Preparation method of tantalump-doped potassium-sodium niobate lead-free piezoelectric single crystal with high electromechanical coupling property

An electromechanical coupling, potassium sodium niobate technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, single crystal growth, single crystal growth, etc., can solve the problem of small single crystal size, low electromechanical coupling coefficient, niobate Potassium-sodium-based lead-free piezoelectric single crystal growth is difficult and other problems, to achieve the effect of uniform composition, outstanding performance, and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

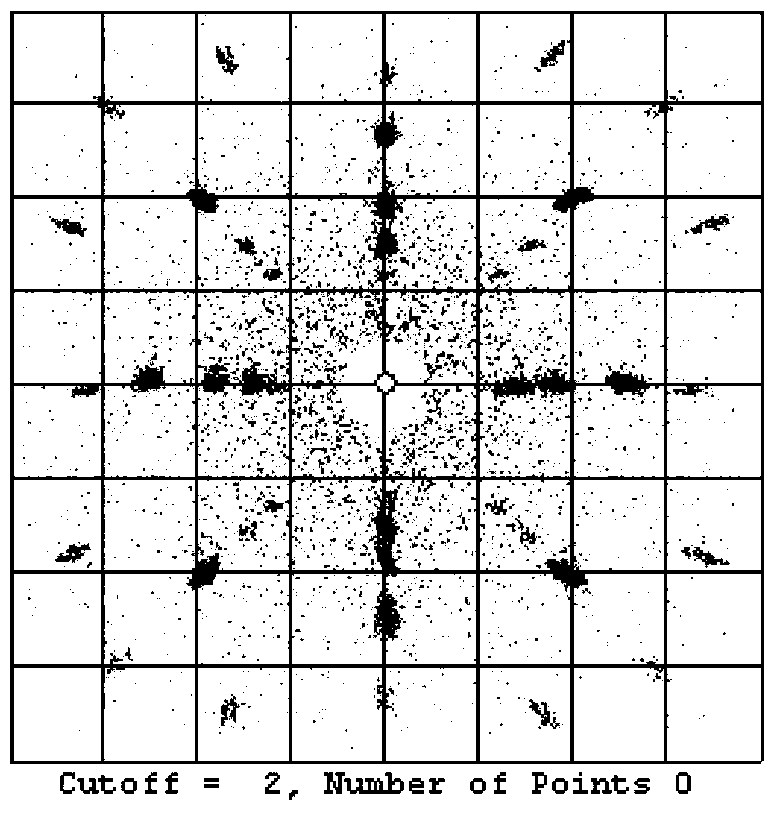

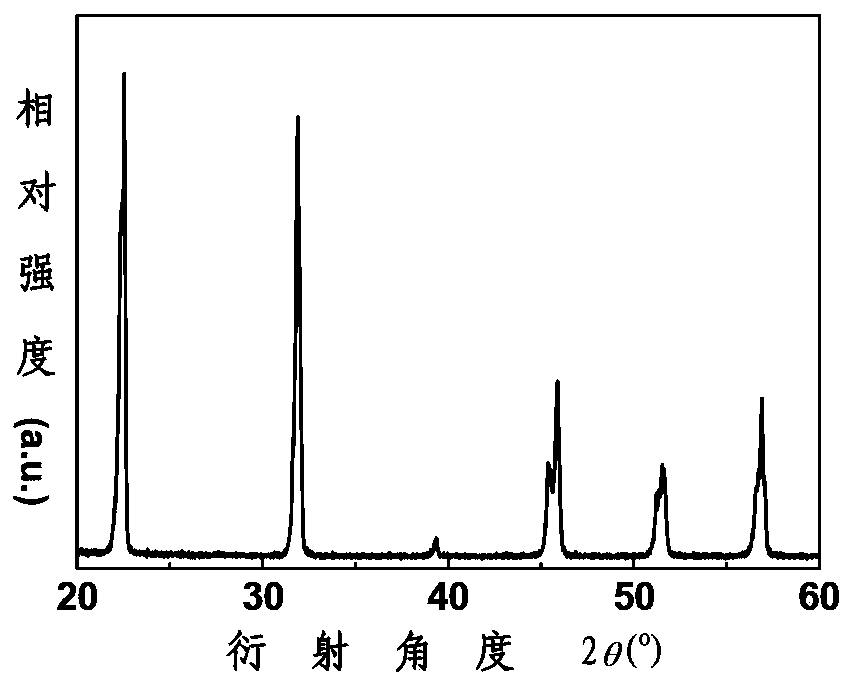

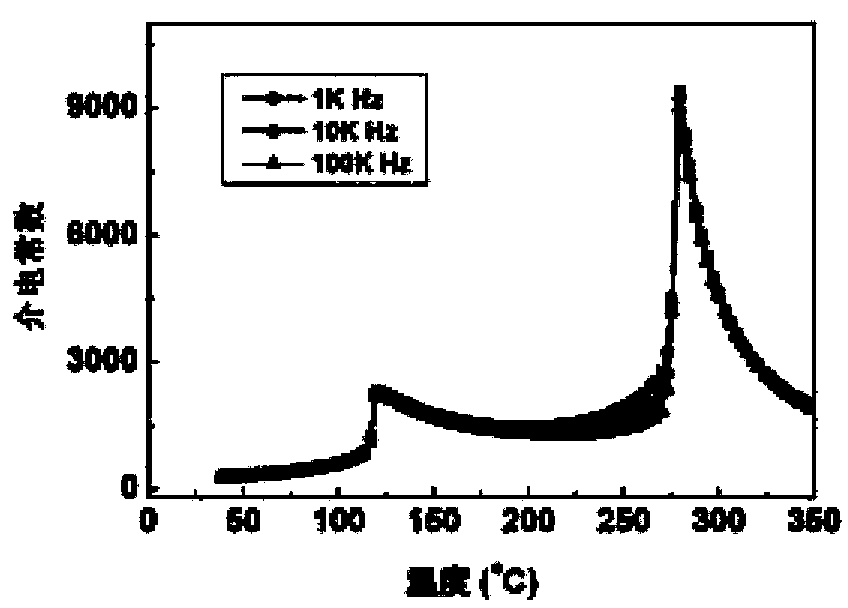

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment 1: This embodiment is a method for preparing tantalum-doped potassium sodium niobate lead-free piezoelectric single crystal with high electromechanical coupling performance, which is characterized in that the tantalum-doped potassium sodium niobate lead-free piezoelectric single crystal with high electromechanical coupling performance The chemical formula of piezoelectric single crystal is (K 1-x Na x )(Nb 1-y Ta y )O 3 , wherein 0.4<x<0.7, 0.20<y<0.35; the specific preparation method is completed in the following steps:

[0021] 1. Raw materials for pre-sintering and synthesizing polycrystalline powder:

[0022] ①. Prepare raw materials: according to the chemical formula (K 1-x Na x )(Nb 1-y Ta y )O 3 According to Na element: K element: Ta element: Nb element molar ratio is x: (1-x): y: (1-y) Prepare Na 2 CO 3 、K 2 CO 3 、 Ta 2 o 5 and Nb 2 o 5 ; said (K 1-x Na x )(Nb 1-y Ta y )O 3 Medium: 0.4<x<0.7, 0.20<y<0.35;

[0023] ②. We...

specific Embodiment approach 2

[0031] Specific embodiment 2: the difference between this embodiment and specific embodiment 1 is: (K) described in step 1. 1-x Na x )(Nb 1-y Ta y )O 3 Middle: x=0.5, y=0.3. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is: in step 1.2, Na 2 CO 3 、K 2 CO 3 、 Ta 2 o 5 and Nb 2 o 5 The volume ratio of the total mass to absolute ethanol is 1g:1mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com