Method for preparing high-quality silicon-based aluminum nitride template

A silicon-based aluminum nitride, high-quality technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem of poor crystallization quality and surface quality of AlN nucleation layer, Si and AlN lattice loss Problems such as large matching and thermal mismatch, unfavorable sputtering process, etc., to achieve the effect of reducing surface roughness, improving crystal quality, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

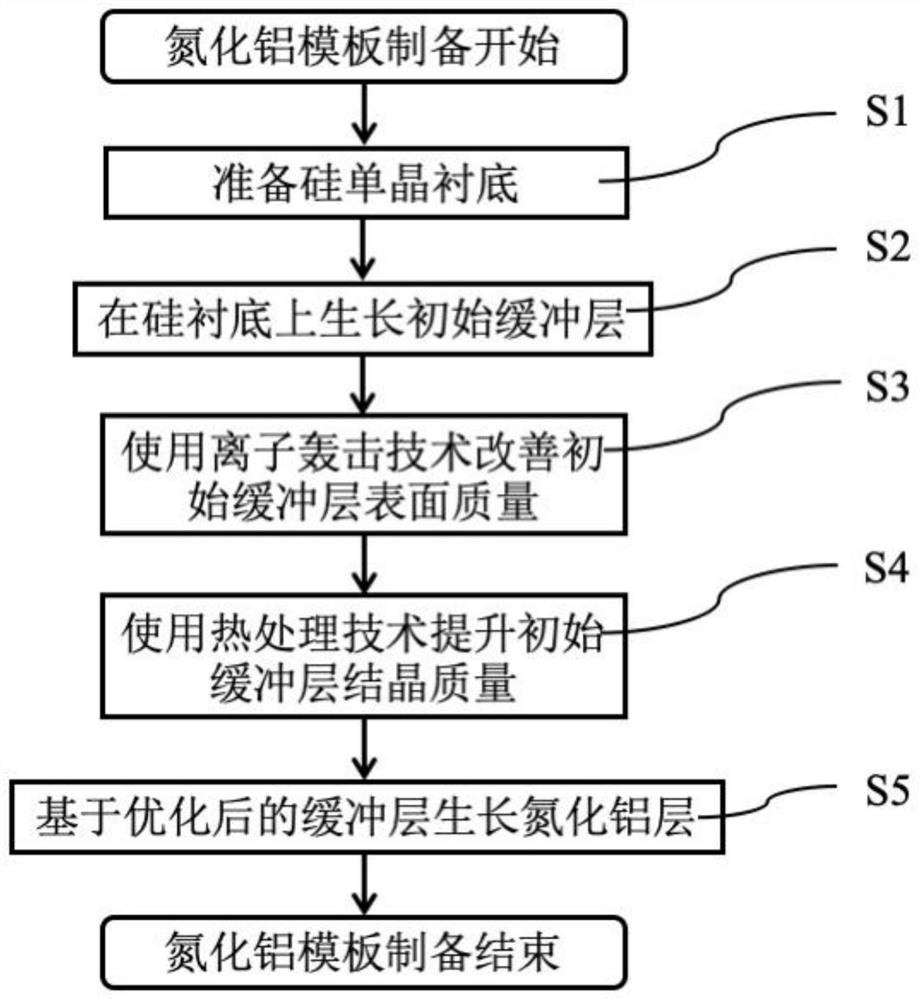

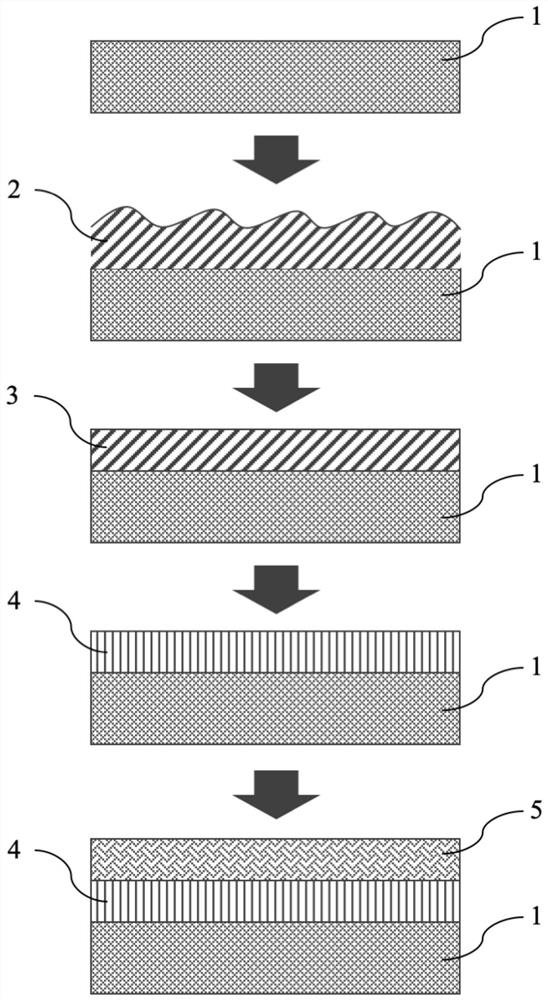

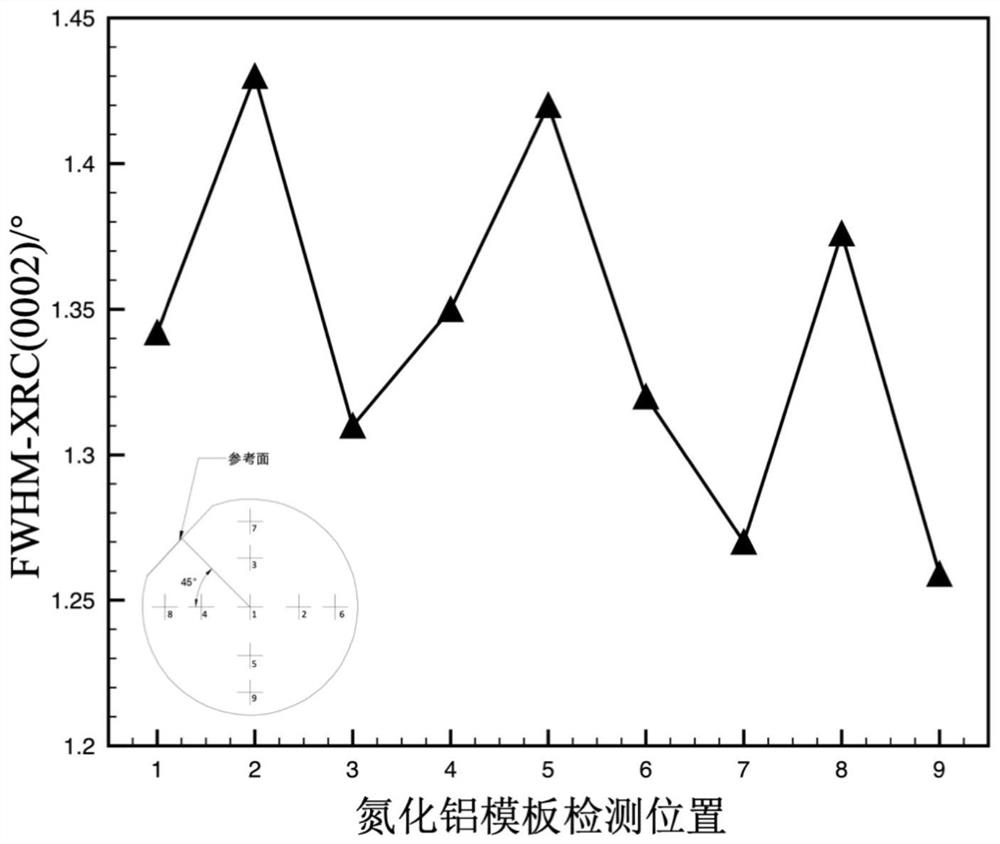

[0036] A method for preparing a high-quality silicon substrate aluminum nitride template: mainly including the preparation of a substrate 1, the preparation and optimization of a buffer layer 4, and the preparation of an aluminum nitride template 5. like figure 1 , 2 As shown, are respectively the schematic diagram of the preparation process of the aluminum nitride template and the schematic diagram of the preparation process of the aluminum nitride template in this embodiment. Next, the method for preparing a high-quality silicon substrate aluminum nitride template of this embodiment will be described in detail with reference to the accompanying drawings.

[0037] 1) Prepare a silicon single crystal substrate 1 (S1). The silicon single crystal substrate 1 is a polished substrate of standard specifications. The surface is an EPI-ready polished surface cleaned by RCA, with a roughness of less than 0.3nm, and the backside is polished, with a roughness of 1±0.2μm.

[0038] 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com