Vapor discharge apparatus and film formation method

A release device and steam technology, applied in the direction of vacuum evaporation plating, ion implantation plating, gaseous chemical plating, etc., can solve the problems of stable and difficult film formation rate, achieve stable film formation rate, prevent polymerization reaction, prevent condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

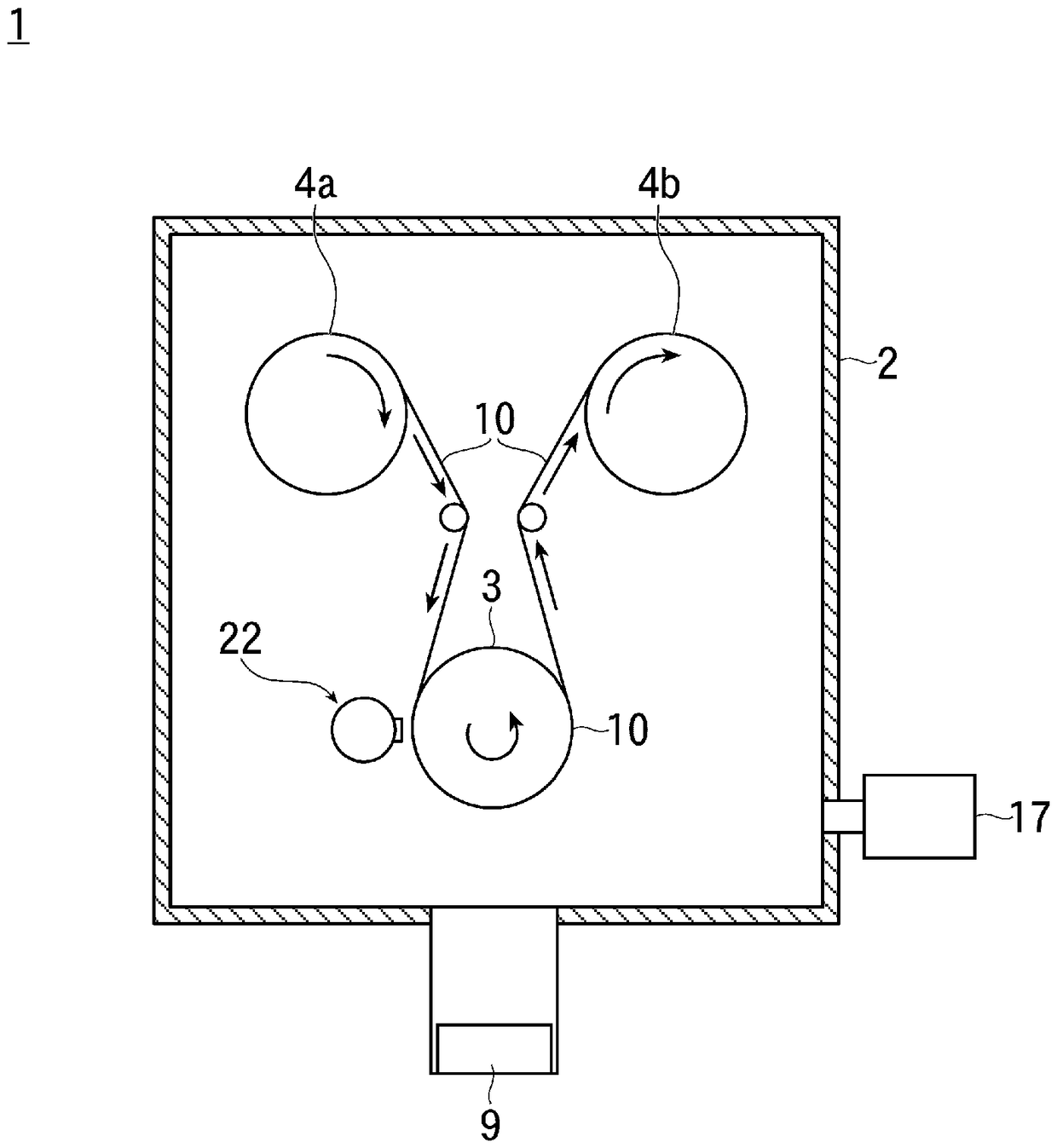

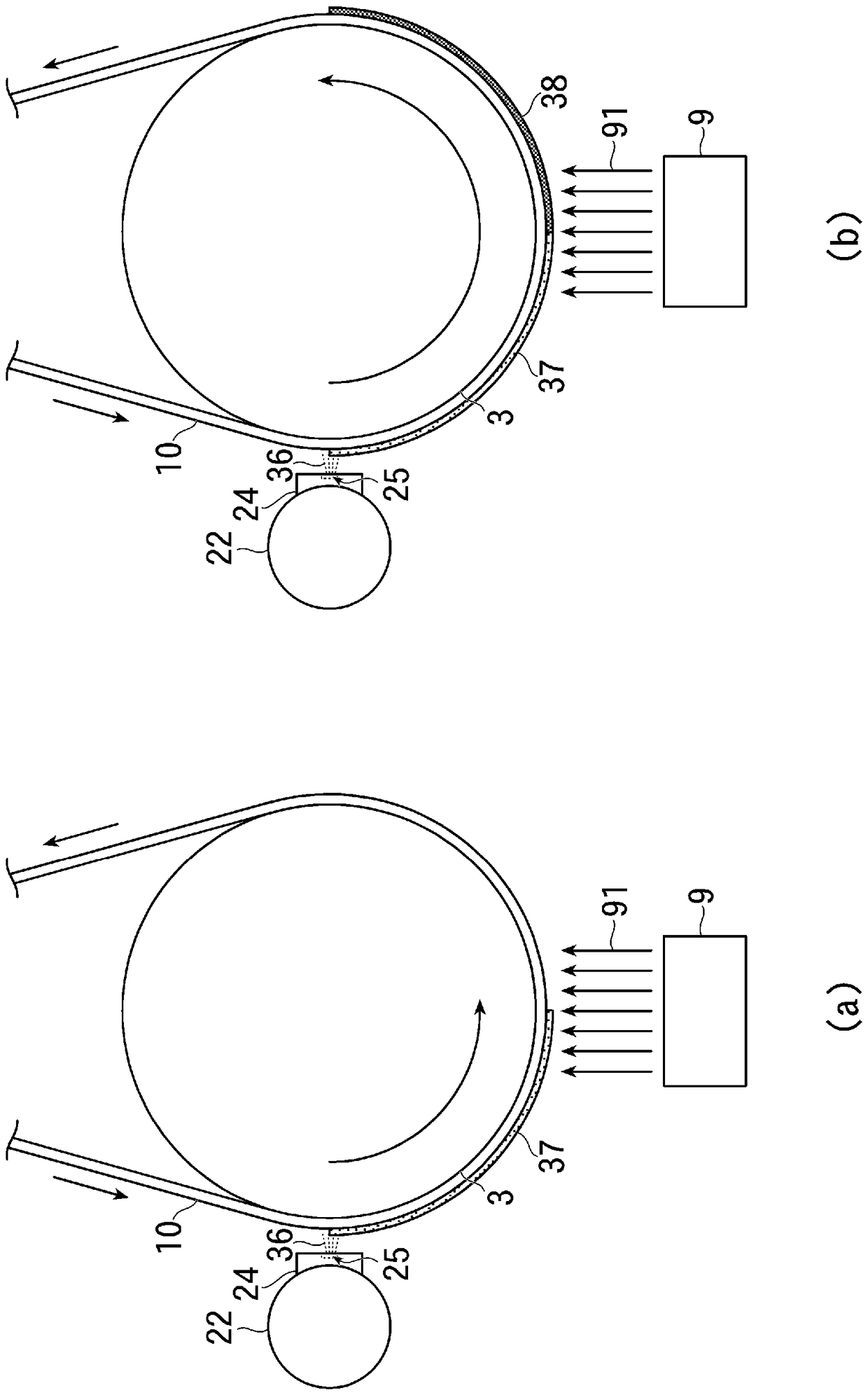

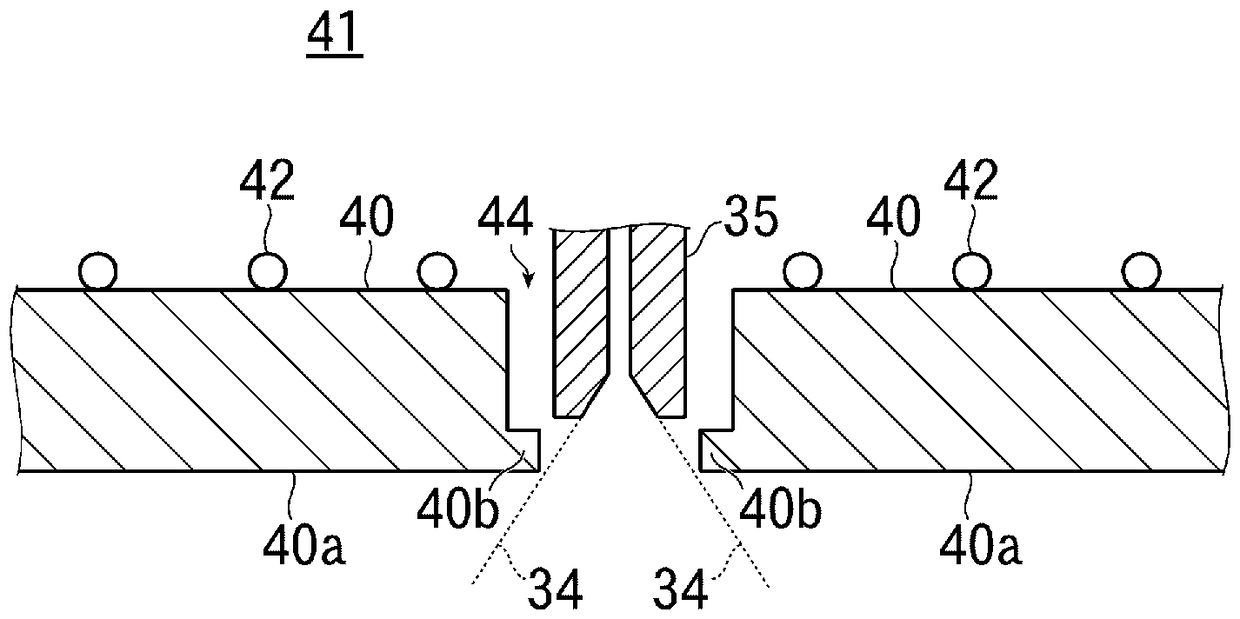

[0036] figure 1 It is an overall configuration diagram of an embodiment of a film forming apparatus using the steam releasing apparatus according to the present invention, figure 2 It is an internal configuration diagram of an embodiment of the steam release device according to the present invention.

[0037] like figure 1 As shown, the film forming apparatus 1 of this embodiment is used to form an organic compound film on a substrate film 10 in a vacuum chamber 2 connected to a vacuum exhaust device 17, and has a vapor releasing device 20 (refer to figure 2 ).

[0038] Here, near the central part of the inside of the vacuum chamber 2, there is provided a cylindrical center roll 3 for contacting and conveying the base material film 10, and around the center roll 3, a steam releasing device 20 described later is provided. The steam discharge par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com