Efficient high-temperature tensile clamping device and testing method

A clamping device, high temperature technology, used in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of long test time, low energy utilization, low test efficiency, etc. Convenient clamping, simple structure, good neutrality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

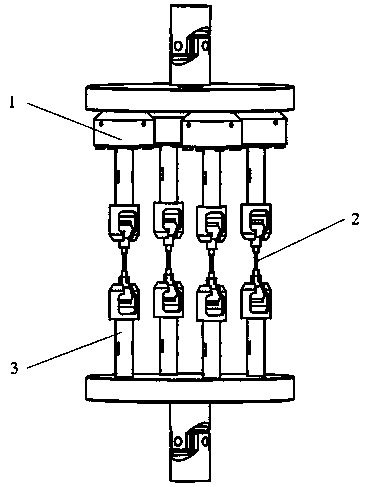

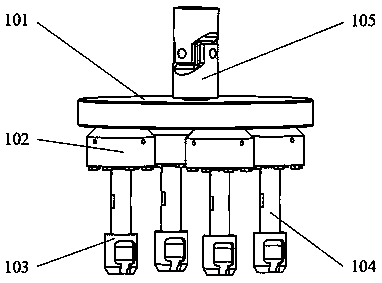

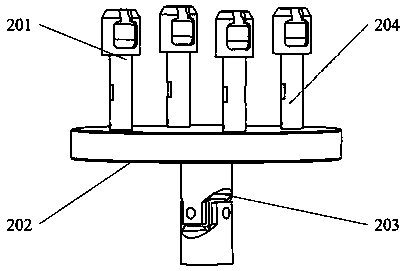

[0027] see Figure 1 to Figure 8 As shown, the high-efficiency high-temperature tensile clamping device of the present invention includes an upper clamp 1, a lower clamp 2 and a clamping assembly 3, and the upper clamp 1 and the lower clamp 2 are respectively connected to the high-temperature The tensile test device (external equipment) is connected, and the overall centering of the clamping device during the test is realized; the clamping assembly 3 passes through the upper ball joint I30101, the lower ball joint I30103 and the upper slotted chuck 103 of the upper fixture 1 respectively , The lower slotted chuck 201 of the lower clamp 2 is connected to realize the automatic centering of each sample during the test. The material of the ball joint is a high-temperature alloy with small thermal expansion coefficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com