Device and process for preparing aluminum nitride crystals by adopting spontaneous crystal seed method

An aluminum nitride, spontaneous crystallization technology, applied in the direction of self-solidification, crystal growth, single crystal growth, etc., can solve the problem of difficult to obtain large-scale, high-quality single crystal, achieve energy saving, simple production process, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

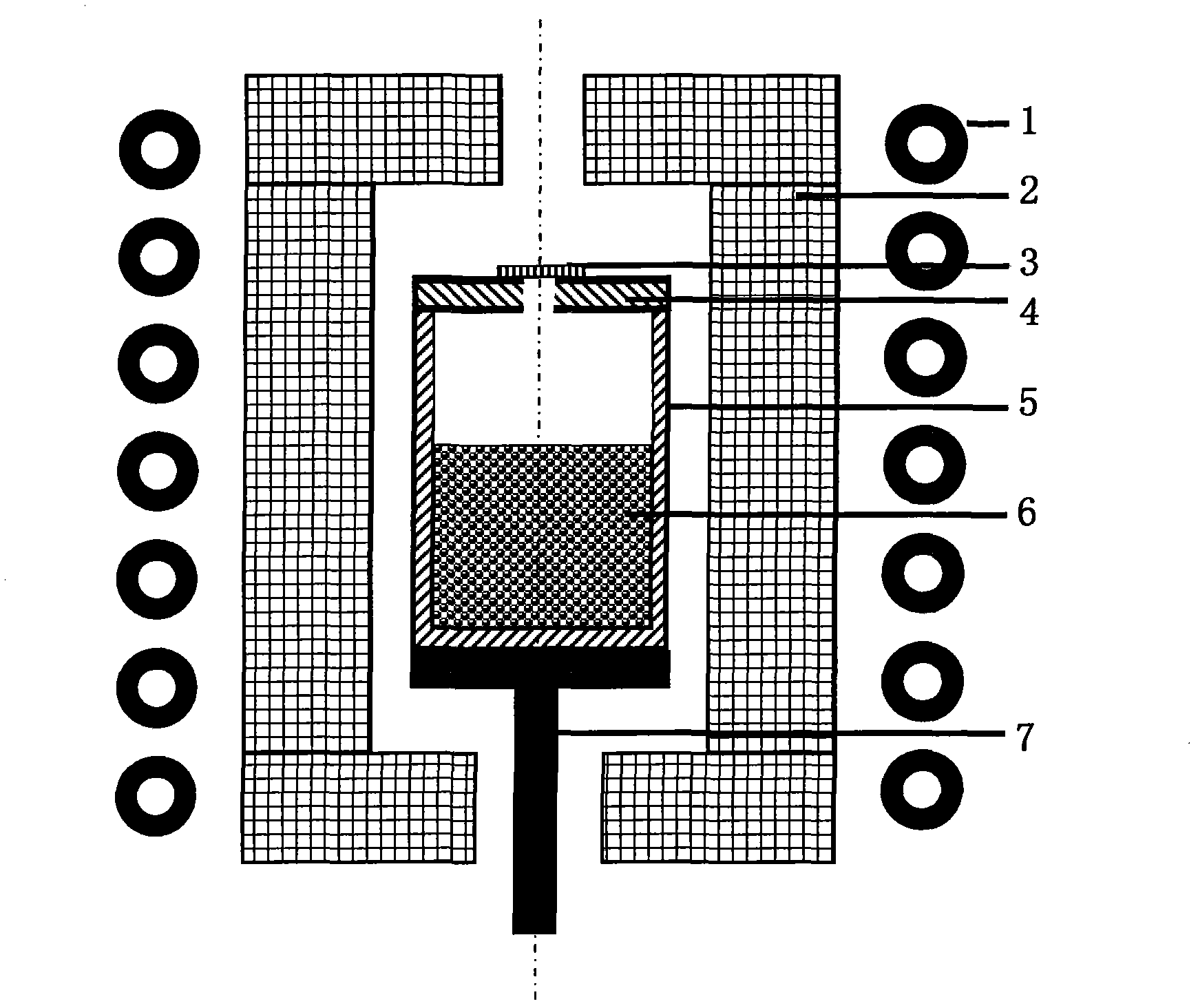

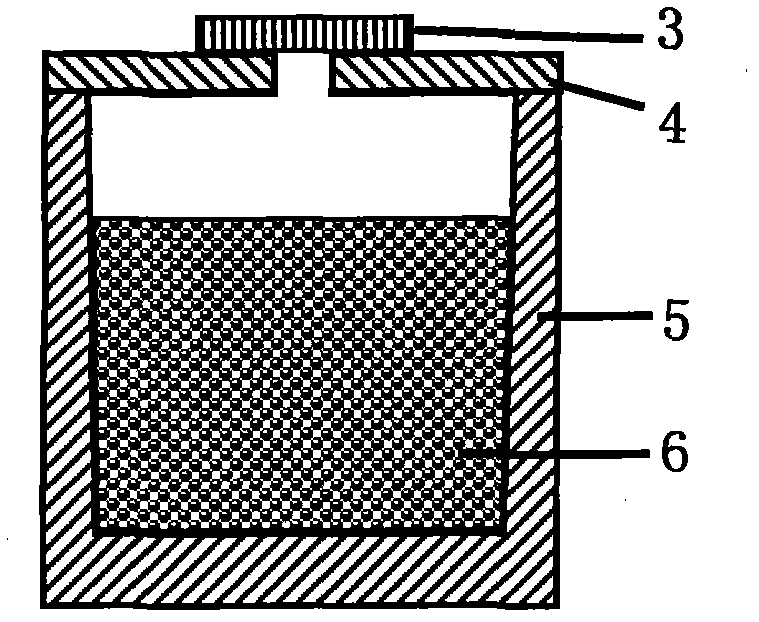

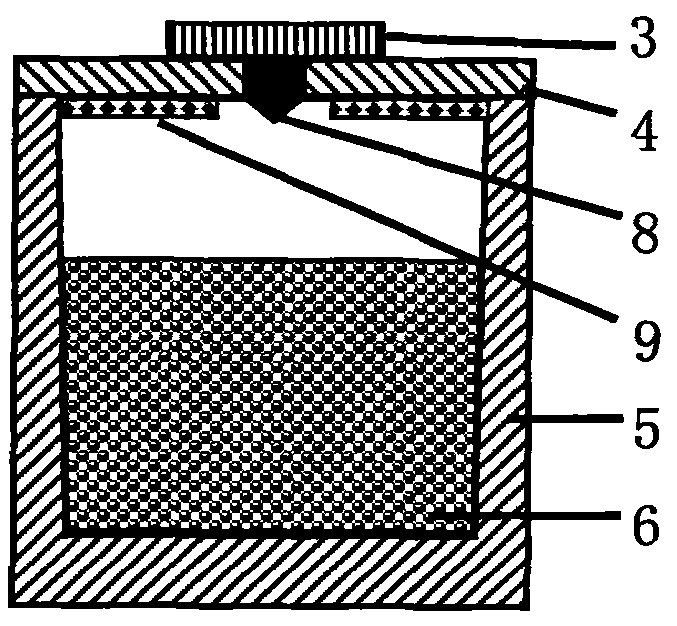

[0012] The invention provides a device and a process for preparing aluminum nitride crystals by a spontaneous seed crystal method. An example of preparing aluminum nitride crystals according to the present invention will be given below to further illustrate the present invention. This embodiment includes the following working stages. (1), using such as figure 1 The shown preparation device comprises an induction heating coil (1), an insulating layer (2), a crucible device and a crucible lifting device (7), wherein the crucible device is as figure 2 As shown, the crucible device is composed of a cover sheet (3), a crucible cover (4) and a crucible body (5), all of which are made of tungsten. The size of the crucible is Φ 外 45×50 mm, Φ 内 36×45 mm, the size of the crucible cover is Φ45×0.5 mm, there is a hole with a diameter of 1 mm in the center of the crucible cover, the size of the cover is Φ5×0.5 mm and placed directly above the hole, the aluminum nitride after sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com