Molding knife for highlight machine

A technology of forming knives and high-gloss machines, which is applied in the direction of milling cutters, manufacturing tools, and metal processing equipment, can solve the problems of not being able to meet complex multi-dimensional corner-clearing requirements and processing patterns, so as to avoid breakage, ensure precision, and clear edges and corners Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

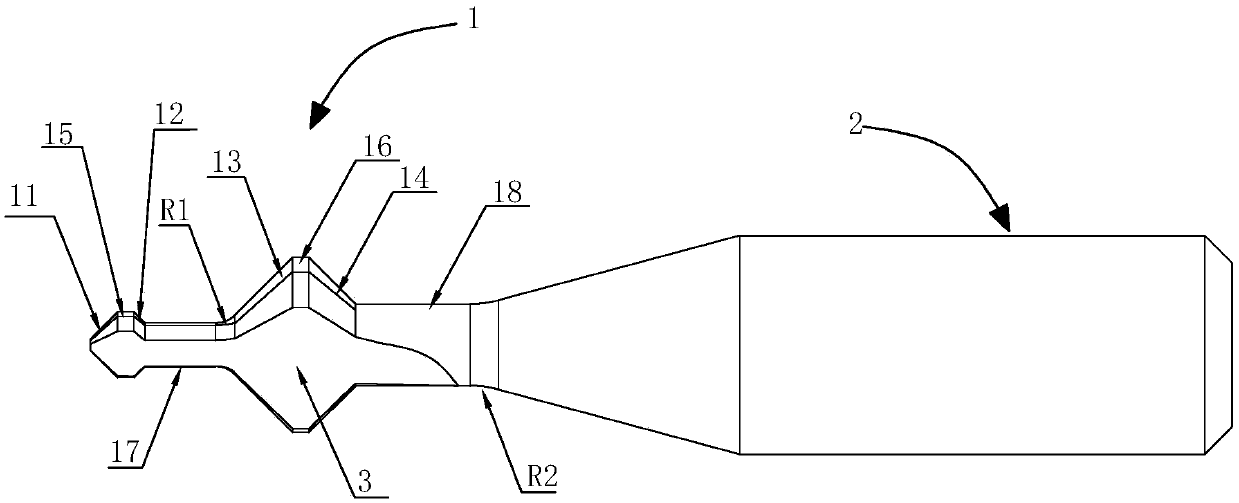

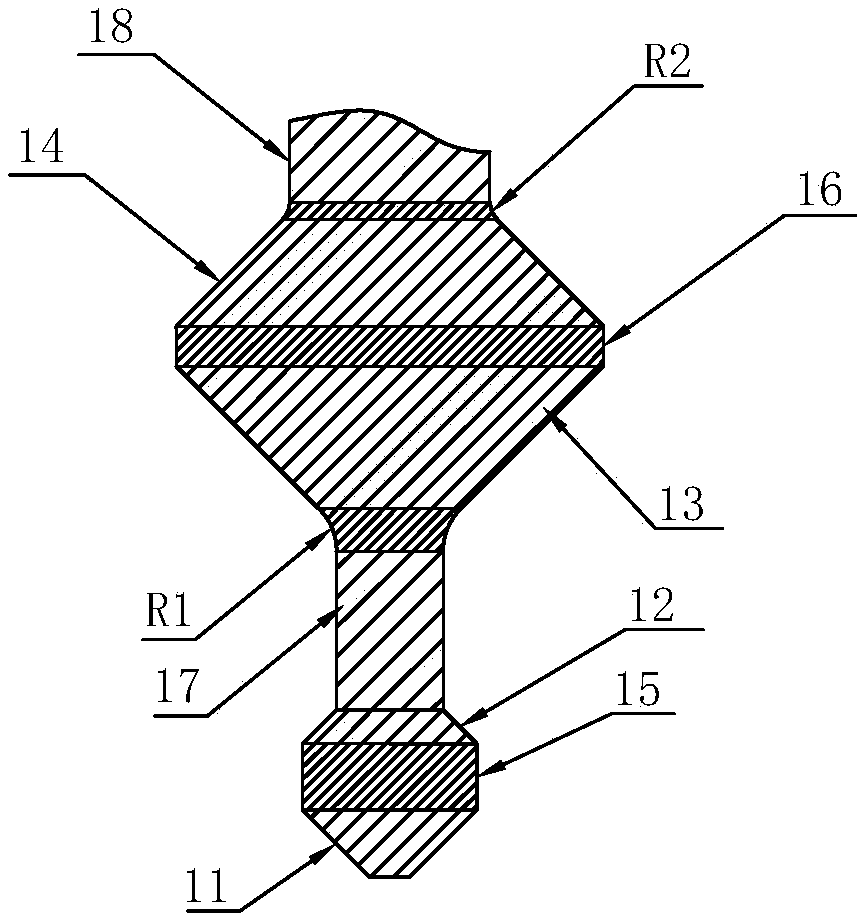

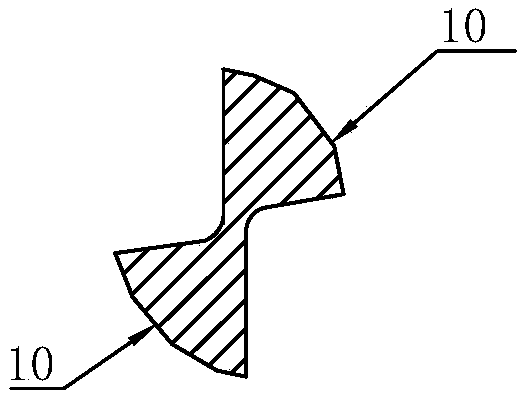

[0015] See attached Figure 1-3 , a high-gloss machine forming knife, including a handle 2, and a cutter head 1 formed at one end of the handle 2, the cutter head 1 includes a first front corner knife 11, a first rear corner knife 12, a second front corner knife 13 and the second rear corner knife 14, a first spacer 15 is provided between the first front corner knife 11 and the first rear corner knife 12, and the second front corner knife 13 and the second rear corner knife 14 There is a second spacer 16 between them, a narrowed first connecting portion 17 is provided between the first rear corner knife 12 and the second front corner knife 13, and the connection between the second rear corner knife 14 and the handle 2 There is a narrowed second connecting portion 18 between them, the diameter of the first spacer 15 is greater than the diameter of the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com