Cuprous oxide fifty-surface crystallite as well as preparation method and application thereof

A cuprous oxide and hexahedral technology is applied in the field of cuprous oxide icosahedral crystallites and their preparation, which can solve the problems of restricting subsequent research and wider application, and achieves excellent visible light catalytic activity, cheap and easy-to-obtain raw materials, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Dissolve the copper source compound copper acetate monohydrate in 5ml deionized water to form an aqueous solution of transparent copper acetate monohydrate with a concentration of 0.2mol / L, then be warming up to 70°C, add 6mol / L precipitating agent sodium hydroxide 2ml of the aqueous solution was reacted for 5 minutes to obtain a suspension;

[0034]2) Add 0.75mol / L of reducing agent glucose aqueous solution 1ml in step 1) to the obtained suspension and react at 70°C for 5 minutes, the reaction is completed to obtain precipitation, the resulting precipitate is separated from the solution by natural sedimentation, and washed with water After 7 times, it was dried in a vacuum drying oven at 60°C and a vacuum degree of 100Pa, and finally cuprous oxide icosahedral crystallites with clear edges and corners, regular shapes, uniform sizes and good dispersibility were obtained.

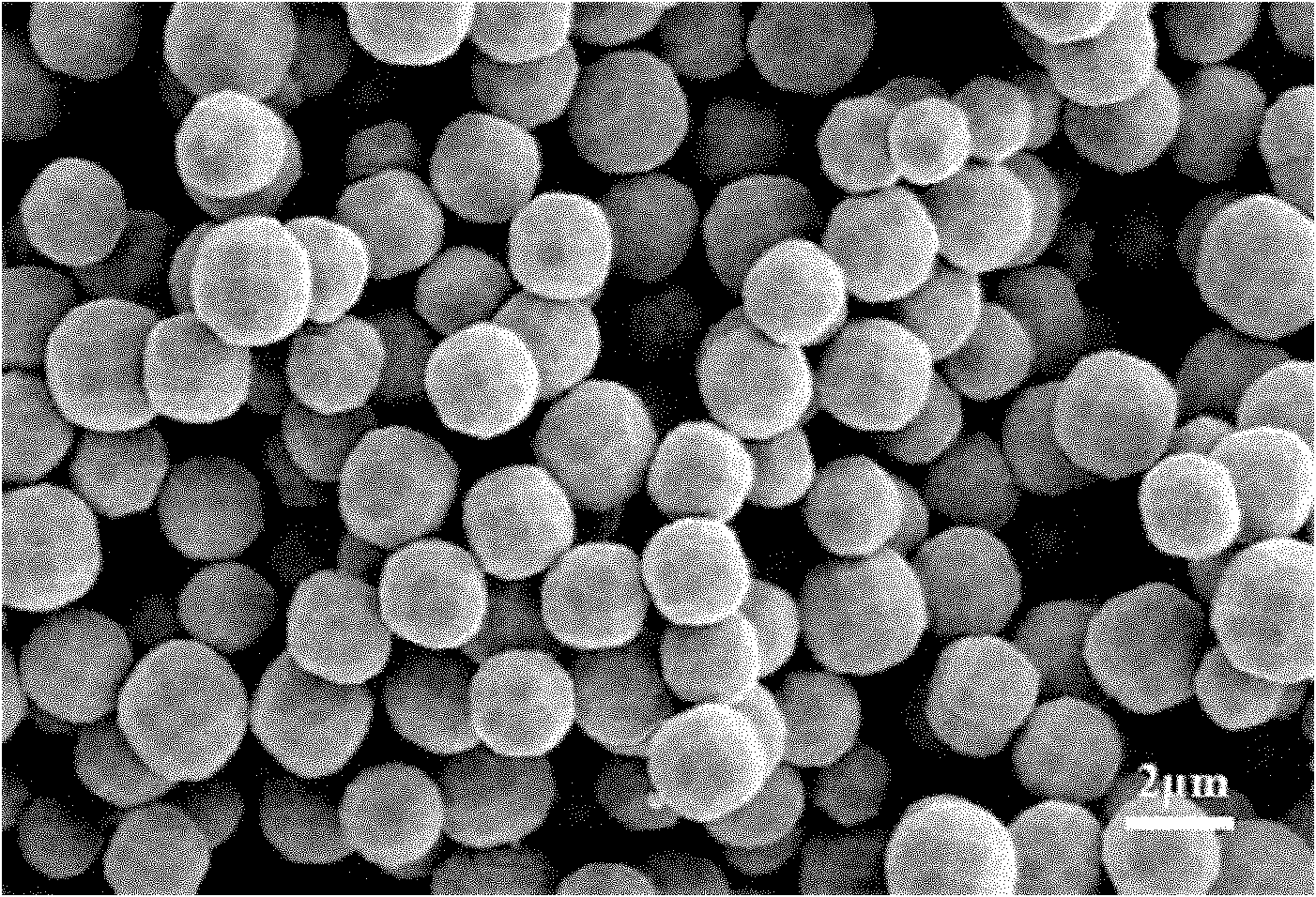

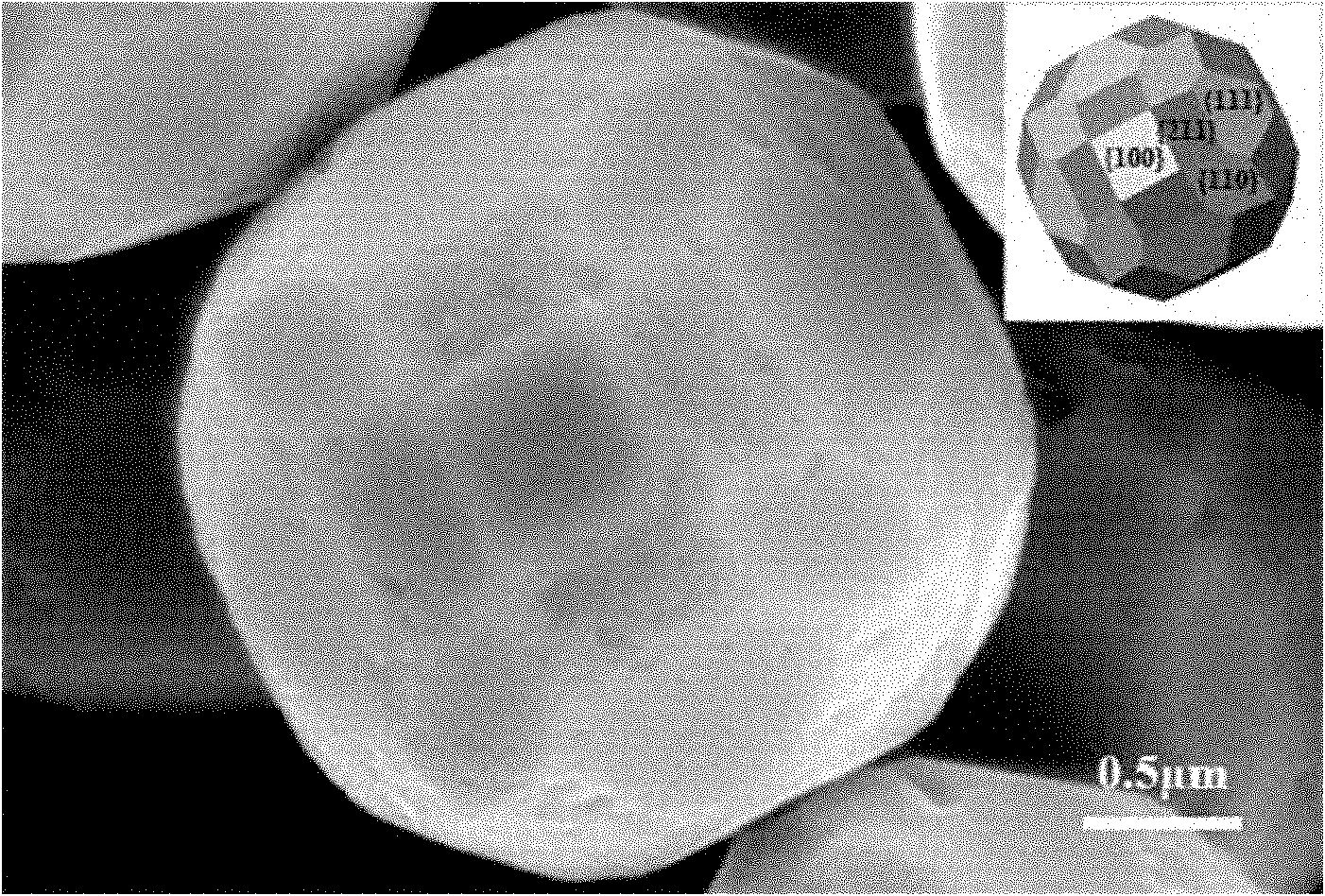

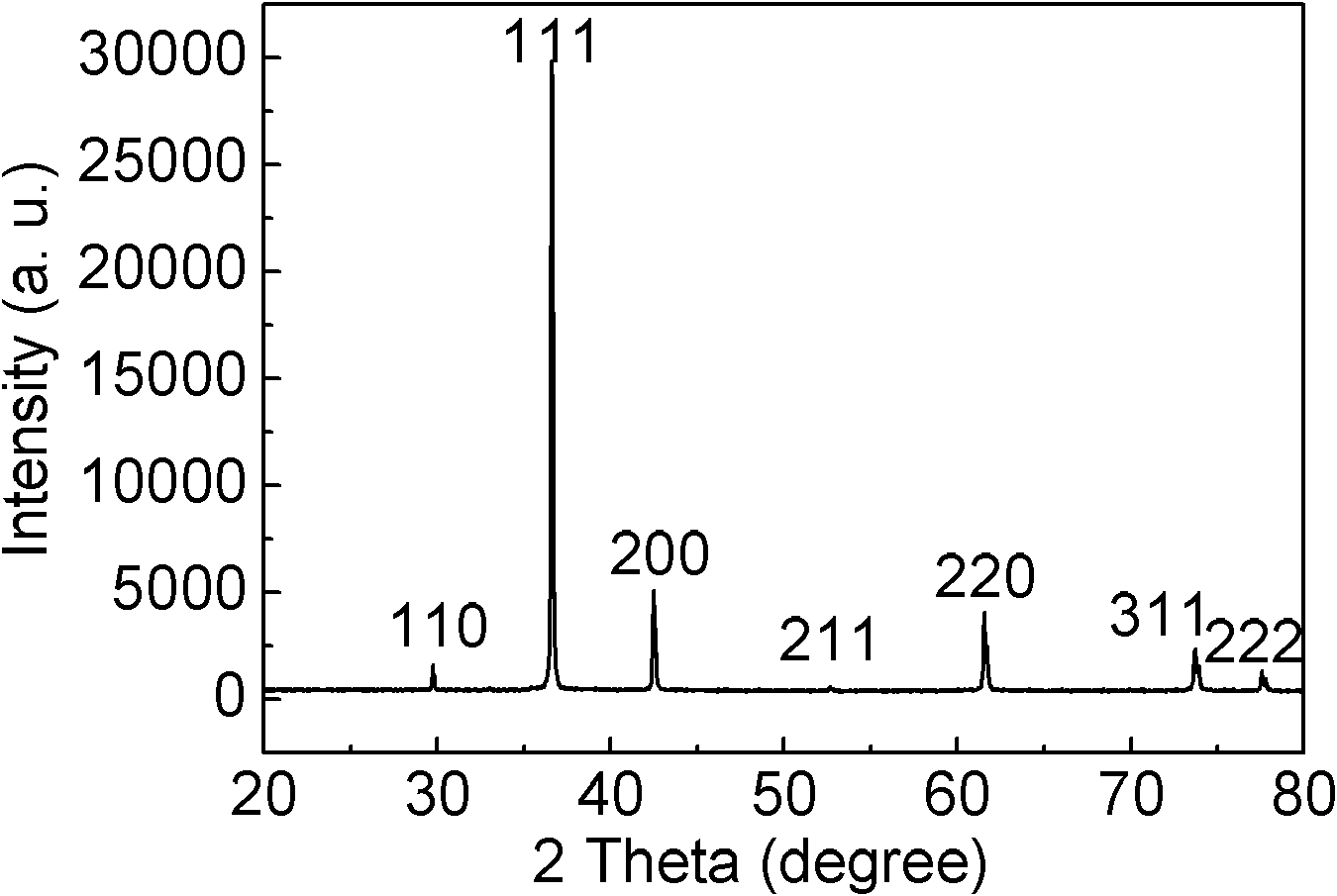

[0035] The scanning electron microscope photo of the product is as follows figure 1 shown, comp...

Embodiment 2

[0037] 1) Dissolve the copper source compound copper acetate monohydrate in 5ml deionized water to form an aqueous solution of transparent copper acetate monohydrate with a concentration of 0.2mol / L, then be warming up to 50°C, add 6mol / L precipitating agent sodium hydroxide 2ml of the aqueous solution was reacted for 5 minutes to obtain a suspension;

[0038] 2) Add 0.65mol / L of reducing agent glucose aqueous solution 1ml in step 1) to the obtained suspension and react at 50°C for 20 minutes. After the reaction is completed, precipitation is obtained, and the resulting precipitate is separated from the solution by natural sedimentation and washed with water. After 7 times, it was dried in a vacuum drying oven at 60°C and a vacuum degree of 100Pa, and finally cuprous oxide icosahedral crystallites with clear edges and corners, regular shapes, uniform sizes and good dispersibility were obtained.

[0039] Compared with Example 1, the cuprous oxide icosahedral crystallites obtain...

Embodiment 3

[0041] 1) Dissolve the copper source compound copper acetate monohydrate in 5ml deionized water to form a solution of transparent copper acetate monohydrate with a concentration of 0.3mol / L, then be warming up to 70°C, add 10mol / L precipitant sodium hydroxide 2ml of the aqueous solution was reacted for 5 minutes to obtain a suspension;

[0042] 2) Add 1 ml of reducing agent glucose solution of 0.8mol / L in step 1) to the obtained suspension and react at 70°C for 5 minutes. After the reaction is completed, precipitation is obtained, and the resulting precipitate is separated from the solution by natural sedimentation and washed with water. After 3 times, drying was performed in a vacuum drying oven at 60° C. and a vacuum degree of 100 Pa to finally obtain cuprous oxide icosahedral crystallites.

[0043] Compared with Example 1, the {211} high-index crystal planes of the cuprous oxide icosahedral crystallites obtained in this example are significantly increased, while the other e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com