A performance testing method and device for a digital twin model of a machine tool

A test device and digital technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve problems such as performance degradation accelerated life test and life prediction that cannot be digital twin models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

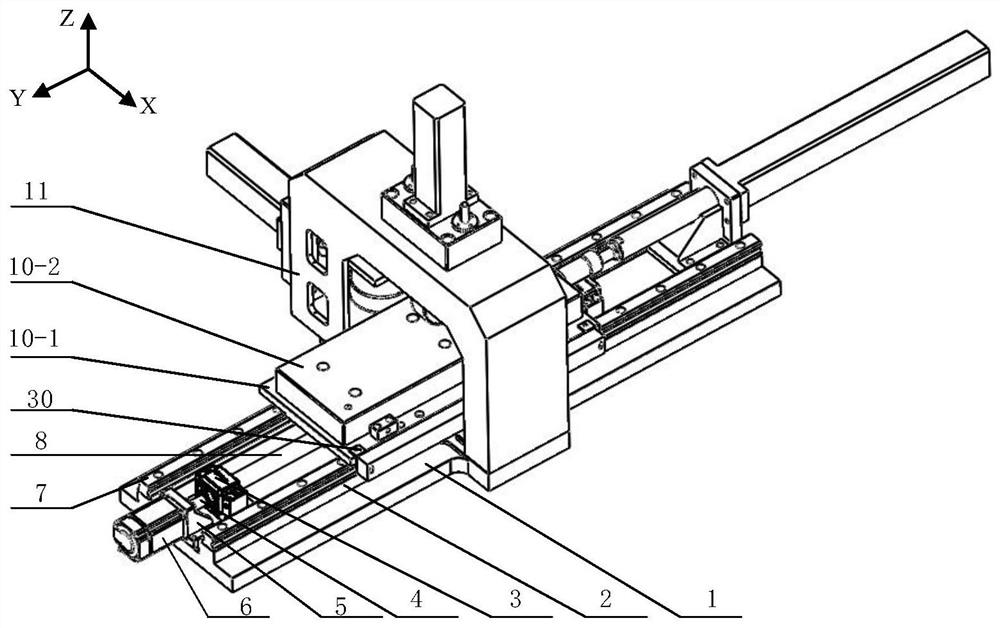

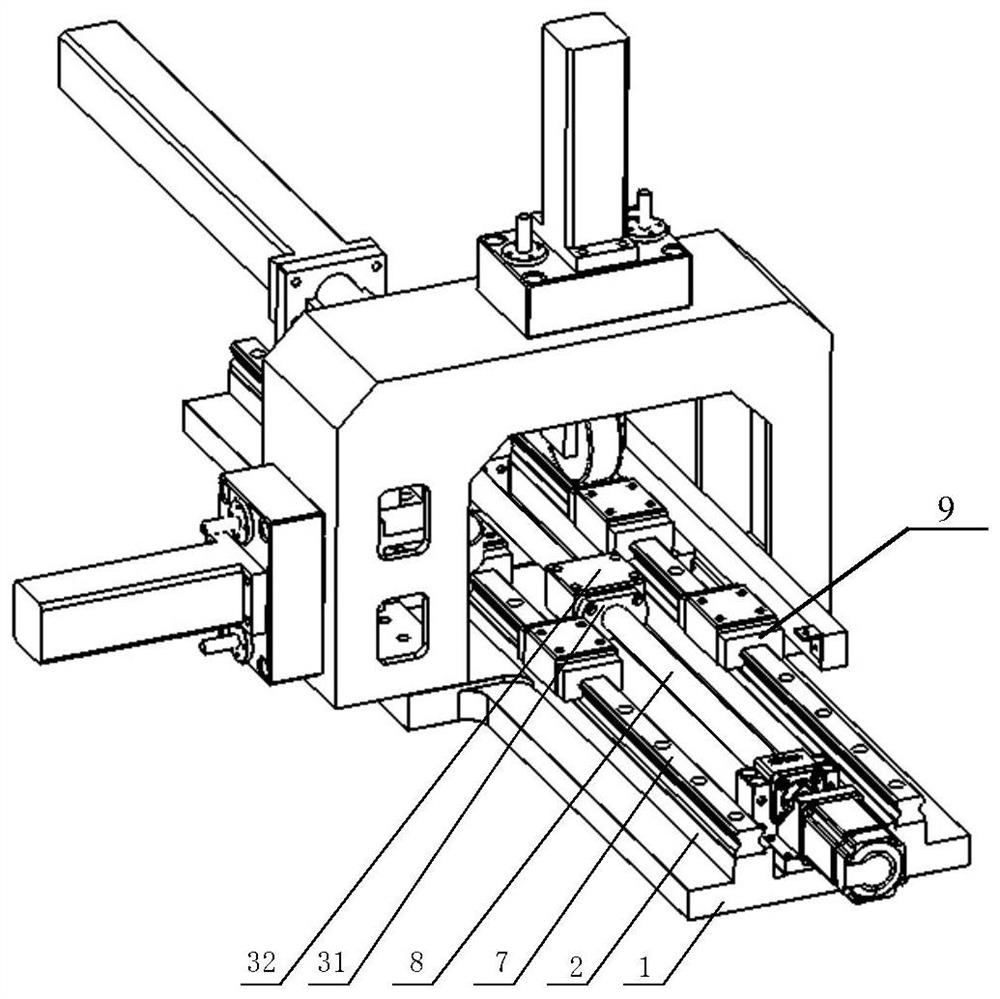

[0054] A machine tool digital twin model performance testing device, such as Figure 1~3 As shown, it includes machine base 1, workbench a 10-1, workbench b 10-2, gantry frame 11 and control system 33. The gantry frame 11 is fixed on the machine base 1, and the upper surface of the machine base 1 is provided with two The guide rail installation platform 2 is fixed with a screw bearing seat 3 between the two guide rail installation platforms 2, and a lead screw 8 is installed on the lead screw bearing seat 3, and one end of the lead screw 8 is connected with a servo motor 6 through a coupling 4, and the servo The motor 6 is fixed on the frame 1;

[0055] The upper surface of each guide rail installation platform 2 is equipped with a linear guide rail 7, and the two linear guide rails 7 are provided with guide rail sliders 9 matched with it, and the two guide rail sliders 9 are fixedly connected with the workbench a 10-1 The lead screw 8 is provided with a nut seat 32, the nut ...

Embodiment 2

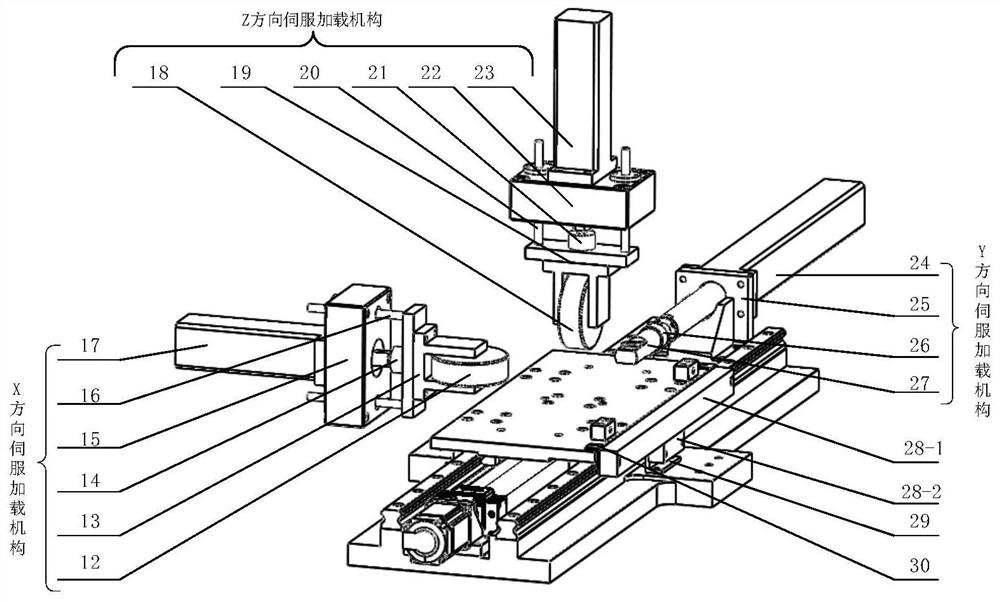

[0064]A machine tool digital twin model performance testing device, its structure is as shown in embodiment 1, the difference is that the grating ruler displacement sensor includes a reading head 28-2 and a grating ruler main ruler 28-1, and the workbench a 10-1 The side door is provided with an L-shaped patch 30, the grating ruler main ruler 28-1 is installed on the L-shaped patch 30, the upper surface of the base 1 is fixed with an L-shaped bracket 29, and the reading head 28-2 is fixed on the L-shaped bracket 29 , and cooperate with the grating ruler main scale 28-1. The grating ruler displacement sensor is composed of two parts: the grating ruler main ruler 28-1 and the reading head 28-2. The grating ruler main ruler 28-1 is generally fixed on the movable parts of the machine tool, and the reading head 28-2 is installed on the fixed parts of the machine tool. An indicator light grid is incorporated in the readhead. The grating ruler displacement sensor is a measurement fe...

Embodiment 3

[0066] A machine tool digital twin model performance testing device, the structure of which is shown in Embodiment 1, the difference is that the X-direction servo loading mechanism includes an X-direction electric cylinder 17, an X-direction electric cylinder mounting seat 15, and an X-direction force wheel installation The bracket 13 and the X-direction force wheel 12, the X-direction electric cylinder 17 mounting seat bolts are connected on the side of the gantry 11, the X-direction electric cylinder 17 is installed on the X-direction electric cylinder mounting seat 15, and the X-direction electric cylinder 17 cylinder The end of the rod passes through the through hole on the X-direction electric cylinder mounting seat 15 and is connected to one end of the first tension pressure sensor 14, and the other end of the first tension pressure sensor 14 is connected to the X-direction force-applying wheel mounting bracket 13, and the X-direction force is applied The wheel 12 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com