Dewaxing casting method for drill bit

A technology of lost wax casting and drill bits, which is applied in the direction of casting molding equipment, molds, and mold components. It can solve the problems of uncontrollable drill bit processing errors, inability to accurately process workpieces, and poor shell strength, so as to reduce mechanical processing. Efforts to reduce workload, improve consistency and work efficiency, and increase coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

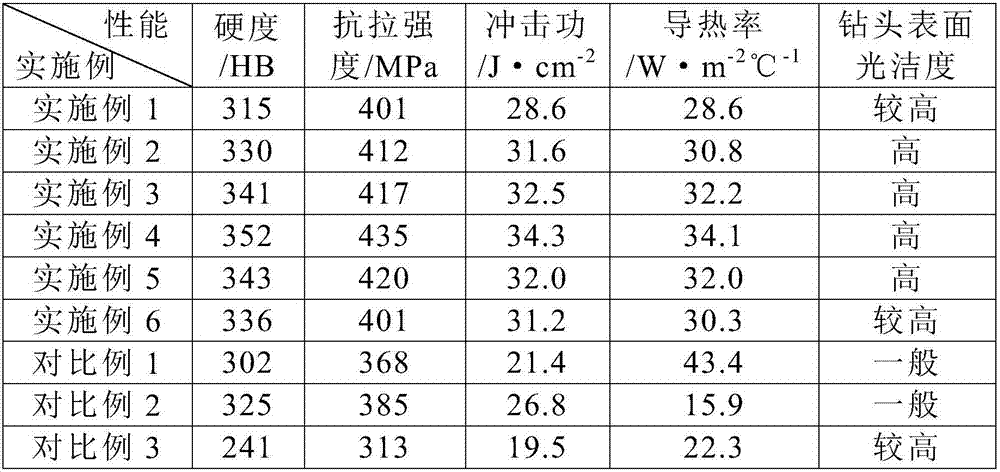

Examples

Embodiment 1

[0046] The lost wax casting method of drill bit among the present invention, comprises the steps:

[0047] Preparation of coating: by weight, 20 parts of zircon powder, 40 parts of corundum powder, 13 parts of primary SiO 2 Sol, 25 parts of secondary SiO 2 Sol, 0.3 parts of carbon nanotubes, 1.3 parts of wetting agent, and 0.3 parts of defoamer were mixed, mechanically stirred for 11 hours while ultrasonically vibrating, and then plasma treated for 4 minutes to make a basic coating, which was diluted with water to make a viscosity of 3 cp Primary paint and secondary paint with a viscosity of 10cp;

[0048] Among them, the mesh numbers of zircon powder and corundum powder are 200-400 mesh. Primary SiO 2 The colloidal particle size of the sol is 8-12nm, and the secondary SiO 2 The colloidal particle size of the sol is 15-20nm.

[0049] Shell making: Spray the primary coating on the surface of the preformed meltable wax pattern under a vacuum of 0.05MPa for the first coating...

Embodiment 2

[0054] The lost wax casting method of drill bit among the present invention, comprises the steps:

[0055] Preparation of coating: by weight, 30 parts of zircon powder, 35 parts of mullite, 11 parts of primary SiO 2 Sol, 24 parts of secondary SiO 2 Sol, 0.4 parts of carbon nanotubes, 1.4 parts of wetting agent, and 0.4 parts of defoamer were mixed, mechanically stirred for 12 hours while ultrasonically vibrating, and then plasma treated for 4 minutes to make a basic coating, which was diluted with water to make a viscosity of 3.5cp The primary paint and the secondary paint with a viscosity of 9cp;

[0056] Among them, the mesh numbers of zircon powder and mullite are 200-300 mesh. Primary SiO 2 The colloidal particle size of the sol is 8-10nm, and the secondary SiO 2 The colloidal particle size of the sol is 15-18nm.

[0057] Shell making: Under the vacuum degree of 0.08MPa, spin-spray the primary paint on the surface of the preformed meltable wax type for the first time,...

Embodiment 3

[0062] The lost wax casting method of drill bit among the present invention, comprises the steps:

[0063] Preparation of coating: by weight, 20 parts of zircon powder, 20 parts of corundum powder, 30 parts of alumina powder, 12 parts of primary SiO 2 Sol, 20 parts of secondary SiO 2 Sol, 0.5 parts of carbon nanotubes, 1.5 parts of wetting agent, and 0.5 parts of defoamer were mixed, mechanically stirred for 14 hours while ultrasonically vibrating, and then plasma treated for 4.5 minutes to make a basic coating, which was diluted with water to make a viscosity of 4cp The primary paint and the secondary paint with a viscosity of 8.5cp;

[0064] Among them, the mesh numbers of zircon powder, corundum powder and alumina powder are 250-350 mesh. Primary SiO 2 The colloidal particle size of the sol is 10-12nm, and the secondary SiO 2 The colloidal particle size of the sol is 18-20nm.

[0065] Shell making: Spray the primary coating on the surface of the preformed meltable wax ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com