A foundation and a method for forming a foundation for a wind turbine tower

A technology for wind turbines and towers, which is applied to the installation/support of wind turbine configurations, wind turbines, and wind turbine components. It can solve the problems of complex manufacturing and expensive conical supports, and achieve torque resistance and height reduction. , the effect of torque reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

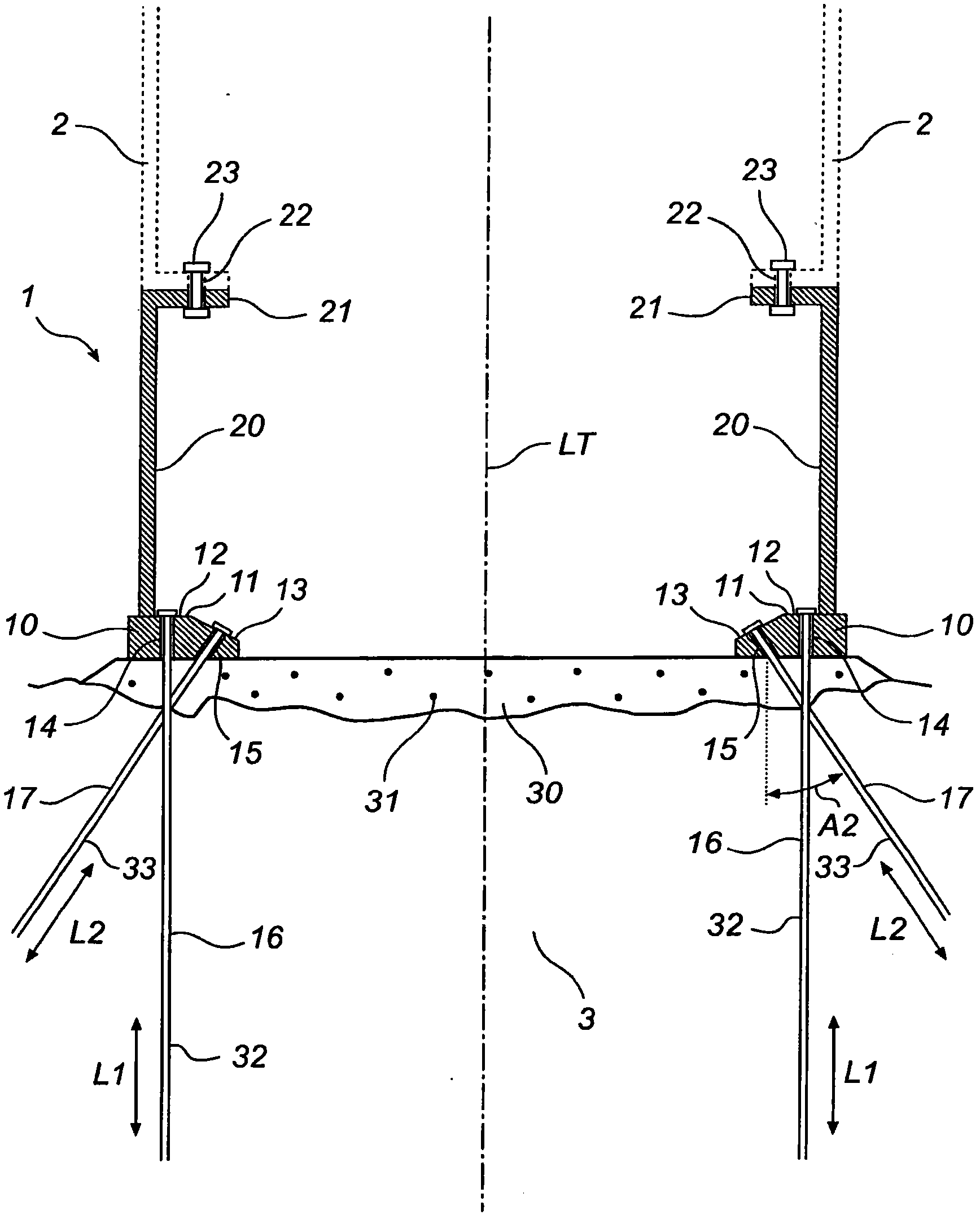

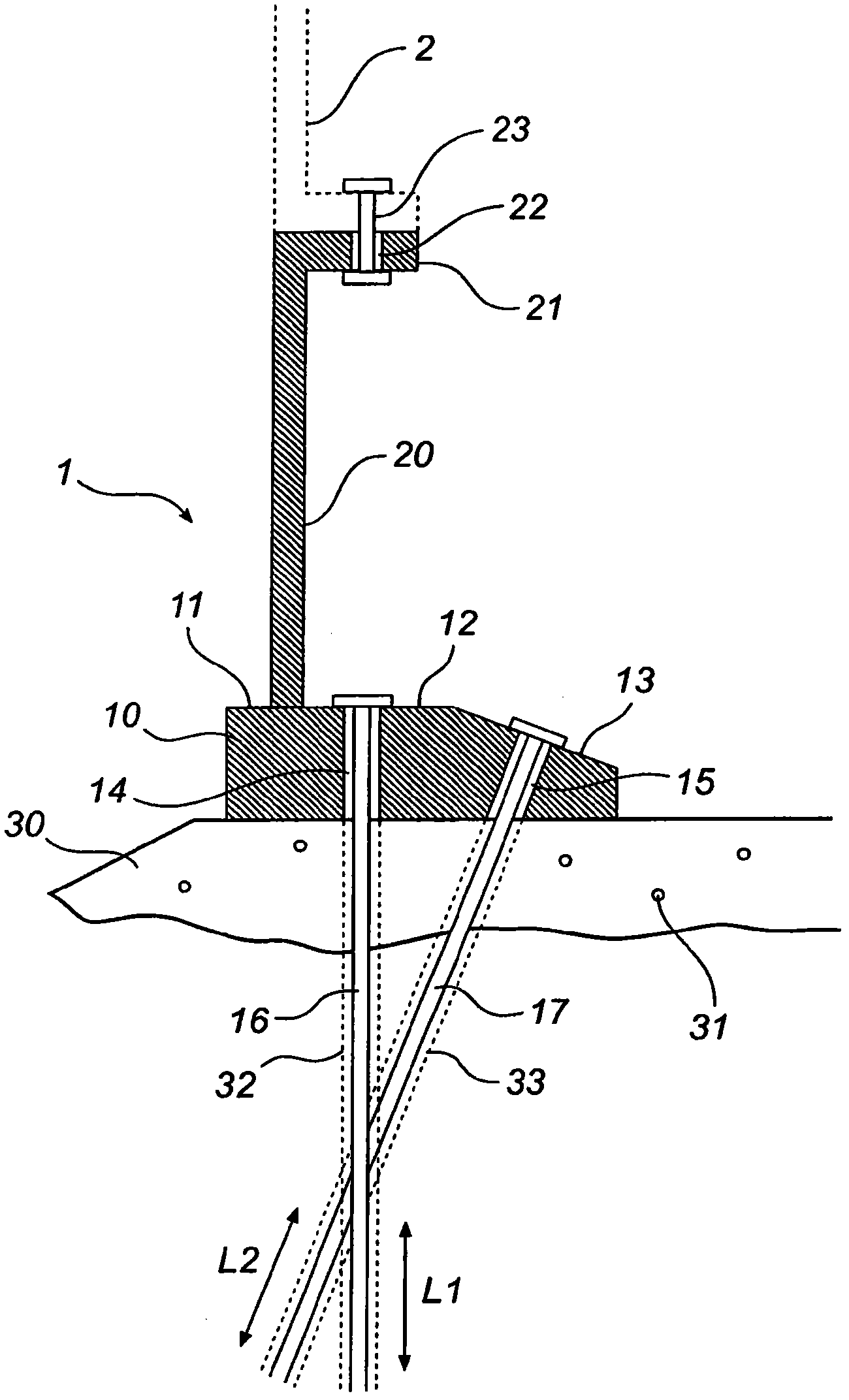

[0054] figure 1 A foundation 1 for a wind turbine tower 2 is described. The foundation 1 is adapted to engage the lower part of the tower 2 and provide a stable support for the tower 2 . The tower 2 may be formed in the circumferential direction from a plurality of tower segments, each tower segment forming a part of the tower 2 . In vertical direction, the tower 2 may be formed from a plurality of tower sections, one tower section being placed on top of the other.

[0055] The base 1 is particularly suitable for placement on rocky or rocky ground.

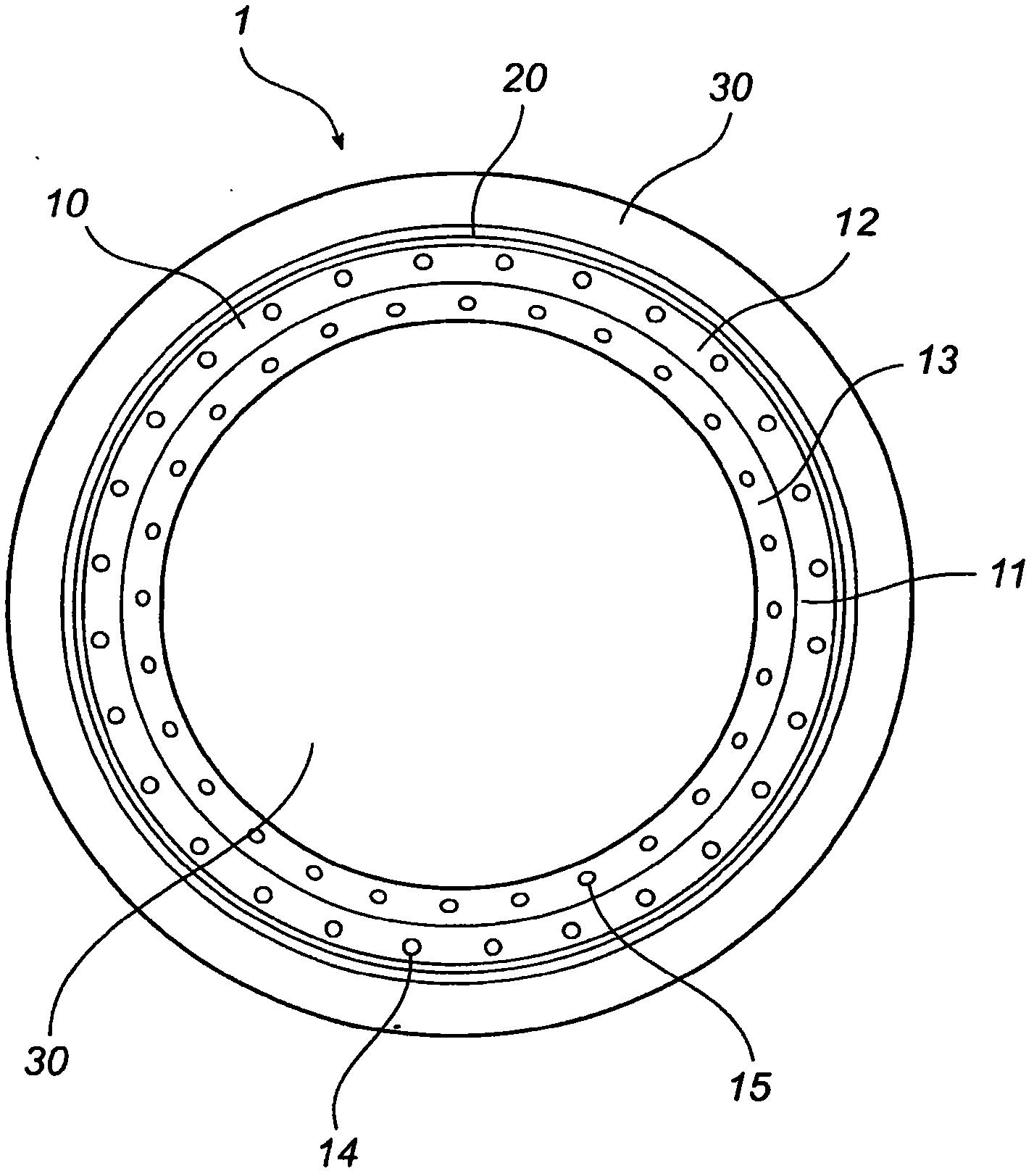

[0056] The foundation 1 includes a rock fixing flange 10 . The shape of the rock flange 10 corresponds to the shape of the periphery of the tower 2 . For example, the rock anchor flange 10 may be as figure 2 The ring shown, or any other shape that roughly corresponds to the shape of the tower 2 . A plurality of anchors 16, 17 are provided for fastening the foundation to the ground 3.

[0057] in such as figure 1 In the il...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com