Method for preparing ZnO (zinc oxide)-based thin film transistor by using metal organic chemical vapor deposition

A metal-organic chemistry, thin-film transistor technology, applied in the field of microelectronics, can solve the problems of complex ZnO thin-film transistor process, low ZnO crystal quality, affecting device characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

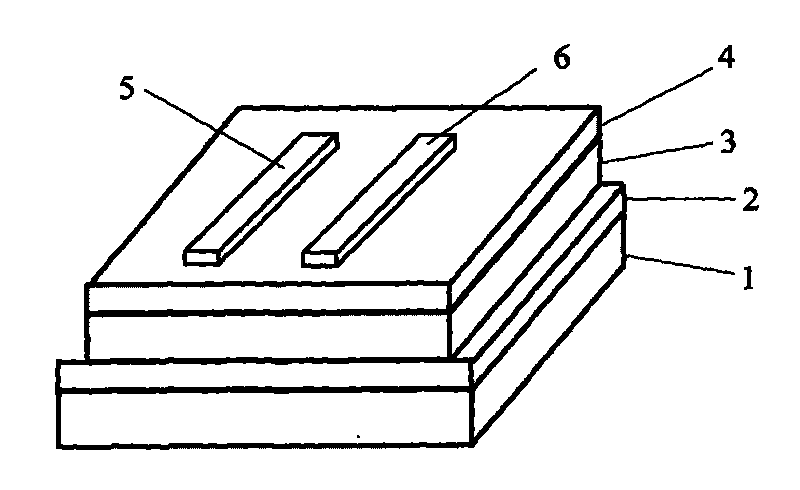

[0024] 1. Select ITO glass as the substrate 1, transparent and conductive ITO film as the gate 2, and chemically clean the substrate. The steps are: ultrasonic cleaning with toluene for 5 minutes, ultrasonic cleaning with acetone for 5 minutes, and ultrasonic cleaning with ethanol for 5 minutes, and then Recirculate once, rinse with deionized water, dry with high-purity nitrogen and set aside;

[0025] 2. Use the MOCVD method on the processed substrate, especially the special growth MOCVD equipment described in ZL 02100436.6 and ZL200410011164.0 patents, use magnesium dicene as the magnesium source, and the magnesium source is carried into the reaction chamber with argon gas. Chemically react with high-purity oxygen at 650°C to epitaxially grow the MgO insulating layer 3 , the flow rate of argon gas is 20 sccm, the flow rate of oxygen gas is 200 sccm, the pressure of the reaction chamber is 150 Pa, and the layer thickness is 200 nanometers. Then continue to adopt the above-men...

Embodiment 2

[0028] The difference between this embodiment and embodiment 1 is that the substrate 1 adopts a resistivity of 10 -3 The silicon substrate of Ω cm is also used as the gate electrode 2 of the transistor, and the others are the same as in embodiment 1, that is, the Al 2 o 3 , MgO or Mg with Mg content (y=0.9) y Zn 1-y O insulating layer 3, prepared Al 2 o 3 The organic source that adopts can be trimethylaluminum, and oxygen source is high-purity oxygen, and flow rate is respectively 2sccm and 200sccm; Preparation Mg y Zn 1-y The organic source used for O is diethylzinc and dichloromagnesium, the oxygen source is high-purity oxygen, and the oxygen flow rate is 200 sccm. The organic source is carried into the reaction chamber by argon gas. The temperature is 650°C, the pressure of the reaction chamber is about 150Pa during growth, and the layer thickness is about 500nm, and then MOCVD is used to grow ZnO or Mg with low Mg (x=0.1) content x Zn 1-X O active channel layer 4, ...

Embodiment 3

[0030] The difference between this embodiment and Embodiment 1 is that the substrate 1 is made of glass, and the gate electrode 2 is a ZnO-doped Ga transparent conductive film grown by MOCVD, and the others are the same as in Embodiment 1; , the insulating layer 3 and the ZnO-based active channel layer 4 are all grown by MOCVD technology, and the material growth of each layer can be completed at one time in the MOCVD growth equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com