Vibration system of sound production device and the sound production device

A vibration system and sound-generating device technology, which is applied to sensors, electrical components, loudspeakers, etc., can solve the problems of insufficient low-frequency performance, small speaker excursion, poor low-frequency performance, etc., and achieve good neutrality, stability, and acoustic performance. Good, the effect of increasing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

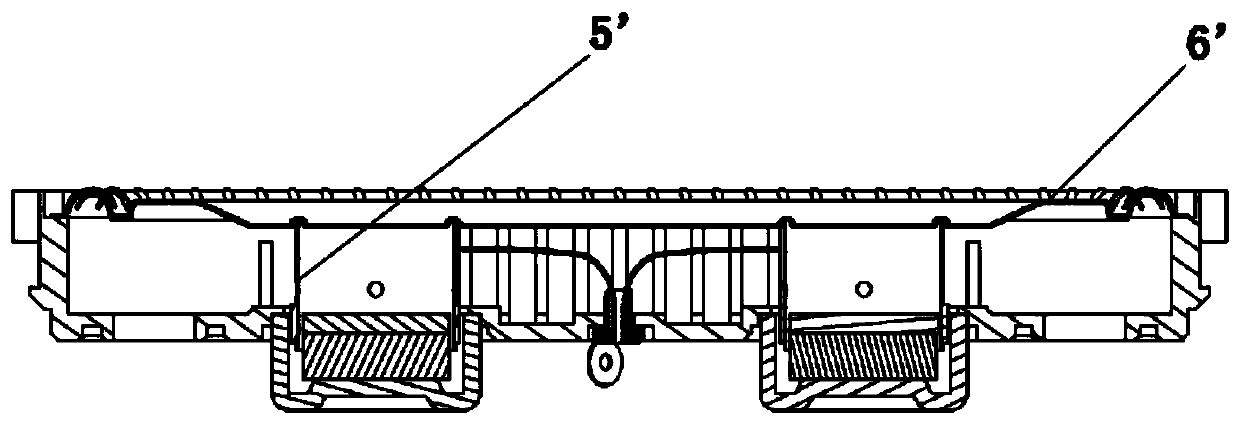

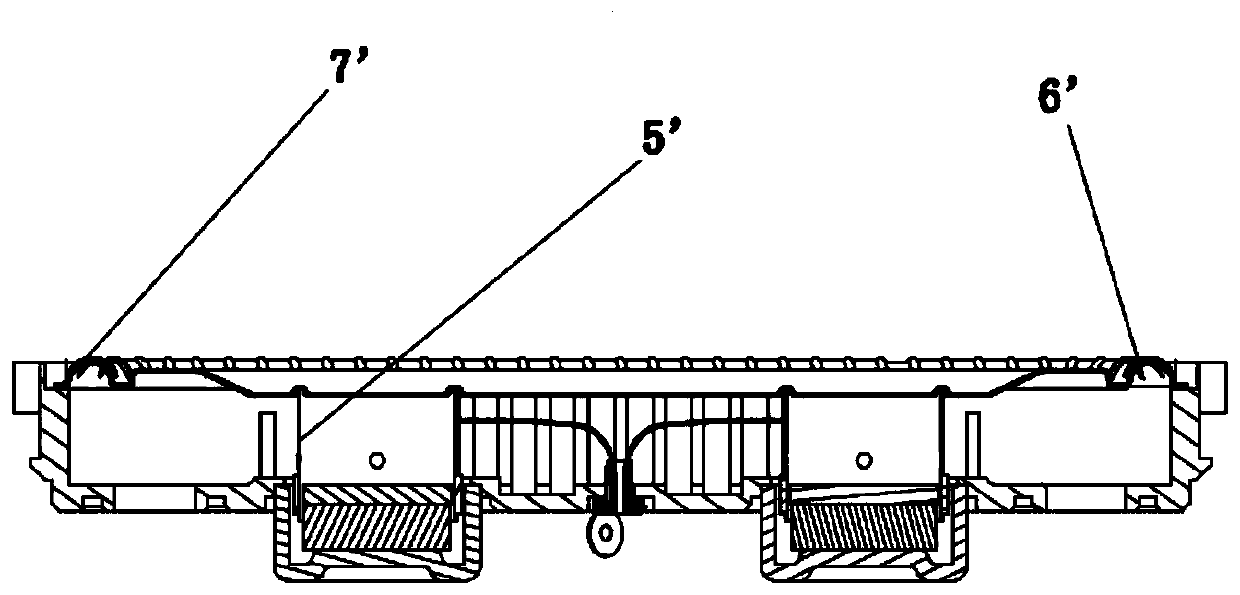

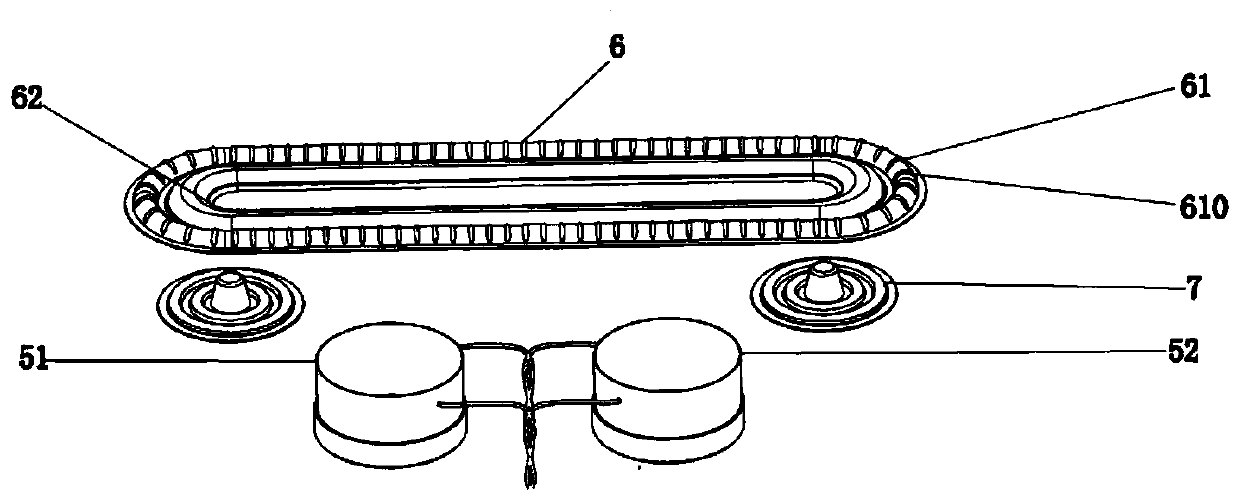

[0048] For example Figure 3 to Figure 5 As shown together, the vibration system of the sound generating device in this embodiment will be described by taking the vibration system of the dual-drive sound generating device applied to narrow and thin electronic equipment as an example. The vibration system includes a voice coil assembly 5 and a diaphragm assembly 6, wherein the voice coil assembly 5 includes two voice coil units, i.e. a first voice coil unit 51 and a second voice coil unit 52, and the diaphragm assembly 6 can be specifically configured as The strip shape includes an outer ring 61 and a body inside the outer ring 61 .

[0049] When assembled, the diaphragm assembly 6 is arranged horizontally as a whole, while the first voice coil unit 51 and the second voice coil unit 52 are arranged in parallel (parallel) in the horizontal direction, and the two voice coil units are arranged in the vertical direction Connect with the diaphragm assembly 6. Of course, specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com