Patents

Literature

42results about How to "Clear edges and corners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

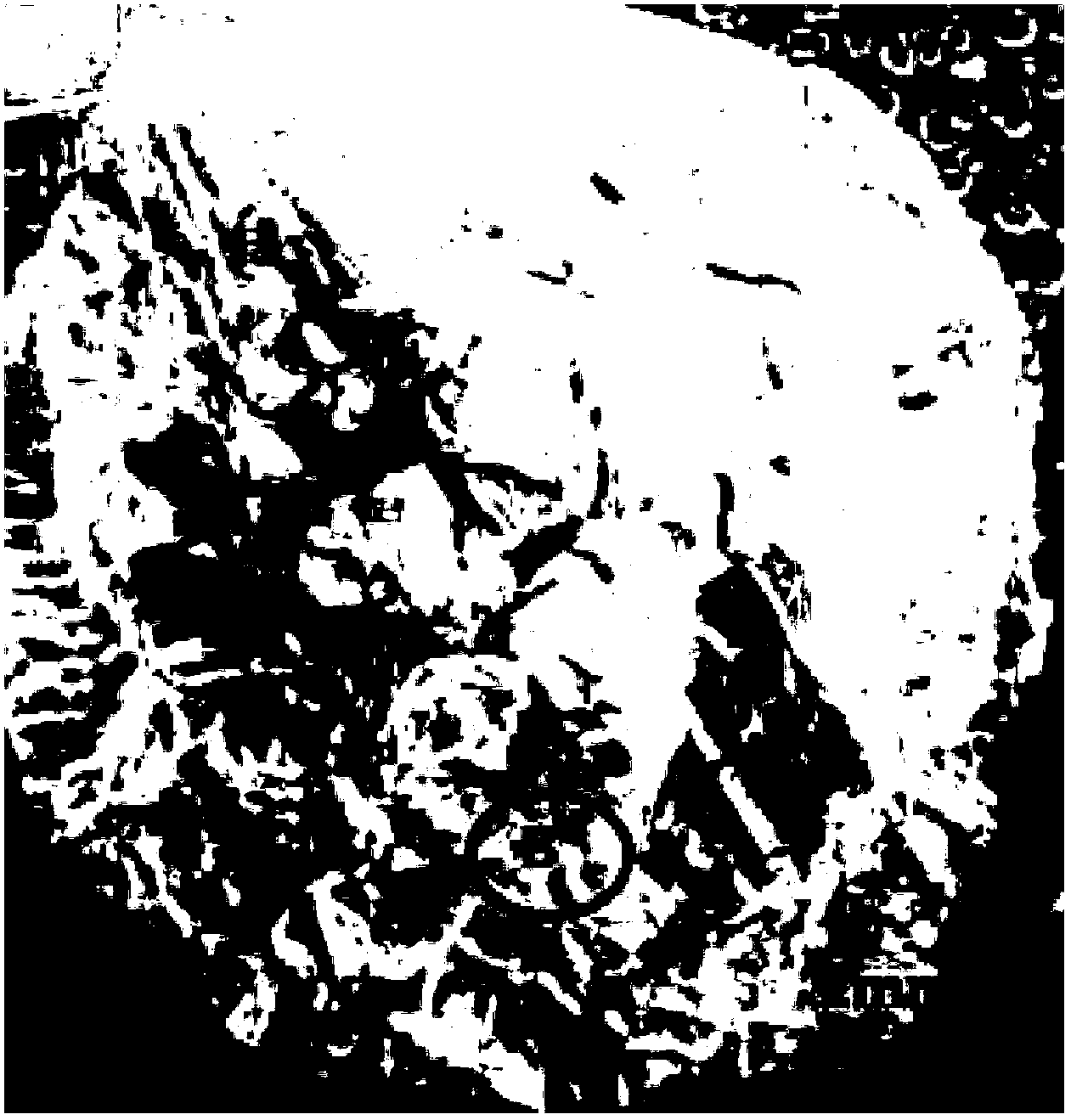

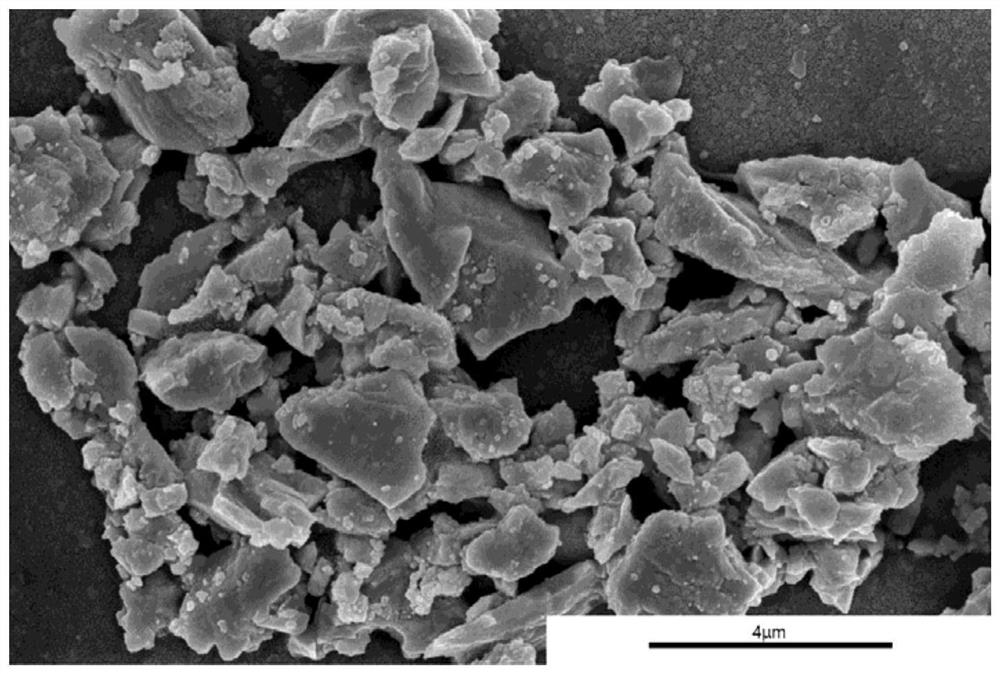

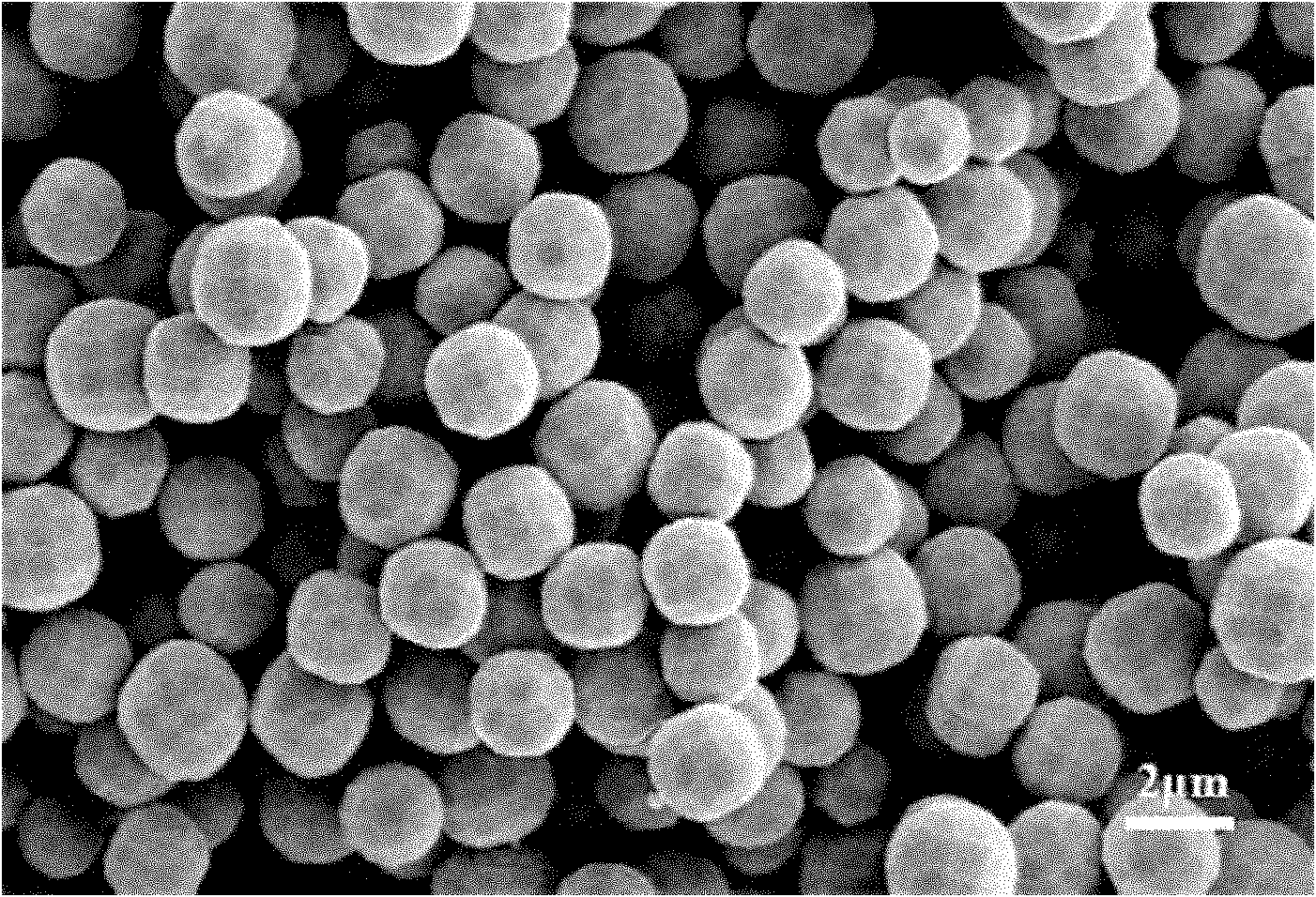

Cuprous oxide fifty-surface crystallite as well as preparation method and application thereof

ActiveCN102653412ALow costSimple post-processingMaterial nanotechnologyCopper oxides/halidesReaction temperatureSolvent

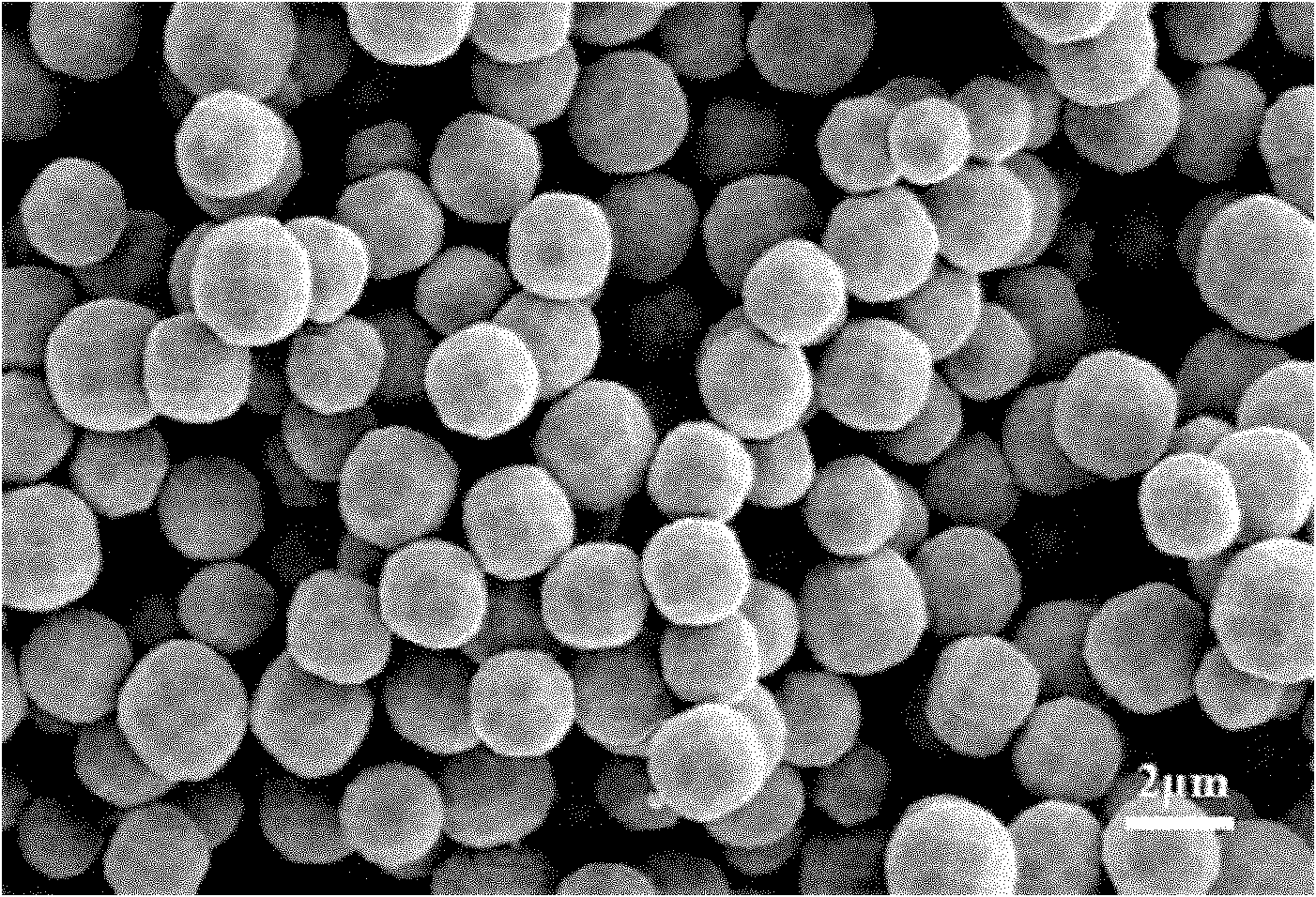

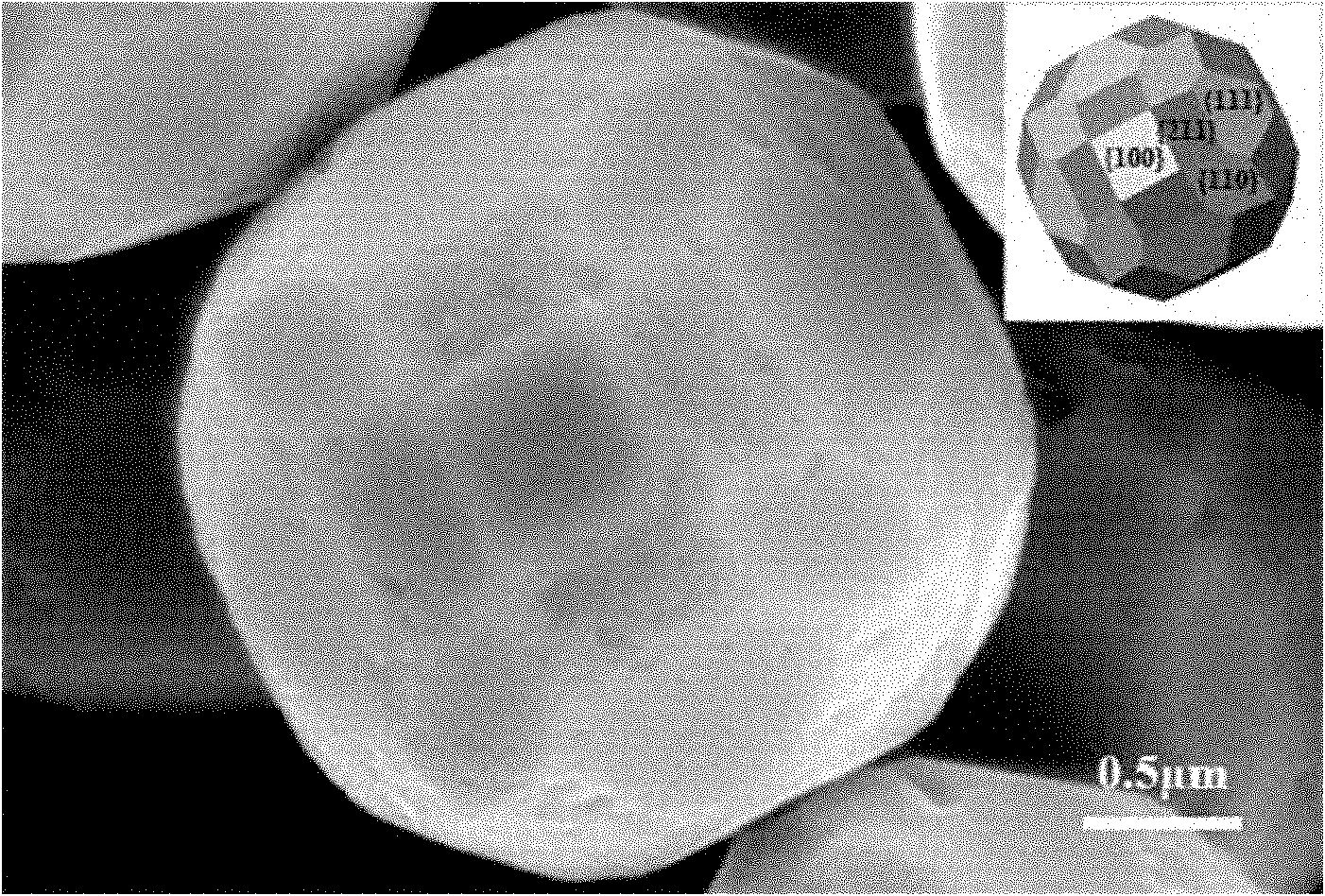

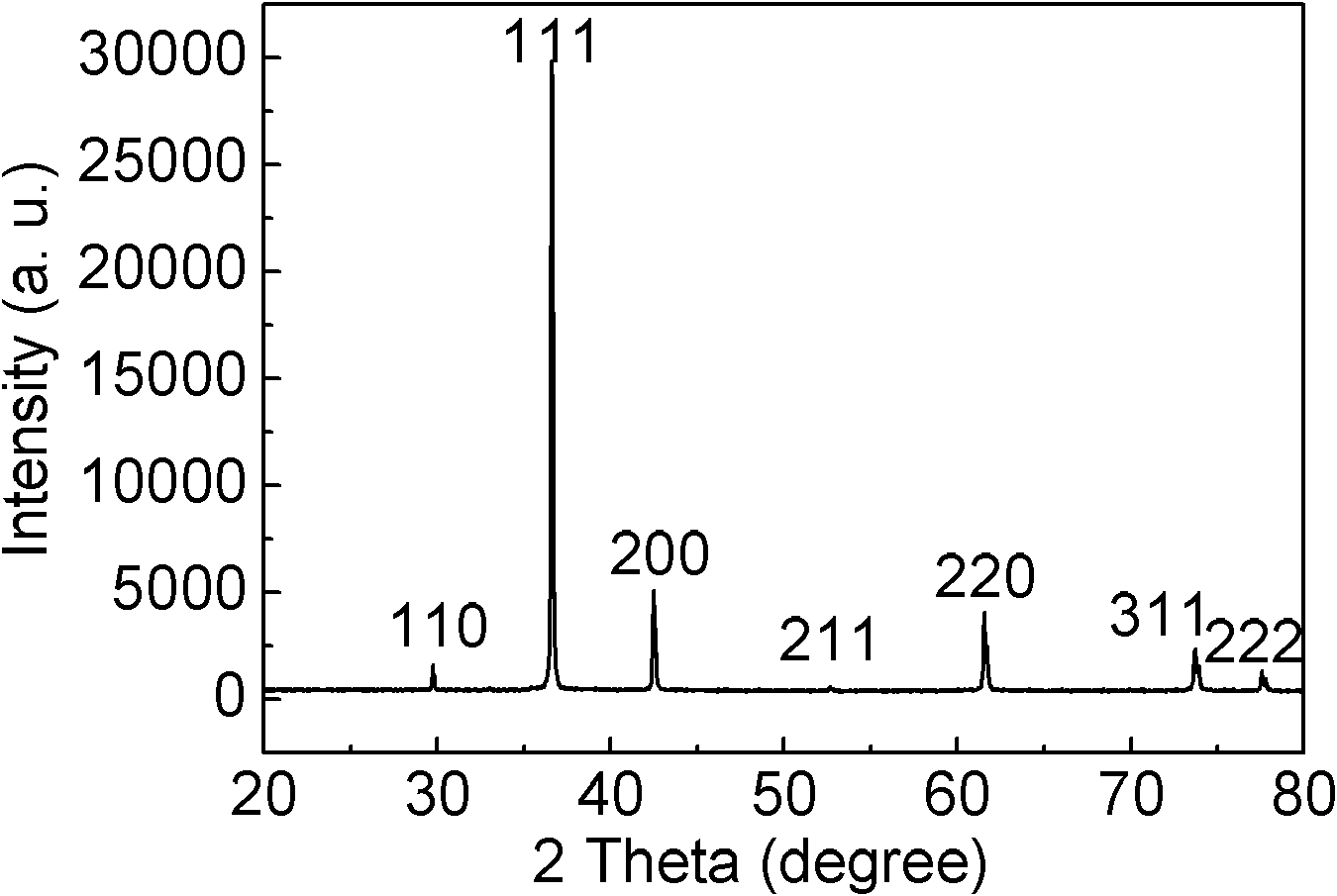

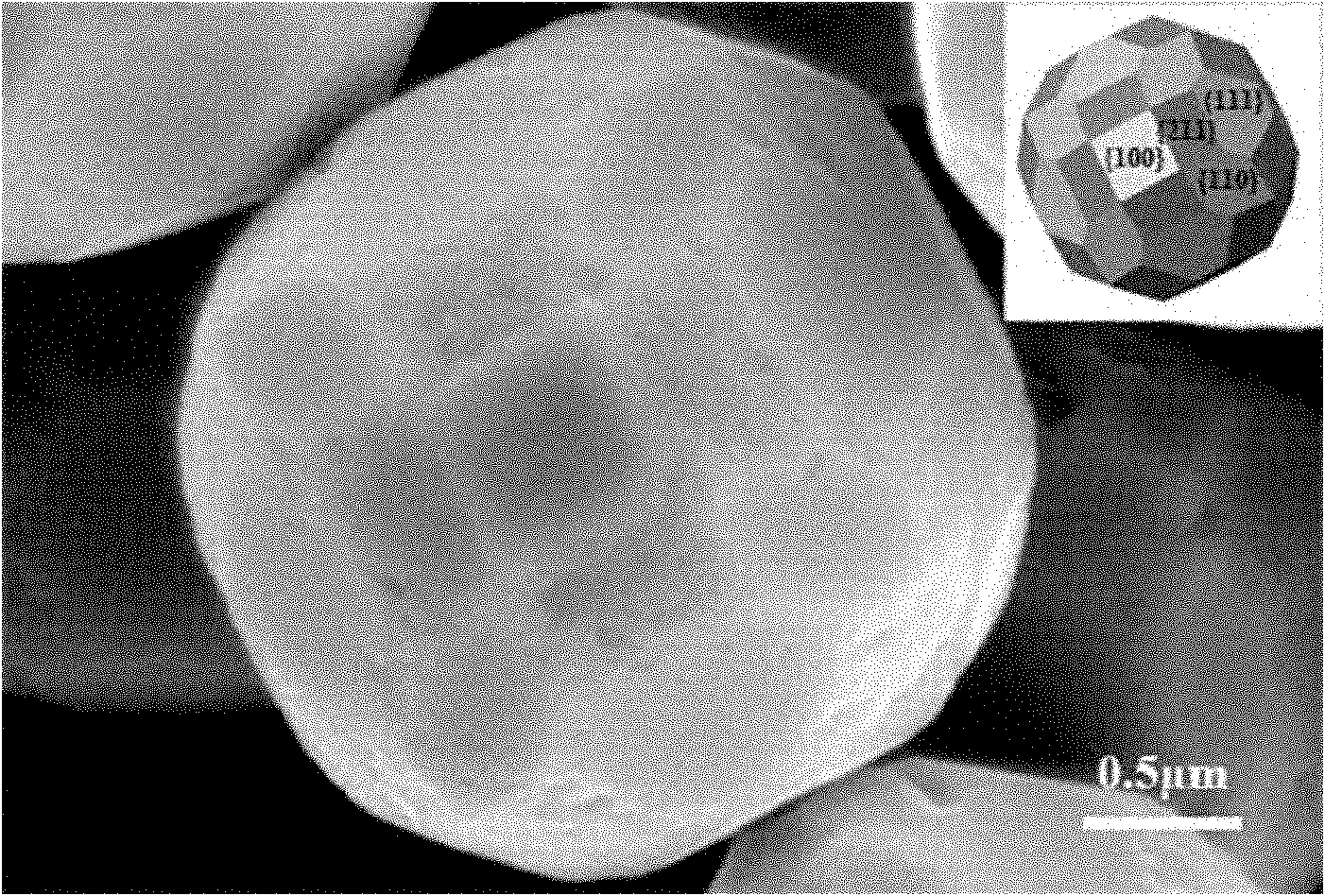

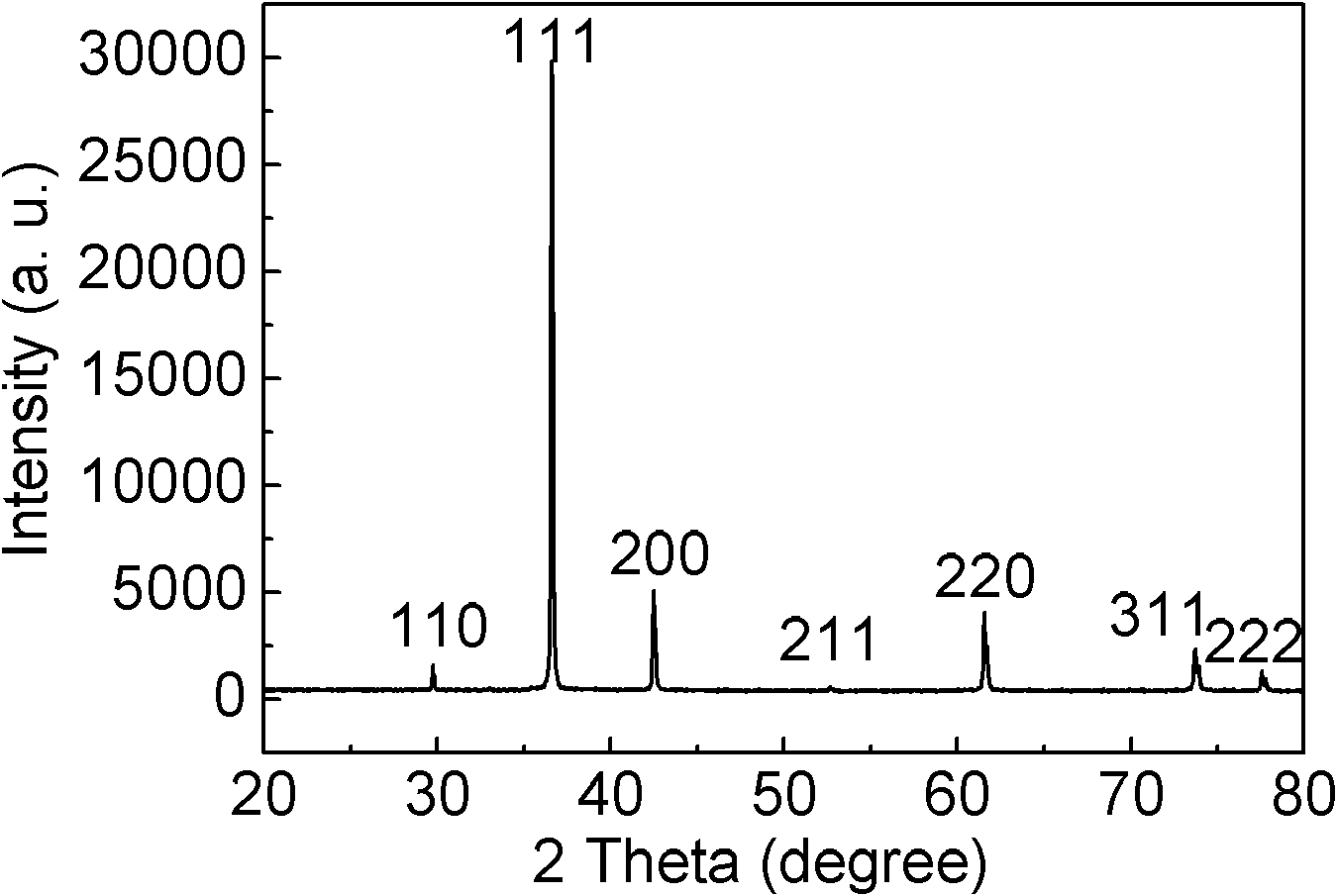

The invention discloses a cuprous oxide fifty-surface crystallite as well as a preparation method and application thereof. According to the preparation method, copper acetate monohydrate is used as a copper source, water, strong base and glucose are respectively used as a solvent, a precipitator and a reducing agent, the reaction temperature is 50-80 DEGC, and the cuprous oxide fifty-surface crystallite is obtained through an oxidation-reduction reaction. The cuprous oxide fifty-surface crystallite prepared according to the invention is formed by closing 24 high-index crystal faces ({211} crystal face or {311} crystal face), 12 {110} crystal faces, 8 {111} crystal faces and 6 {100} crystal faces, and comprises 120 ridges and 72 vertexes. The method has the advantages of gentle reaction condition, simple equipment, convenient operation, low cost, high yield, environment protection, suitability for large-scale industrial production and the like. The crystallite has excellent visible light catalytic activity, and has wide application prospect in aspects of solar batteries, hydrogen production, lithium ion batteries, biosensors and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

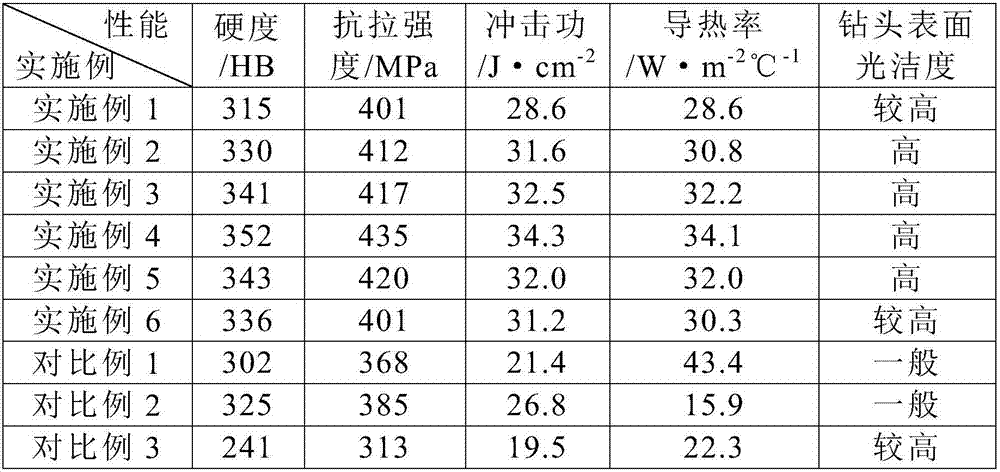

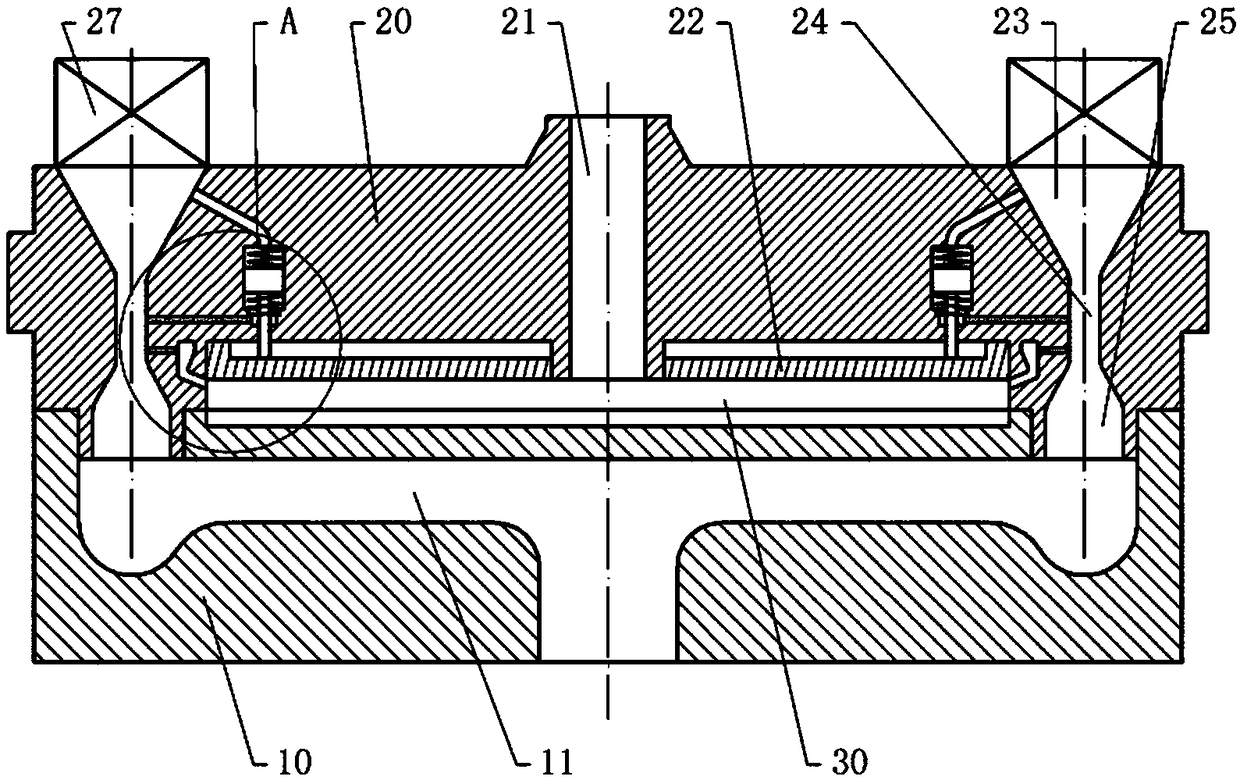

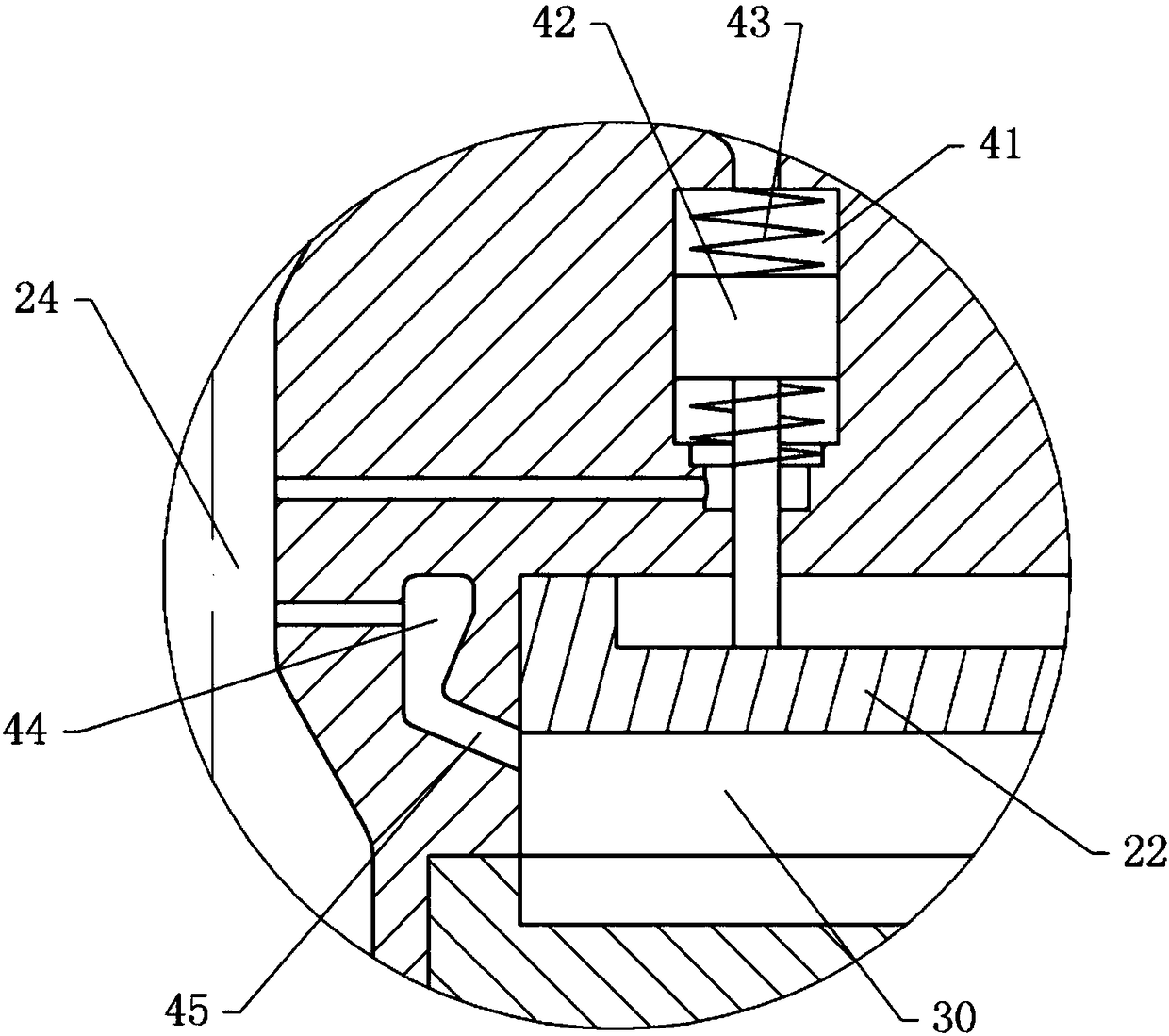

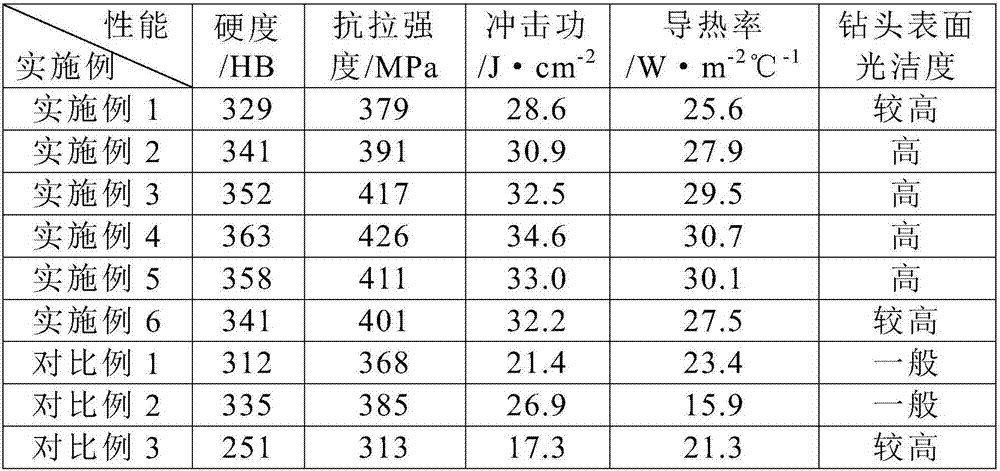

Dewaxing casting method for drill bit

InactiveCN106975729AImprove performanceReduce brittlenessFoundry mouldsFoundry coresWaxSand blasting

The invention relates to a dewaxing casting method for a drill bit and belongs to the technical field of casting. The casting method includes the steps of coating preparation, shell preparation, calcinations, melting casting and post-processing. The coating preparation includes the steps that materials are mixed, ultrasonic vibration is performed while mechanical stirring is performed for 8-15 hours, then plasma processing is performed for 3-5 minutes, and a basic coating is fabricated; and water is added to the basic coating to dilute the basic coating into a first-grade coating and a second-grade coating, and the viscosity of the first-grade coating is smaller than that of the second-grade coating. The shell preparation includes the steps that the coating is smeared on the preformed fusible wax mould surface, sand blasting and drying are performed, then dewaxing is performed, and a mould shell billet is fabricated. Smearing of the coating includes the steps of primary smearing and secondary smearing, in the primary smearing process, the first-grade coating is rotatably sprayed on the fusible wax mould surface, in the secondary smearing process, the fusible wax mould coated with the first-grade coating is soaked in the secondary coating and then taken out, and the steps of coating smearing, sand spraying and drying are repeatedly performed for 2-5 times. The drill bit prepared through the method is small in error, precise in size and smooth and clean in surface.

Owner:宁波神钻工具有限公司

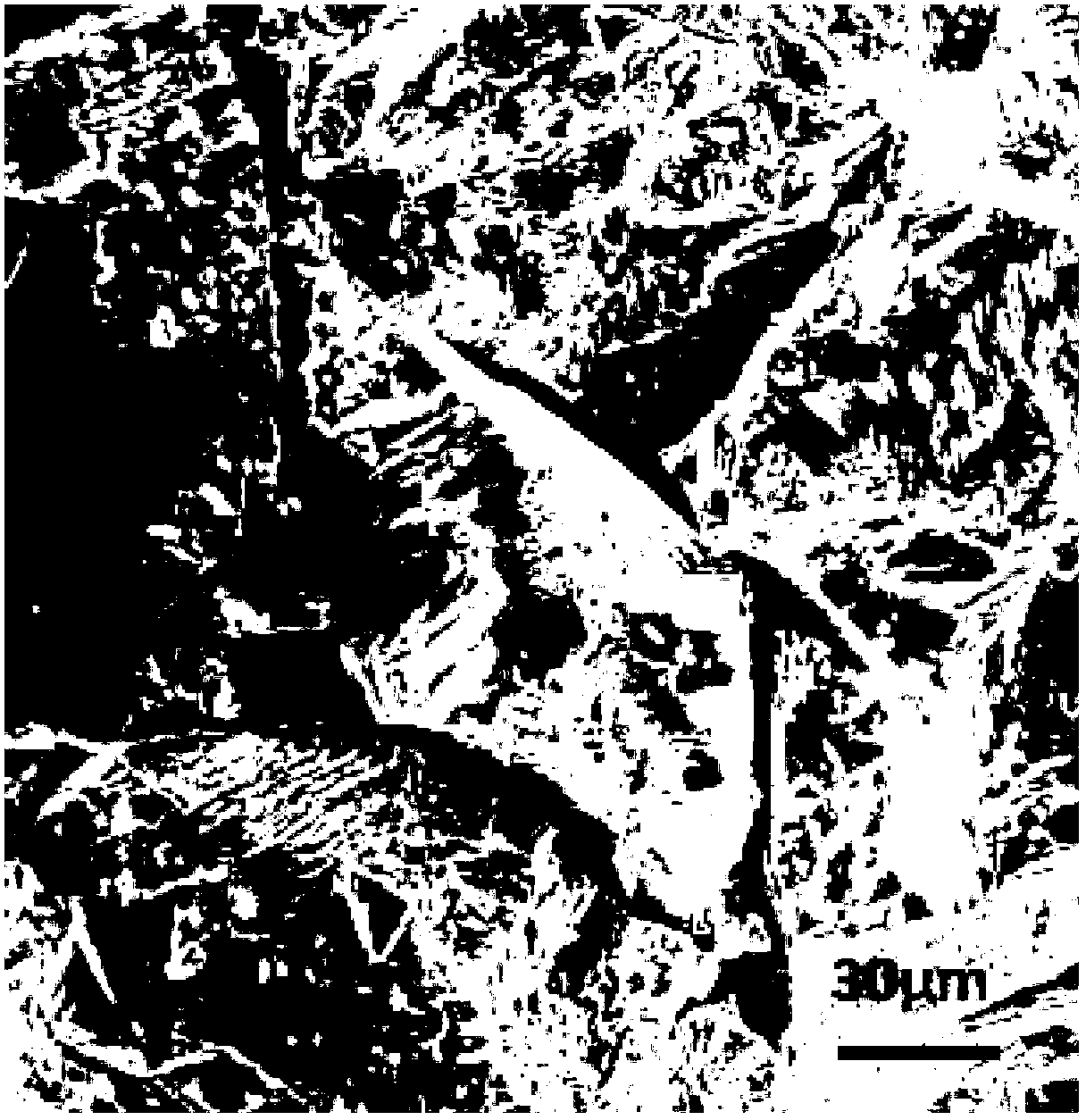

Preparation method of high-plasticity Ni-Mn-In alloy

InactiveCN103243241AIncreased compressive fracture strengthHigh strengthAlloyUltimate tensile strength

The invention discloses a preparation method of a high-plasticity Ni-Mn-In alloy, and relates to the preparation method of the alloy. The preparation method aims at solving the problem that the Ni-Mn-In alloy series is brittle. The method comprises the following steps of: firstly, weighting; secondly, smelting; and thirdly, preparing the high plasticity Ni-Mn-In alloy. Since the Co element is added, the compression fracture strength and fracture strain of the Ni-Mn-In alloy can be obviously improved, and the method is used for preparing the high-plasticity Ni-Mn-In alloy.

Owner:HARBIN INST OF TECH

Method for plating boron carbide on diamond surface

The invention discloses a method for plating boron carbide on a diamond surface. The method comprises the following steps: boriding on the diamond particle surface under the conditions that the vacuum degree is less than 100 Pascal, the temperature is preserved to 300 DEG C for 30 minutes and the temperature is preserved to 1200 DEG C for 3-12 hours, thereby plating a boron carbide film on the diamond surface. According to the diamond of which the surface is plated with the boron carbide film prepared by the invention, the binding force between a metal matrix and the diamond can be improved, the erosion resistance of the diamond to oxygen, iron, nickel and cobalt can be greatly improved, and the phenomena such as oxidation and graphitization of the diamond in the process of preparing a diamond-impregnated drill bit can be effectively avoided, so that the diamond inlaid into the metal matrix is complete in appearance, clear in edges and stable in performance. Therefore, the abrasive ratio of the manufactured appliances is greatly improved, and the service life is obviously prolonged.

Owner:JILIN UNIV

Aluminum magnesium alloy pattern ring of radial tire segmented mold

The invention relates to an aluminum magnesium alloy pattern ring of a radial tire segmented mold. The production method of the aluminum magnesium alloy pattern ring comprises the steps that the pattern ring comprises the components in percentage by weight as follows: 99.80% of pure aluminum, 0.003% of copper, 0.01% of magnesium, 0.002% of zinc, 0.003% of silicon, 0.001% of manganese and 0.001% of titanium alloy powder T15.2; a gas melting furnace is used, and pure aluminum is put into a graphite crucible for warming and melting; the temperature is raised to 950 DEG C, copper wires and a manganese agent in the proportion are put into melted pure aluminum; the temperature is lowered to 730 DEG C, magnesium, zinc, silicon, and the titanium alloy T15.2 powder in the proportion are put into an aluminum alloy; and after refining and deslagging, aluminum magnesium alloy liquid is poured into a model fitted with pattern blocks for natural solidification cooling through casting ladle pouring and gravity casting, the mold is opened, punching is performed, and the plaster model is removed, so that tire pattern blocks meeting the requirements are obtained. Compared with other commonly-used aluminum, the produced aluminum magnesium alloy pattern ring has the benefits that a novel casting tire mold pattern ring (block) aluminum material with high stability and reliability is used, the energy is saved, and the cost is reduced.

Owner:SHANDONG HENGYI MOLD

Formula of GaAs semiconductor material etching liquid

InactiveCN102627972ACorrosion rate is stableAvoid damageSurface treatment compositionsSemiconductor materialsCitric acid

The invention provides a formula of a GaAs semiconductor material etching liquid. The formula comprises: citric acid, hydrogen peroxide and deionized water. First, citric acid and deionized water are mixed according to a predetermined proportion, and then hydrogen peroxide is added and mixed uniformly. Specifically, the etching liquid is prepared by adding 1g of a citric acid crystal into 1ml of deionized water, stirring them uniformly, and then adding hydrogen peroxide with a concentration of 30%. The volume ratio of the sum of the citric acid crystal and the deionized water to the hydrogen peroxide is 66:1. The use of the citric acid formula provided in the invention can control the etching rate to a GaAs material at 2.0nm / s-2.8nm / s.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

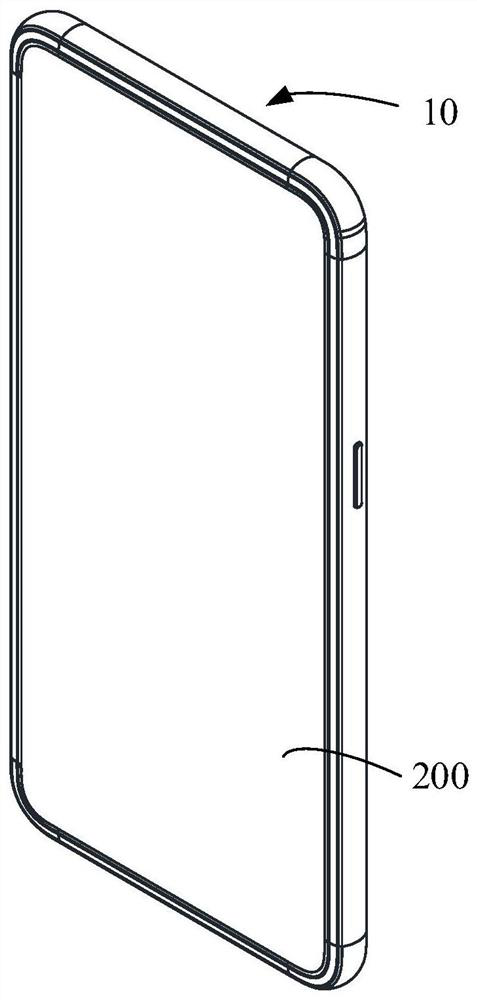

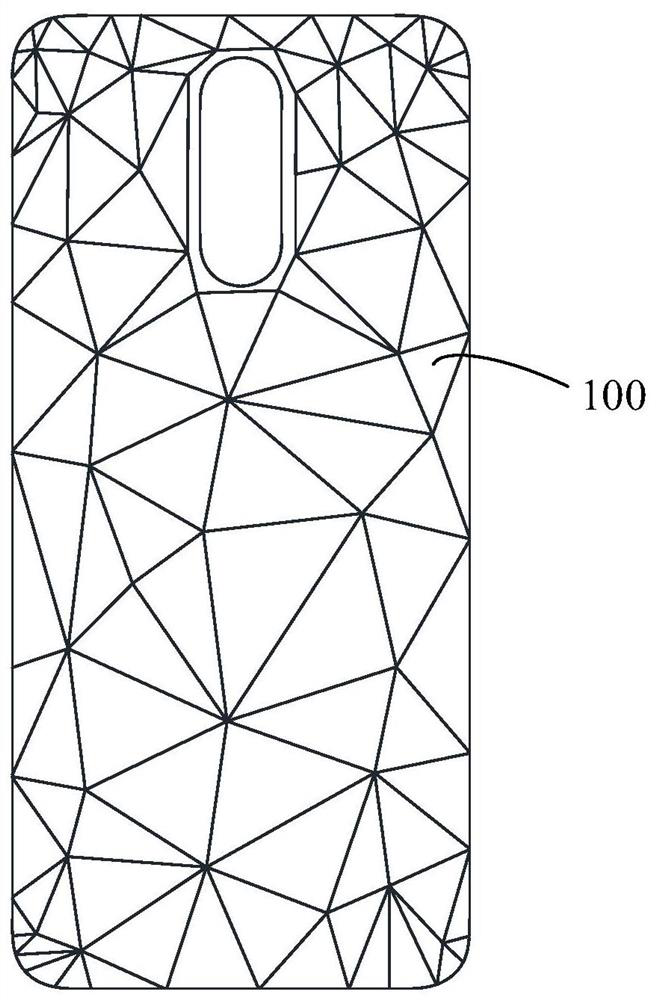

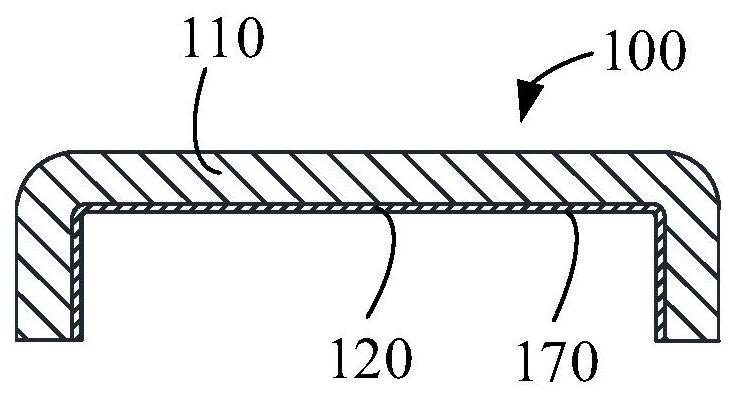

Battery cover manufacturing method and mobile terminal

ActiveCN111645383AGood lookingClear edges and cornersLayered product treatmentOrnamental structuresDiamond cuttingAdhesive

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Segmental mold aluminum-titanium-boron aluminum-magnesium alloy pattern block casting material and production method thereof

The invention relates to a segmental mold aluminum-titanium-boron aluminum-magnesium alloy pattern block casting material and a production method thereof. According to the technical scheme, the casting material is prepared from the following components in parts by weight: 99.85% of pure aluminum ingots, 0.20% of silicon, 0.10% of iron, 0.10% of copper, 0.10% of manganese, 3.80% of magnesium, 0.01% of chrome, 0.0050% of nickel, 0.0047% of zinc, 0.000108% of beryllium, 0.0032% of bismuth, 0.0108% of lithium, 0.00063% of sodium, 0.0030% of titanium alloy powder T15.2, and 0.0025% of aluminum-titanium-boron ALTi5B1. The casting material has the beneficial effects that: 1, a die casting is precise in cooling shrinkage contour curved surface and good in surface precision, and has no defects such as pinholes, shrinkage porosity, cold shut, and the like; 2, pattern edges and corners are clear, and the surface smoothness is good; 3, the casting material is corrosion-resistant, does not stick scourings, and resists blast cleaning; 4, the casting material is high in strength, good in toughness, and uneasy to have plastic deformation after being machined; 5, the casting material is wear-resistant, long in service life, and resists die opening-closing impact; and 6, an aluminum-titanium-boron aluminum-magnesium alloy is taken as an independent ingredient, the element proportioning of the alloy is accurate, and the rate of finished products is high, thereby reducing the cost spending of enterprises.

Owner:SHANDONG HENGYI MOLD

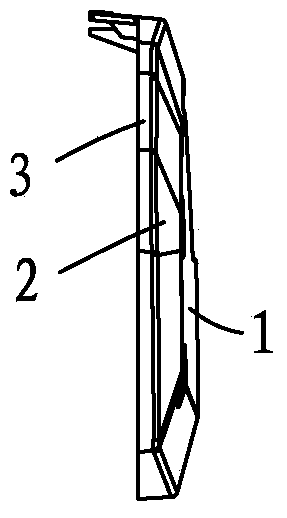

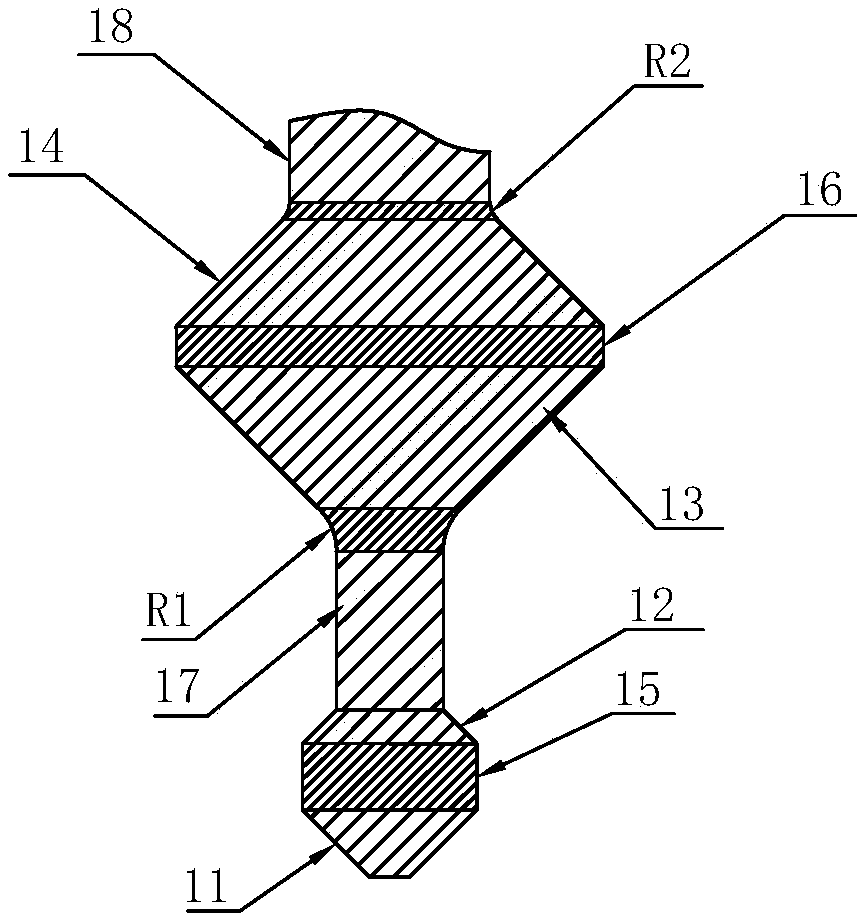

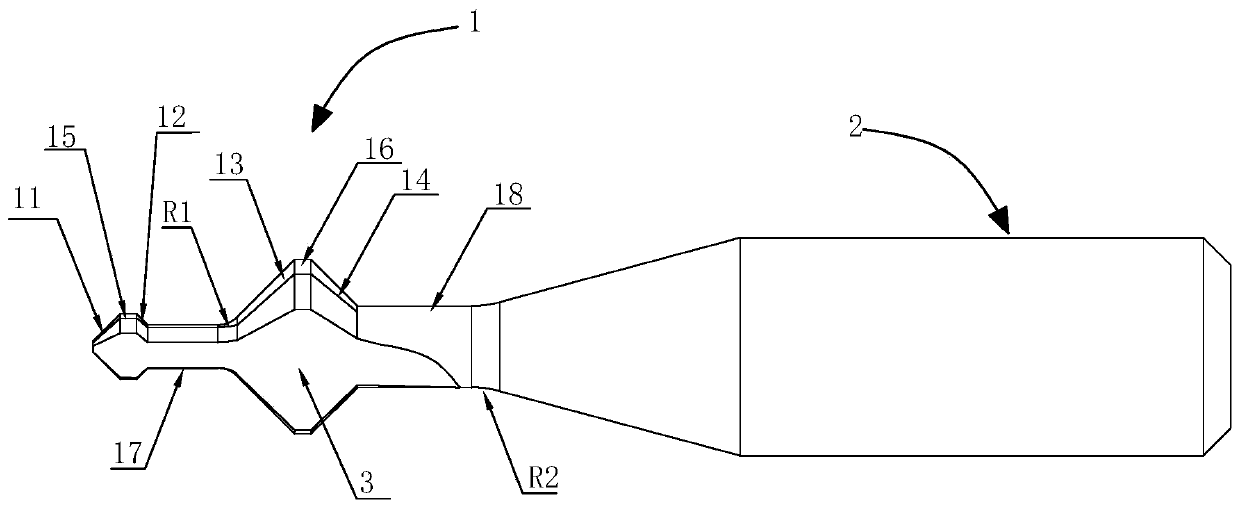

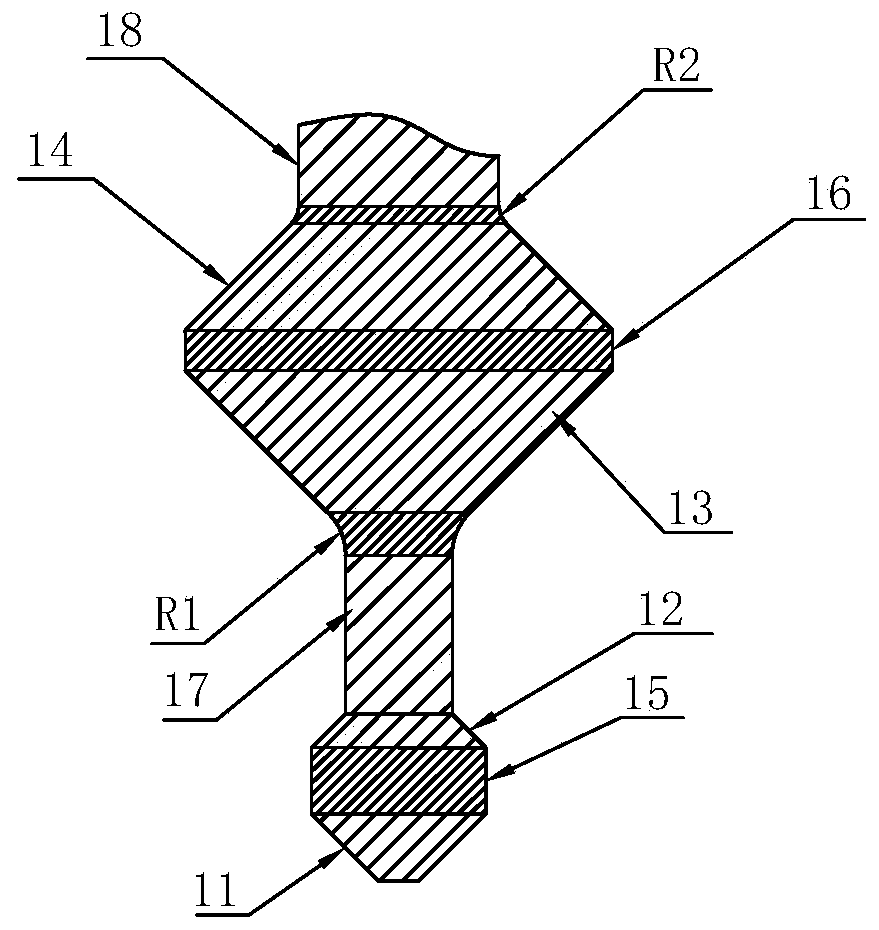

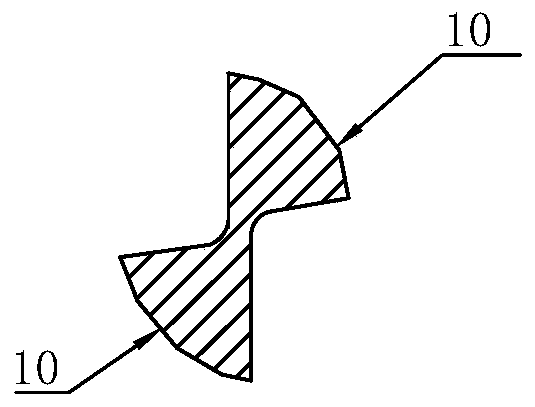

Appearance forming cutter

InactiveCN107695402ASmooth side wallsClear edges and cornersMilling cuttersKnife bladesBiomedical engineering

The present invention proposes an appearance forming knife, which includes a handle and a cutter head formed at one end of the handle in turn, the connection between the cutter head and the handle is a narrowed neck, and the cutter head includes a rake knife and the rear corner knife, and the spacer between the front corner knife and the back corner knife, the diameter of the spacer is greater than the diameter of the front end of the cutter head, and the front corner knife is from the front end of the knife head to the spacer Inclined, the rear corner knife is inclined from the spacer to the neck. The appearance forming knife proposed by the present invention is suitable for the requirement of corner clearing and finishing of parts with many chamfered edges, and the processed side wall is smooth and smooth, free of burrs, and has clear edges and corners.

Owner:ZHONGSHAN YUANFENG PRECISION CUTTING TOOL CO LTD

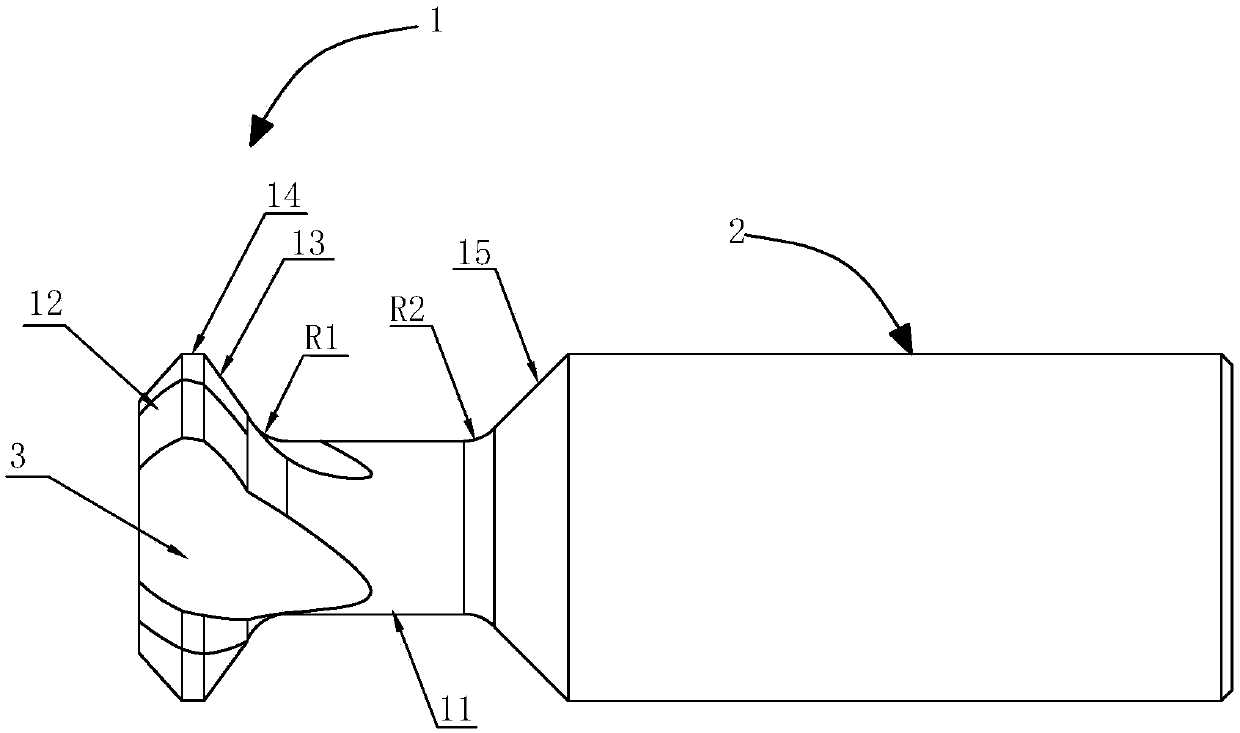

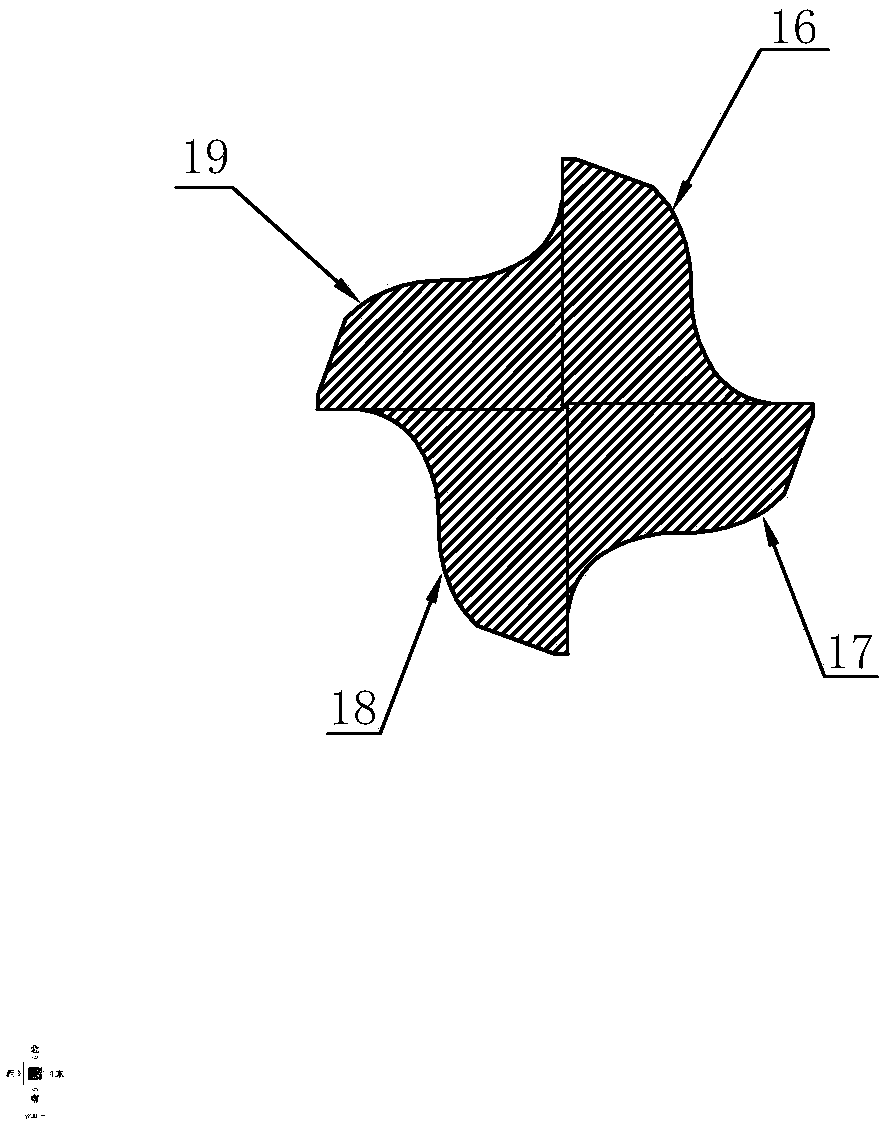

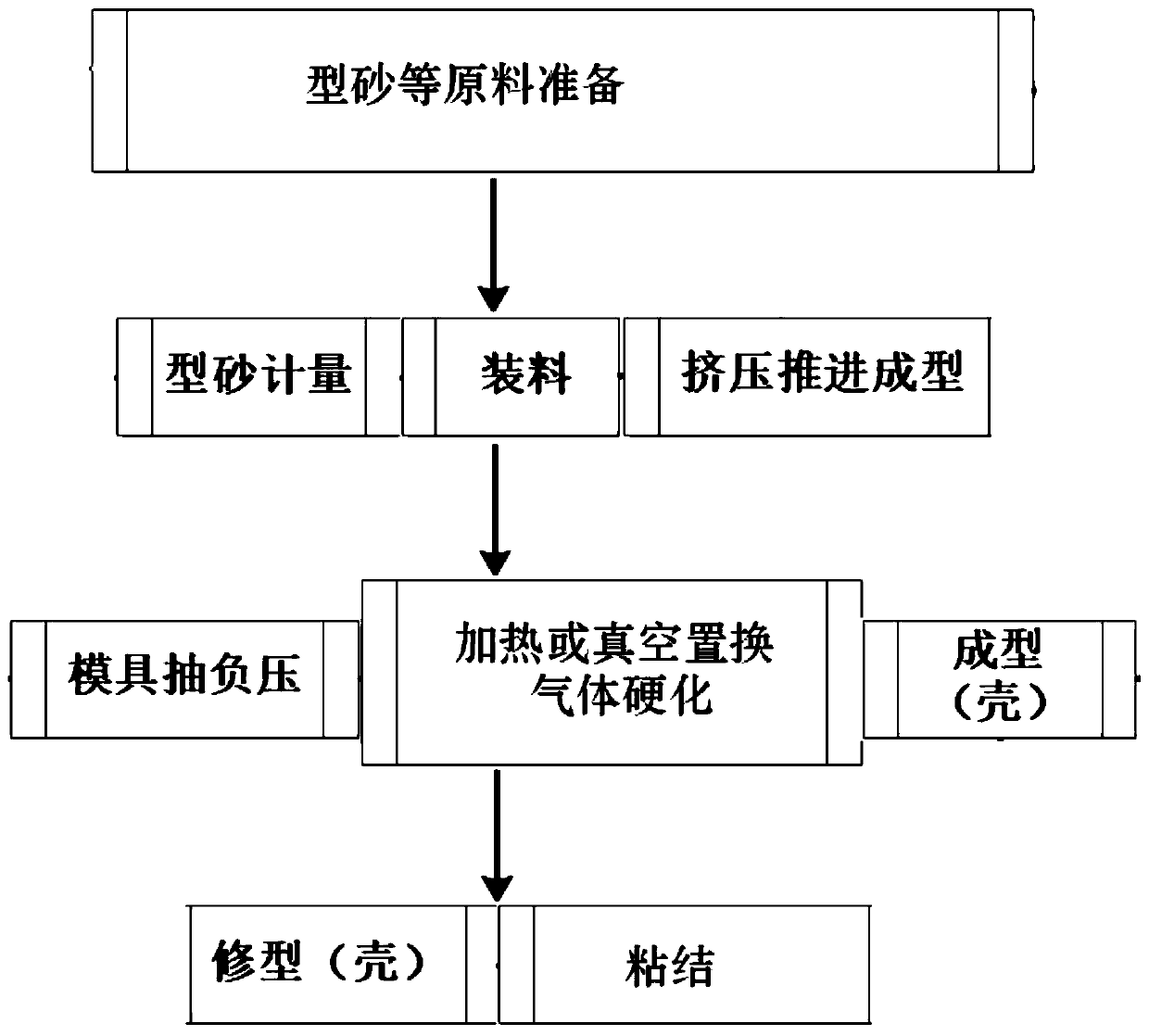

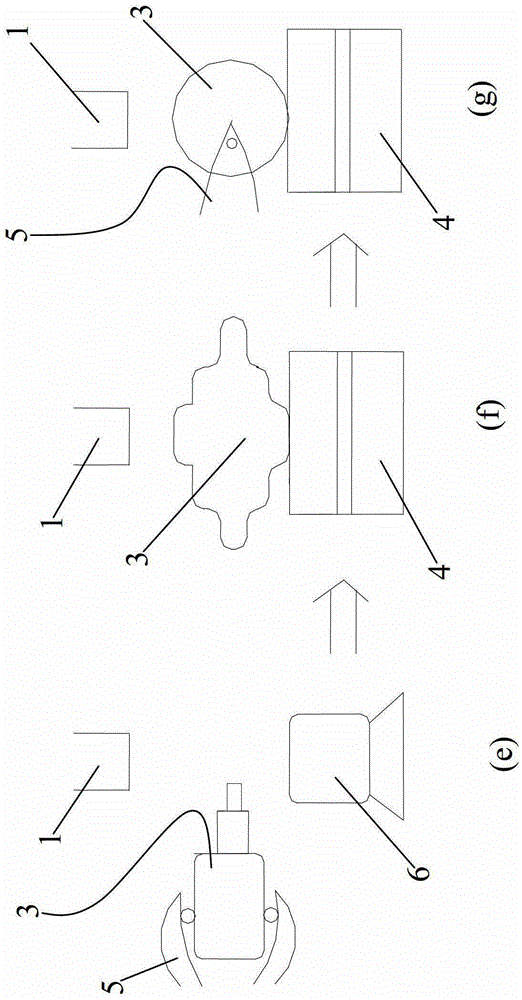

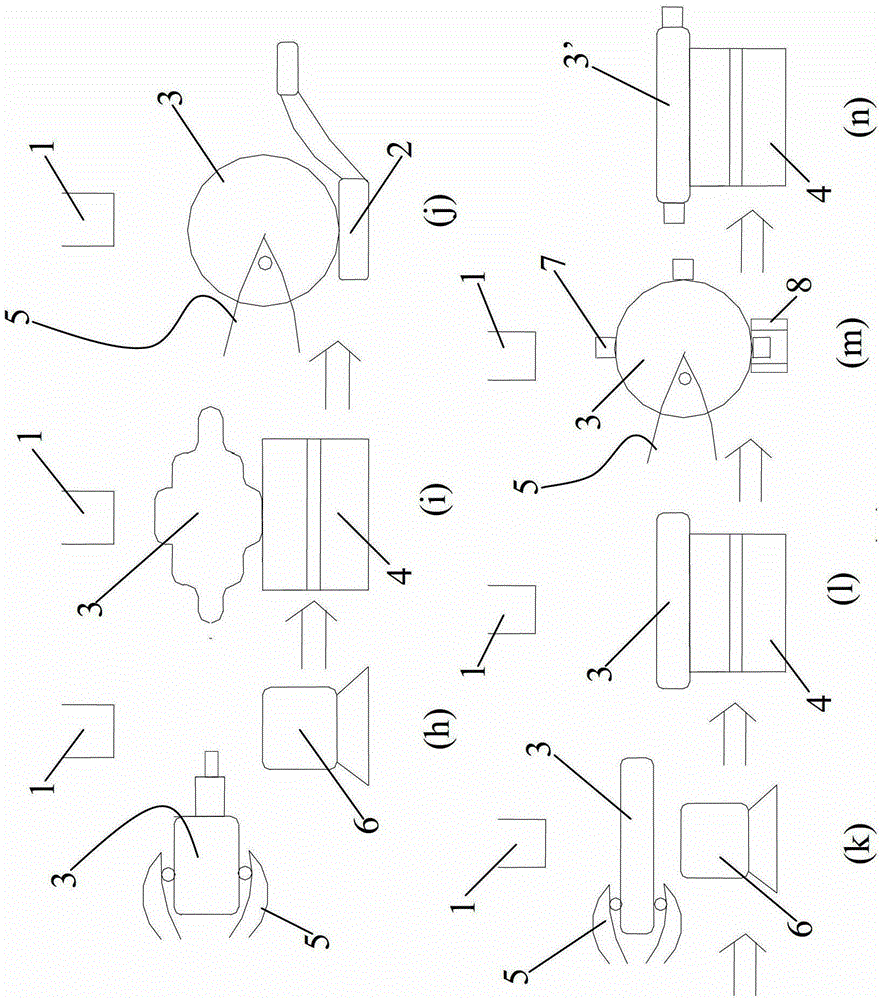

Extrusion molding process method for sand mold or shell for casting

PendingCN110860650ASimple structureImprove firmnessFoundry mouldsMoulding machinesAdhesiveCasting mold

The invention relates to an extrusion molding process method for a sand mold or a shell for casting. The method comprises the following steps of 1, preparing raw materials, wherein the raw materials comprise a casting sand mold, a surface modifying material and an adhesive; 2, metering the raw materials and adding the raw materials into a loading cylinder, and rapidly propelling and extruding theraw materials in the loading cylinder to a mold cavity through extrusion propelling forming equipment; 3, forming the mold or the shell through curing forming; and 4, bonding and assembling the formedmold or shell after the formed mold or shell is subjected to inspection and modification so that a casting mold capable of pouring can be formed. According to the method, the sand mold for casing isadopted to carry out rapid forming inside an extruding propelling mold cavity, so that the method has the advantages that the extrusion propelling forming equipment is simple structure, an air storagebag is not required, and safety and reliability can be achieved; furthermore, the propulsion forming efficiency is high, and rapid and efficient filling type compaction can be achieved; and finally,the mold (shell) is distinct in edge angles, high in compactness and good in dimensional stability.

Owner:王海江

Stainless steel ground spring door or show window section bar and production method thereof

InactiveCN101089352AHigh strengthSave materialWing framesMetal rolling arrangementsMaterials scienceSurface finishing

The present invention relates to a stainless steel section material for making spring door or show-window. Said section material is characterized by that the side edge of said section material can be made into the concavo-convex form through a certain production process. Said production process includes the following steps: annealing stainless steel coiled material, spreading said coiled material, cutting, rolling and forming, surface treatment, sticking protective film on its surface and packaging.

Owner:顾为民

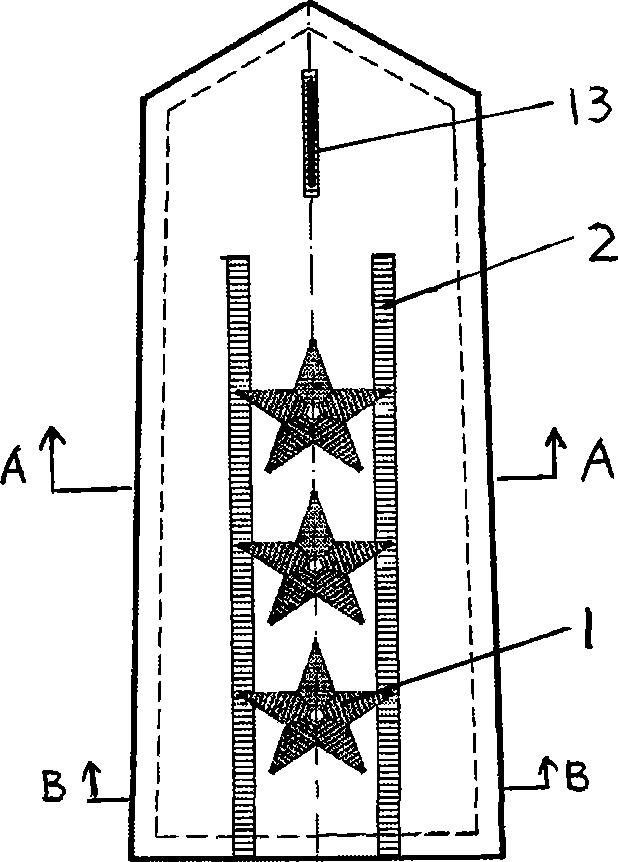

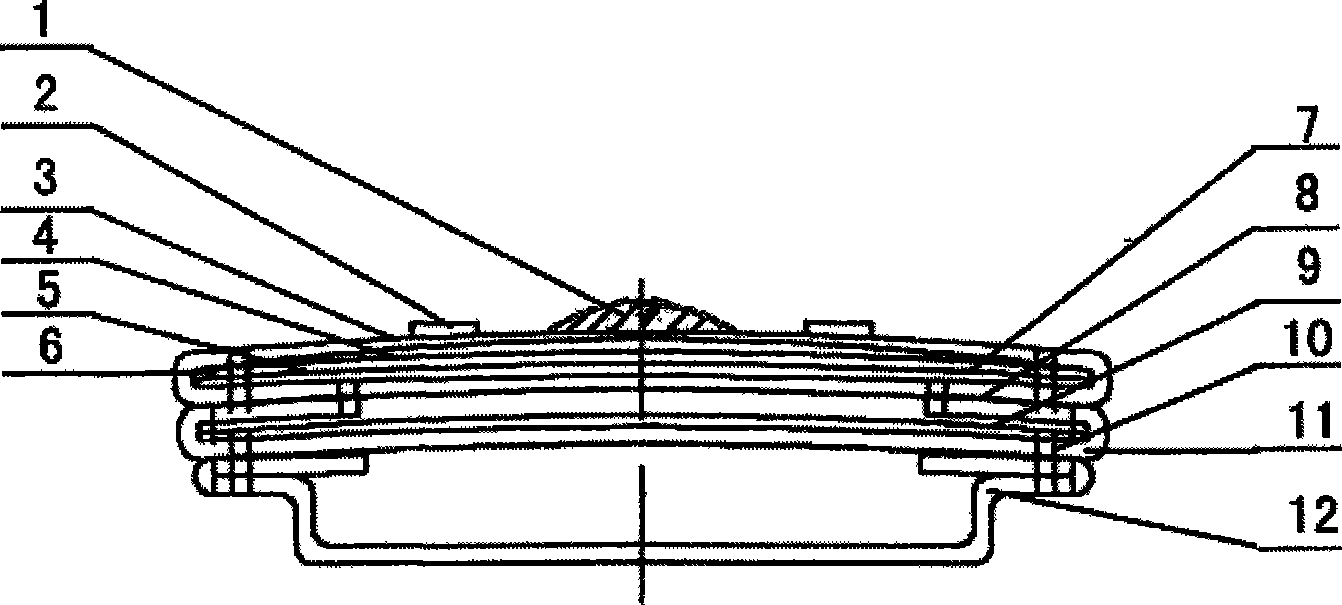

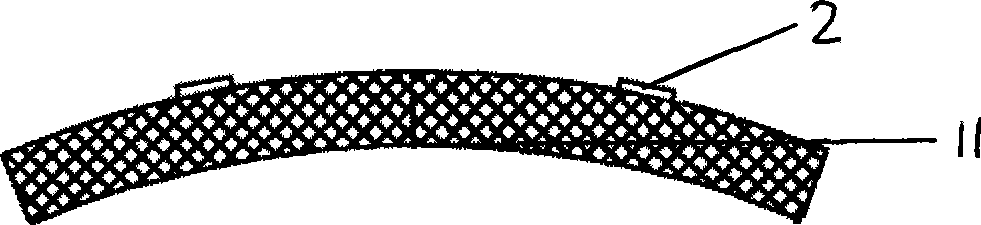

Arc non-delaminating shoulder board and brassard, and preparation method thereof

The invention discloses an arc shaped non-delaminating epaulet and an arc shaped non-delaminating armband as well as a production method thereof, which belong to the field of clothing accessories. The epaulet comprises a shoulder badge and grade strips which are arranged on the surface of an epaulet plate, a belt loop arranged on the rear side of the epaulet plate, and a locking hole with an opening, wherein the shoulder badge and the grade strips are all protruded out of the epaulet plate, and the epaulet plate has uniform and upward radin, and is produced by a composite surface layer, a lining board, and a composite bottom layer which are adhered through hot melt glue sheets and then are sewn and shaped; the armband comprises a body, a pattern layer on the surface, a terylene tape on the bottom surface, and a nylon yarn buckle tape, and the body of the armband has uniform and upward radin, and is produced by a surface layer, an intermediate thermoplastic rubber lining, and a bottom layer which are adhered through the hot melt glue sheets and then are sewn and shaped. The epaulet and the armband are produced by the instantaneous heat setting at a temperature of between 110 and 130 DEG C and the instantaneous cold forming at a temperature below 25 DEG C. The epaulet and the armband have the advantages of shape-keeping whole shape, clear edges and corners, regular molding, neat appearance, close attachment of various layers of materials, no bubbling, no delamination, and no deformation after washing for 20 times.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

High-precision casting die

Owner:CHANGSHU HONGQIAO CAST STEEL CO LTD

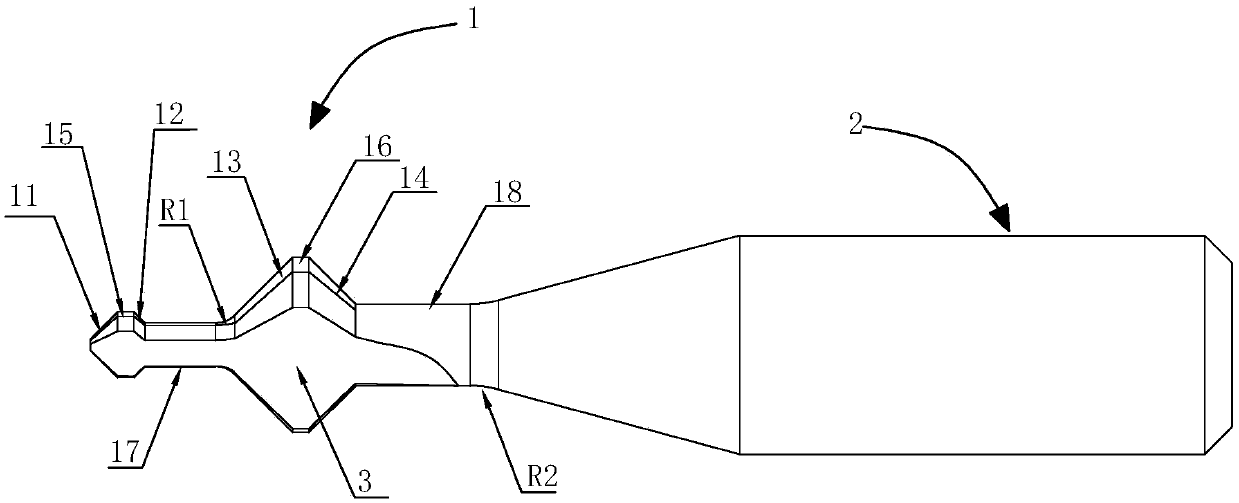

Method for casting high-precision drill

ActiveCN106984772AClear edges and cornersHigh dimensional accuracyFoundry mouldsFoundry coresWaxAfter treatment

The invention relates to a method for casting a high-precision drill and belongs to the technical field of casting. The method comprises the steps of shell making, roasting, melting casting and after-treatment, wherein the shell making step comprises the following sub-steps: coating the surface of a preformed fusible wax pattern with a coating, performing sand blasting and drying, and after that, performing dewaxing to manufacture a shell blank; the coating sub-step comprises first-time coating and second-time coating; during the first-time coating, a primary coating is rotationally sprayed onto the surface of the fusible wax pattern; during the second-time coating, the fusible wax pattern coated with the primary coating is immersed into a secondary coating and then taken out; the viscosity of the primary coating is smaller than that of the secondary coating; and the coating, sand blasting and drying substeps are repeated for 2-5 times. The manufactured drill is small in error, precise in dimension and smooth in surface.

Owner:宁波神钻工具有限公司

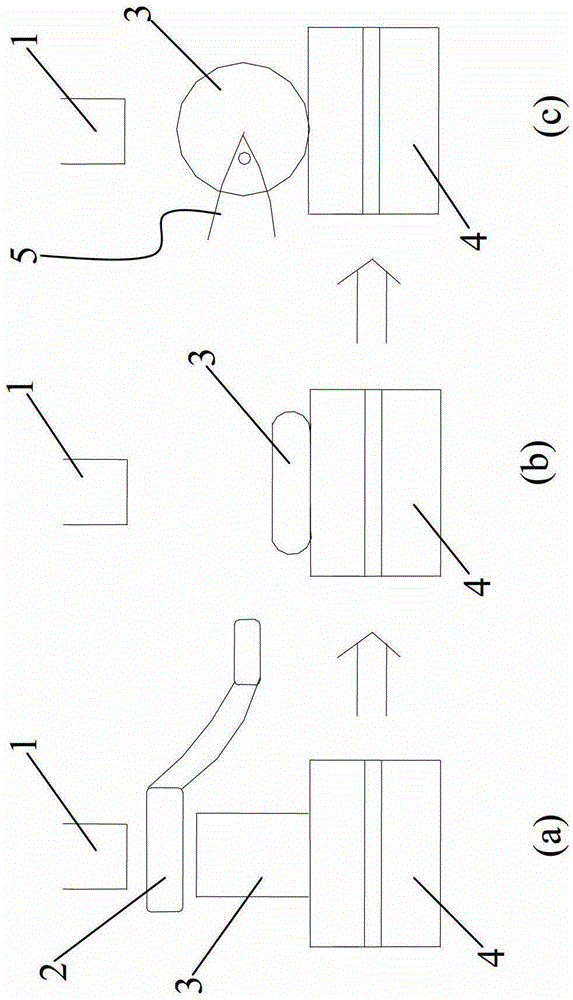

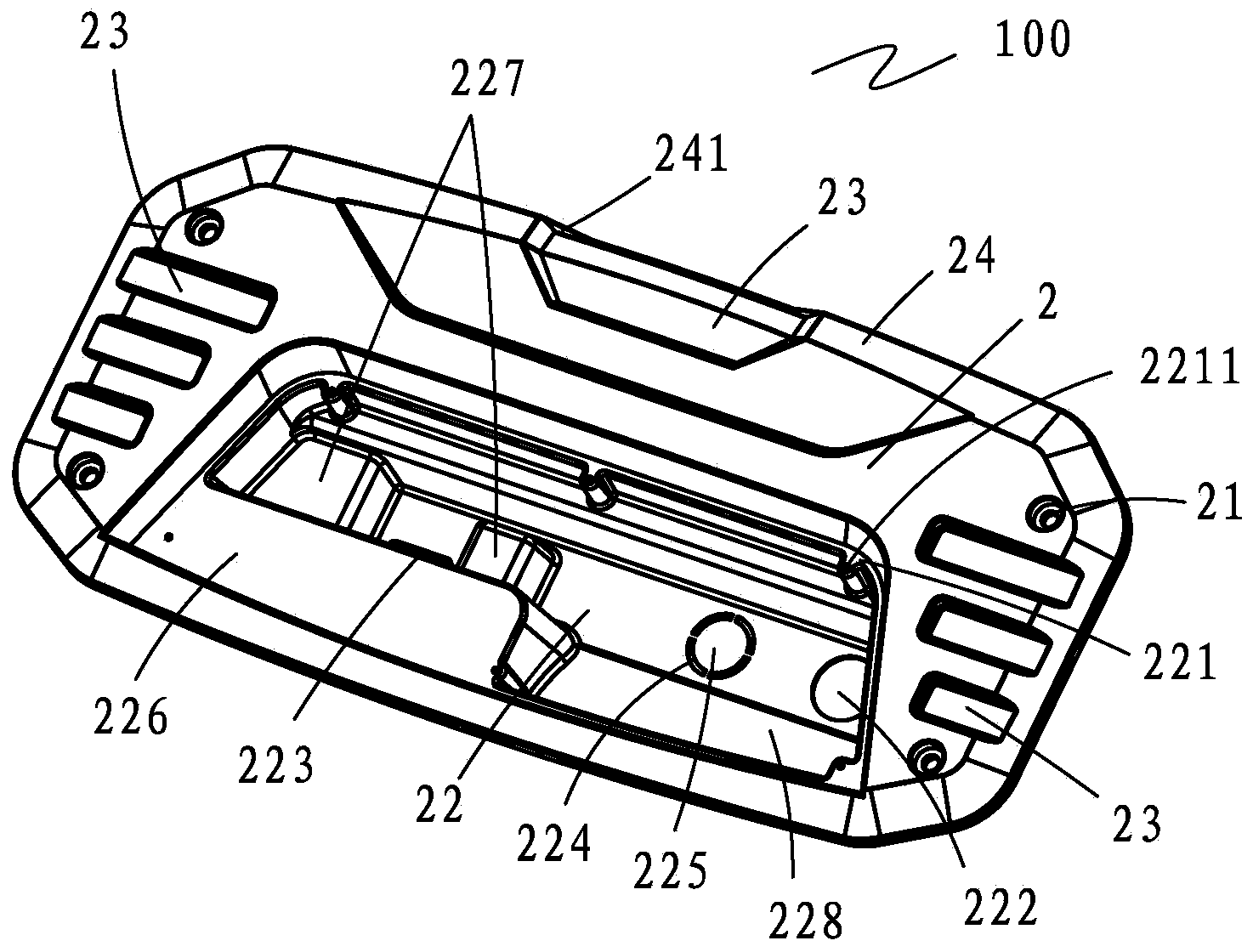

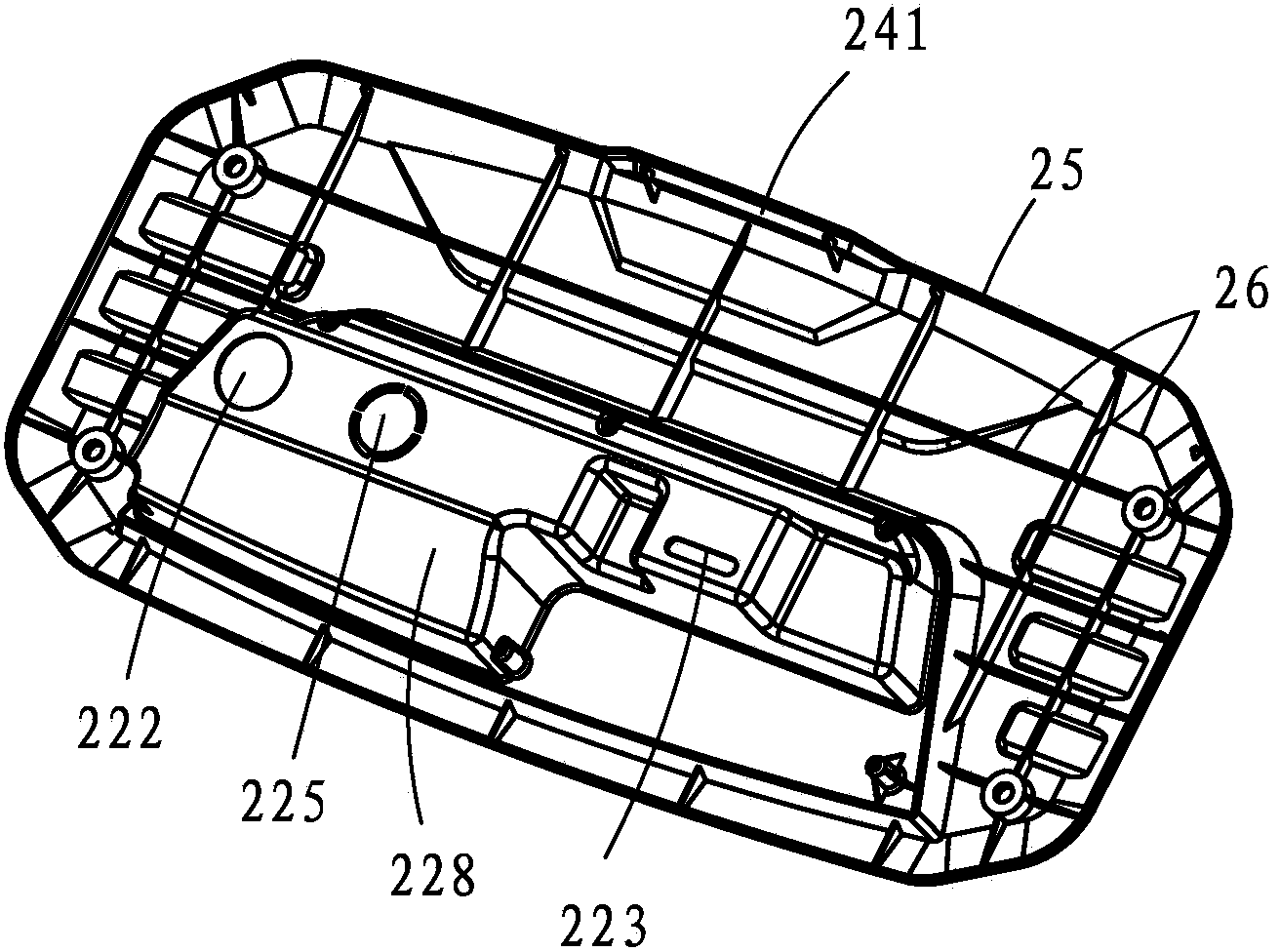

Back decorative plate of generating set

ActiveCN104295372AEasy to operateEasy maintenanceMachines/enginesEngine componentsComputer engineeringGenerating unit

Owner:FUJIAN EVERSTRONG LEGA POWER EQUIP CO LTD

Combined auto parts injection mold

The invention relates to an injection mold and specifically discloses a combined auto parts injection mold, which comprises a base equipped with a cavity. A male die and a female die are successivelyarranged from top to bottom inside the cavity. The bottom of the cavity is provided with a limited pillar. The sidewall of the base is provided with a location hole. By inserting a positioning pin into the location hole, the male die can be fixed in the cavity. A boiling water tank is arranged below the female die. Left and right sides of the female die are provided with valve cores which are slidingly connected to the base. The female die is equipped with spacing grooves for the valve cores being inserted therein. When the female die falls on the limited pillar, there is an excess material gap between the male die and the female die. When the valve cores are inserted in the spacing grooves, the male die and the female die cooperate to form an enclosed mold cavity. The top of the base is provided with a cover plate for sealing the cavity. A water chamber is arranged between the cover plate and the male die. The base is provided with a water inlet, and the cover plate is provided with awater outlet. When the valve cores are inserted in the spacing grooves, the water inlet, the water boiling tank, the water chamber and the water outlet are communicated. The mold of the invention ishelpful for letting plastic enter the narrow gap of the mold cavity so as to endow a workpiece with clear edges and corners.

Owner:CHONGQING YINSHENG MOLD

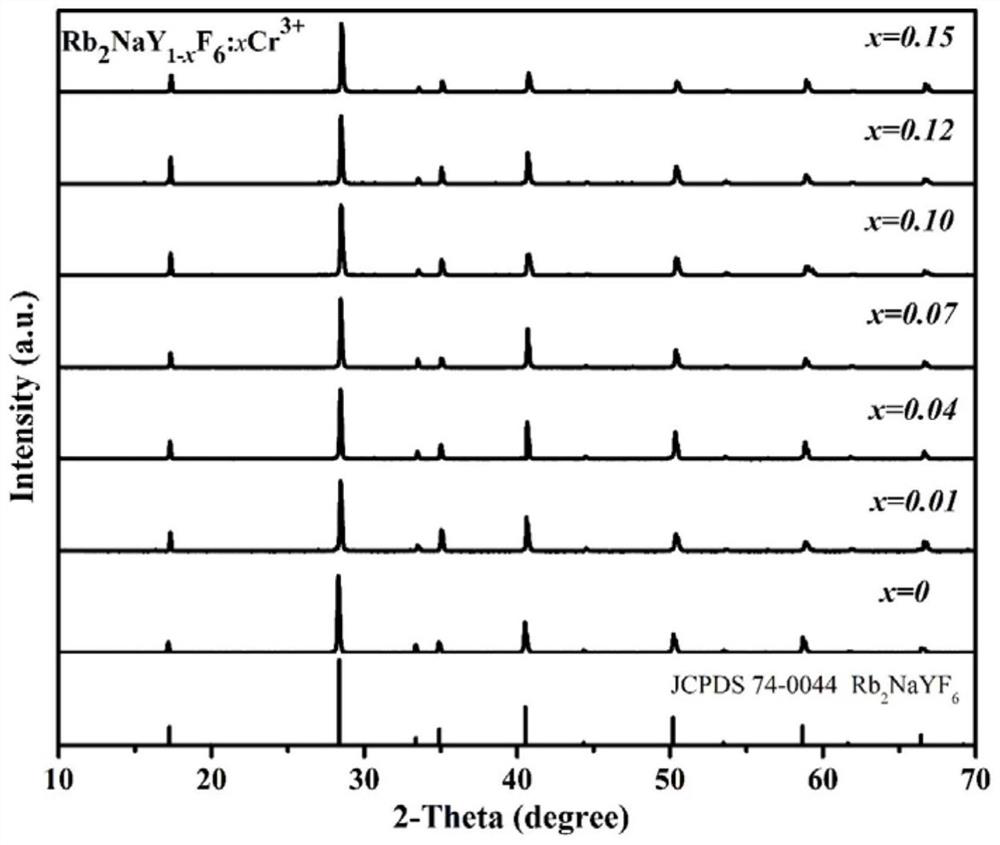

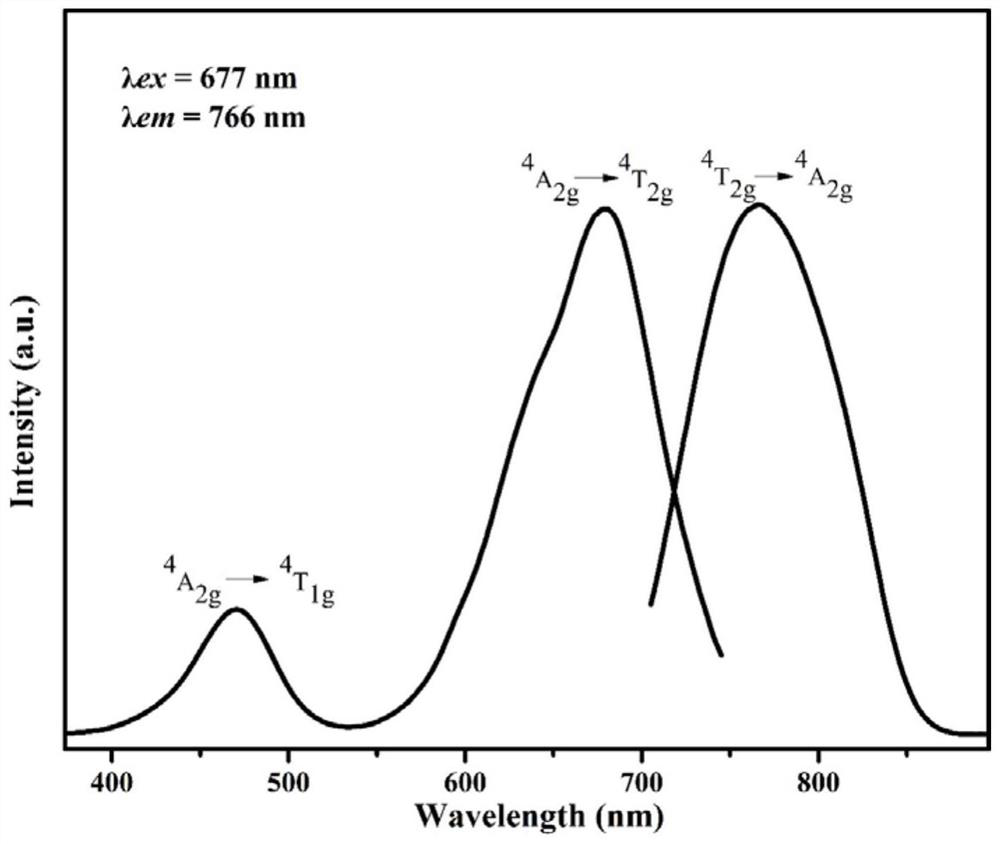

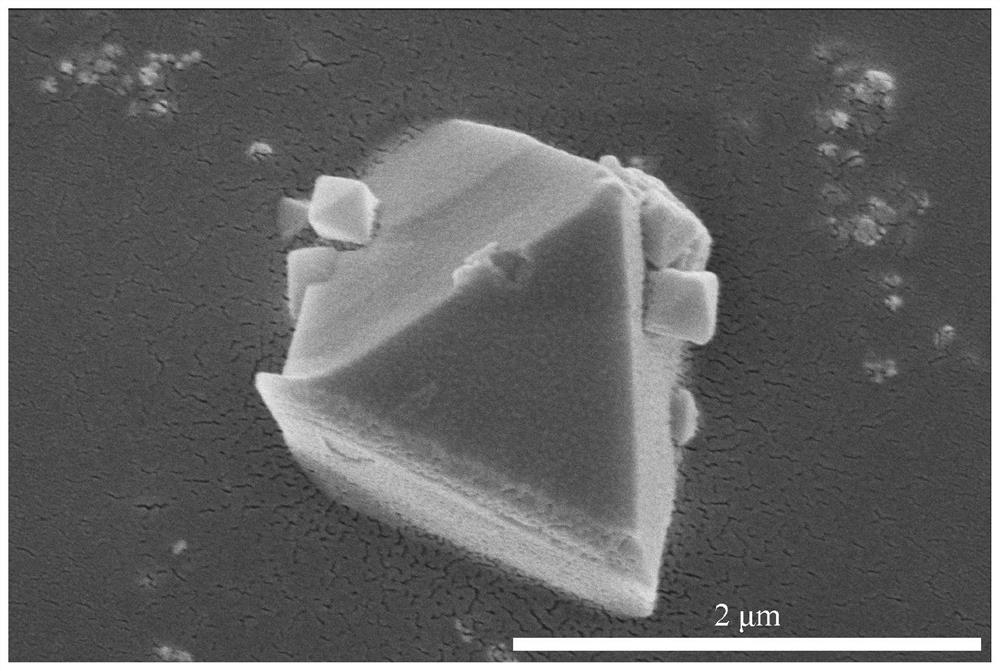

Double-perovskite type near-infrared luminescent material and preparation method thereof

PendingCN114196404AUniform particlesClear edges and cornersLuminescent compositionsNear infrared luminescenceChromic Ion

The invention discloses a double perovskite type near-infrared luminescent material, the chemical composition is Rb2NaY (1-x) F6: xCr < 3 + >, x is the mole percentage coefficient of doped chromium ions relative to yttrium ions, and 0 lt; x is greater than or equal to 0.15; the preparation method comprises the following steps: (1) weighing 80-85 parts of rubidium fluoride, 15-20 parts of sodium fluoride, 55-40 parts of yttrium fluoride and 0-6 parts of chromium fluoride; (2) adding the weighed rubidium fluoride, sodium fluoride, yttrium fluoride and chromium fluoride into a mortar, and grinding for more than 30 minutes to fully and uniformly mix the raw materials; and (3) putting the ground raw materials into a tubular furnace, and reacting at the high temperature of 650-700 DEG C for 8-10 hours to obtain the product. The luminescent material capable of emitting near-infrared light is prepared by taking positive trivalent transition metal Cr < 3 + > as doping ions and double perovskite fluoride as a matrix.

Owner:YUNNAN MINZU UNIV

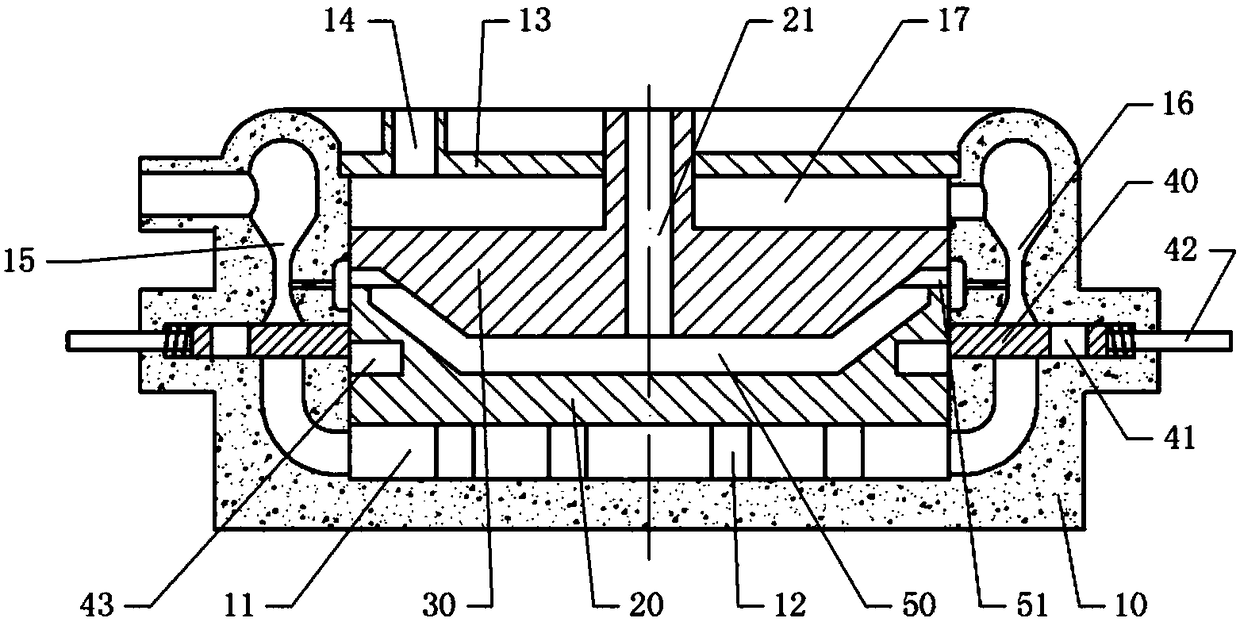

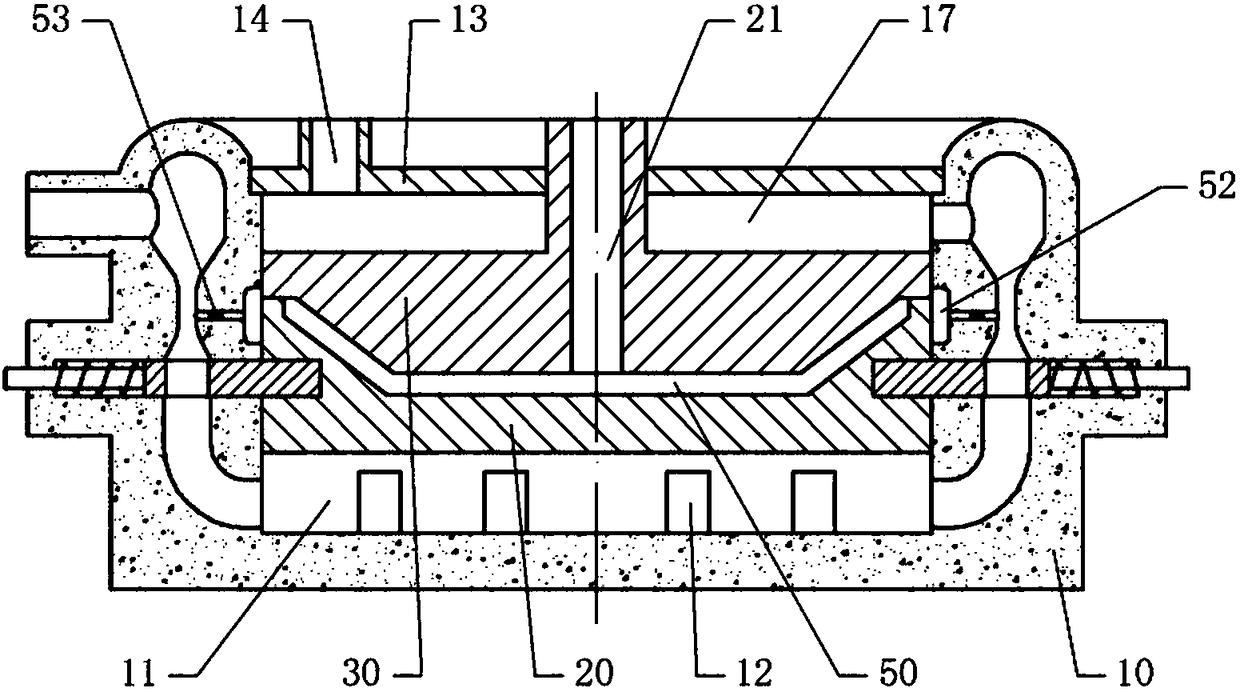

Injection molding method for plate grids

InactiveCN108453995AEasy accessIntegrity guaranteedElectrode carriers/collectorsCooling channelEngineering

The invention relates to the technical field of battery processing, and particularly discloses an injection molding method for plate grids. The method comprises the following steps that 1, the side wall of a die cavity is cleaned, and an upper die and a lower die are combined to form the complete die cavity; 2, a pump body and the entrance section are disconnected, and a water flow cooling channeland a vacuum pump are connected; 3, materials are injected into the die cavity, and meanwhile a jet channel is vacuumized; 4, the pump body and the entrance section are connected, cooling water is introduced into the water flow cooling channel continuously till a plate grid inside the die cavity is cooled and molded, the pump body is turned off, and water injection into the water flow cooling channel is stopped; 5, the upper die and the lower die are disassembled, and the mold plate grid is taken out from the die cavity. According to the injection molding method, when materials are injected into the die cavity, the space of the die cavity is larger than the space, formed when cooling water is injected, of the die cavity, the purpose that materials are extruded when the die cavity is decreased after materials are injected into the die cavity, and materials can enter the small interval so that the molded plate grid can have the clear corner angles.

Owner:GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

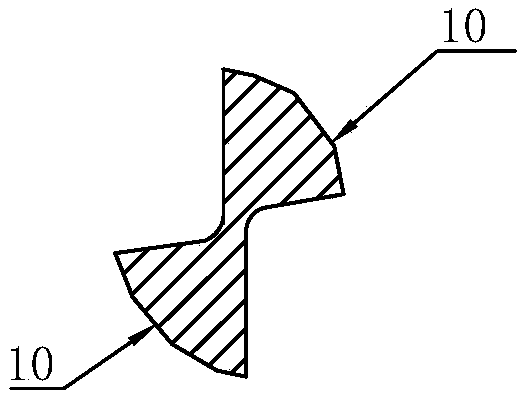

Molding knife for highlight machine

ActiveCN107695404AClear edges and cornersImprove connection strengthMilling cuttersEngineeringKnife handles

The invention discloses a molding knife for a highlight machine. The molding knife comprises a knife handle and a cutting head formed at one end of the knife handle, wherein the cutting head comprisesa first front angle knife, a first rear angle knife, a second front angle knife and a second rear angle knife, wherein a first separation part is arranged between the first front angle knife and thefirst rear angle knife, a second separation part is arranged between the second front angle knife and the second rear angle knife, a narrowed first connecting part is arranged between the first rear angle knife and the second front angle knife, a narrowed second connecting part is arranged between the second rear angle knife and the first knife handle, the first front angle knife inclines towardsthe first separation part through the front end surface of the cutting head, and the first rear angle knife inclines towards the first connecting part through the first separation part; and the secondfront angle knife inclines towards the second separation part through the front connecting part, and the second rear angle knife inclines towards the second connecting part through the second separation part. By virtue of the common effect of multiple angle-cleaning cutting knives, the molding knife can meet the angle-cleaning requirements of multi-chamfer parts and can be used for carving relatively stereoscopic and resplendent patterns, the machined side wall is smooth, fluent and burr-free, and corner angles are clear.

Owner:ZHONGSHAN YUANFENG PRECISION CUTTING TOOL CO LTD

An alkali-free high-strength concrete accelerator

InactiveCN105753364BImprove performanceGood hygroscopicitySolid waste managementHigh strength concreteSodium Bentonite

The invention discloses an alkali-free high-strength concrete flash setting admixture.The flash setting admixture comprises, by weight, 11%-20% of Portland cement, 13%-19% of aluminum oxygen chamotte, 5%-11% of naphthalenesulfonic acid-formaldehyde condensate, 6%-12% of bentonite, 15%-21% of coal ash, 5%-11% of gypsum, 1%-7% of zinc sulfate, 1%-2% of sodium aluminate, 2%-8% of sodium carbonate, 4%-10% of hydroxypropyl methyl cellulose and 6%-12% of silica fume.The alkali-free high-strength concrete flash setting admixture has the advantages that the flash setting admixture is short in setting time and capable of promoting concrete to set primarily within 3 minutes and set finally within 8 minutes and can have strength after 0.8 hour, later strength develops slowly, and both early strength and later strength are high; the concrete is excellent in homogeneity, high in anti-penetrability performance, little in dust and small in rebound quantity; the alkali-free chloride-free concrete has no corrosive effect on rebars and is highly adaptable to cement.

Owner:HUNAN CONSTR ENG GRP COR +1

Method for forging large cakes by upsetting and throwing combined with flat anvil rotary forging edge

ActiveCN104107871BLarge diameterReduce the stress areaMetal-working apparatusEngineeringHeating furnace

Owner:宝武特种冶金有限公司

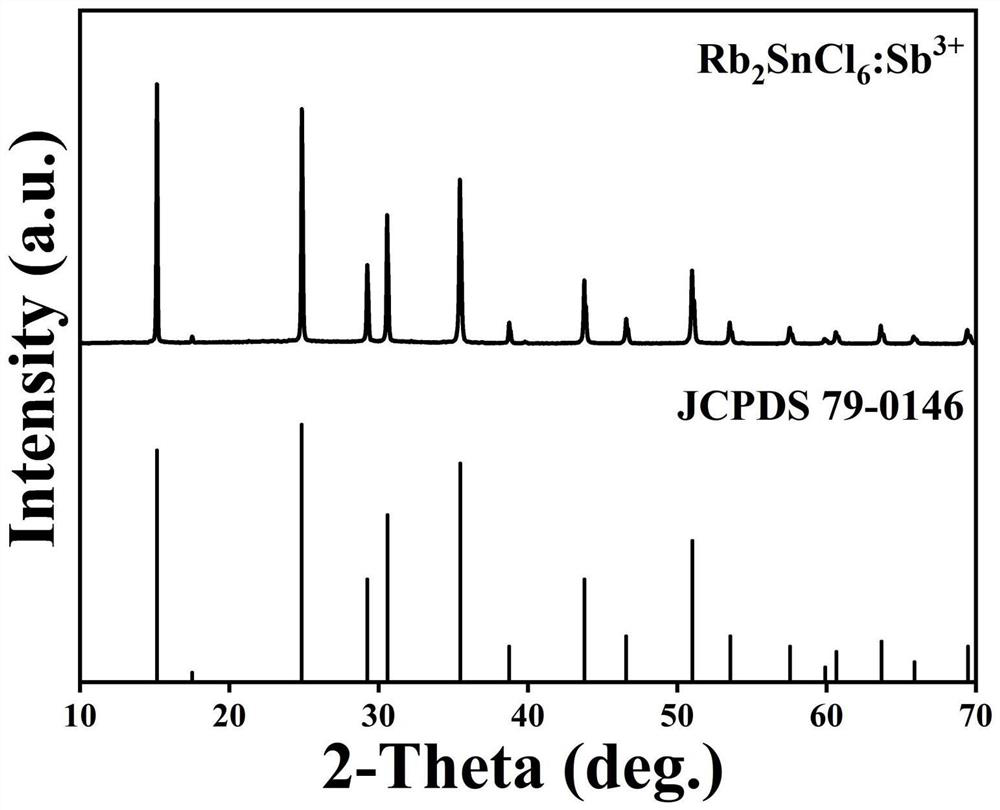

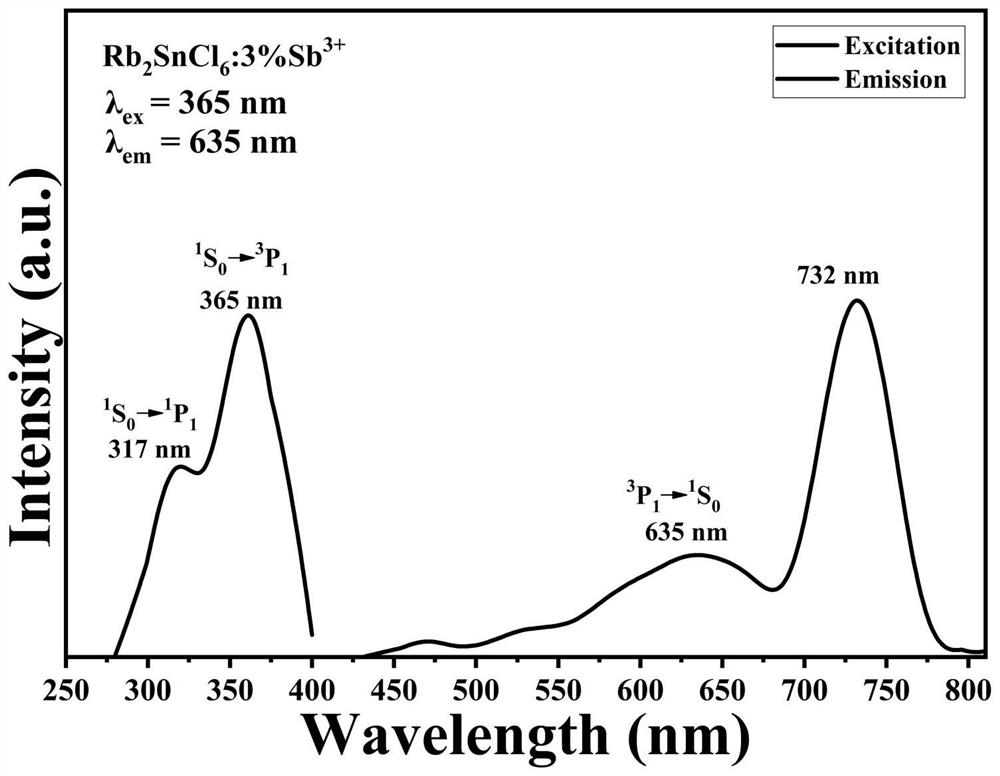

Sb<3+> ion activated and color-adjustable perovskite chloride luminescent material

PendingCN114032100AUniform particlesClear edges and cornersLuminescent compositionsSemiconductor devicesAntimony oxideInorganic chemical compound

The invention discloses a color-adjustable perovskite type chloride luminescent material, the chemical composition is Rb2Sn1-xCl6:xSb<3+>, x is the molar percentage coefficient of doped Sb<3+> relative to tin ions in a matrix, and x is more than 0 and less than or equal to 0.1. The perovskite type chloride is an inorganic compound of which the anion of a matrix material is chloride ion and the structure is perovskite. According to the color-adjustable luminescent material disclosed by the invention, when the material is excited under different wavelengths, the position of the strongest emission peak corresponding to the material changes correspondingly. The preparation method comprises the following steps: (1) weighing 10-20 parts of a hydrochloric acid solution, 300-400 parts of tin chloride, 200-300 parts of rubidium chloride and 0-30 parts of antimony oxide; (2) sequentially adding tin chloride, rubidium chloride and antimony oxide into a hydrochloric acid solution, and magnetically stirring to obtain a precipitate; and (3) washing the precipitate with ethanol, and drying to obtain the product. The color-adjustable luminescent material is prepared by taking Sb<3+> as a luminescent center and perovskite chloride as a matrix.

Owner:YUNNAN MINZU UNIV

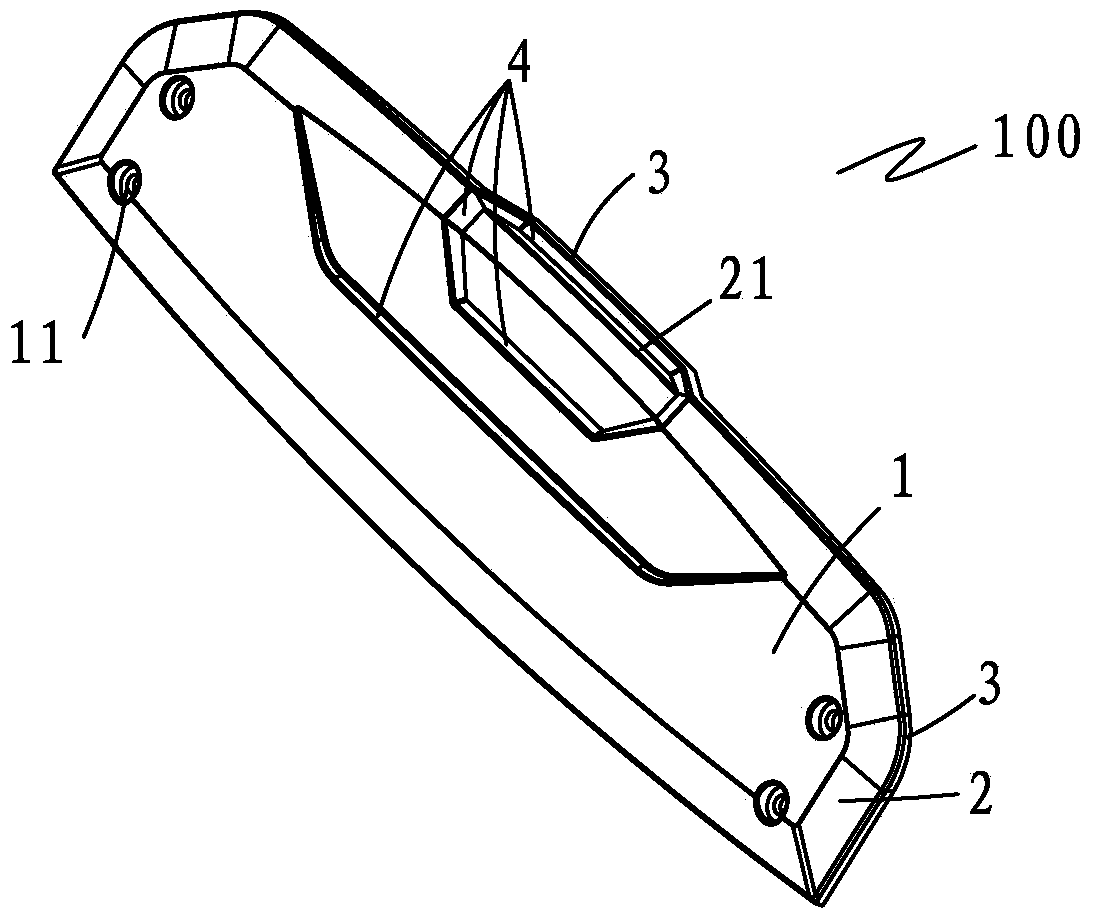

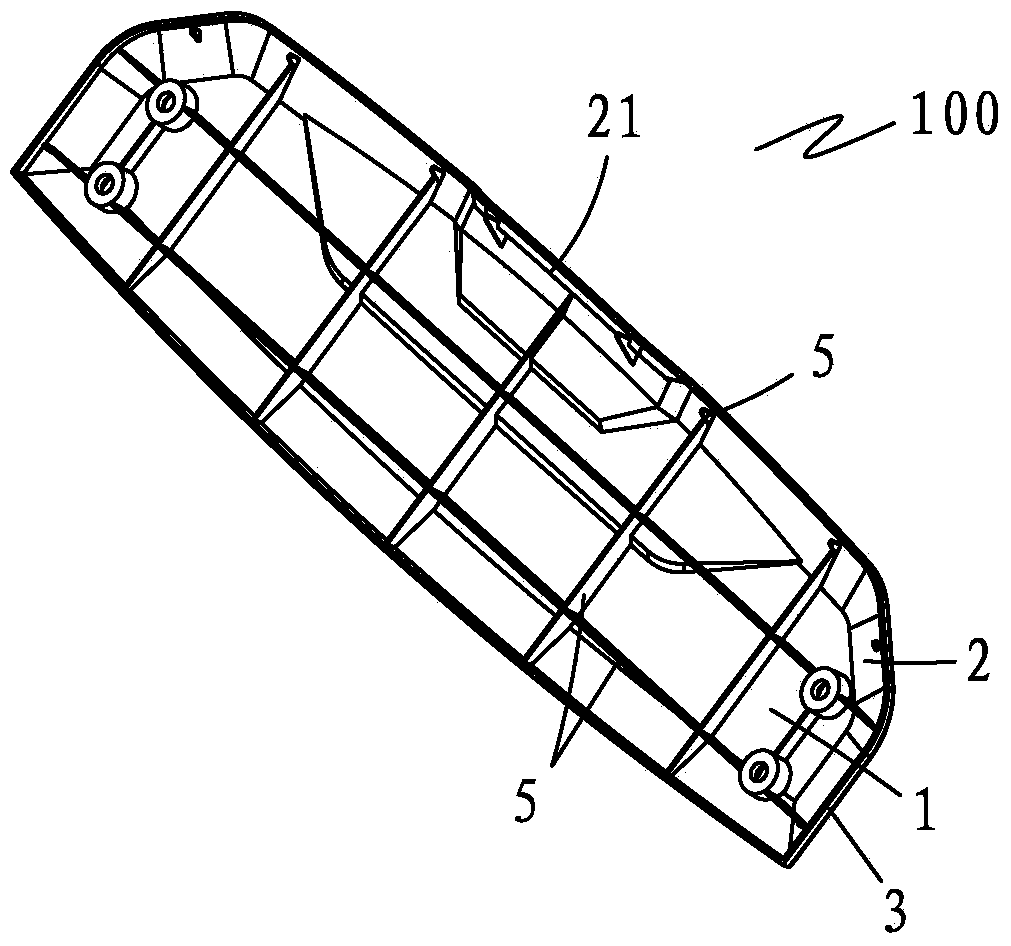

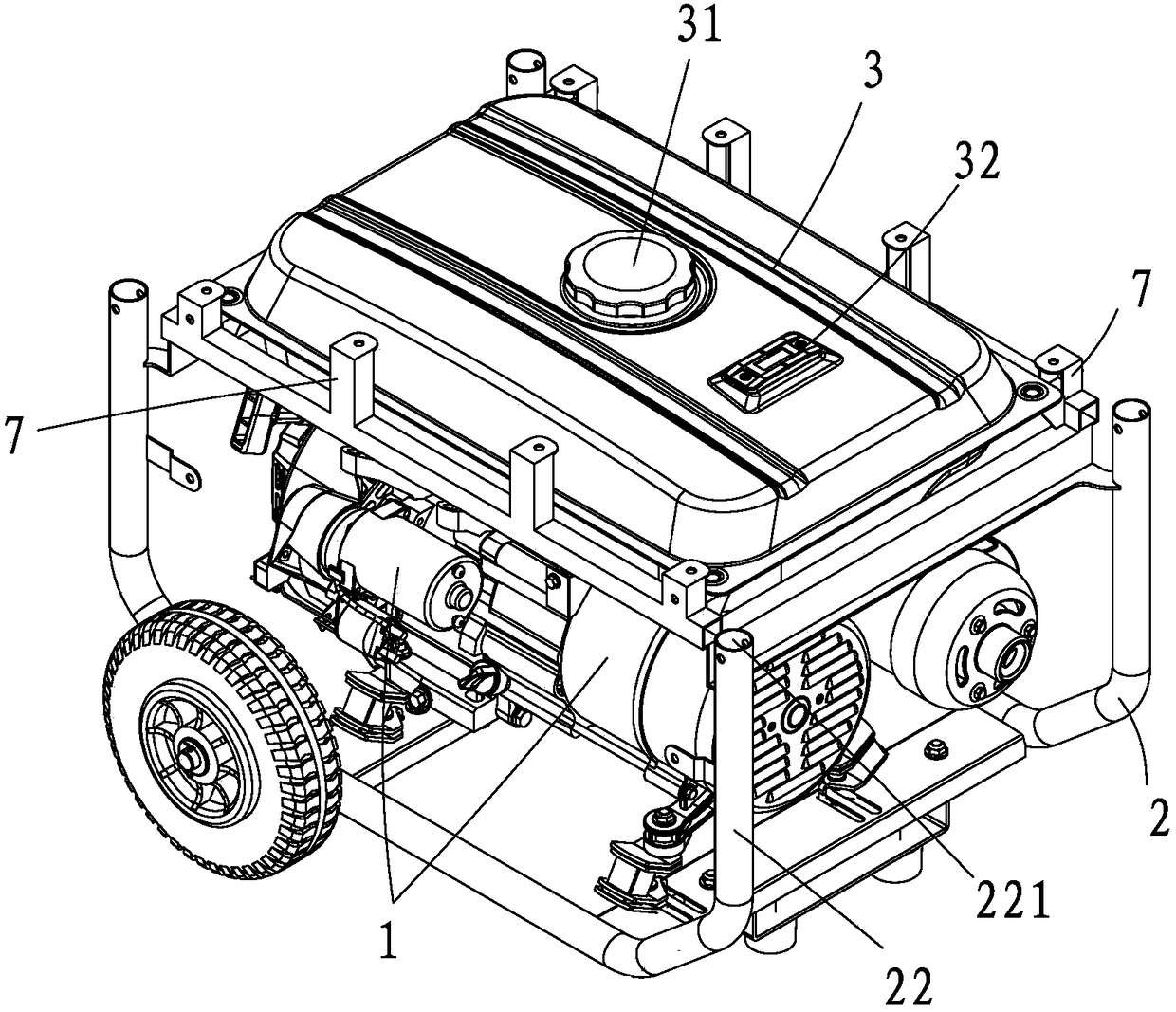

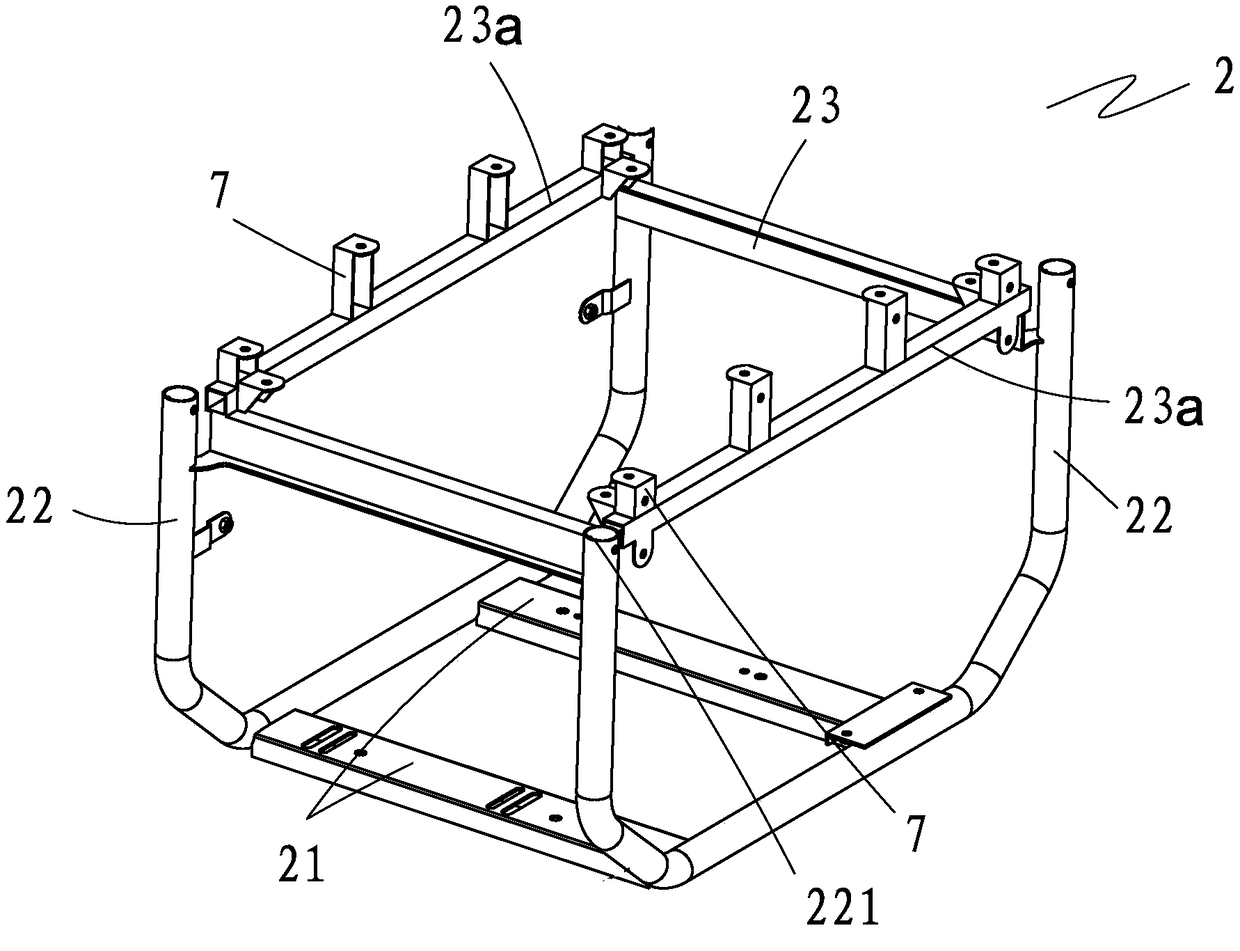

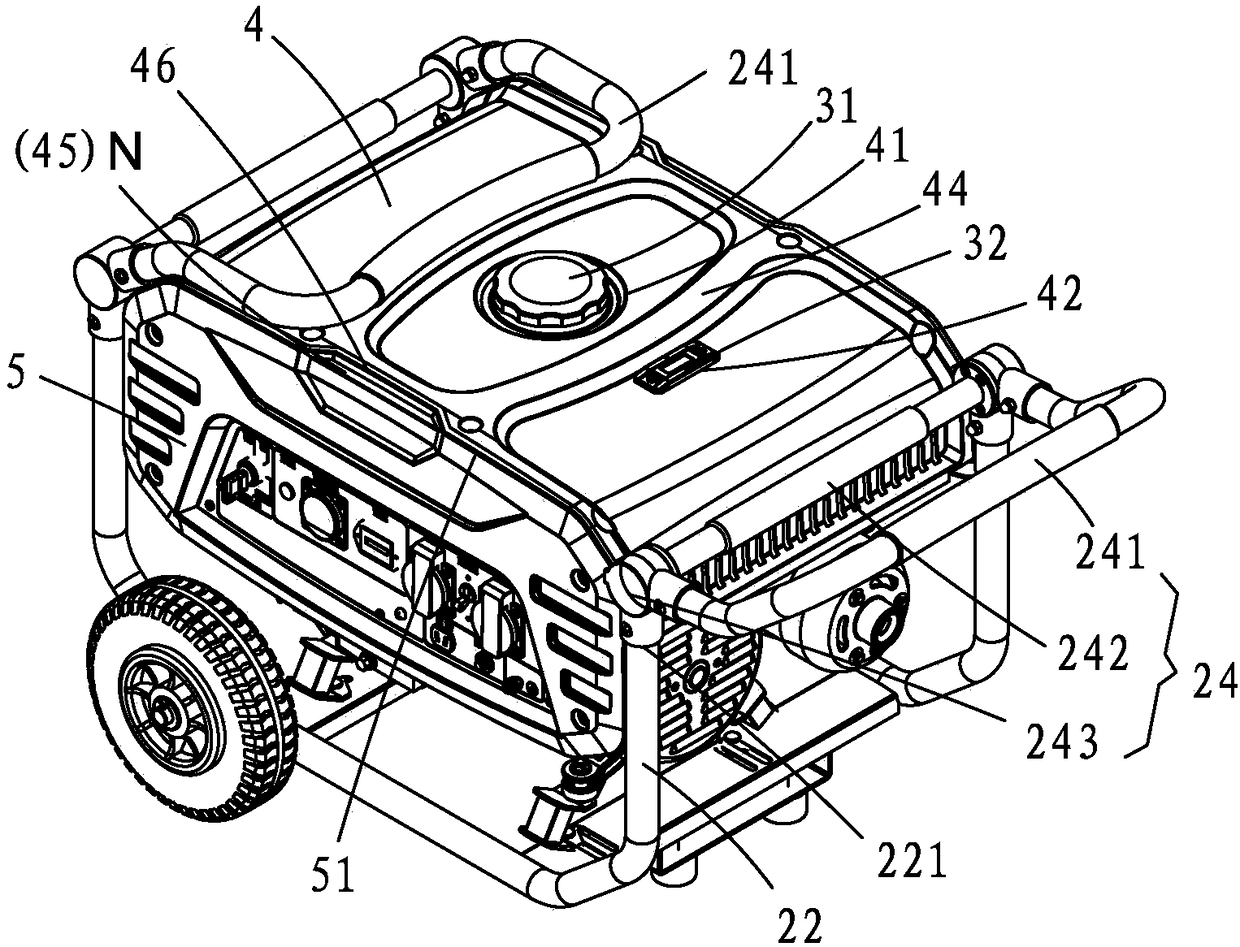

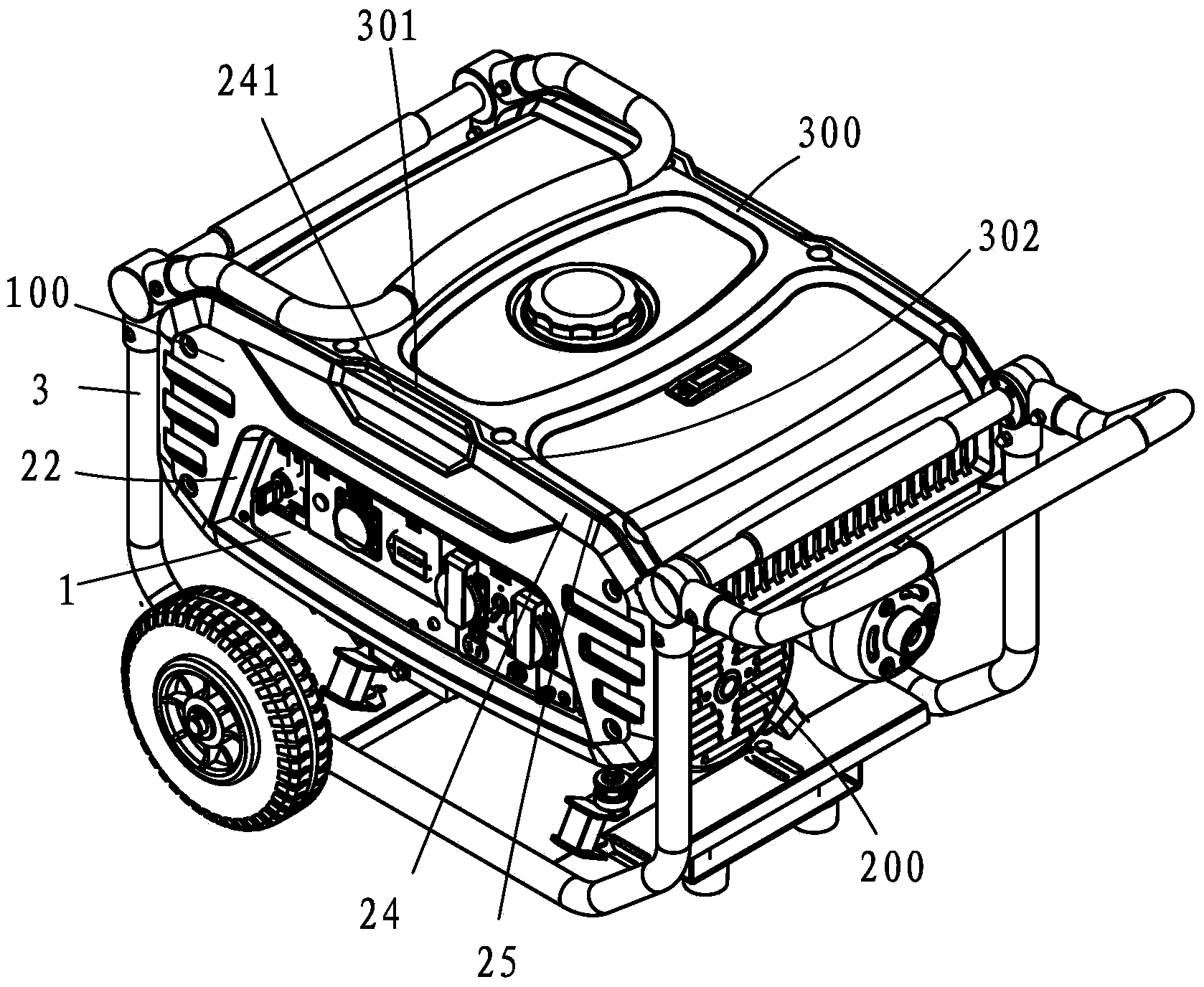

a generator set

A generator set, including a frame, a fuel tank and an upper decorative plate; the frame includes two bases, two guard beams, four beams and two armrest mechanisms; each of the guard beams is a U-shaped guard beam; the Among the four beams, the two beams corresponding to the two U-shaped guard beams are respectively provided with a plurality of pillars, and the front and rear ends of the upper decorative board are locked on these pillars; each of the handrail mechanisms It includes a handrail, a link and two overturning mechanisms. The first and last ends of the link are respectively inserted into the two overturning mechanisms; one end of the two overturning mechanisms is respectively fixed on a free end of the two U-shaped guard beams, The other end is respectively fixedly connected with the first and last ends of the handrail, and the handrail can be rotatably arranged relative to the U-shaped guard beam through the two overturning mechanisms. The frame structure is simple, reasonable, economical and applicable, and the handrails can be opened to easily push and pull the mobile unit. When packing, the handrails are folded away, which does not increase the packaging space and can realize the multi-layer stacking load-bearing function.

Owner:FUJIAN EVERSTRONG LEGA POWER EQUIP CO LTD

Aluminum-magnesium alloy pattern ring for radial tire active mold

Owner:SHANDONG HENGYI MOLD

Rear cover of panel

ActiveCN104300720ANice appearanceClear edges and cornersSupports/enclosures/casingsArchitectural engineeringTroffer

A rear cover of a panel is arranged on a generator set. The generator set is provided with a control panel assembly. The rear cover of the panel comprises a rear cover body. A plurality of installation holes are formed in the rear cover body. The lower middle portion of the rear cover body is sunken downwards to form a groove. The upper portion of the inner wall of the groove is annularly provided with a rabbet for installation of the control panel assembly. A main harness leading-out hole and a flameout line leading-out hole are formed inside the groove. Electrical components and wire harnesses of the control panel assembly are completely hidden into the rear cover of the panel, so that the electrical components and the wire harnesses are not exposed out of the rear cover of the panel and are well protected. Meanwhile, the rear cover of the panel is low in weight, novel and attractive in appearance, has clear corners and angles, and has the effect of decorating and beautifying the generator set.

Owner:FUJIAN EVERSTRONG LEGA POWER EQUIP CO LTD

Cuprous oxide fifty-surface crystallite as well as preparation method and application thereof

ActiveCN102653412BLow costSimple post-processingMaterial nanotechnologyCopper oxides/halidesReaction temperatureSolvent

The invention discloses a cuprous oxide fifty-surface crystallite as well as a preparation method and application thereof. According to the preparation method, copper acetate monohydrate is used as a copper source, water, strong base and glucose are respectively used as a solvent, a precipitator and a reducing agent, the reaction temperature is 50-80 DEGC, and the cuprous oxide fifty-surface crystallite is obtained through an oxidation-reduction reaction. The cuprous oxide fifty-surface crystallite prepared according to the invention is formed by closing 24 high-index crystal faces ({211} crystal face or {311} crystal face), 12 {110} crystal faces, 8 {111} crystal faces and 6 {100} crystal faces, and comprises 120 ridges and 72 vertexes. The method has the advantages of gentle reaction condition, simple equipment, convenient operation, low cost, high yield, environment protection, suitability for large-scale industrial production and the like. The crystallite has excellent visible light catalytic activity, and has wide application prospect in aspects of solar batteries, hydrogen production, lithium ion batteries, biosensors and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A high-gloss machine forming knife

ActiveCN107695404BSmooth side wallsImprove connection strengthMilling cuttersRake angleKnife handles

The invention discloses a molding knife for a highlight machine. The molding knife comprises a knife handle and a cutting head formed at one end of the knife handle, wherein the cutting head comprisesa first front angle knife, a first rear angle knife, a second front angle knife and a second rear angle knife, wherein a first separation part is arranged between the first front angle knife and thefirst rear angle knife, a second separation part is arranged between the second front angle knife and the second rear angle knife, a narrowed first connecting part is arranged between the first rear angle knife and the second front angle knife, a narrowed second connecting part is arranged between the second rear angle knife and the first knife handle, the first front angle knife inclines towardsthe first separation part through the front end surface of the cutting head, and the first rear angle knife inclines towards the first connecting part through the first separation part; and the secondfront angle knife inclines towards the second separation part through the front connecting part, and the second rear angle knife inclines towards the second connecting part through the second separation part. By virtue of the common effect of multiple angle-cleaning cutting knives, the molding knife can meet the angle-cleaning requirements of multi-chamfer parts and can be used for carving relatively stereoscopic and resplendent patterns, the machined side wall is smooth, fluent and burr-free, and corner angles are clear.

Owner:ZHONGSHAN YUANFENG PRECISION CUTTING TOOL CO LTD

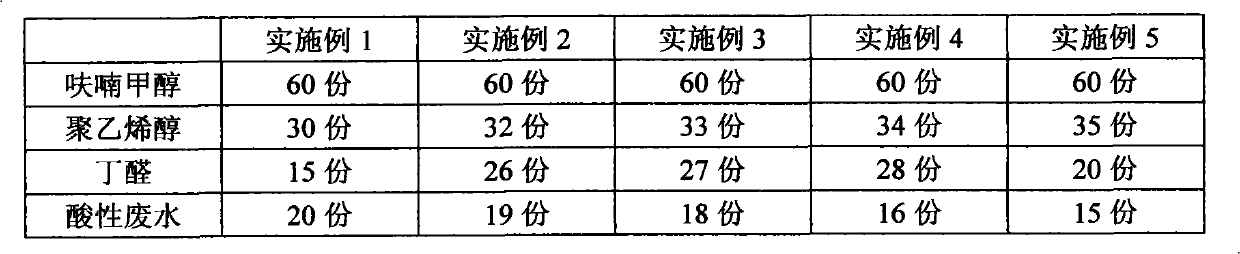

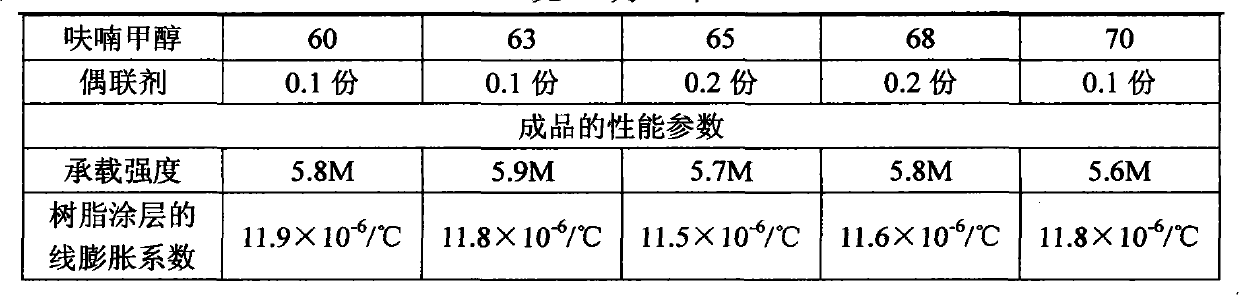

Preparation method for furan nitrogen-free environment protection casting resin adhesive

InactiveCN102898985BAvoid pollutionReduce pollutionFoundry mouldsAldehyde/ketone condensation polymer adhesivesFuranPolyvinyl alcohol

Owner:SHIJIAZHUANG WORLDWIDE FURFURAL & FURFURYL ALCOHOL CO LTD

Preparation method for high-precision drilling bit

InactiveCN107096885AClear edges and cornersHigh dimensional accuracyFoundry mouldsFoundry coresWaxDrill bit

The invention relates to a method for preparation method for a high-precision drilling bit, and belongs to the technical field of casting. The preparation method includes shell preparing, roasting, melting casting and postprocessing, wherein the shell preparing comprises the steps: spraying a coating on a surface of a preformed fusible wax molding, sandblasting, drying, then dewaxing, preparing a shell green body, spraying the coating, and repeating the sandblasting and drying step for 2 to 5 times; the roasting comprises the steps: putting the shell green body into a roasting furnace, and roasting under a vacuum degree with 0.08 to 0.20MPa to obtain a shell. The drilling bit prepared by the invention is small in error, accurate in size and smooth in surface.

Owner:宁波神钻工具有限公司

A kind of aluminum-titanium-boron-aluminum-magnesium alloy tread block casting material and its production method

The invention relates to a segmental mold aluminum-titanium-boron aluminum-magnesium alloy pattern block casting material and a production method thereof. According to the technical scheme, the casting material is prepared from the following components in parts by weight: 99.85% of pure aluminum ingots, 0.20% of silicon, 0.10% of iron, 0.10% of copper, 0.10% of manganese, 3.80% of magnesium, 0.01% of chrome, 0.0050% of nickel, 0.0047% of zinc, 0.000108% of beryllium, 0.0032% of bismuth, 0.0108% of lithium, 0.00063% of sodium, 0.0030% of titanium alloy powder T15.2, and 0.0025% of aluminum-titanium-boron ALTi5B1. The casting material has the beneficial effects that: 1, a die casting is precise in cooling shrinkage contour curved surface and good in surface precision, and has no defects such as pinholes, shrinkage porosity, cold shut, and the like; 2, pattern edges and corners are clear, and the surface smoothness is good; 3, the casting material is corrosion-resistant, does not stick scourings, and resists blast cleaning; 4, the casting material is high in strength, good in toughness, and uneasy to have plastic deformation after being machined; 5, the casting material is wear-resistant, long in service life, and resists die opening-closing impact; and 6, an aluminum-titanium-boron aluminum-magnesium alloy is taken as an independent ingredient, the element proportioning of the alloy is accurate, and the rate of finished products is high, thereby reducing the cost spending of enterprises.

Owner:SHANDONG HENGYI MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com