GaN film growing on magnesium aluminate scandium substrate as well as preparation method and application of GaN film

A magnesium-scandium aluminate and substrate technology, which is applied in the field of GaN thin film and its preparation, can solve the problems affecting the performance of GaN-based devices, reducing the carrier mobility of materials, and reducing the quantum efficiency of devices, so as to achieve mature production technology, The effect of reducing production cost and relieving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

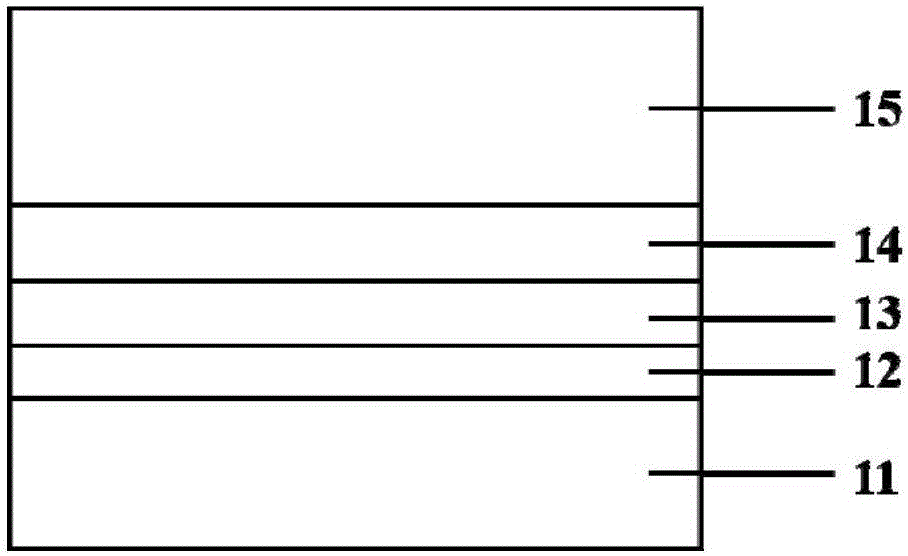

[0037] A method for preparing a high-quality GaN film grown on a magnesium-scandium aluminate substrate, comprising the following steps:

[0038] (1) Selection of substrate and its crystal orientation: using ScMgAlO 4 The substrate, with the (0001) plane offset from the (11-20) plane by 0.5° as the epitaxial plane, the crystal epitaxial orientation relationship is: the (0001) plane of GaN is parallel to ScMgAlO 4 (0001) face;

[0039] (2) Substrate annealing treatment: the magnesium scandium aluminate substrate was annealed at 600 ° C for 1 hour in the molecular beam epitaxy vacuum growth chamber of the substrate to obtain an atomically flat surface;

[0040] (3) Epitaxial growth of GaN buffer layer: the substrate temperature is adjusted to 450°C, and the pressure of pulsed laser deposition in the reaction chamber is 2.0×10 -5 Pa, laser energy density is 1.8J / cm 2 A 30nm-thick GaN buffer layer was grown under conditions;

[0041] (4) Epitaxial growth of the GaN nucleation ...

Embodiment 2

[0051] The preparation method of the GaN film grown on the magnesium scandium aluminate substrate comprises the following steps:

[0052] (1) Selection of substrate and its crystal orientation: using ScMgAlO 4 The substrate, with the (0001) plane offset from the (11-20) direction by 0.5° as the epitaxial plane, the crystal epitaxial orientation relationship is: the (0001) plane of GaN is parallel to ScMgAlO 4 (0001) face;

[0053] (2) Substrate annealing treatment: the magnesium scandium aluminate substrate was annealed at 700°C for 2 hours in the molecular beam epitaxy vacuum growth chamber of the substrate to obtain an atomically flat surface;

[0054] (3) Epitaxial growth of GaN buffer layer: the substrate temperature is adjusted to 500°C, and the pressure in the reaction chamber is 3.0×10 by pulsed laser deposition. -5 Pa, laser energy density is 2.0J / cm 2 An 80nm-thick GaN buffer layer is grown under conditions;

[0055] (4) Epitaxial growth of the GaN nucleation laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com