Lithium ion storage battery formation method

A chemical formation method and battery technology, which are applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, battery pack components, etc., can solve problems such as affecting battery life and gas can not be released, and improve the formation of dense SEI film, low cost , Improve the effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0020] The schematic diagram of this chemical synthesis method can be found in figure 1 , the gas release valve 7 is installed on the pole 10 of the lithium ion battery 8 with the liquid injection hole 9 .

[0021] The steps of this chemical formation method are:

[0022] 1. Formation preparation

[0023] 1. Prepare the vent valve

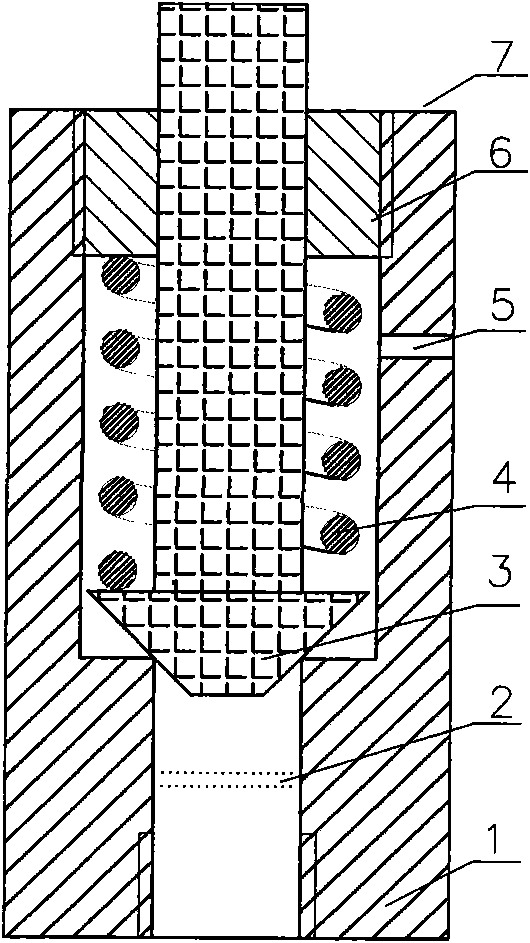

[0024] see figure 2 The valve body 1 with stepped holes is made of stainless steel material, the holes at both ends of the valve body are processed into partial threads, and the air-liquid separation membrane 2 of breathable PP / PE / PP three-layer composite film material is sealed and pasted on the valve body On a section of the small hole, a through hole is punched on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com