Extrusion molding process method for sand mold or shell for casting

A process method and technology for casting sand, which are applied in casting molding equipment, casting mold components, casting molds, etc., can solve the problems of uneven strength, uneven sand mold compactness, insufficient sand shooting, etc., and achieve high compactness. , Promote the effect of high molding efficiency and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

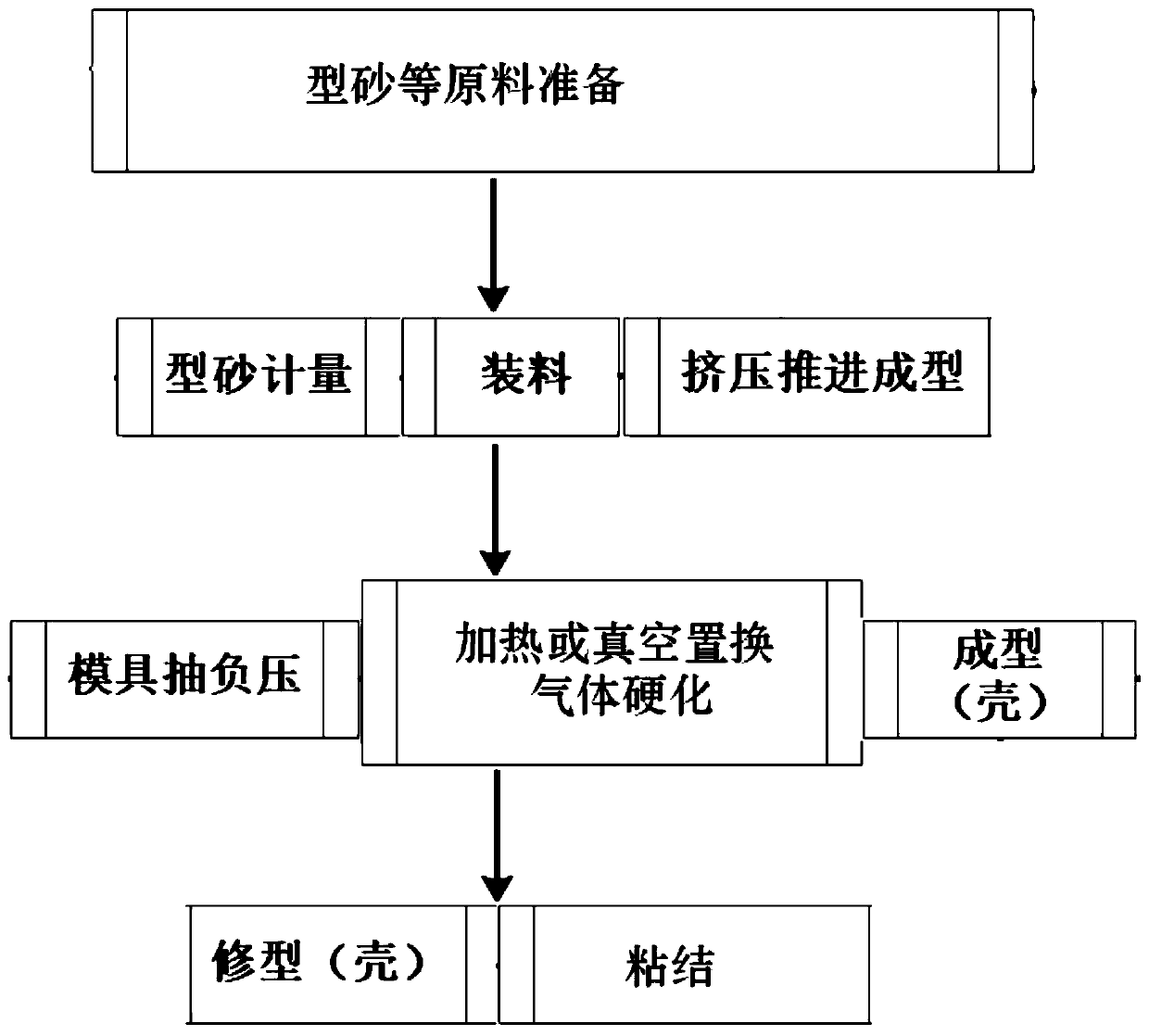

Method used

Image

Examples

Embodiment 1

[0032] The invention utilizes molds of dry and wet coated sand to extrude and form the shell mold used for producing train brake discs.

[0033] Step 1, prepare raw materials such as dry or wet coated sand, organic resin and high-purity silane coupling agent;

[0034] Step 2: Measuring the raw materials and adding them to the charging barrel, and quickly pushing and extruding the raw materials in the charging barrel into the pre-prepared cavity of the mold through extrusion molding equipment; cleaning the mold during pre-preparation.

[0035] The third step is to form a mold or shell with a thickness of 5mm by replacing the hot air with vacuum for a certain period of time and simultaneously hardening with electric heating; the heating temperature is 200°C.

[0036] Step 4: The formed mold or shell is bonded and assembled after being demoulded, checked and repaired to form a casting mold that can be used for pouring train brake discs.

Embodiment 2

[0038] Using cold box sand molds, extrusion molding shells for the production of railway couplers.

[0039] Step 1, prepare raw materials such as cold box sand, water glass resin and high-purity silane coupling agent;

[0040] Step 2: Measuring the raw materials and adding them to the charging barrel, and quickly pushing and extruding the raw materials in the charging barrel into the pre-prepared cavity of the mold through extrusion molding equipment; cleaning the mold during pre-preparation.

[0041] The third step is to form a mold or a shell with a thickness of 3mm by replacing triethylamine with vacuum for a certain period of time.

[0042] Step 4, the formed mold or shell is bonded and assembled after demolding, checking and repairing to form a casting mold that can be poured into the train coupler.

Embodiment 3

[0044] Using the mold of silicate binder molding sand, extrusion molding is used to produce shell molds for knuckle products.

[0045] Step 1: Equip raw materials such as silicate adhesive molding sand, acid-cured environment-friendly adhesive and silicon powder mixture; acid-cured environment-friendly adhesive refers to the invention patent of patent No. The binder in "Agent and its preparation method".

[0046] Step 2: Measuring the raw materials and adding them to the charging barrel, and quickly pushing and extruding the raw materials in the charging barrel into the pre-prepared cavity of the mold through extrusion molding equipment; cleaning the mold during pre-preparation.

[0047] Step 3, the carbon dioxide is replaced by vacuum for a certain period of time to harden and form a mold or shell with a thickness of 2mm.

[0048] Step 4, after demoulding, checking and repairing the molded mold or shell, bonding and assembling are carried out to form a casting mold for pouri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com