Preparation method for furan nitrogen-free environment protection casting resin adhesive

A casting resin and adhesive technology is used in the preparation of casting resin adhesives, furan-based nitrogen-free environmentally friendly casting resin adhesives, and in the field of cast iron. The problem of high free formaldehyde content can achieve the effect of improving working conditions and working environment, facilitating popularization and use, and good high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The key to the preparation method of the furan nitrogen-free environmental casting resin adhesive is that the specific steps of the preparation method include:

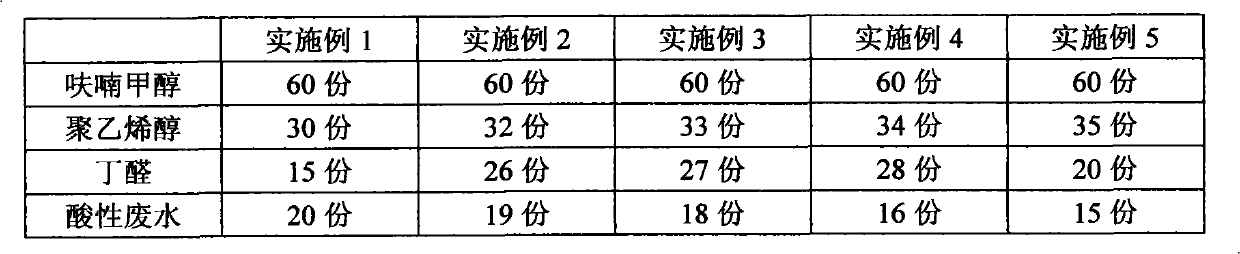

[0017] a. Proportioning raw materials according to the following parts by mass, 60 parts of furan methanol, 30-35 parts of polyvinyl alcohol, 15-20 parts of butyraldehyde;

[0018] b. Add the above raw materials into the reaction kettle, and while stirring, add 15-20 parts of furan resin acid waste water with a concentration of 12% in the reaction kettle as a catalyst;

[0019] c. Turn on the heat source, and control the temperature at 38-45°C to react to generate alcohol prepolymerization products;

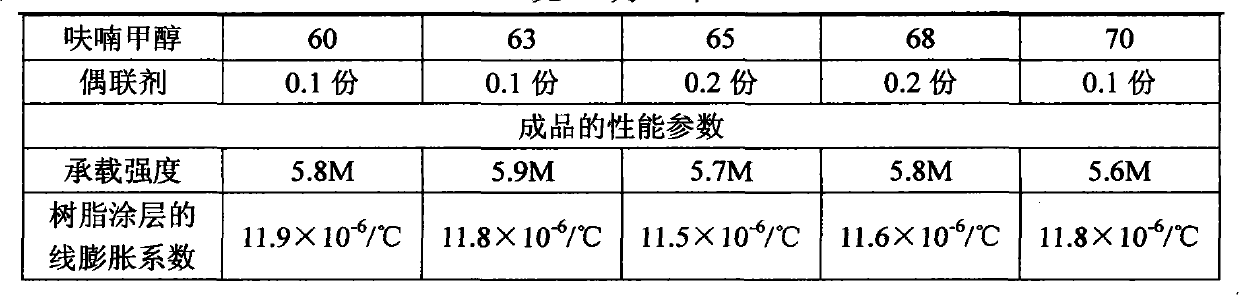

[0020] d. Further heat up to 48-58°C, and then add 60-70 parts of furan methanol to the reaction kettle;

[0021] e. Turn off the heat source, adjust the PH value to be neutral, add 0.1-0.2 parts of coupling agent when the temperature in the reaction kettle reaches room temperature and stir, and filter the impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com