Bowden cable connection for a motor vehicle lock

A motorized and car lock technology, applied in the field of terminal equipment, can solve problems such as functional failure, damaged function, failure, etc., and achieve the effect of preventing functional failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

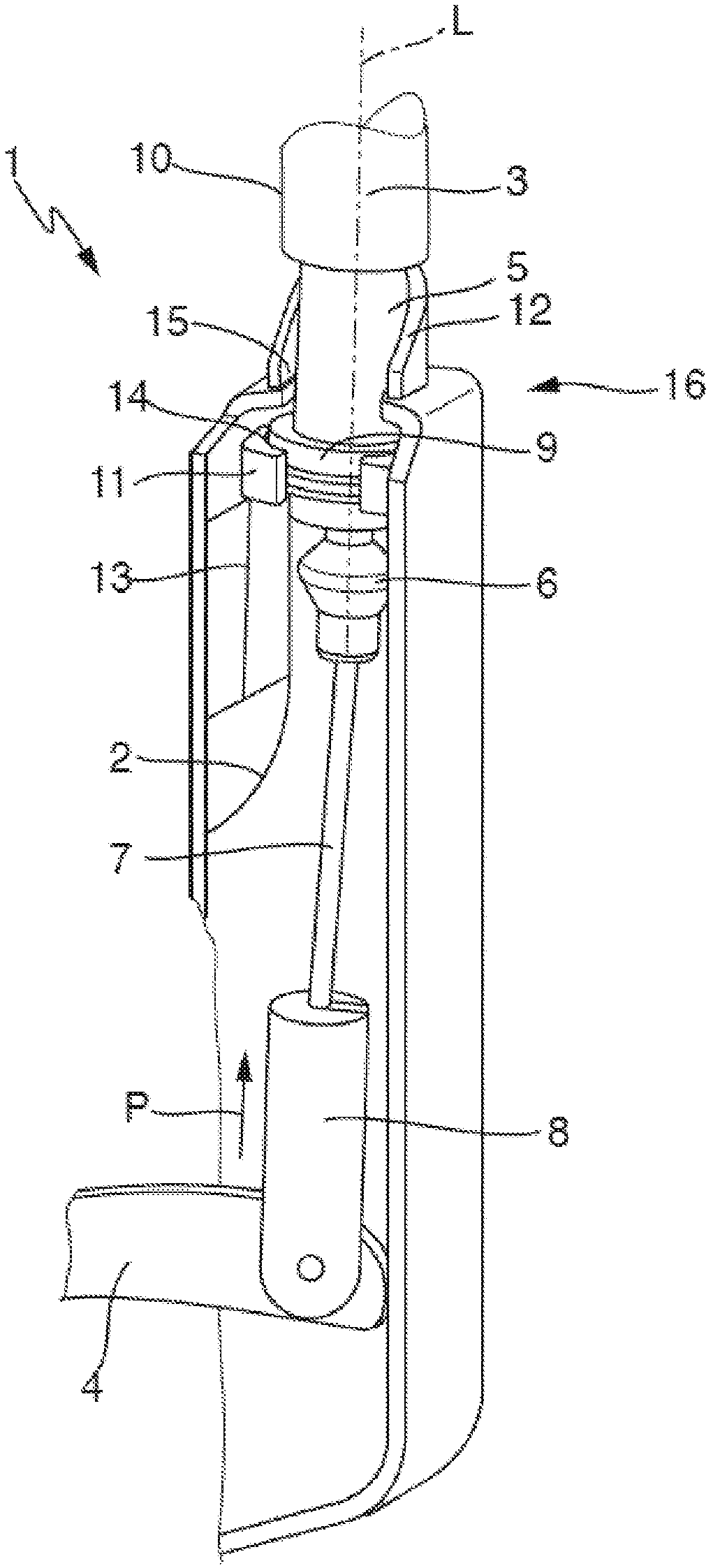

[0037] exist figure 1 A device 1 is shown in , which has a housing 2 , a Bowden cable 3 and an actuating lever 4 . The housing 2 is part of an at least two-part motor vehicle lock housing, in which the actuating lever 4 is accommodated in a pivotable manner. The actuating lever 4 can be moved in the direction of the arrow P by means of the Bowden cable 3 .

[0038] The Bowden cable 3 has a Bowden cable sheath 5 , a Bowden cable seal 6 (seal ring), a Bowden cable core 7 , and a connecting member 8 that is swingably connected to the actuating rod 4 . The Bowden cable 5 also has a flange 9 and an additional jacket 10 for the Bowden cable sheath 5 . The housing 2 is made of plastic and has a receptacle 11 and an introduction part 12 , wherein the receptacle 11 and the introduction part 12 are integrally formed with the housing 2 in this exemplary embodiment. In the housing 2 additional weitere rib 13.

[0039] The flange 9 of the Bowden cable sheath 5 has a larger diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com