder. The plunger is formed at its upper surface with a vertical rod extending upwardly from an eccentric position, whereas the adapter is defined with a conical cavity. The upper end of the rod is inserted into the cavity while being bent inwardly. When the injection needle is withdrawn into the cylinder, the injection needle is firmly tilted in a lateral direction due to the strong restoring force of the rod so that it can be collapsed simply against the inner surface of the cylinder. In addition, a circular plate is formed at a certain lower position of the plunger. The circular plate enables the user's fingers gripping the safety syringe not to come into contact with the plunger to be entered into the cylinder, thereby achieving the sanitary use of the safety syringe.

Owner:SEZ

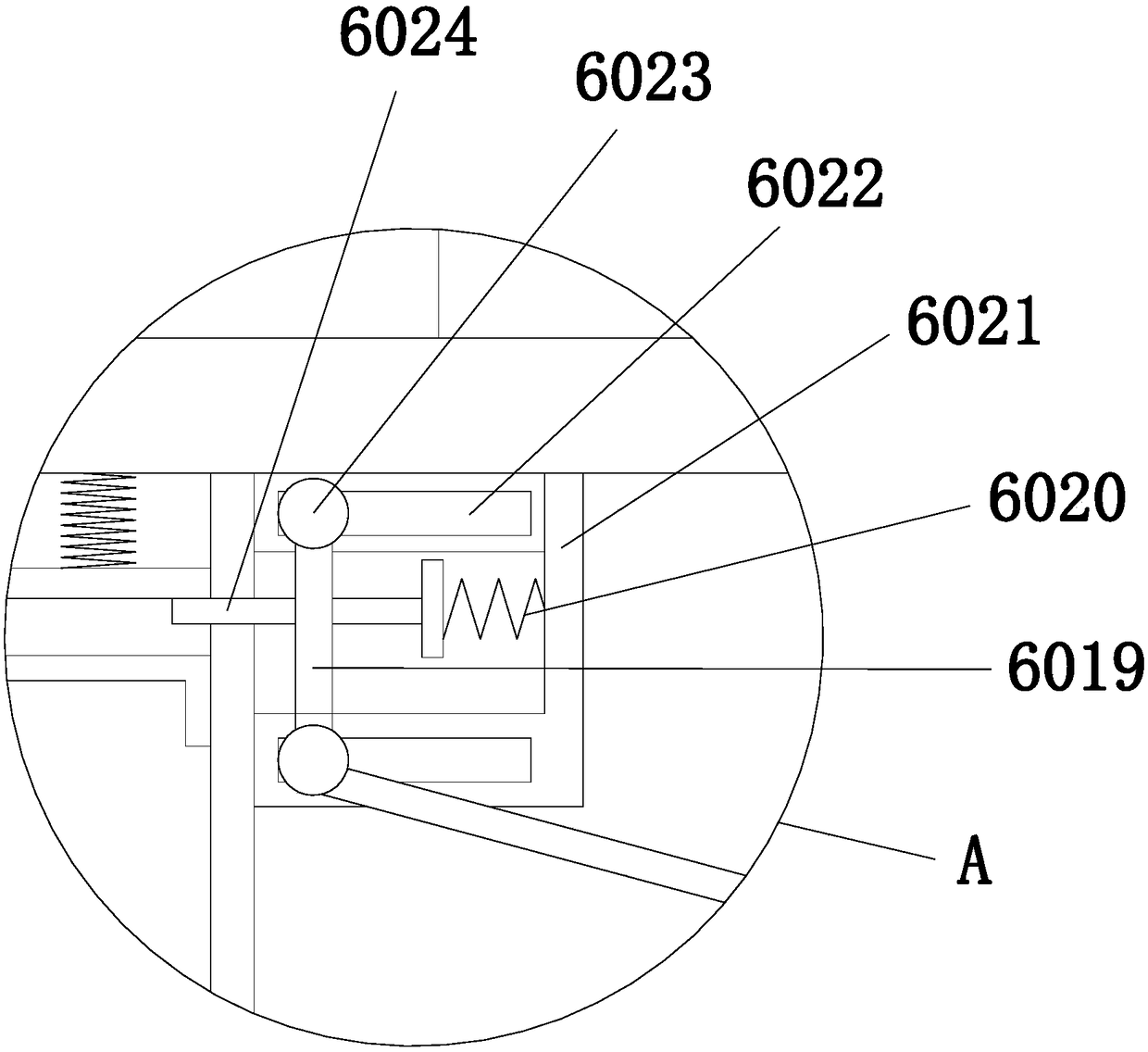

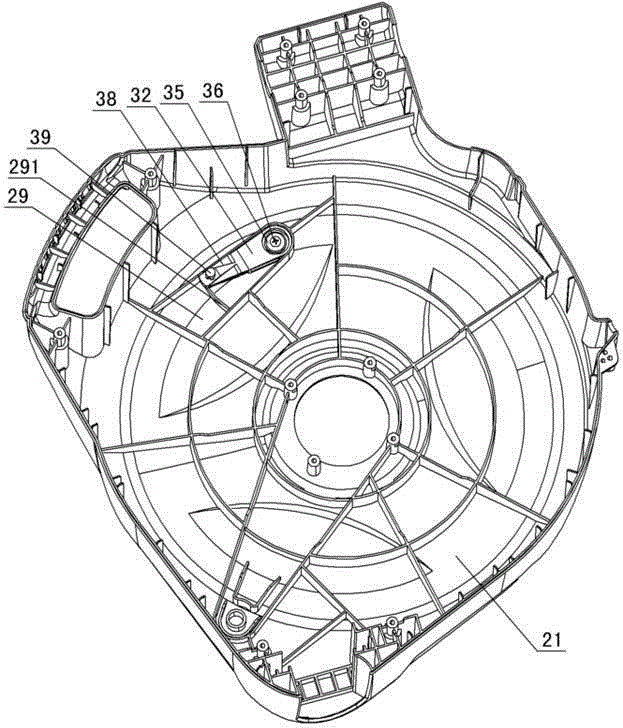

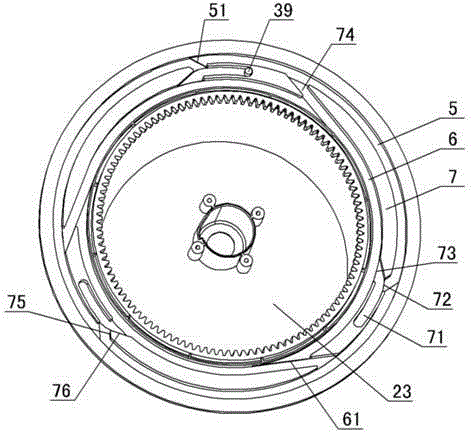

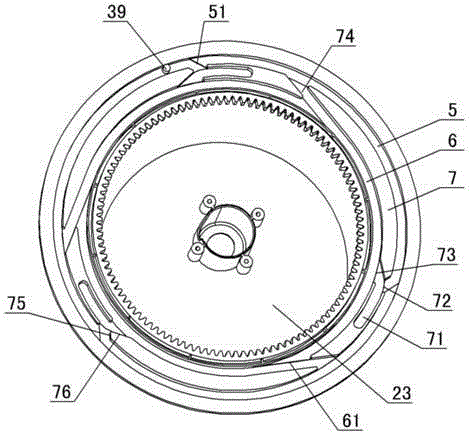

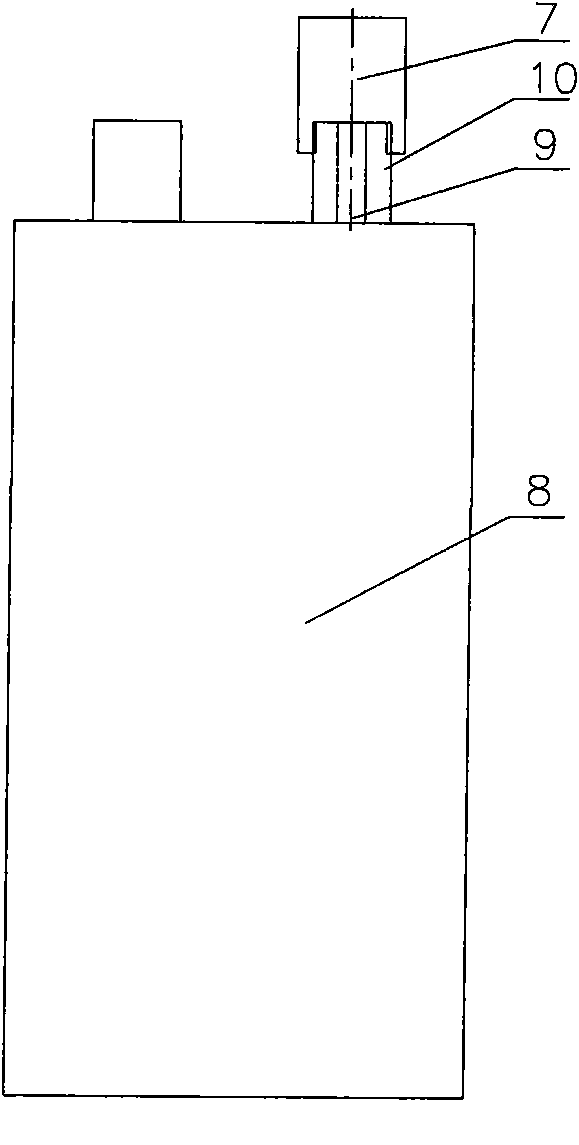

Labyrinth type self-locking device of winder

A labyrinth type self-locking device of a winder comprises a right cover and a right reel of the winder, and is characterized in that the inner side wall of the right cover is provided with a limit cavity and a fixing column, a screw hole is formed in the fixing column, a check clamp is arranged in the limit cavity and comprises a body, a round groove is formed in the body and provided with a penetrating hole, the body is arranged on the fixing column in a sleeving mode through the penetrating hole, a limit gasket is arranged in the round groove, a screw penetrates through the limit gasket to be in threaded fit with the screw hole of the fixing column, the other end of the body is provided with an elastic board and a pressing board, the pressing board is provided with a guide column, one side of the right reel is provided with a labyrinth type guide annular groove to be matched with the guide column, the labyrinth type guide annular groove comprises an outer annular groove, an inner annular groove and a middle check ring, the middle check ring is provided with a self-locking groove, a self-locking groove inlet, a self-locking groove outlet and an inner groove and outer groove switching channel, an inlet guide step is manufactured at the position, located on the self-locking groove inlet, of the outer annular groove, and a switching channel guide step is manufactured at the position, located the inner groove and outer groove switching channel, of the inner annular groove.

Owner:SEESA HLDG

Lithium ion storage battery formation method

InactiveCN102376983AImprove cycle lifePrevent overflowFinal product manufactureCell component detailsInternal pressureBattery charge

The invention relates to a lithium ion storage battery formation method, which comprises the following steps of: formation preparation: installing an air escape valve on a liquid injection hole-carrying terminal post of a battery, and connecting the battery to a formation device; parameter setting and formation starting: determining formation charge and discharge parameters according to parameters of lithium ion battery current, voltage and time, carrying out charge and discharge cycling for 3-5 times and stopping charging and discharging; unlatching or sealing a sealing plug and a valve body of an air escape valve according to internal pressure of the battery during the process of battery formation; formation accomplishment: stopping battery charge and discharge by the formation device and breaking a battery formation cable; placing the battery with the air escape valve in a drying compartment with humidity being less than 5%; dismantling the air escape valve, and sealing the liquid injection hole to complete formation. According to the formation method provided by the invention, the liquid injection hole of the battery is equipped with the air escape valve to release superfluous gas of the battery, prevent the electrolyte from overflowing and external water from introducing, enhance the generation of a compact SEI membrane during the formation process of the lithium ion storage battery and raise cycle life of the battery. The formation method is simple and has characteristics of high efficiency and low cost.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

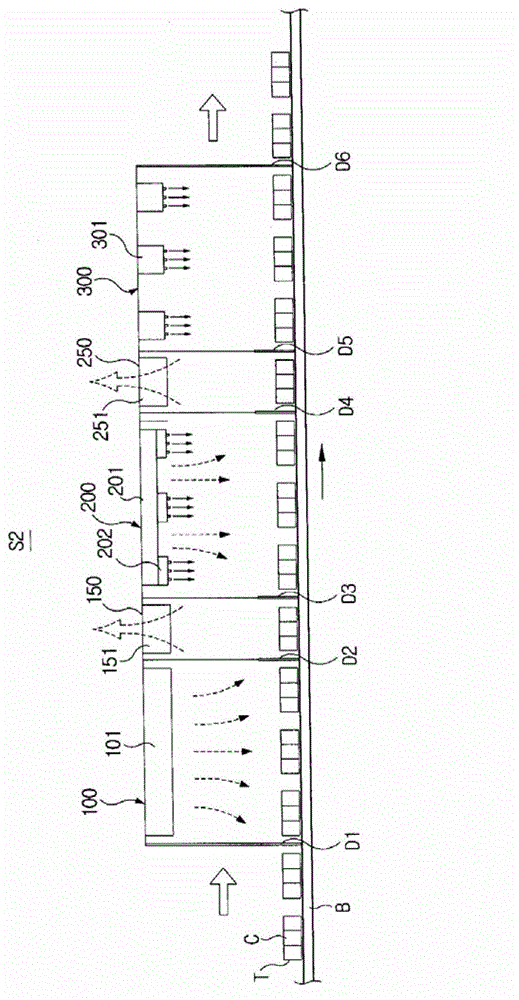

Apparatus and method for preparing instant cooked rice that is sterilized and completely cooked

InactiveCN103068286APrevent importAvoid contactFood preservationPackaging foodstuffsNitrogenProcess engineering

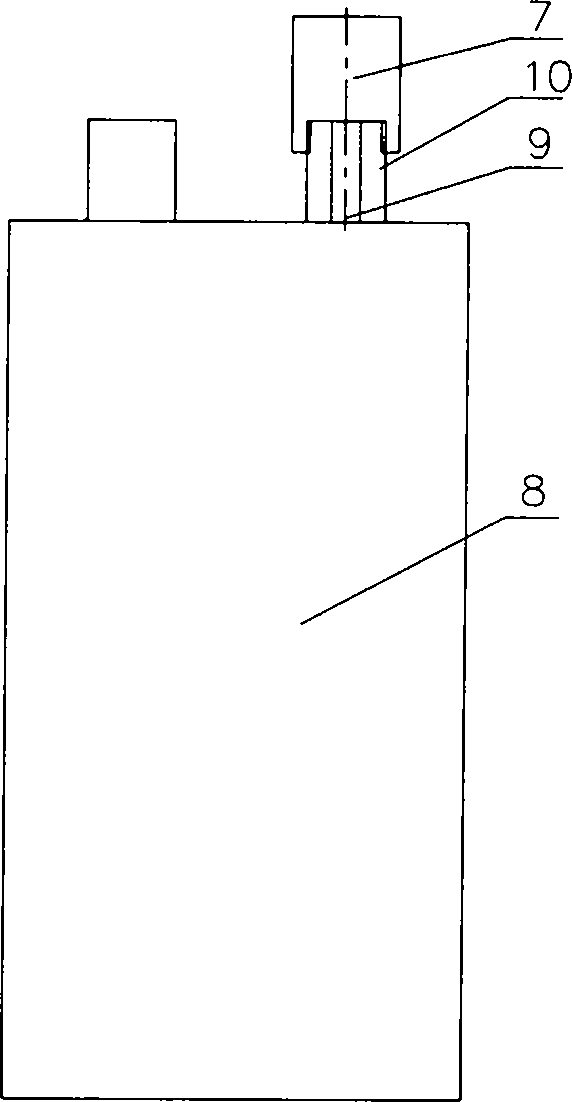

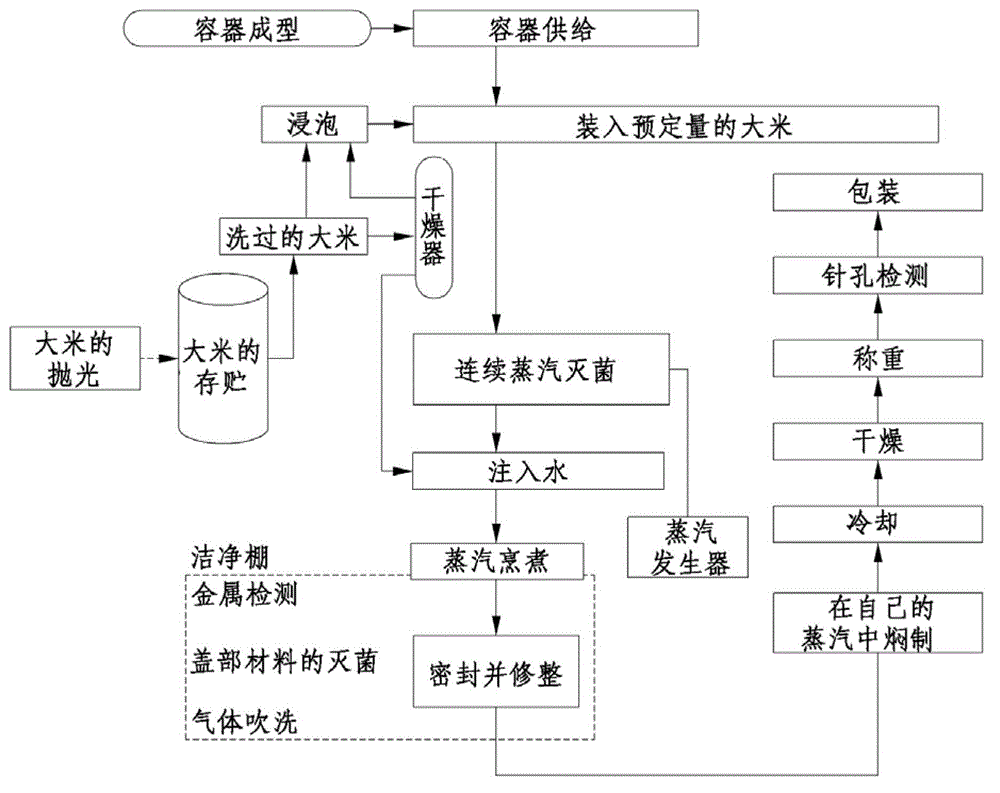

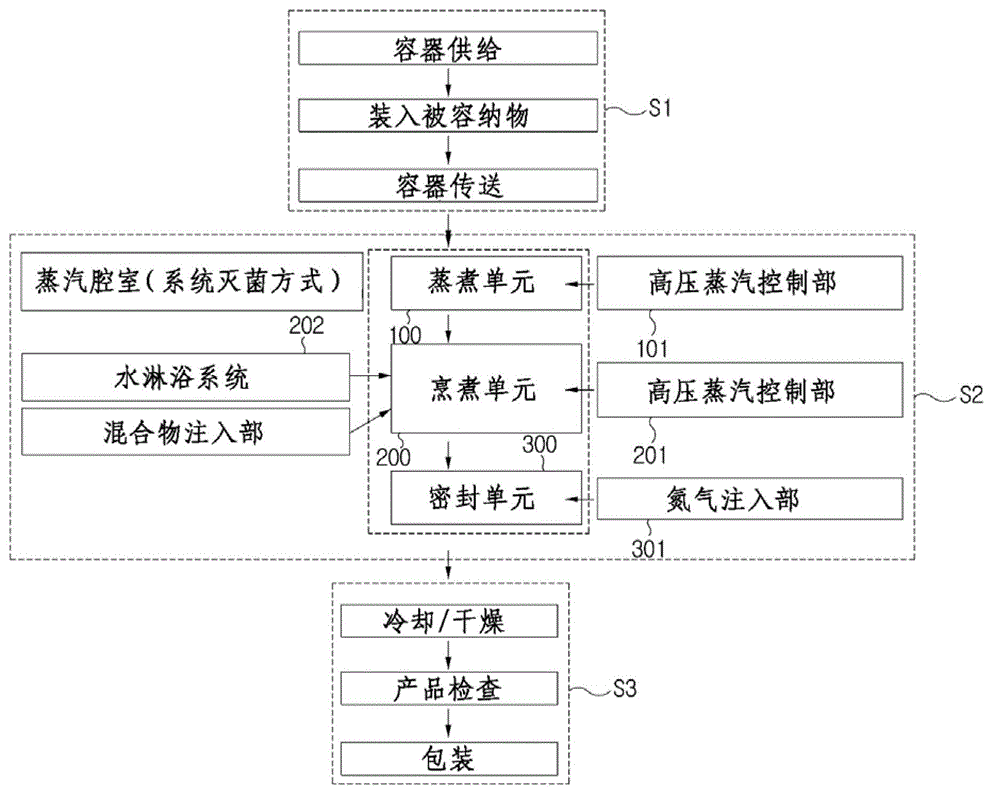

The present invention relates to an apparatus for preparing instant cooked rice, in which a steaming module, a cooking module, and a sealing module are integrated into a single chamber to which high-temperature, high-pressure steam is supplied. The steaming module performs a steaming process in which high-temperature, high-pressure steam fills the steam module to sterilize and primarily cook the contents in an open container arranged in an upper portion of the steaming module. The cooking module performs a cooking process in which high-temperature, high-pressure steam fills the cooking module to further sterilize the contents in the open container and supply moisture to the contents and completely cook the contents.,The sealing module performs a sealing process in which clean nitrogen gases are supplied to the completely cooked contents, and the top of the open container is sealed with a lid film. According to the present invention, as each process is adjusted to be performed at different temperatures and at different pressures, users may instantly eat the completely cooked combination of a variety of additives such as grains containing rice and nuts and the flour of grains and nuts without any additional heating process.

Owner:廉光锡

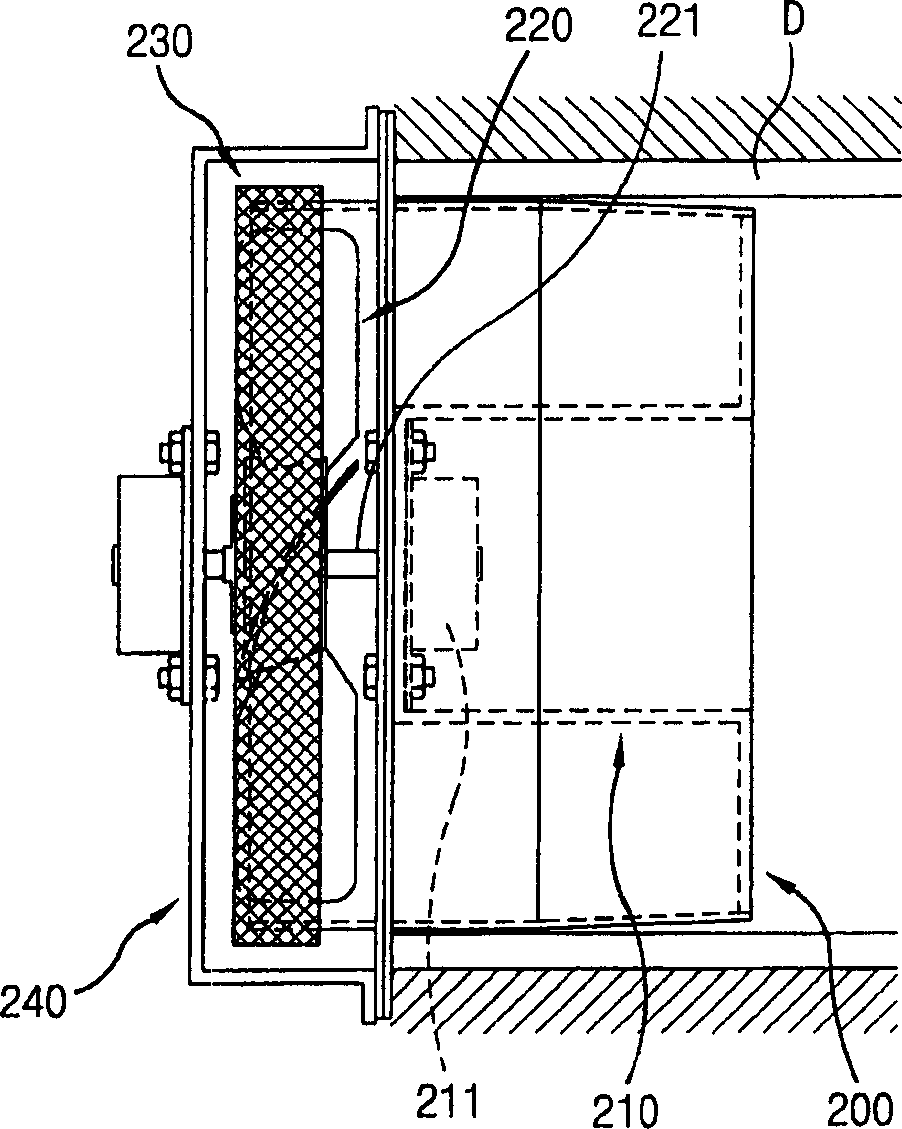

Smart home indoor noise reduction device

InactiveCN107507608ALower the decibelPrevent importSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringNoise reduction

The invention relates to the technical field of noise reduction equipment, and specifically relates to a smart home indoor noise reduction device. The smart home indoor noise reduction device comprises a wall, a window, fixed plates, a noise reduction device, a fan, a first ventilation pipe, first air inlet holes, a first sound absorbing chamber, a second sound absorbing chamber, a third sound absorbing chamber, a fourth sound absorbing chamber, a humidity sensor, a controller, a humidifier, dehumidifier, a second ventilation pipe, first air outlet holes, a sound insulation plate, an air purifier, a sealing rubber pad, a third ventilation pipe, second air inlet holes, an electromagnetic valve, a fourth ventilation pipe and second air outlet holes, and is characterized in that the wall is provided with the window, the fixed plates are arranged on the indoor wall, the two fixed plates are respectively arranged above and below the window, and each fixed plate is provided with a sliding slot. The smart home indoor noise reduction device is easy to install and remove, and has excellent noise reduction processing for the outdoor noise. Meanwhile, the smart home indoor noise reduction device has the functions of air purification, humidification and dehumidification, is diversified in function, greatly meets requirements of people for the functions of the device and has very high practicability.

Owner:肇庆高新区恒泰信息服务有限公司

Fuel battery vehicle anode hydrogen/oxygen interface formation suppressing structure

The present invention relates to an anode side hydrogen / oxygen interface formation inhibition structure of a fuel cell vehicle which prevents a high voltage field due to hydrogen / oxygen interface formation from being formed so that a stable stack driving may be realized when the fuel cell vehicle starts up or shuts down.

Owner:HYUNDAI MOTOR CO LTD

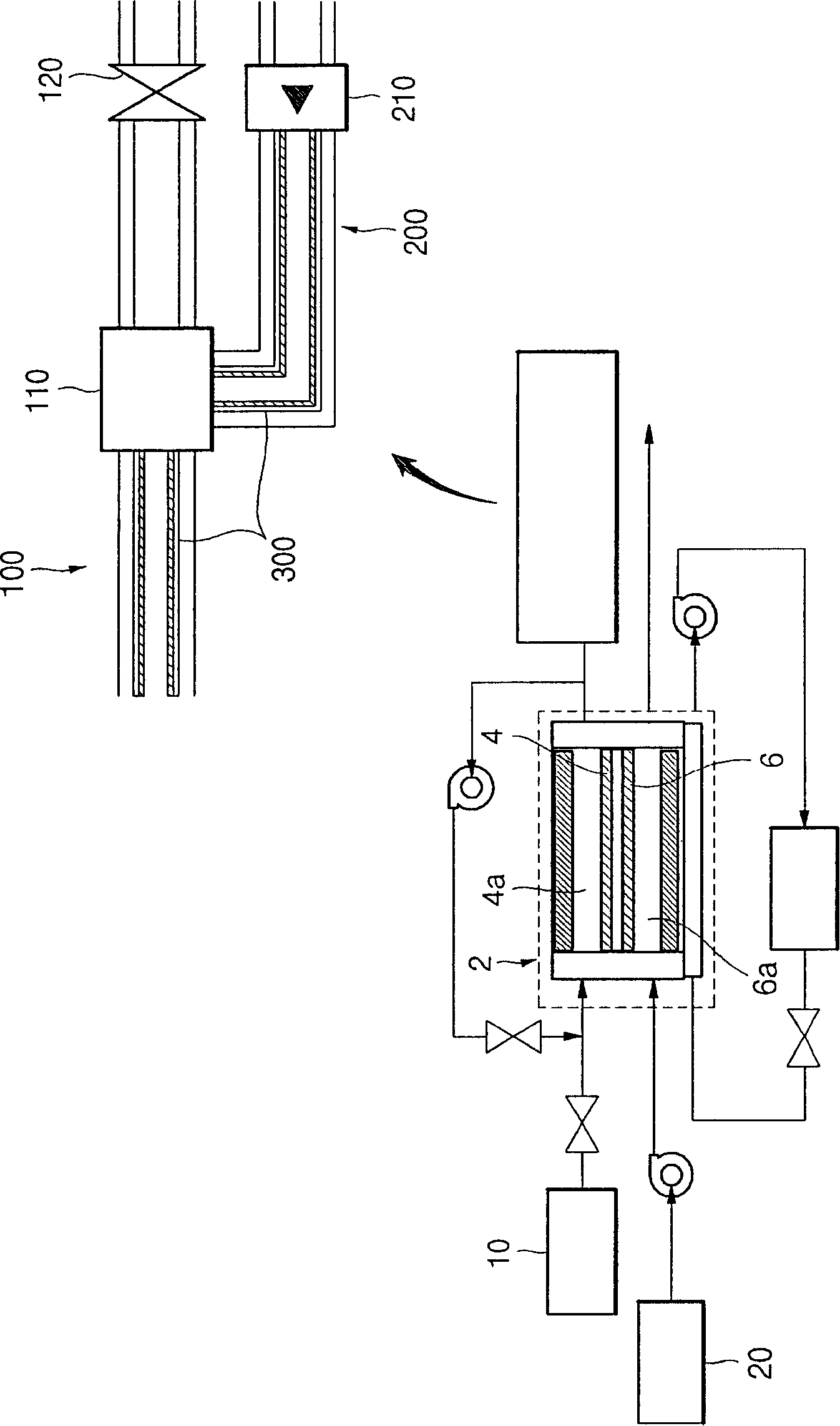

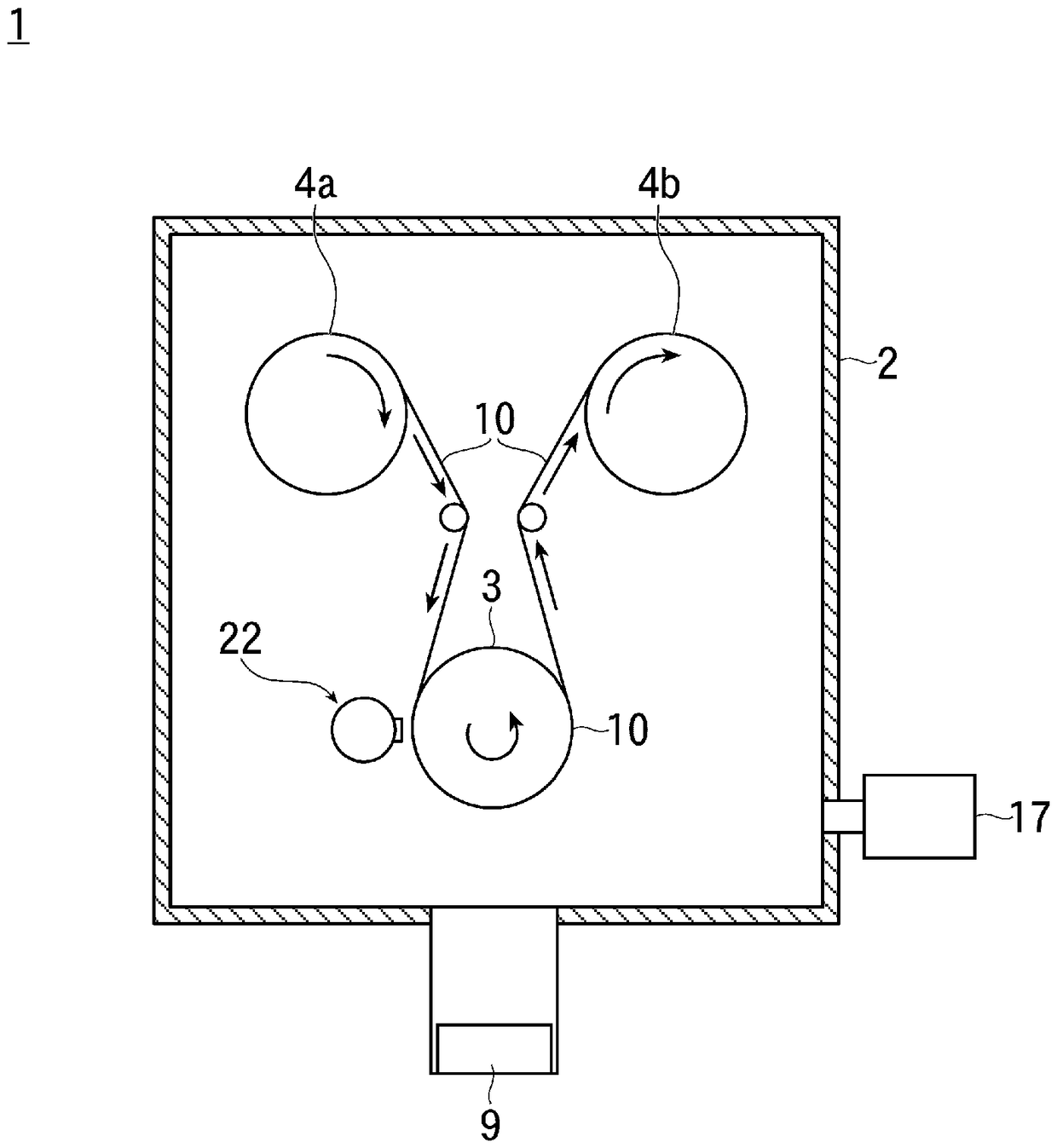

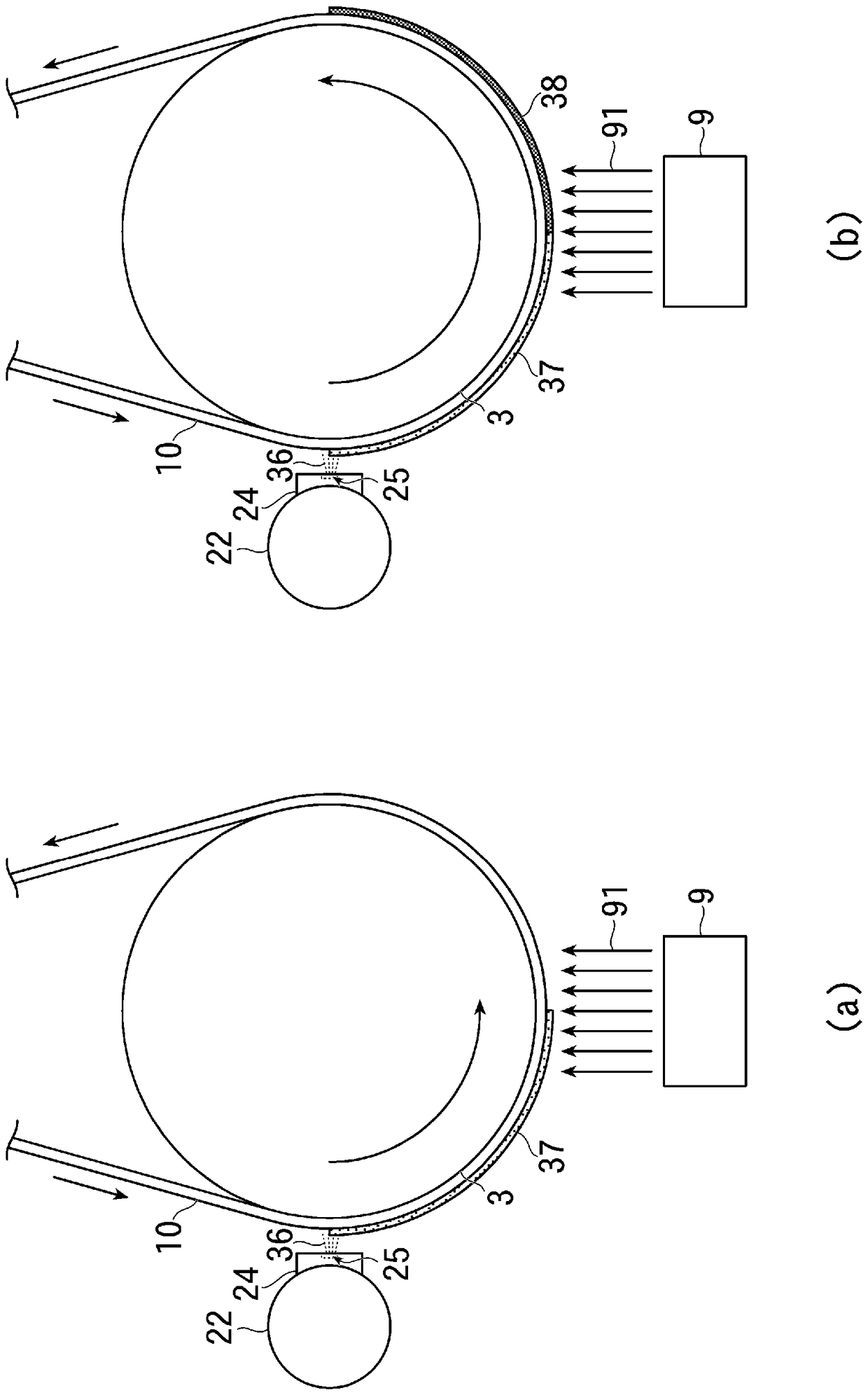

Vapor discharge apparatus and film formation method

ActiveCN108291292AGuaranteed steam volumeFilm formation rate is stableVacuum evaporation coatingSputtering coatingVaporizationOrganic compound

The purpose of the present invention is to provide a technique such that when forming an organic compound film on a substrate film in vacuum, vapor of an organic compound monomer can be generated at aconstant rate, thereby stabilizing the film formation rate. This vapor discharge apparatus discharges vapor of an organic compound monomer in vacuum and comprises: a vaporization unit 21 for vaporizing a liquid organic compound monomer; and a vapor discharge unit 22 that is in communication with the vaporization unit 21 and discharges the vapor of the organic compound monomer vaporized by the vaporization unit 21. The vaporization unit 21 is provided therein with a hollow vaporizer 40. The vaporizer 40 is configured such that a mist of the liquid organic compound monomer is introduced therein, the organic compound monomer mist 34 is heated and vaporized, and the organic compound monomer vapor is discharged to the vaporization unit 21.

Owner:ULVAC INC

Underwater high-pressure ultrasonic probe

InactiveCN104181236ANo changePrevent importMaterial analysis using sonic/ultrasonic/infrasonic wavesWorking environmentHigh pressure

The invention discloses an underwater high-pressure ultrasonic probe. The underwater high-pressure ultrasonic probe comprises a probe shell, wherein a probe wafer is arranged in the front part of the probe shell, a space between the rear part of the probe wafer and the probe shell is filled with a damping block, a pressure separation delay block is arranged on the front part of the probe wafer in an attaching manner, and the pressure separation delay block is a pressure-resisting part; the middle part of the pressure separation delay block is internally cut to form a sealing clamping shoulder, the pressure separation delay block is divided by the sealing clamping shoulder into a combination part which is close to the probe wafer and an extension part which is far away from the probe wafer, the front end of the probe shell pushes against the sealing clamping shoulder so as to enable the combination part to stretch into the probe shell, the combination part is matched with the probe shell in a sealing manner through a sealing part, and the extension part pushes the sealing clamping shoulder towards the end part of the probe shell through external water pressure, so that the self sealing of the sealing clamping shoulder and the probe shell can be realized. The underwater high-pressure ultrasonic probe has the advantages that the influence of high water pressure working environment can be effectively overcome, ultrasonic detection can be carried out under the high water pressure, the structure is reasonable, and the use is convenient.

Owner:NANTONG UNION DIGITAL TECH DEV +1

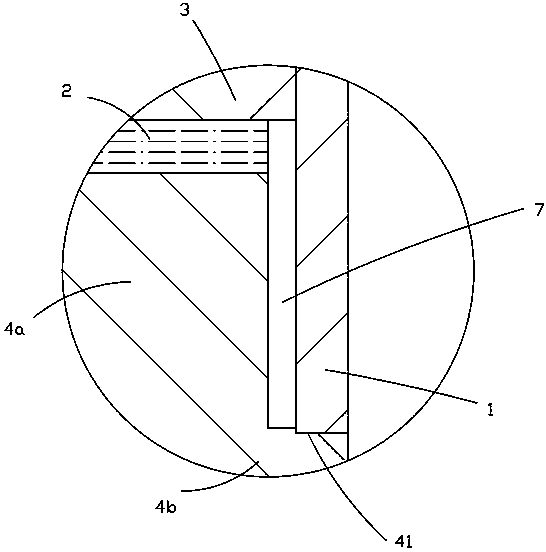

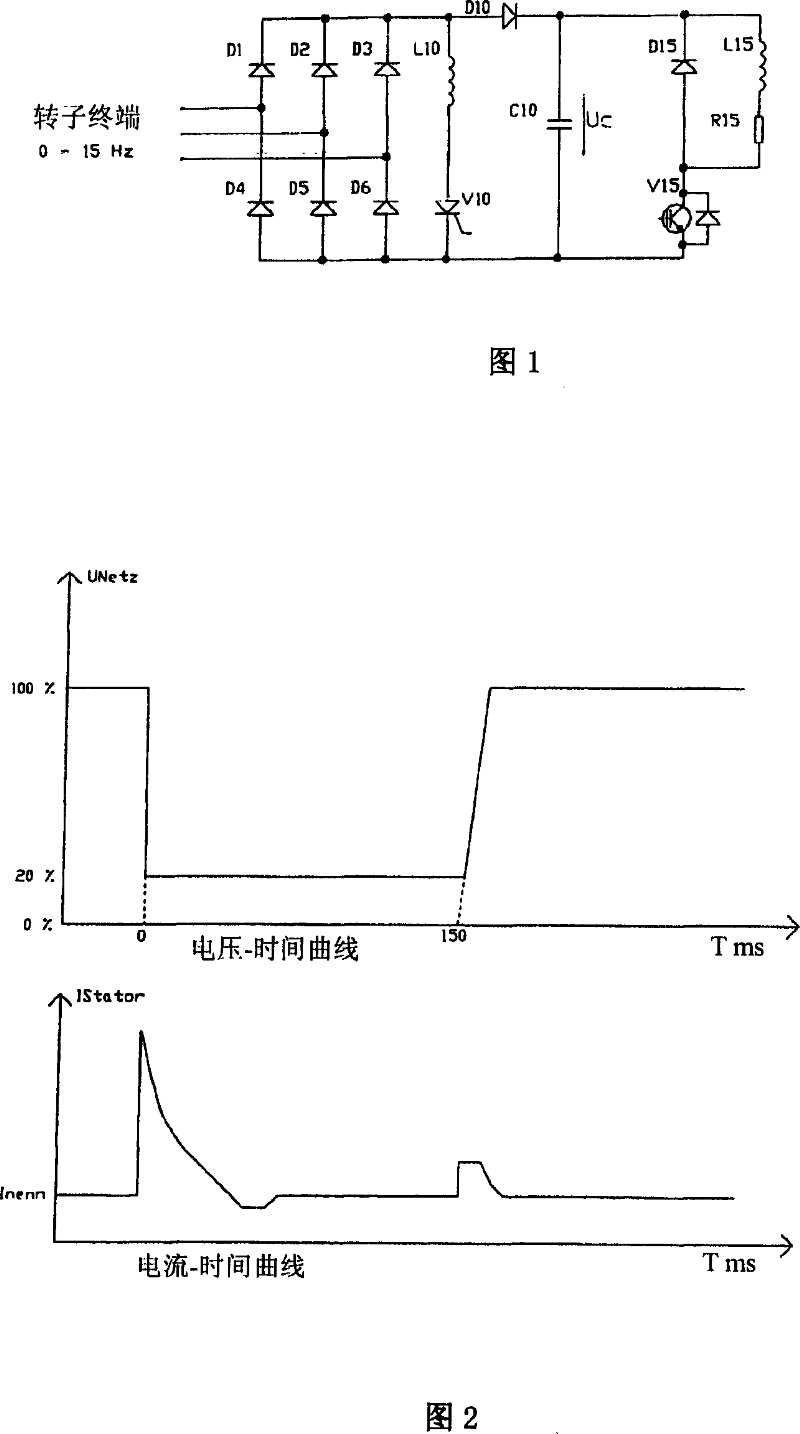

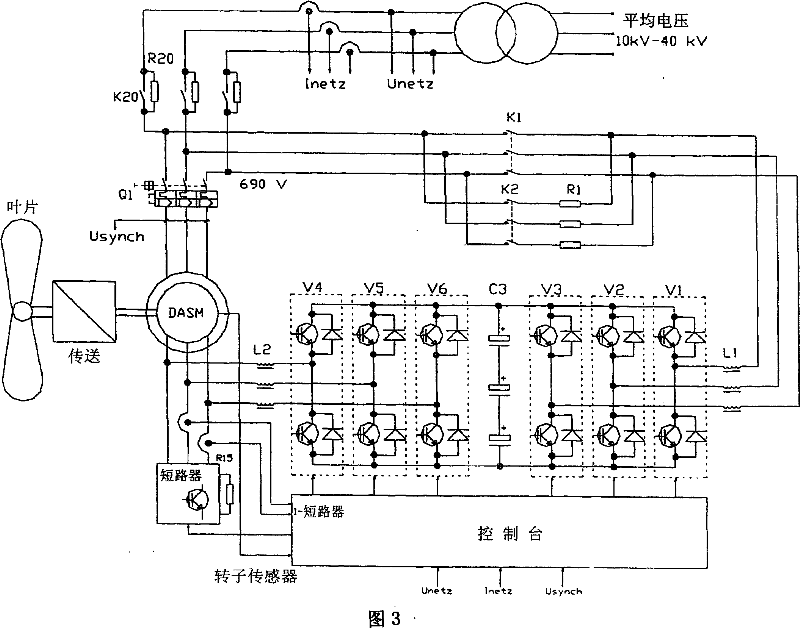

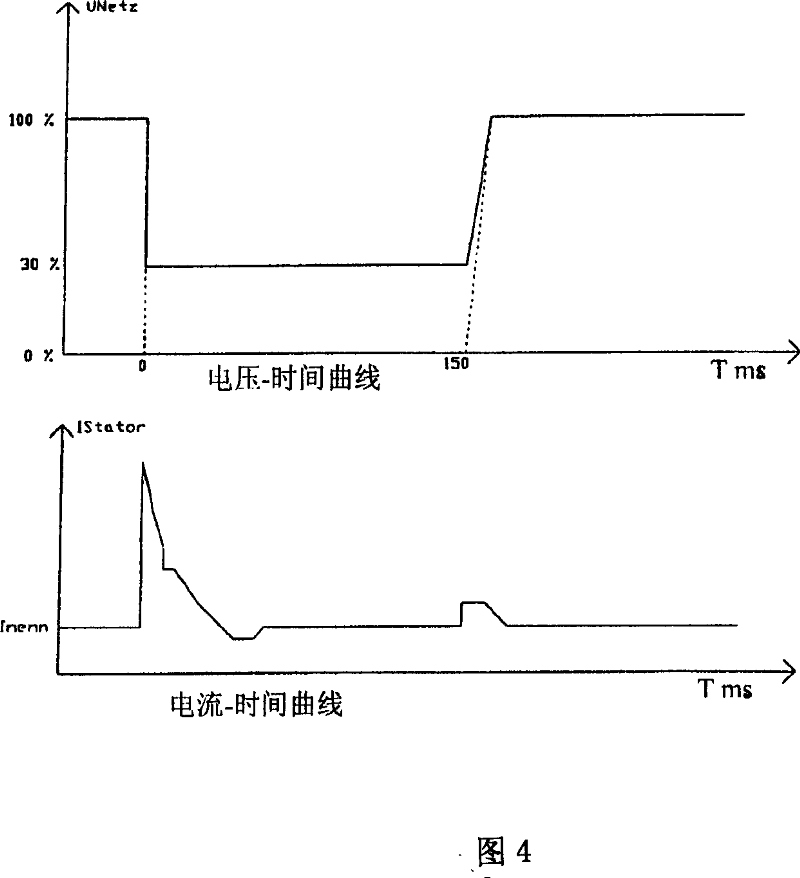

Circuit to be used in a wind power plant

InactiveCN100356683CEfficient modificationReliable controlGenerator control circuitsWind motor controlPeaking power plantPower station

The invention relates to a circuit with a variable rotational speed to be used particularly in a wind power plant, comprising a double fed asynchronous generator (DASM), a crow-bar, an additional resistor (R15) and a converter. In order to meet the requirements of the network provider, whereby a particularly permanent coupling to the network should be ensured so that the wind power plant can start up and stabilize the network during and after medium voltage short circuit in the network, the additional resistor can be regulated with the aid of a fast switch in such a way that the converter can be provisionally disconnected at least partly in case of a short circuit in the network. The rotor current is momentarily assumed by the additional resistor and disconnected after the rotor short circuit current dies out so that the converter can be subsequently connected once again and so that it can supply the desired active short circuit current to the network.

Owner:VESTAS WIND SYST AS

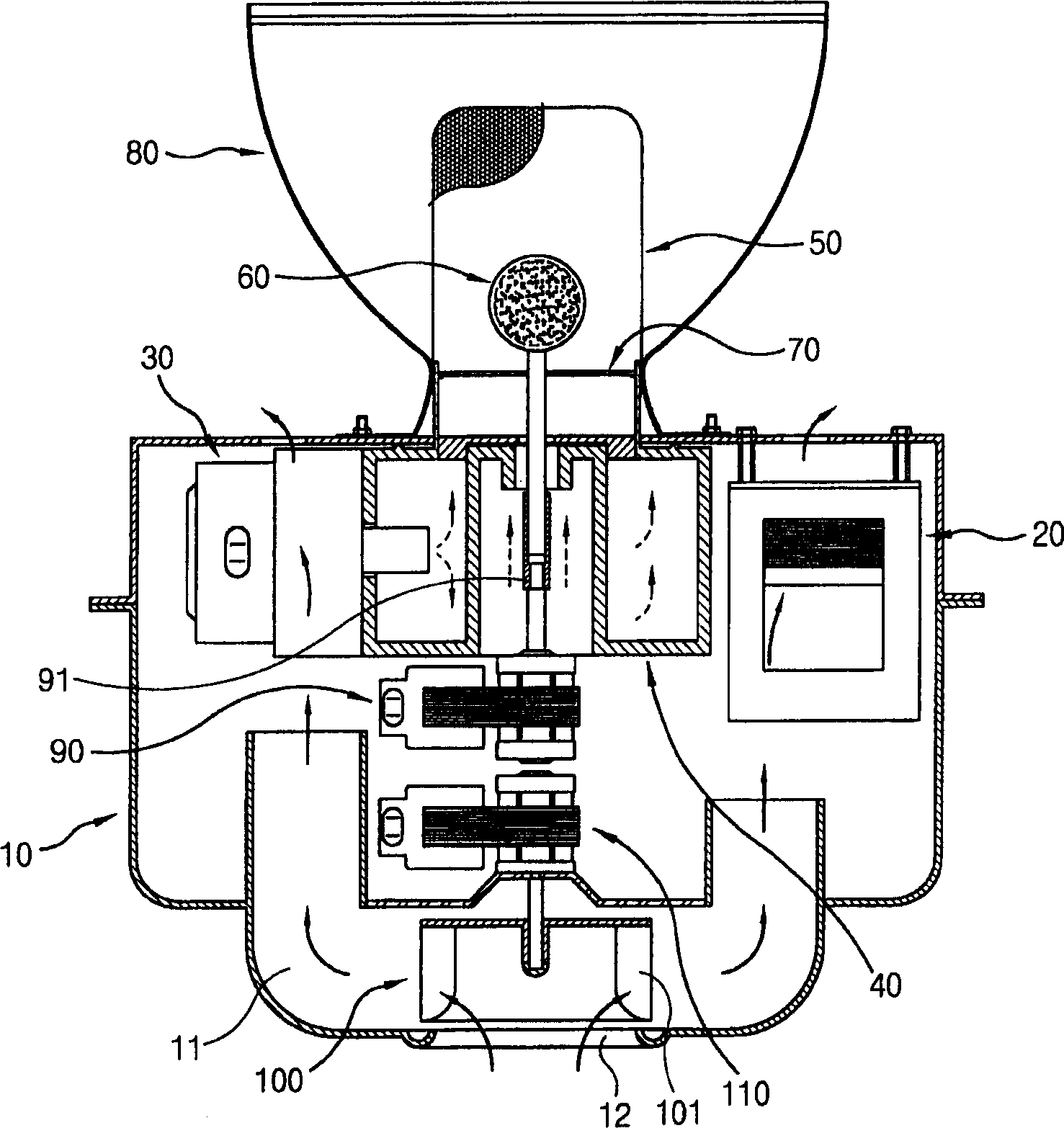

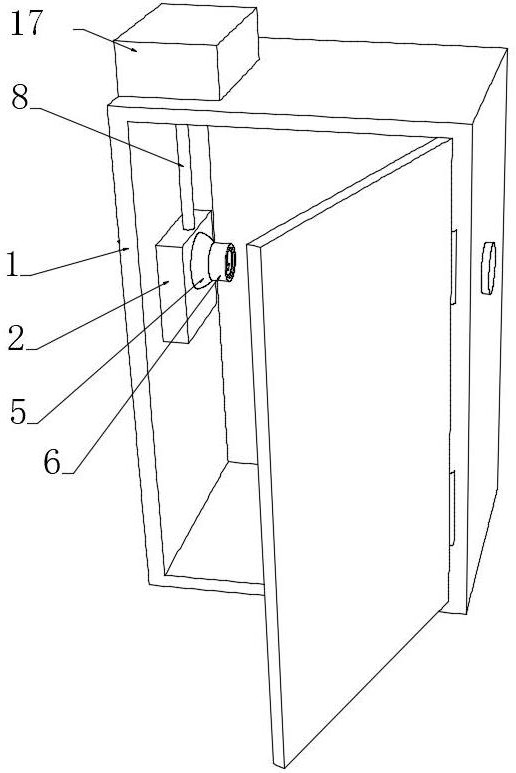

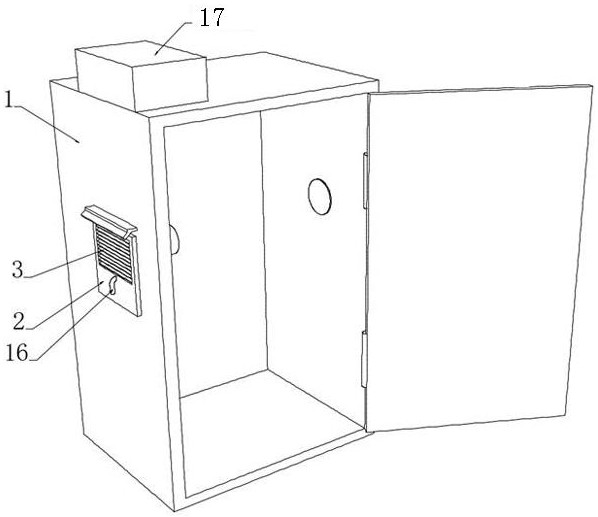

Anti-condensation equipment and electrical control cabinet thereof

InactiveCN113964684AImprove cooling effectPlay a dehumidifying roleSubstation/switching arrangement cooling/ventilationDispersed particle separationWater vaporElectrical control

The invention discloses anti-condensation equipment and an electrical control cabinet thereof, and belongs to the field of anti-condensation electrical control cabinets. The anti-condensation equipment is characterized in that a condensation box with a condensation assisting ball is additionally arranged at the wind inlet of a cabinet body, external air is guided into an air inducing condensation cavity formed by the condensation assisting ball and a flow guide cover, and due to the fact that the temperature difference exists between the condensation assisting ball and the air and between the flow guide cover and the air, water vapor in the air is attached to the end surfaces ofthe flow guide cover and the condensation assisting ball to be condensed and guided into a liquid storage box through the arc-shaped end surfaces of the flow guide cover and the condensation assisting ball, so that the water vapor is effectively removed, the dehumidification cotton layer at the inner end is matched to dehumidify the air, and the air is guided into the cabinet body after making contact with the low-temperature condensation assisting ball to be cooled so as to improve the cooling effect on the cabinet body; and the refrigeration balls filled with refrigerants are arranged on the inner sides of the condensation assisting balls, in the high-temperature environment, the heat drainage pieces deform to guide the cooling liquid in the condensation assisting balls into the refrigeration balls, and the refrigerants and the cooling liquid are fused to absorb heat and refrigerate, so that the refrigeration effect is improved, and the temperature difference is increased to facilitate pre-condensation.

Owner:JIANGSU HENGRONG IND CO LTD

Intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine

The invention discloses an intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine. The intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine comprises a first motor, a material containing tank, a heating cavity and a material storage cavity, wherein the first motor is fixedly installed at the bottom of the left side of the material containing tank, and a conveying auger shaft is rotatably installed in the material containing tank; and an output shaft of the first motor is fixedly connected with the end of the middle conveying auger shaft in the material containing tank, the heating cavity is connected to the bottom of the other side of the material containing tank through a communicating pipe in a penetrating manner, a reciprocating lead screw is fixedly connected to the portion, located at the end of the conveying auger shaft, of the communicating pipe, and a threaded hose is connected to the edge of the end of the inner hollow rod in a penetrating manner. According to the intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine, the injection molding frequency can be changed according to different specifications of injection molding parts, and meanwhile, the melting efficiency and stability of injection molding raw materials can be improved, subsequent injection molding machining is facilitated, the injection molding quality is improved, and molding deformation damage to the injection molding parts is effectively reduced.

Owner:赵秉辉

Test device for heat-resistant material performance test

ActiveCN109655484AImprove cooling effectFree from high temperature meltingMaterial heat developmentQuasi one dimensionalEngineering

The invention relates to a test device for a heat-resistant material performance test. The test device comprises an inner shell and an outer shell which are coaxially arranged, and a cooling water channel is formed between the outer shell and the inner shell; a connecting ring is arranged on the periphery of one end of the inner shell, the inner shell is connected with one end of the outer shell through a connecting ring, and a water inlet and a water outlet are formed in the connecting ring and communicated with the cooling water channel, so that the cooling water enters from the water inlet,flows through the cooling water channel and then flows out of water outlet; a first mounting cavity used for installing a to-be-tested mold and a second mounting cavity used for allowing a thermocouple device to penetrate through are formed in the end, away from the connecting ring, of the inner shell in sequence in the axial direction of the inner shell, the to-be-tested mold is prepared from aheat-resistant material, and the thermocouple device is used for detecting the temperature of the to-be-tested mold. According to the test device, longitudinal heat conduction of the heat-resistant material in the evaluation process can be effectively reduced, and it is ensured that the surface of the to-be-tested model is heated uniformly and heat conduction of the heat-resistant material is quasi one dimensional conduction.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

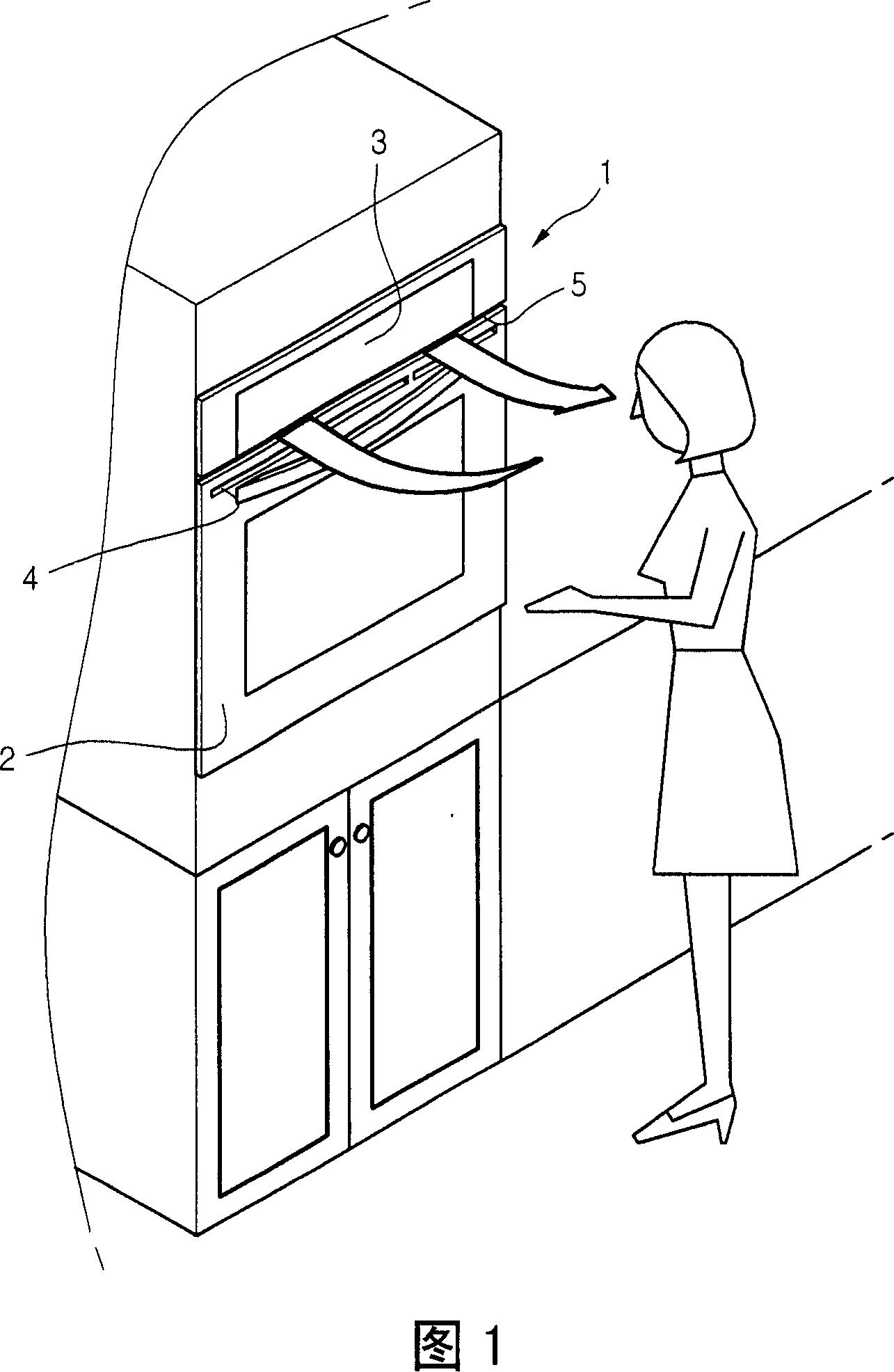

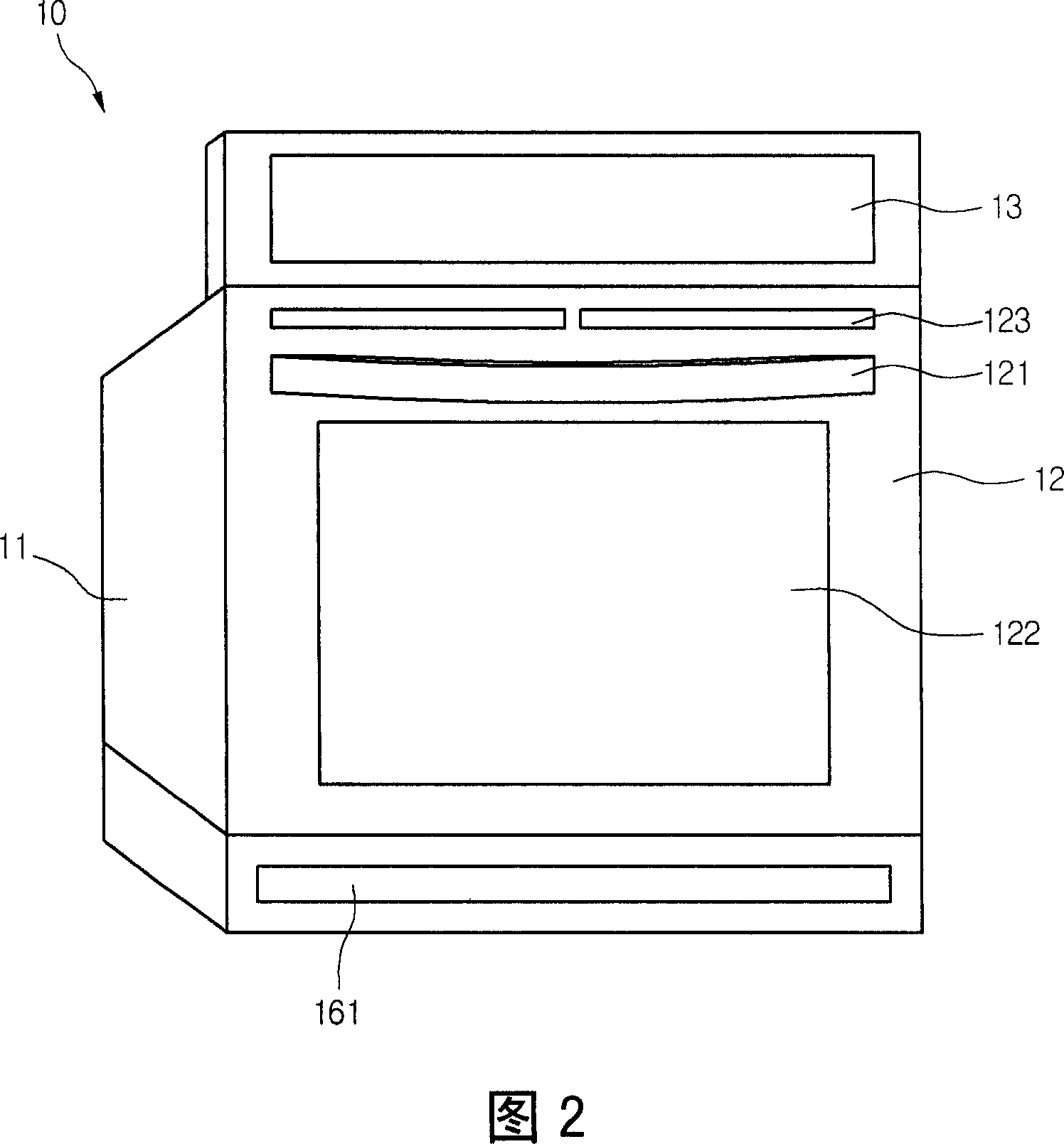

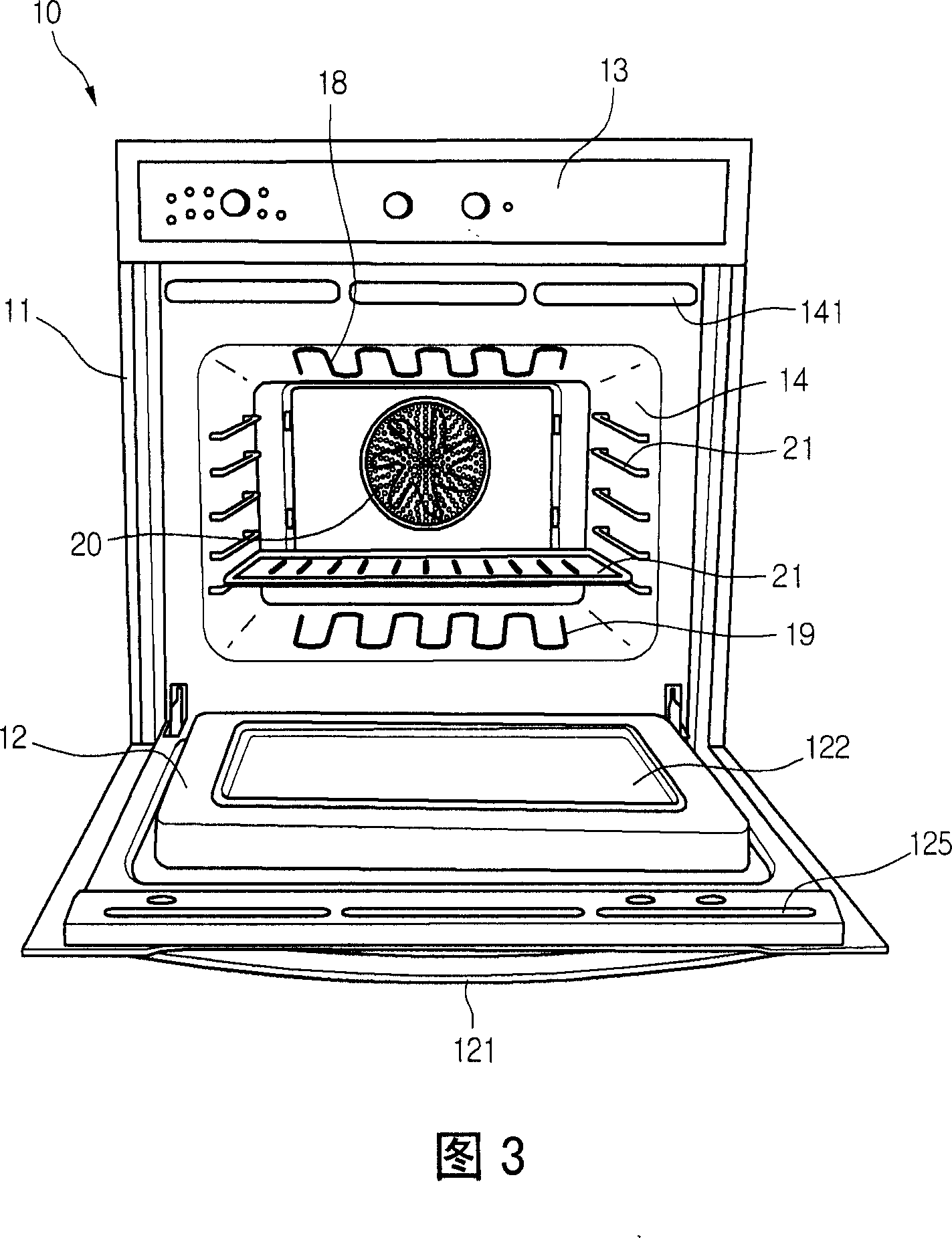

Electric oven

InactiveCN1979003AImprove securityImprove cooling efficiencyDomestic stoves or rangesDoors for stoves/rangesIndoor airAerospace engineering

An electric oven includes a cavity, a door rotatably installed at a front surface and including an air suction hole formed at one side of the outside thereof and an air discharge hole formed at one side of the inside thereof; and an air suction / discharge member mounted outside the cavity and allowing the indoor air to be sucked through the air suction hole and to be discharged to a lower side of the cavity.

Owner:LG ELECTRONICS INC

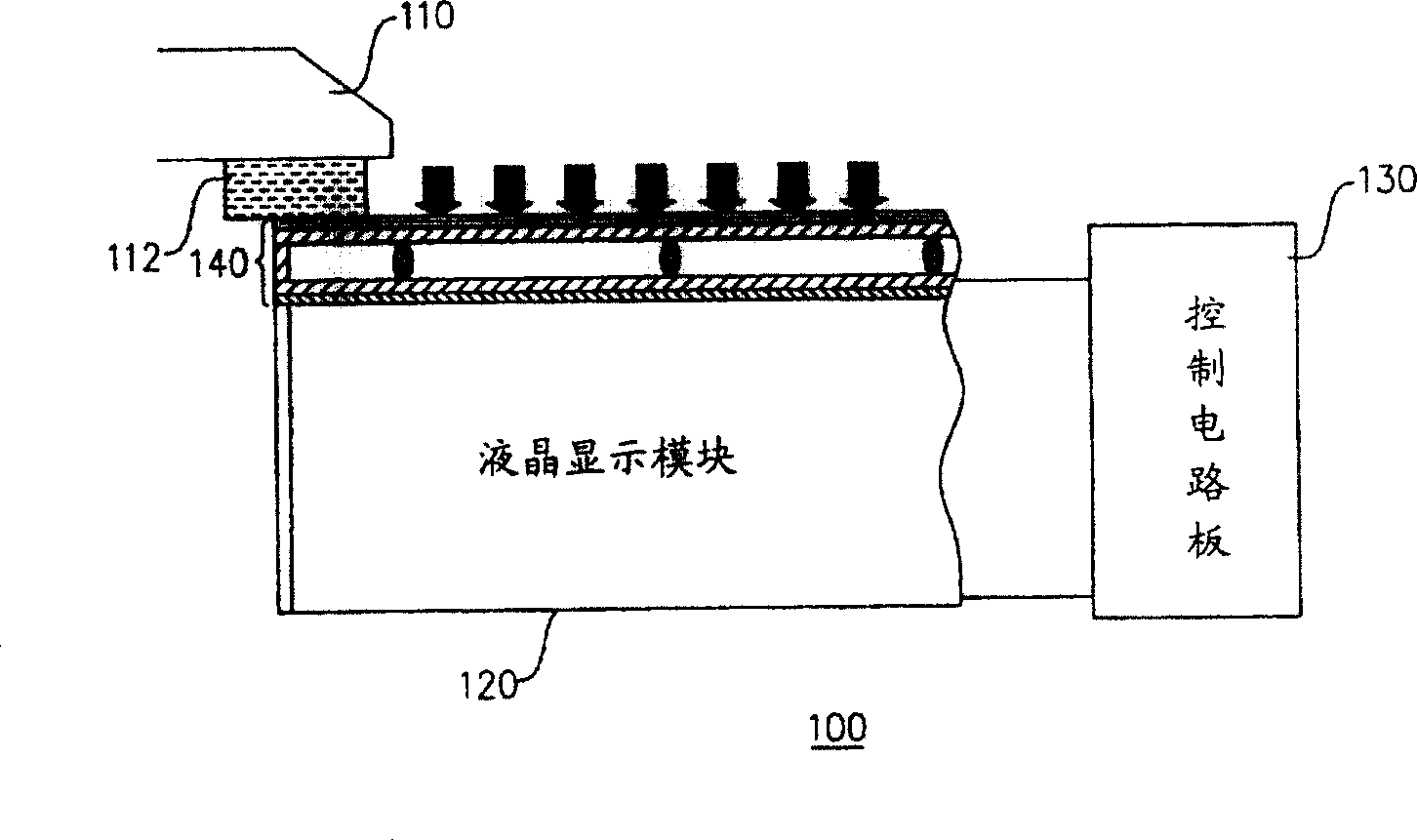

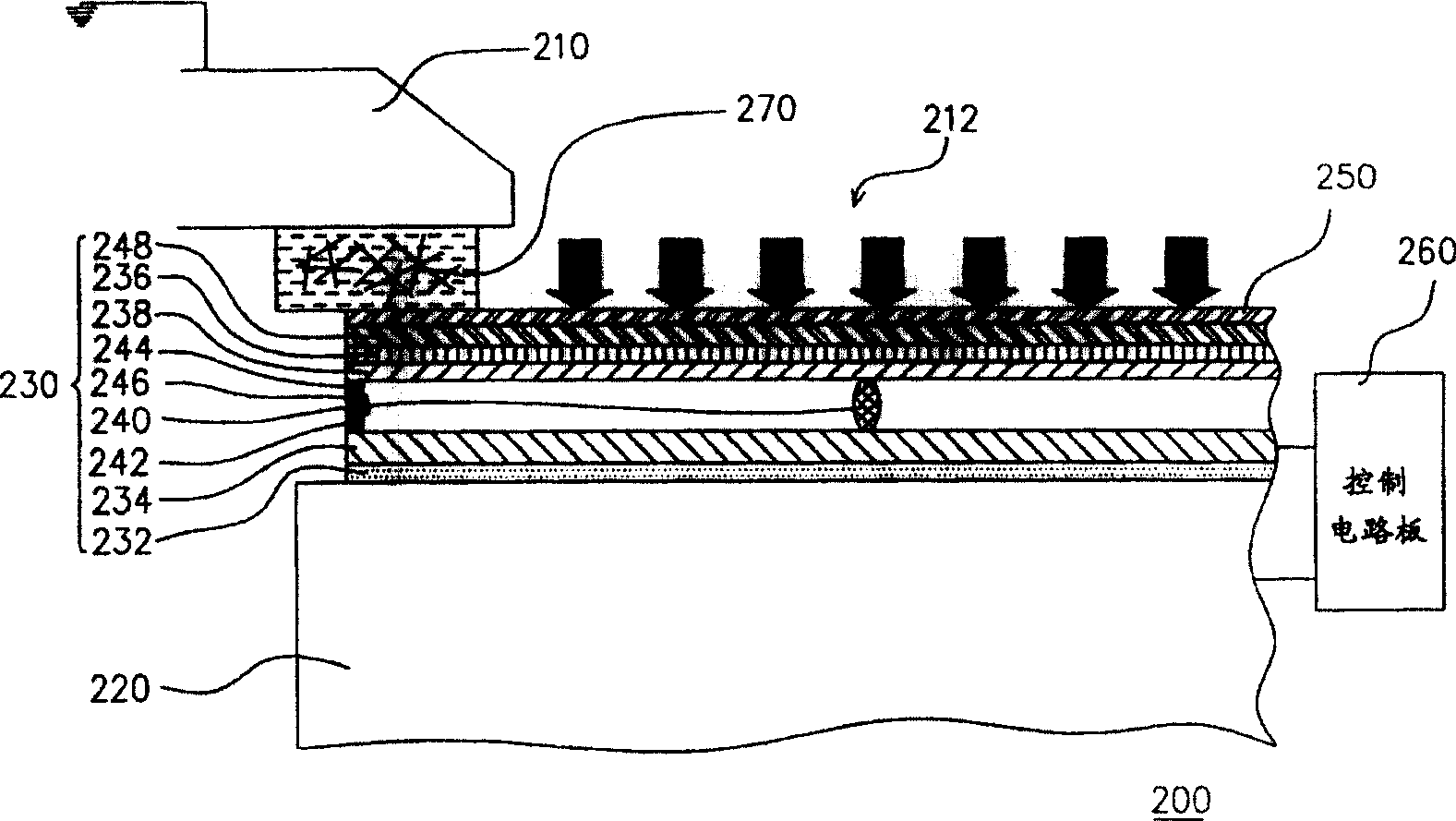

Contact-controlling LCD device

InactiveCN100507644CImprove conductivityEffective exportStatic indicating devicesNon-linear opticsElectricityLiquid-crystal display

A touch-type liquid crystal display device at least includes a shell, a liquid crystal display component, a touch panel, a transparent conductive layer, a control circuit board and a conductive buffer. There is a transparent conductive layer on the surface of the touch panel, and the conductive buffer is arranged between the shell and the transparent conductive layer. The conductive buffer can be electrically connected with the electrically grounded shell or the conductive component shell in the electrically grounded liquid crystal display assembly, to discharge static electricity. The touch liquid crystal display device can prevent static electricity from being introduced into the control circuit board through the touch panel, and can effectively export static electricity to protect the electronic components in the control circuit board.

Owner:TPO DISPLAY

High-efficiency spraying device for plastic dipping of gauze element and using method of high-efficiency spraying device

InactiveCN113385365AImprove processing qualitySolve the problem that the dipping and spraying effect is not idealLiquid surface applicatorsSpraying apparatusEngineeringFan blade

The invention relates to the technical field, in particular to a high-efficiency spraying device for plastic dipping of a gauze element. The high-efficiency spraying device comprises a plastic dipping pool, wherein a reversing roller A and a reversing roller B are sequentially and rotatably mounted at the symmetrical positions, close to two sides of an upper port of the plastic dipping pool, of the surface of the inner wall of the plastic dipping pool, and a driving assembly is arranged at the position, above the bottom of the plastic dipping pool, in the side wall of the plastic dipping pool; and fanning assemblies are symmetrically arranged between the side walls of the plastic dipping pool and located on the two sides of the driving assembly. According to the high-efficiency spraying device for plastic dipping of the gauze element and a using method of the high-efficiency spraying device, fixing ring sleeves are fixedly connected with fan blades, so that the fan blades synchronously rotate along with the fixing ring sleeves, in the rotating process of the fan blades, due to the fact that the surfaces of arc-shaped blades and the fan blades generate certain pressure on the air, the air, located below the gauze element, in the plastic dipping pool rolls, and plastic powder at the bottom of the plastic dipping pool can be driven to rise, so that the situation that because plastic powder falls on the bottom surface of the plastic dipping pool, plastic dipping spraying of the gauze element is not thorough is effectively prevented, and the plastic dipping spraying machining quality of the gauze element is improved to a certain degree.

Owner:LIXIN FUYA GAUZE CO LTD

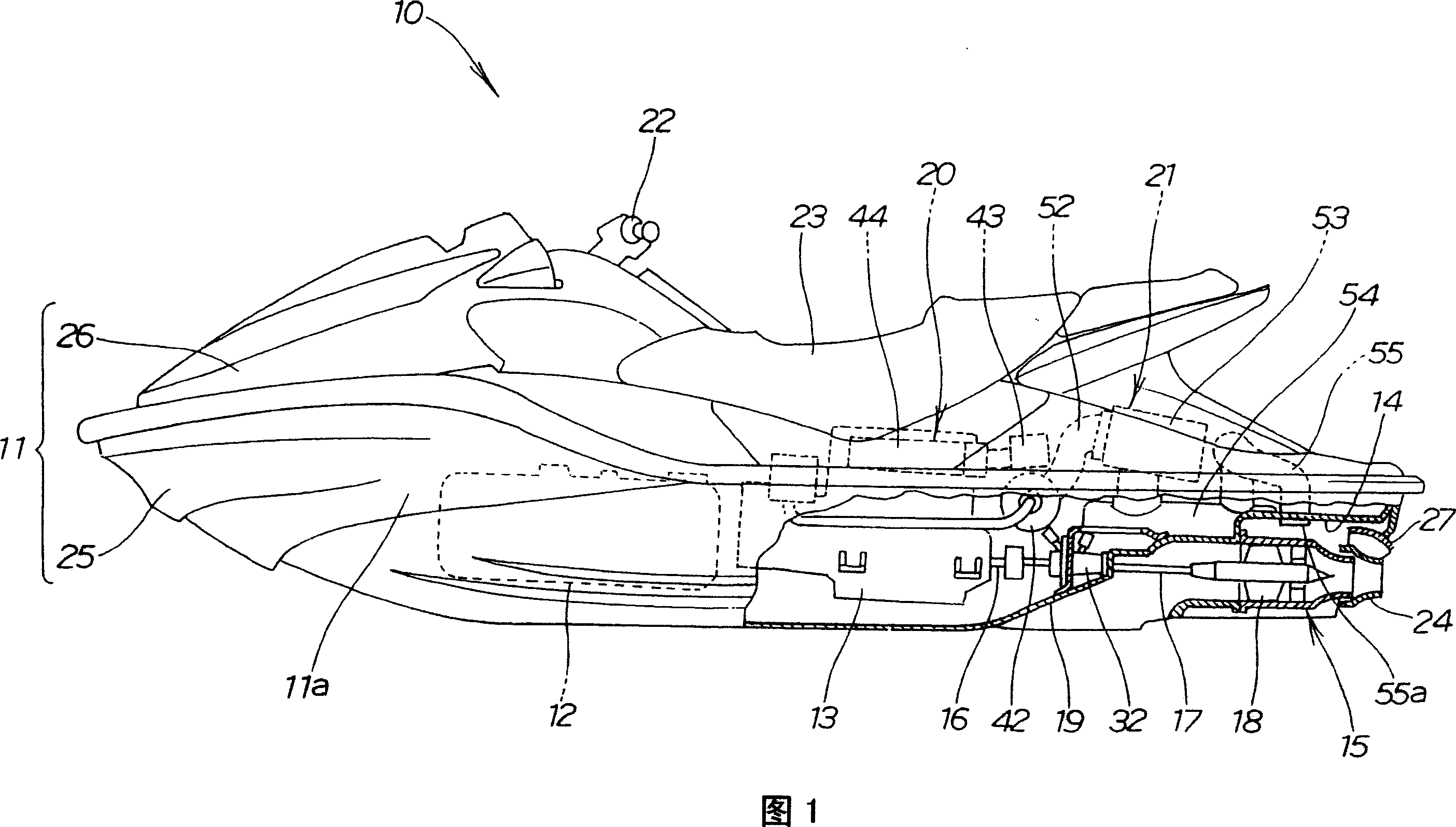

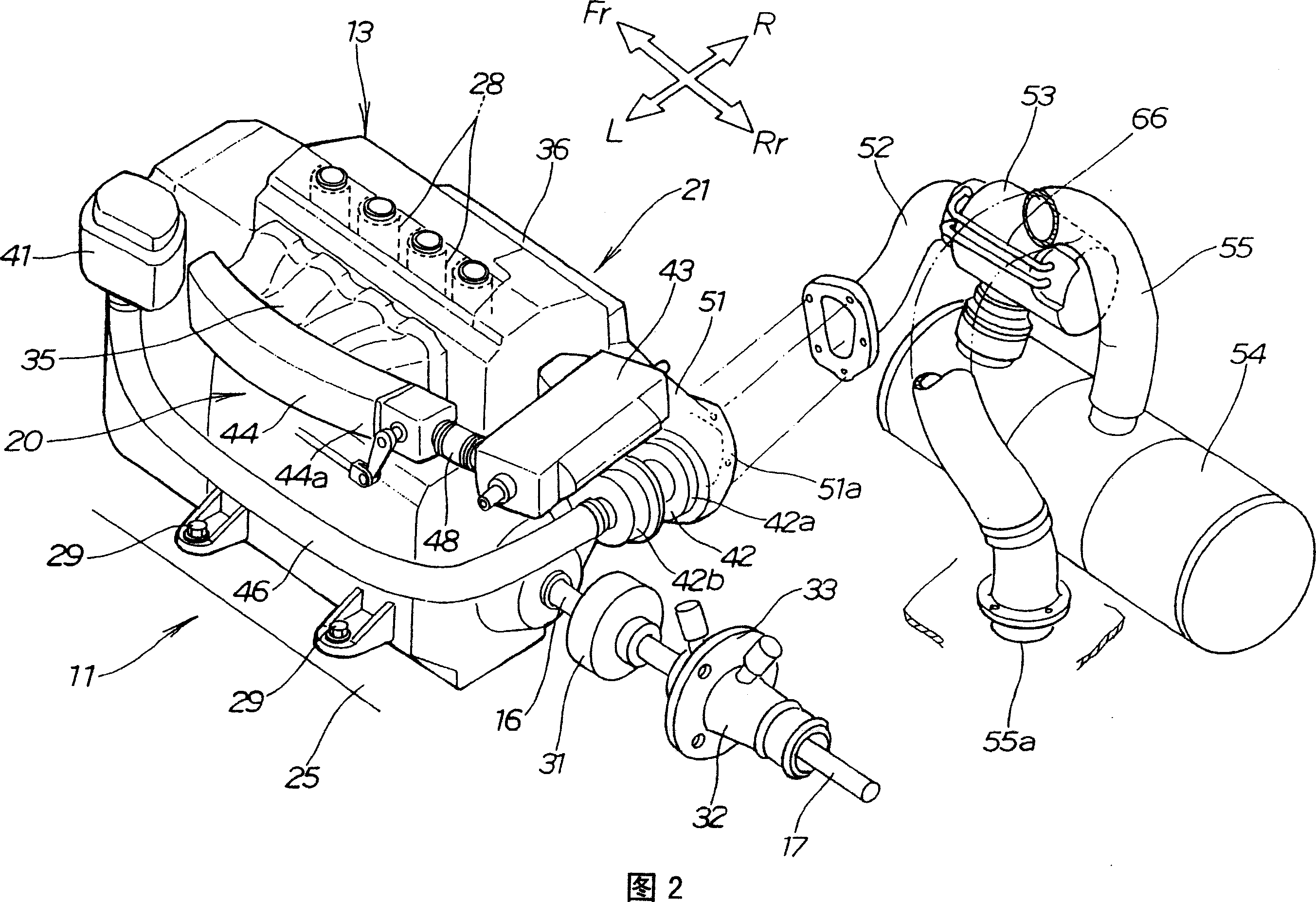

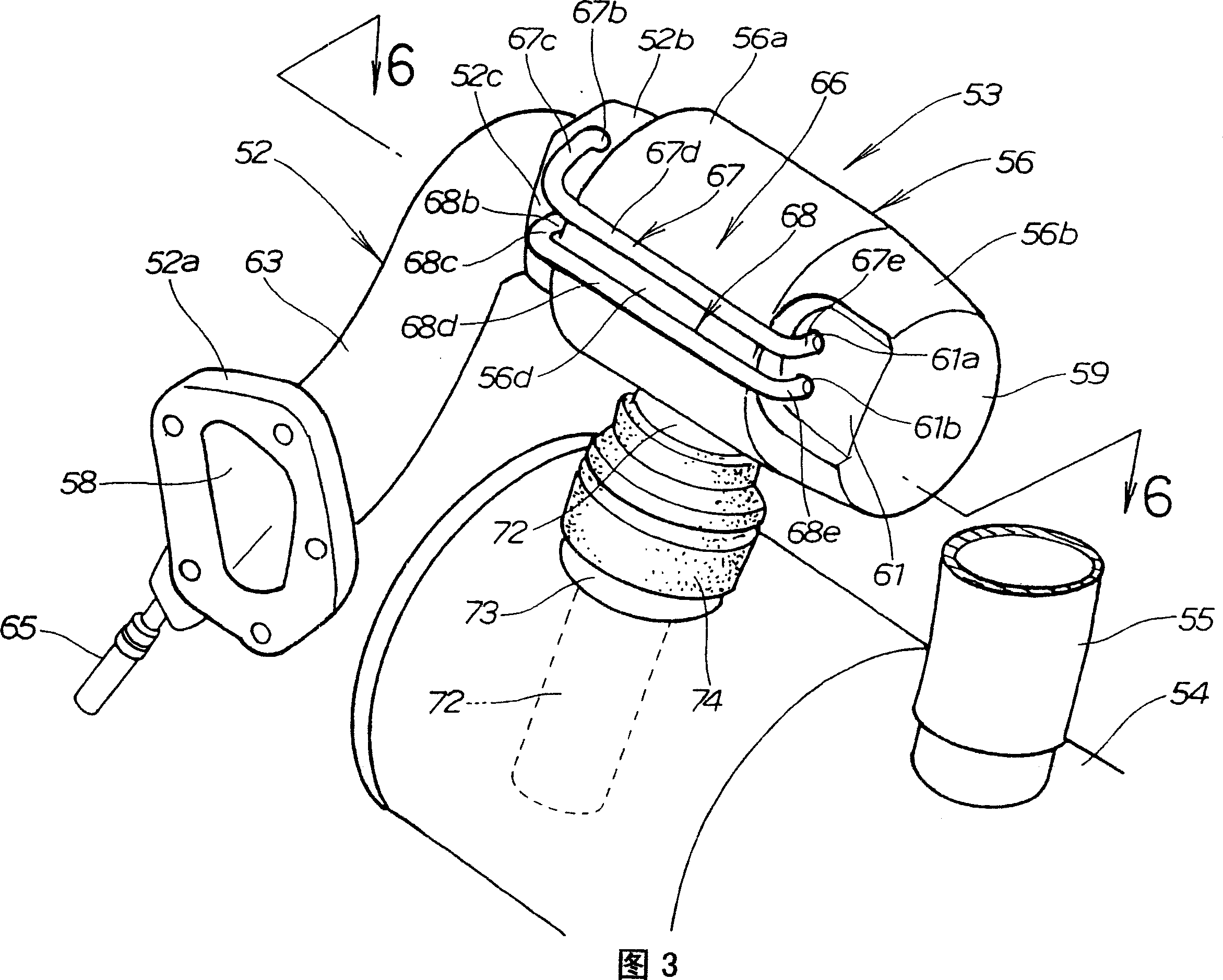

Exhaust structure for small watercraft

InactiveCN101024420APrevent intrusionImprove cooling effectInternal combustion piston enginesExhaust apparatusWatercraftEngineering

The invention provides an exhaust structure for a small watercraft that can cool exhaust gas, reduce a size, weight, and also the cost of a backflow prevention chamber. The exhaust structure 21 for a small watercraft is configured to cool exhaust gas in the course of leading the gas to the outside when the exhaust gas of an engine is led to the outside for discharge. This exhaust structure 21 includes a water muffler 54 containing water therein, and provided in the course of leading the exhaust gas to the outside. A backflow prevention chamber 53 is disposed above the water muffler 54 and adapted to prevent water from entering the side of the engine 13 from the side of the water muffler 54. The backflow prevention chamber 53 is provided with a cooling water injecting portion 66 adapted to spray cooling water to the exhaust gas in an internal space 76. An outlet 71 is formed at the bottom 56c of the backflow prevention chamber 53 to communicate with the water muffler 54.

Owner:HONDA MOTOR CO LTD

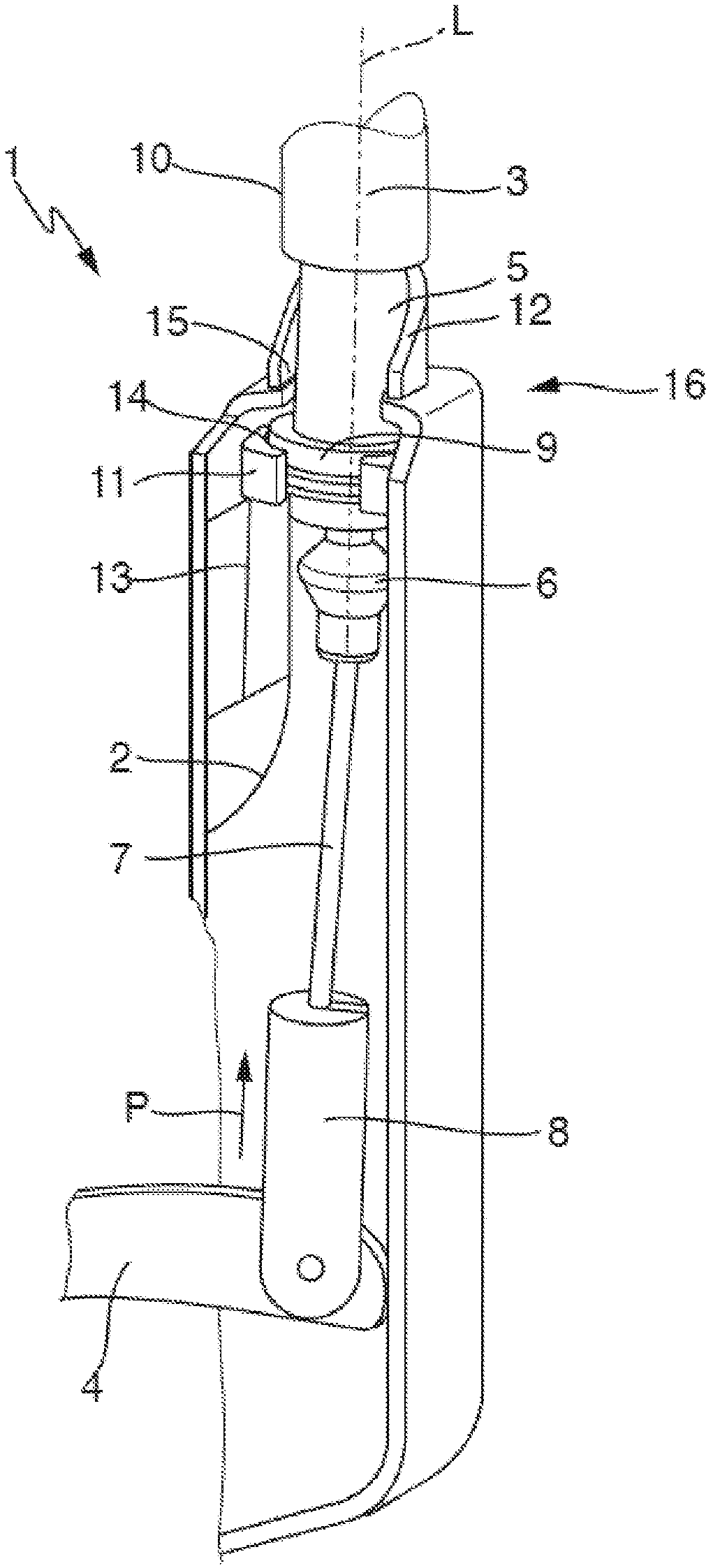

Bowden cable connection for a motor vehicle lock

ActiveCN107810340AGuaranteed functionPrevent importVehicle locksShaft for linear movementBowden cableEngineering

The object of the invention is a device (1) for axially fixing one end (9) of a Bowden cable (3), in particular a motor vehicle lock, comprising a housing (2), a Bowden cable (3), wherein the housing(2) has a receptacle (11), in which the end (9) of the Bowden cable (3) can be fixed, wherein the housing (2) has a means for introducing (12) the Bowden cable (3) into the receptacle (11) so that anincorrect assembly of the Bowden cable (3) can be prevented.

Owner:KIEKERT AG

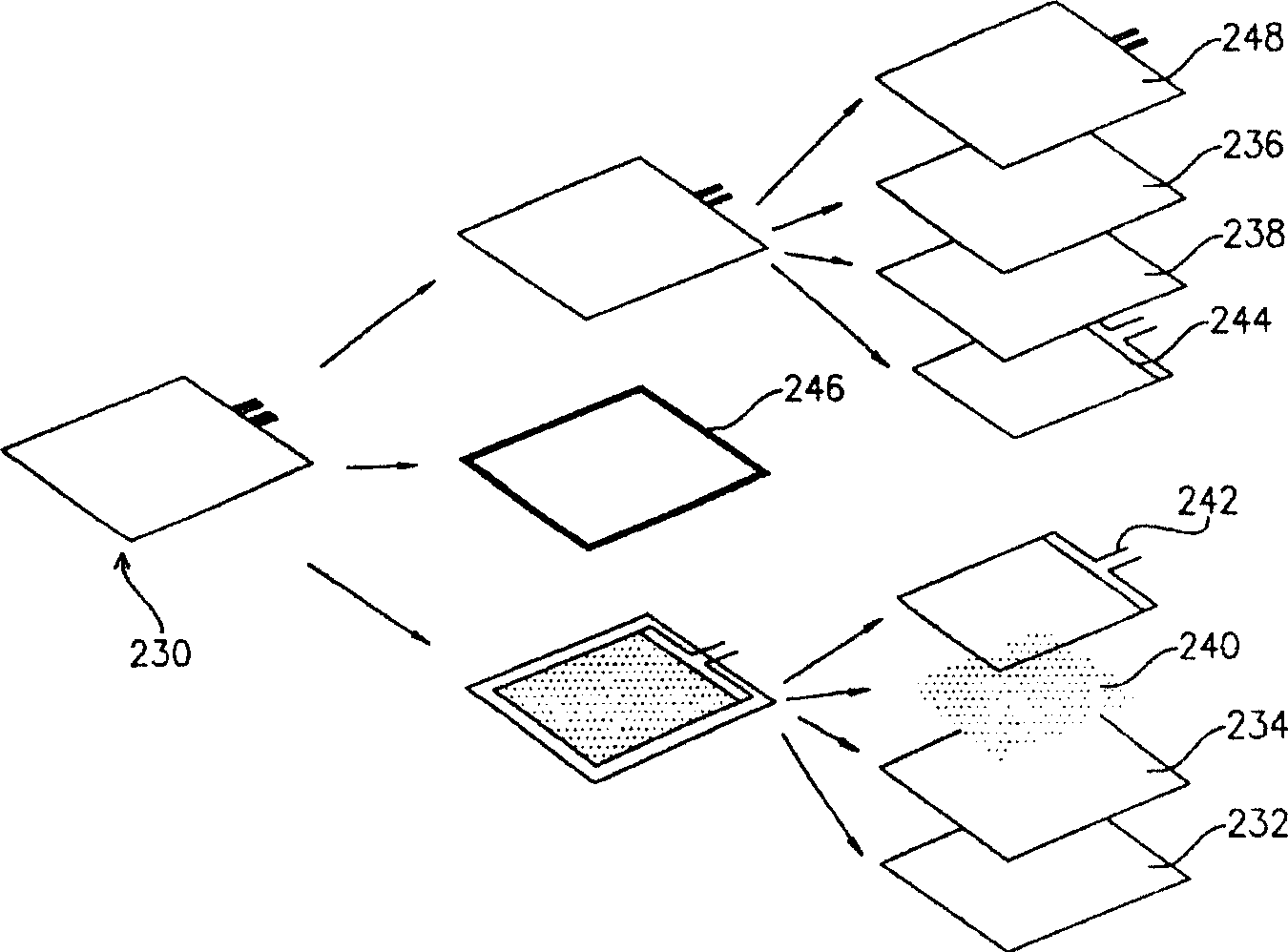

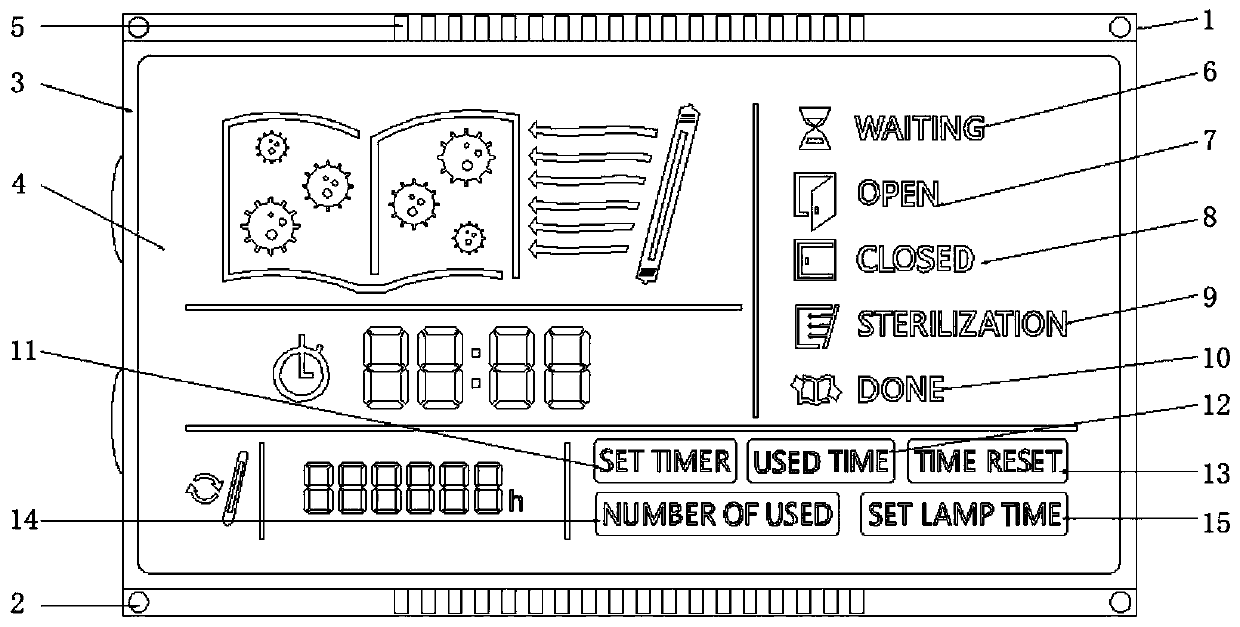

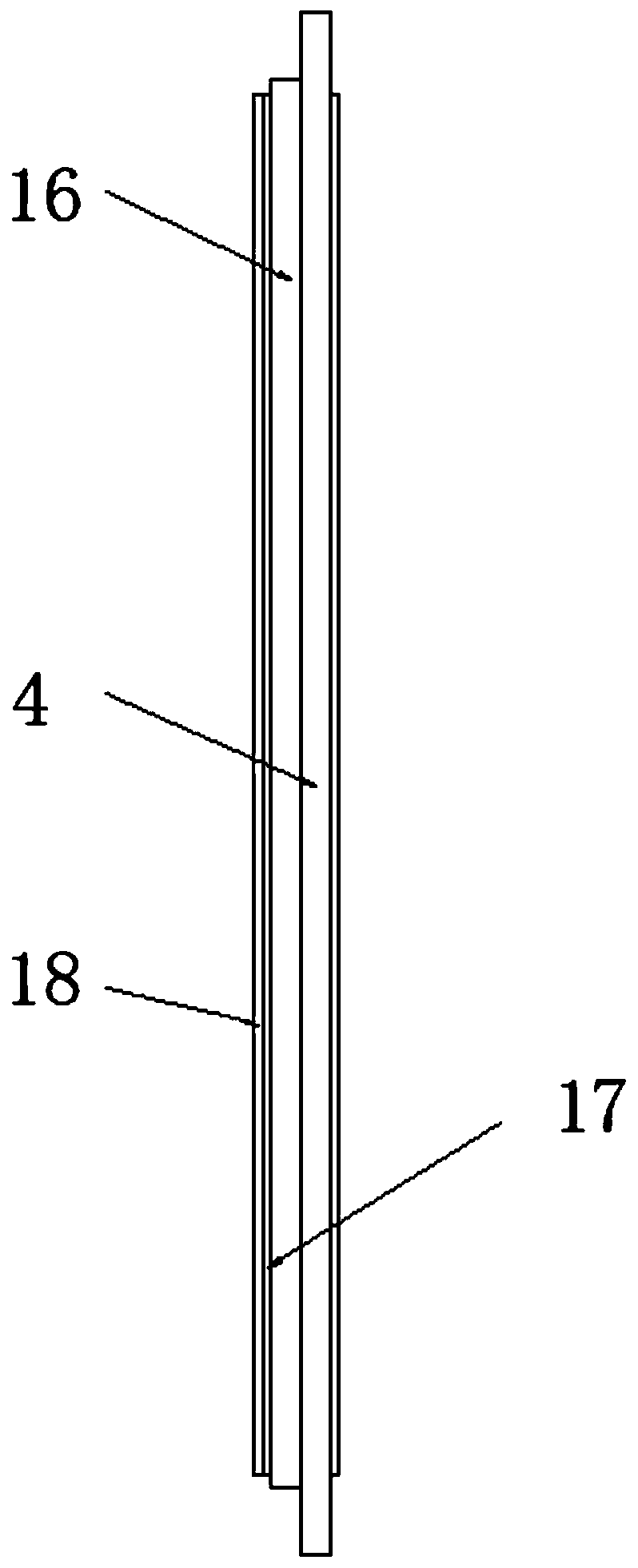

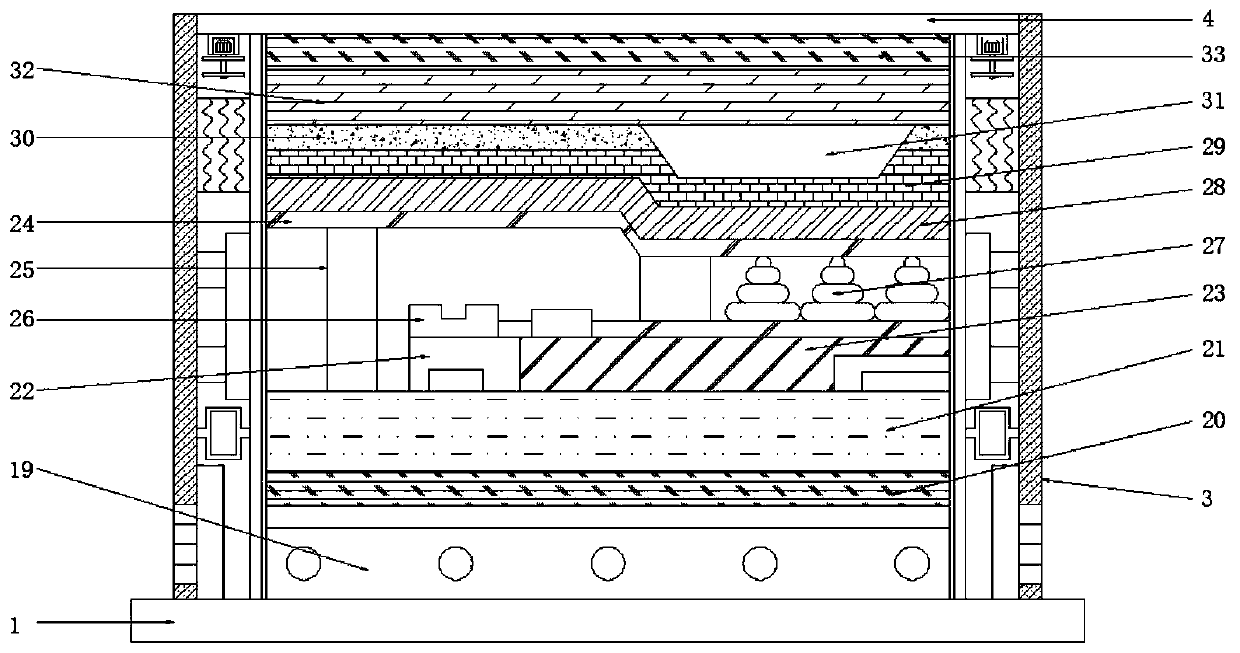

LCD black film display device

The invention discloses an LCD black film display device. The device comprises a positioning plate, positioning holes, a shell, a panel, terminals, a waiting button, an opening button, a closing button, a sterilization button, a completion button, a timer setting button, a use time button, a time reset button, a use frequency button, a lamp time setting button, an elastic silica gel spraying layer, a waterproof film, a dustproof film, a backlight module, a lower polarizing plate, a PCB substrate, a thin film transistor, liquid crystal, a common electrode, a protective film, a black film, a color filter, a heating pipe, an activated carbon net, a through hole and a rubber insulating layer. The shell is welded to the middle of the top of the positioning plate. According to the display device, the contrast is high, the visual angle is sound, use is convenient, the heat radiation effect is good, a certain anti-static effect is achieved, and a certain waterproof and dustproof effect is achieved.

Owner:HUNAN GUIDE TECH CO LTD

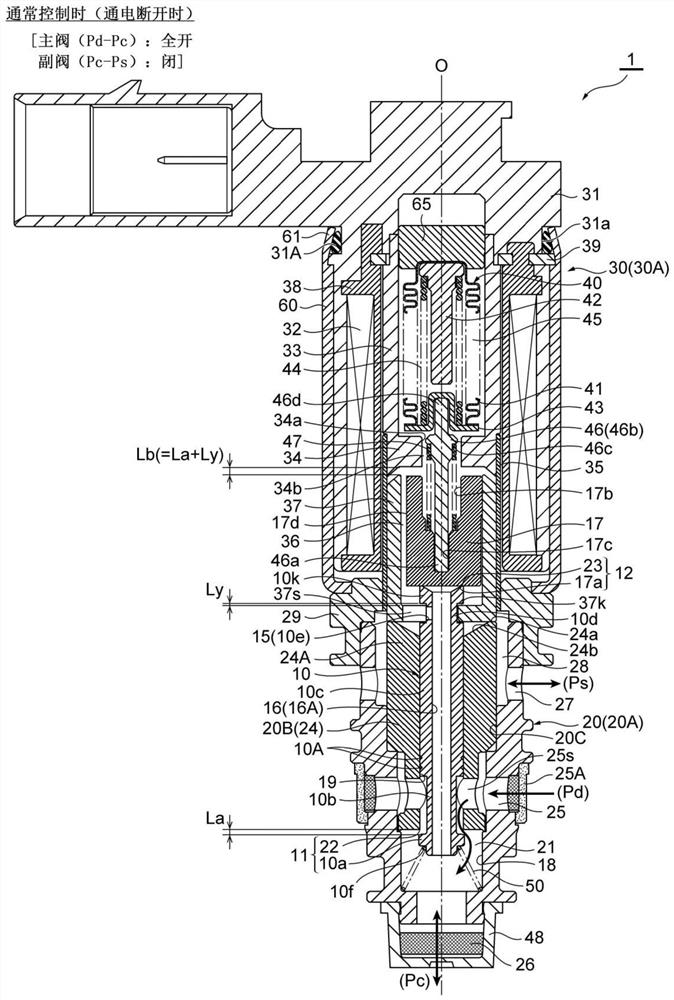

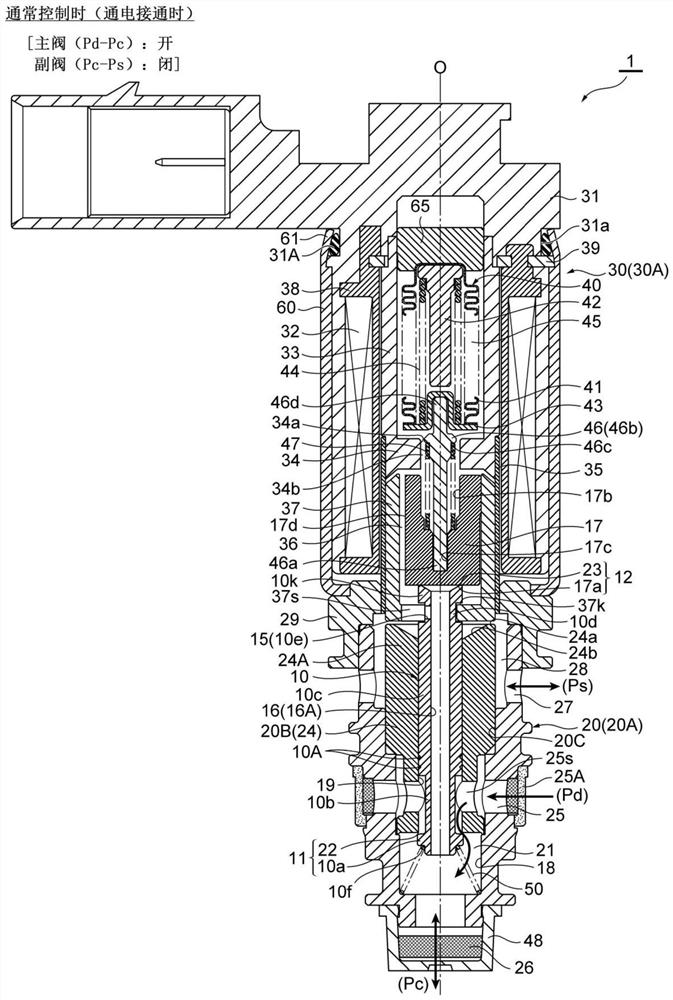

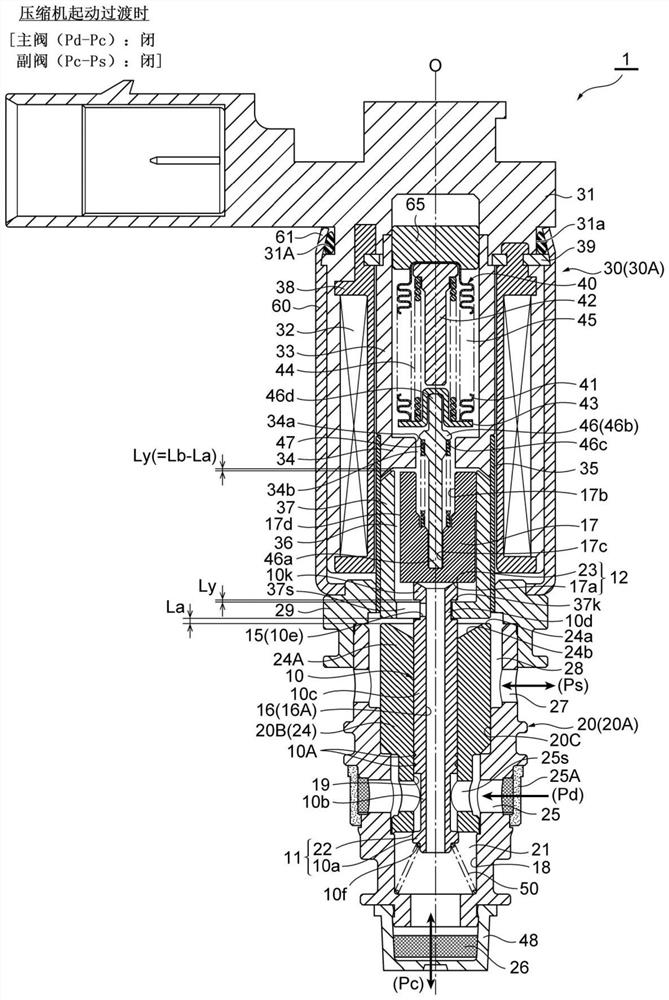

Control valve for variable displacement compressor

InactiveCN111699319AReduce the effects of stressPrevent importOperating means/releasing devices for valvesWorking fluid for enginesEngineeringIntake pressure

Provided is a control valve for a variable displacement compressor, with which the effects of refrigerant pressure on a main valve body can be effectively canceled out, and it is possible to avoid structural complications and size increases in physical constitution. A pressure-equalizing passage 15 is provided for guiding pressure Pc of a crank chamber exerted on a lower end of a main valve body 10 to a pressure-sensitive chamber 45, and causing the pressure Pc of the crank chamber to be exerted on an upper end of the main valve body 10, and when current conduction to (a solenoid part 30A of)an electromagnetic actuator 30 has been turned off (when a valve port 22 is fully open), intake pressure Ps is prevented from being guided into the pressure-sensitive chamber 45 from a Ps inlet / outlet27 (a Ps in / out chamber 28), the pressure Pc of the crank chamber is guided into the pressure-sensitive chamber 45 via the pressure-equalizing passage 15, and the pressure Pc of the crank chamber isexerted on both the upper and lower ends of the main valve body 10.

Owner:FUJIKOKI MFG CO LTD

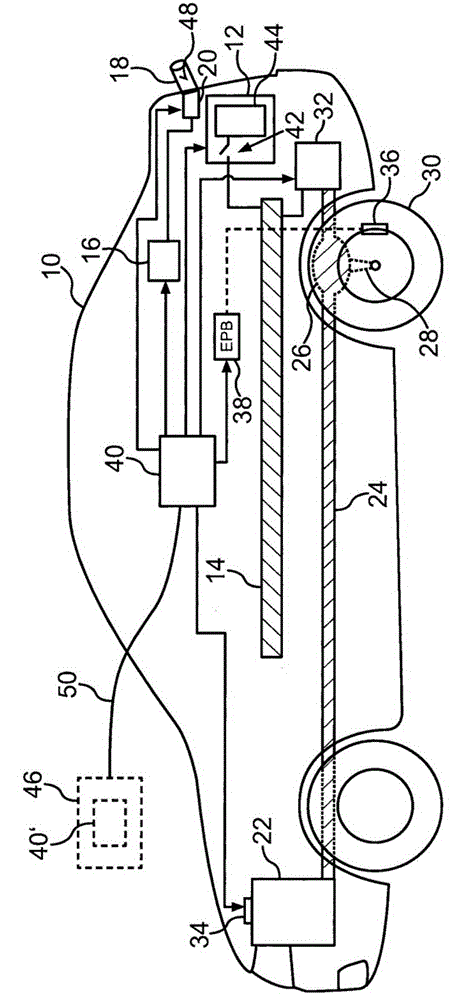

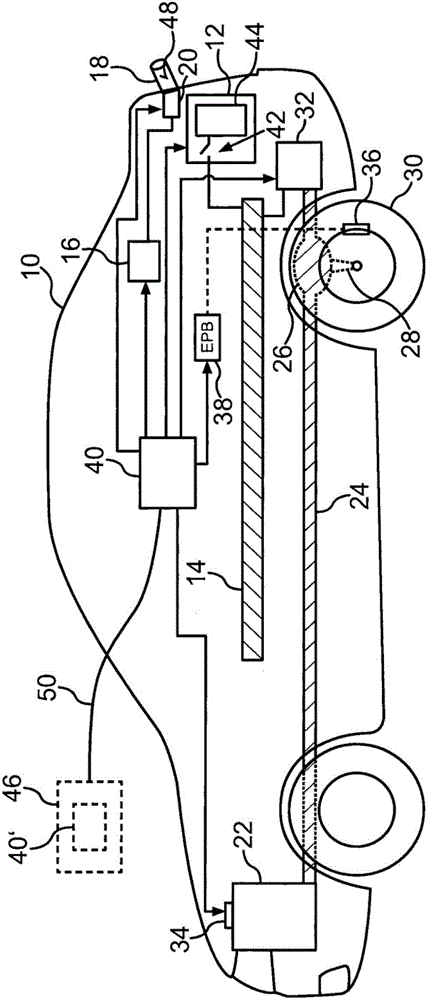

Voltage disconnection of a high voltage vehicle

ActiveCN105121213APrevent importPropulsion by batteries/cellsVehicular energy storageOn boardEnergy supply

The invention relates to a method for securing a high voltage on-board power supply (14) of a motor vehicle (10) for repair and / or maintenance of the motor vehicle (10). The problem addressed by the invention is that of securing the high-voltage on-board power supply by technical means instead of procedural measures. For this purpose, the energy inflow of the energy supply unit (12) is blocked during or after a voltage disconnection of the high-voltage on-board power supply (14), in which an energy inflow of an energy supply unit (12) to the high-voltage on-board power supply is interrupted. Additionally or alternatively, at least one other energy inflow (16, 20, 32, 34, 38) is blocked, wherein the at least one other energy inflow (16, 20, 32, 34, 38) is designed in order to supply energy from a further energy source (22) to the high-voltage on-board power supply (14).

Owner:AUDI AG

Voltage disconnect for high volt vehicles

The invention relates to a method for protecting a high-voltage on-board electrical system (14) of a motor vehicle (10) for repair and / or maintenance work on the motor vehicle (10). The invention is based on the task of protecting a high-voltage vehicle electrical system by means of technical measures instead of technological measures. In the method, during or after a voltage disconnection of the high-voltage on-board electrical system (14), wherein the energy input source of the energy supply device (12) to the high-voltage on-board electrical system is interrupted, the energy input of the energy supply device (12) is blocked source. Additionally or alternatively to this, at least another energy input source (16, 20, 32, 34, 38) is locked, wherein the at least another energy input source (16, 20, 32, 34, 38) is designed for , providing energy from another energy source (22) to the high-voltage vehicle electrical network (14).

Owner:AUDI AG

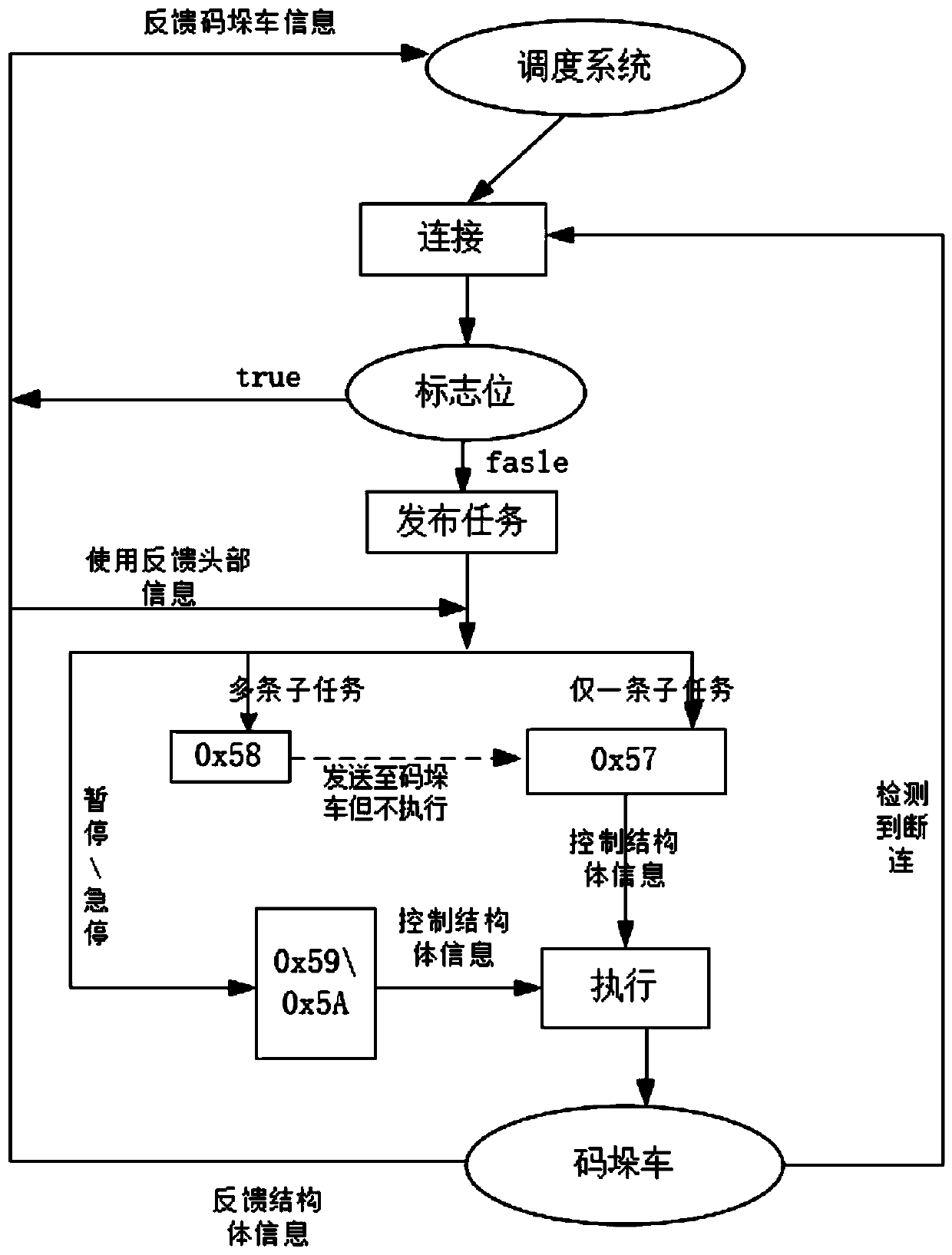

A communication method for scheduling control

ActiveCN110942605APrevent importControl instant stopError prevention/detection by using return channelNetwork traffic/resource managementPacket lossDistributed computing

The invention discloses a communication method for scheduling control. The communication method is used for realizing data communication between an upper computer and a lower computer. The upper computer is used for sending published information to the lower computer, and the lower computer is used for sending feedback information to the upper computer, the published information and the feedback information both adopt a structural body form with verification information to send information. The method has the advantages that communication is reliable and safe, packet loss can be prevented, wrong control can be prevented when wrong information is imported, and whether data packet loss occurs or not can be verified; instant stop of the lower computer and efficient use of task information areeffectively controlled. According to the set sign check bit, a reconnection mechanism is combined to ensure that reconnection does not miss the reception of effective tasks during operation.

Owner:WUHU HIT ROBOT TECH RES INST

Duplex air governor

InactiveCN1272594CPrevent importPrevents cooling performance from deterioratingMechanical apparatusHeat pumpsSuper coolingProcess engineering

Multi-type air conditioner including an outdoor unit having a compressor, an outdoor heat exchanger, a flow path control valve for controlling a flow path of the refrigerant from the compressor, an outdoor expansion device for expanding liquid refrigerant introduced thereto in a condensed state via indoor units and providing to the outdoor heat exchanger when the room is heated, and an outdoor unit piping system, a plurality of indoor units each having an indoor expansion device, an indoor heat exchanger, and an indoor piping system, a distributor for selectively distributing the refrigerant from the outdoor unit to the indoor units and returning to the outdoor unit again proper to respective operation modes, and means for super cooling the refrigerant condensed at the outdoor heat exchanger or the indoor heat exchangers and flowed to the indoor expansion devices or to the outdoor expansion device, thereby super cooling the refrigerant supplied to the evaporator.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com