Cuprous oxide fifty-surface crystallite as well as preparation method and application thereof

A technology of cuprous oxide and hedrons, which is applied in the field of cuprous oxide pentahedral microcrystals and its preparation, can solve problems that limit follow-up research and wider application, and achieve excellent visible light catalytic activity, mild reaction temperature, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Dissolve the copper source compound copper acetate monohydrate in 5ml deionized water to form a transparent aqueous solution of copper acetate monohydrate with a concentration of 0.2mol / L, then raise the temperature to 70°C, and add 6mol / L precipitant sodium hydroxide 2ml of the aqueous solution was reacted for 5 minutes to obtain a suspension;

[0034]2) Add 1ml of 0.75mol / L reducing agent glucose aqueous solution to the suspension obtained in step 1) and react at 70°C for 5 minutes. After the reaction is completed, a precipitate is obtained, and the formed precipitate is separated from the solution by natural sedimentation and washed with water. After 7 times, it was dried in a vacuum drying oven at 60°C and a vacuum of 100 Pa, and finally obtained cuprous oxide pentahedral microcrystals with clear edges, regular shapes, uniform sizes, and good dispersion.

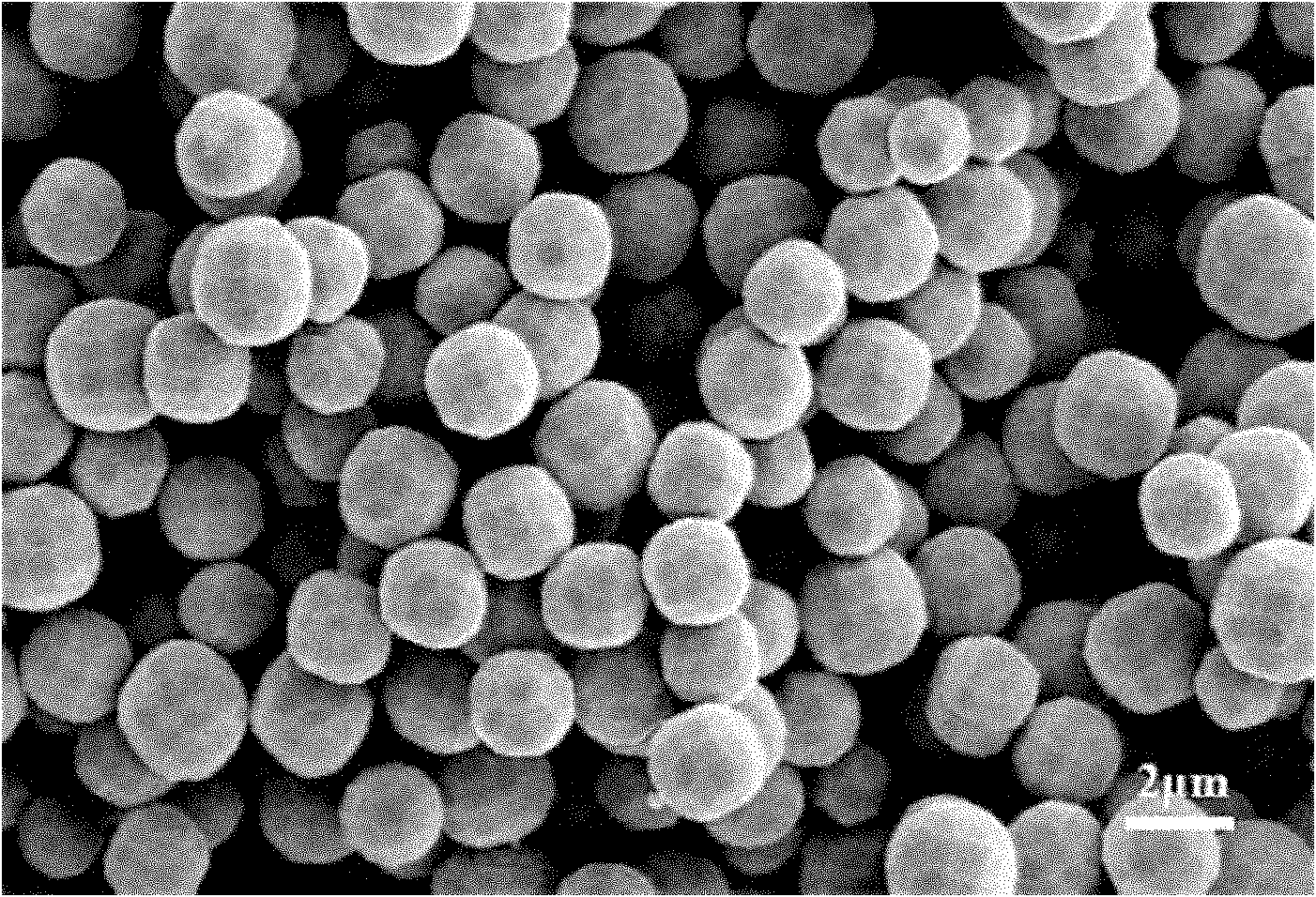

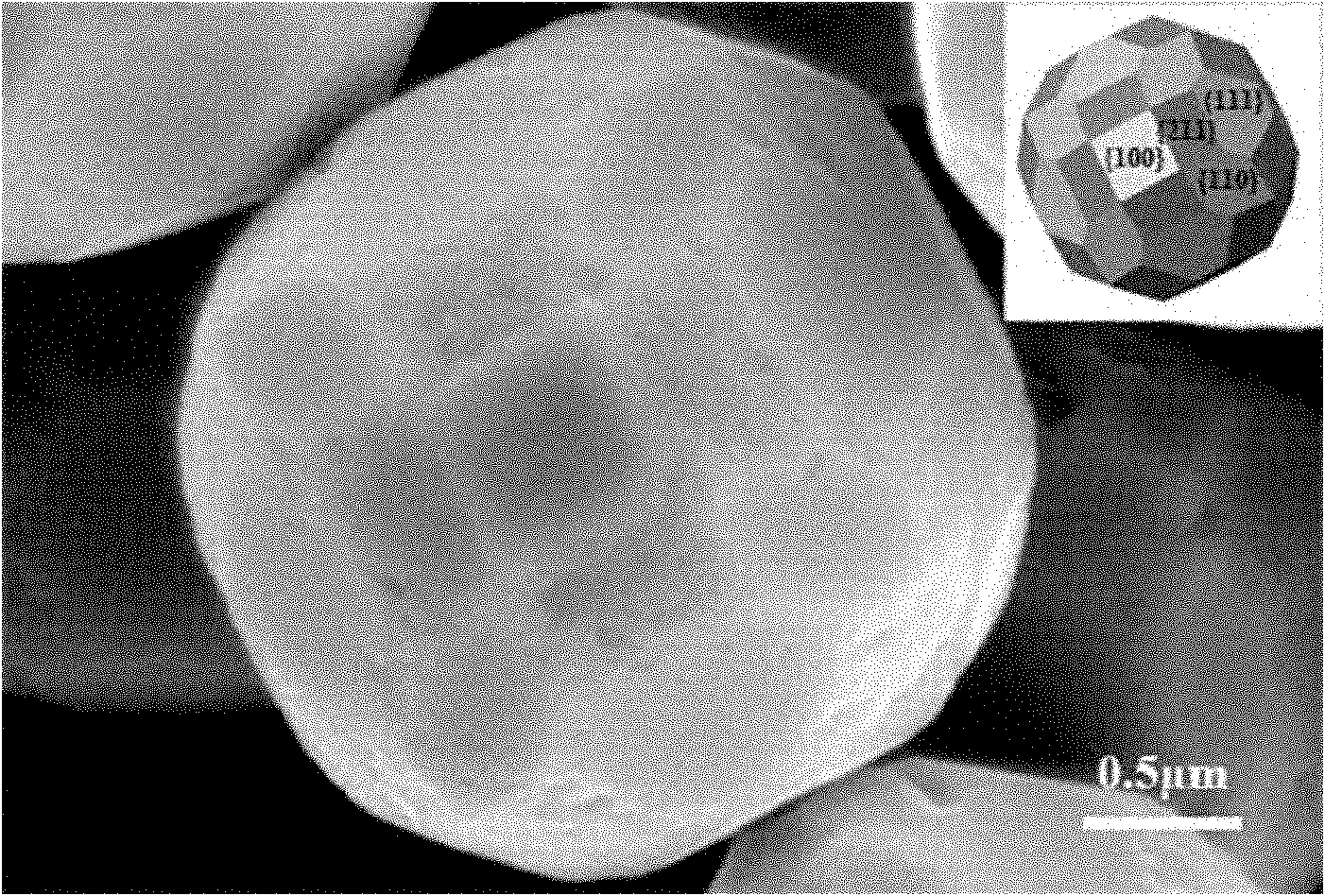

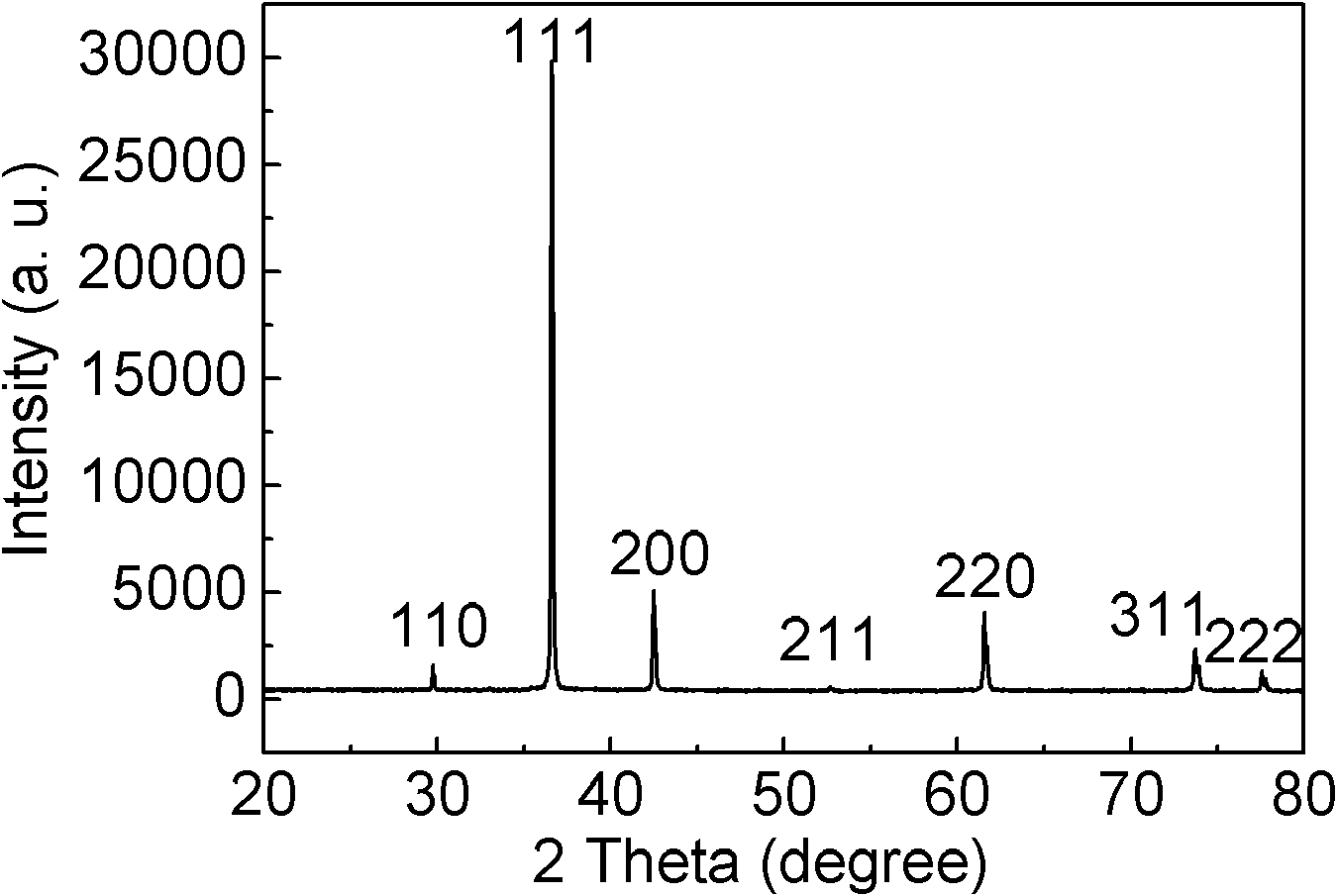

[0035] The scanning electron microscope photograph of the product is as follows figure 1 , compared with th...

Embodiment 2

[0037] 1) Dissolve the copper source compound copper acetate monohydrate in 5ml deionized water to form a transparent aqueous solution of copper acetate monohydrate with a concentration of 0.2mol / L, then raise the temperature to 50°C, and add 6mol / L precipitant sodium hydroxide 2ml of the aqueous solution was reacted for 5 minutes to obtain a suspension;

[0038] 2) Add 1ml of 0.65mol / L reducing agent glucose aqueous solution to the suspension obtained in step 1) and react at 50°C for 20 minutes. After the reaction is completed, a precipitate is obtained, and the formed precipitate is separated from the solution by natural sedimentation and washed with water. After 7 times, it was dried in a vacuum drying oven at 60°C and a vacuum of 100 Pa, and finally obtained cuprous oxide pentahedral microcrystals with clear edges, regular shapes, uniform sizes, and good dispersion.

[0039] Compared with Example 1, the cuprous oxide pentahedral crystallites obtained in this example have a...

Embodiment 3

[0041] 1) Dissolve the copper source compound copper acetate monohydrate in 5ml deionized water to form a transparent solution of copper acetate monohydrate with a concentration of 0.3mol / L, then raise the temperature to 70°C, and add 10mol / L precipitant sodium hydroxide 2ml of the aqueous solution was reacted for 5 minutes to obtain a suspension;

[0042] 2) Add 1ml of 0.8mol / L reducing agent glucose solution to the suspension obtained in step 1) and react at 70°C for 5 minutes. After the reaction is completed, a precipitate is obtained, and the formed precipitate is separated from the solution by natural sedimentation, and washed with water After three times, it was dried in a vacuum drying oven at 60° C. and a vacuum degree of 100 Pa to finally obtain cuprous oxide pentahedral microcrystals.

[0043] Compared with Example 1, the {211} high-index crystal face of the cuprous oxide pentahedral crystallites obtained in this embodiment is obviously increased, and other exposed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com